10

OPERATING YOUR FILTER

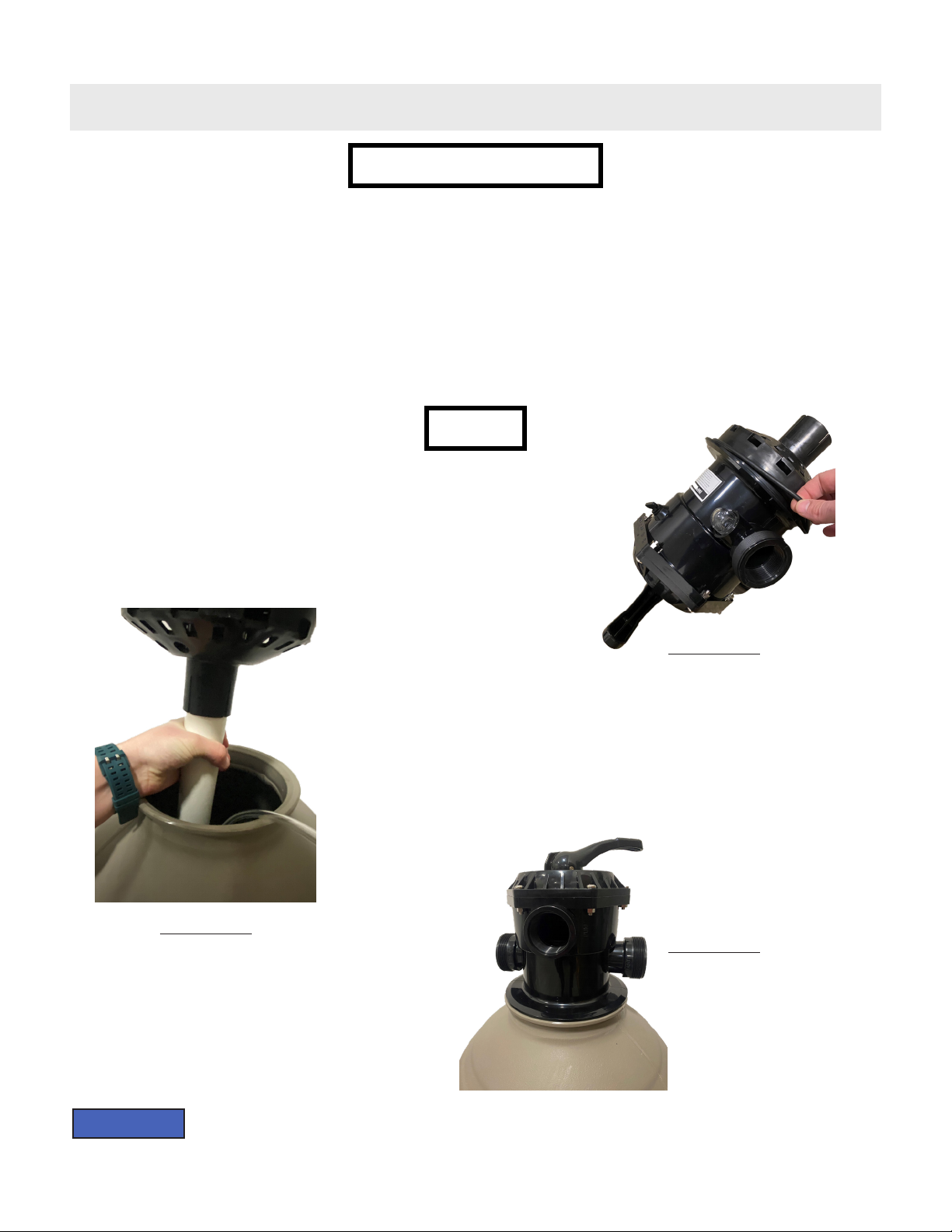

• Prime your lter prior to starting up the lter system. DO NOT turn the motor on until the system has been

primed or you can damage your pump.

• Make sure that the water in the pool is up to middle of the skimmer(s) and that there is nothing blocking the

water ow from the return(s) and skimmer(s) (i.e. plug, plate, etc.).

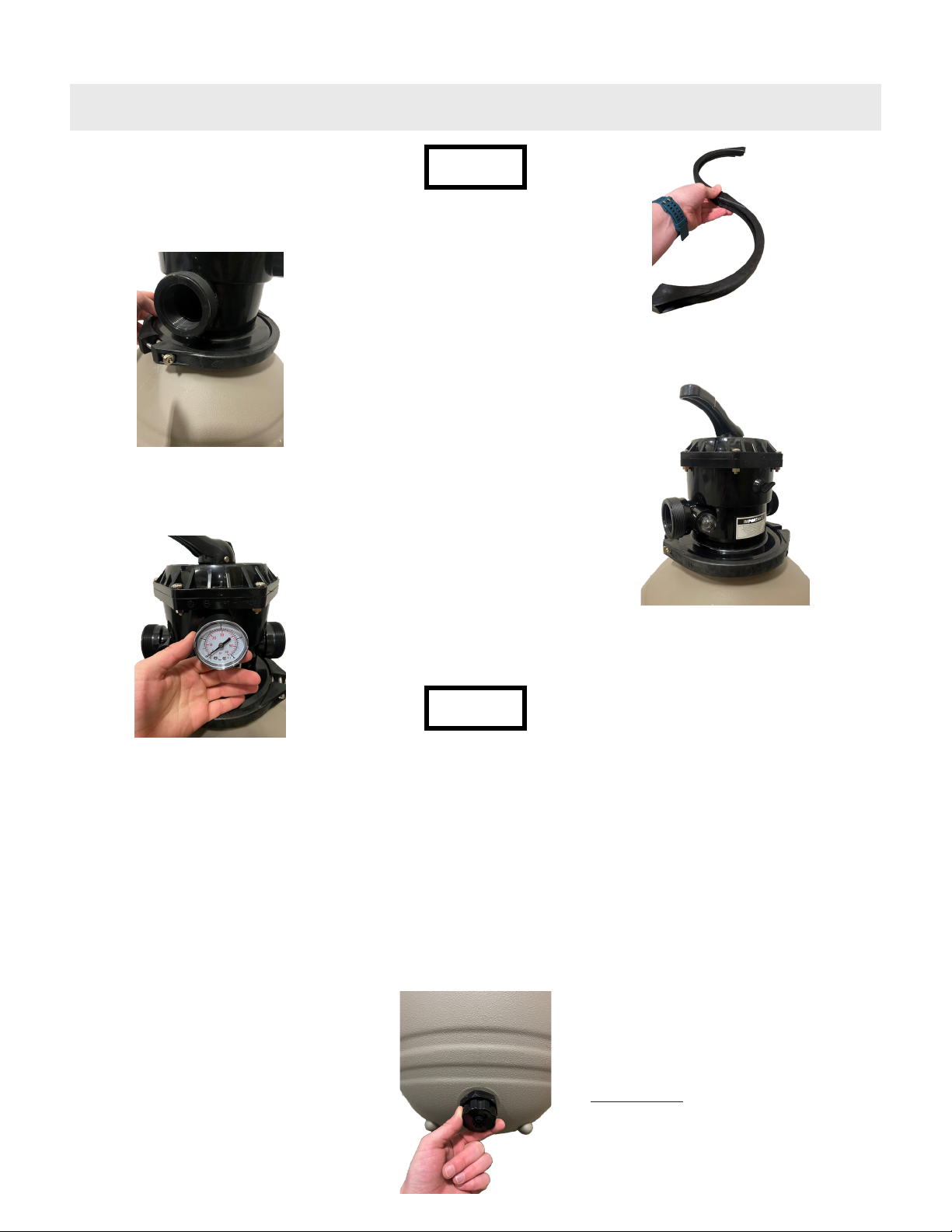

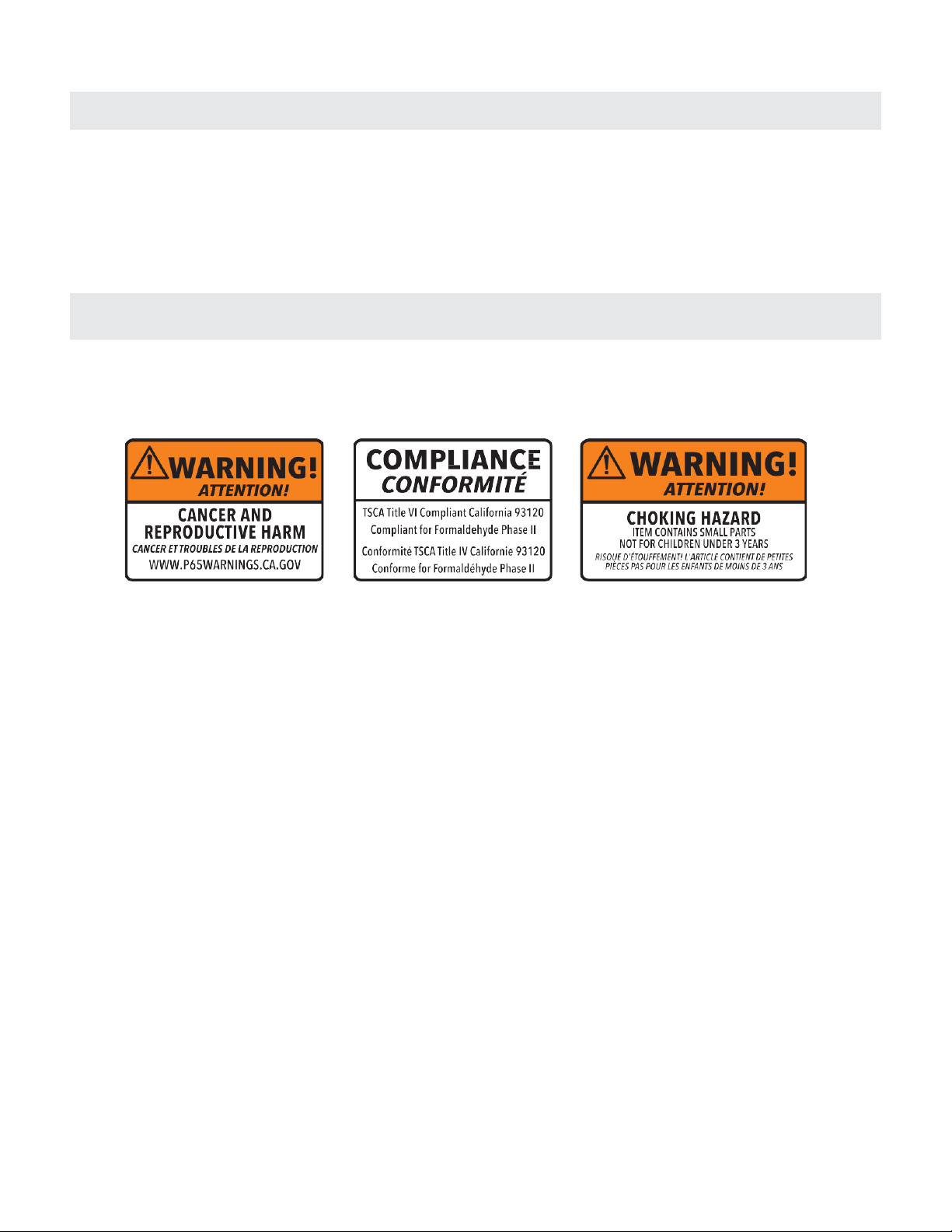

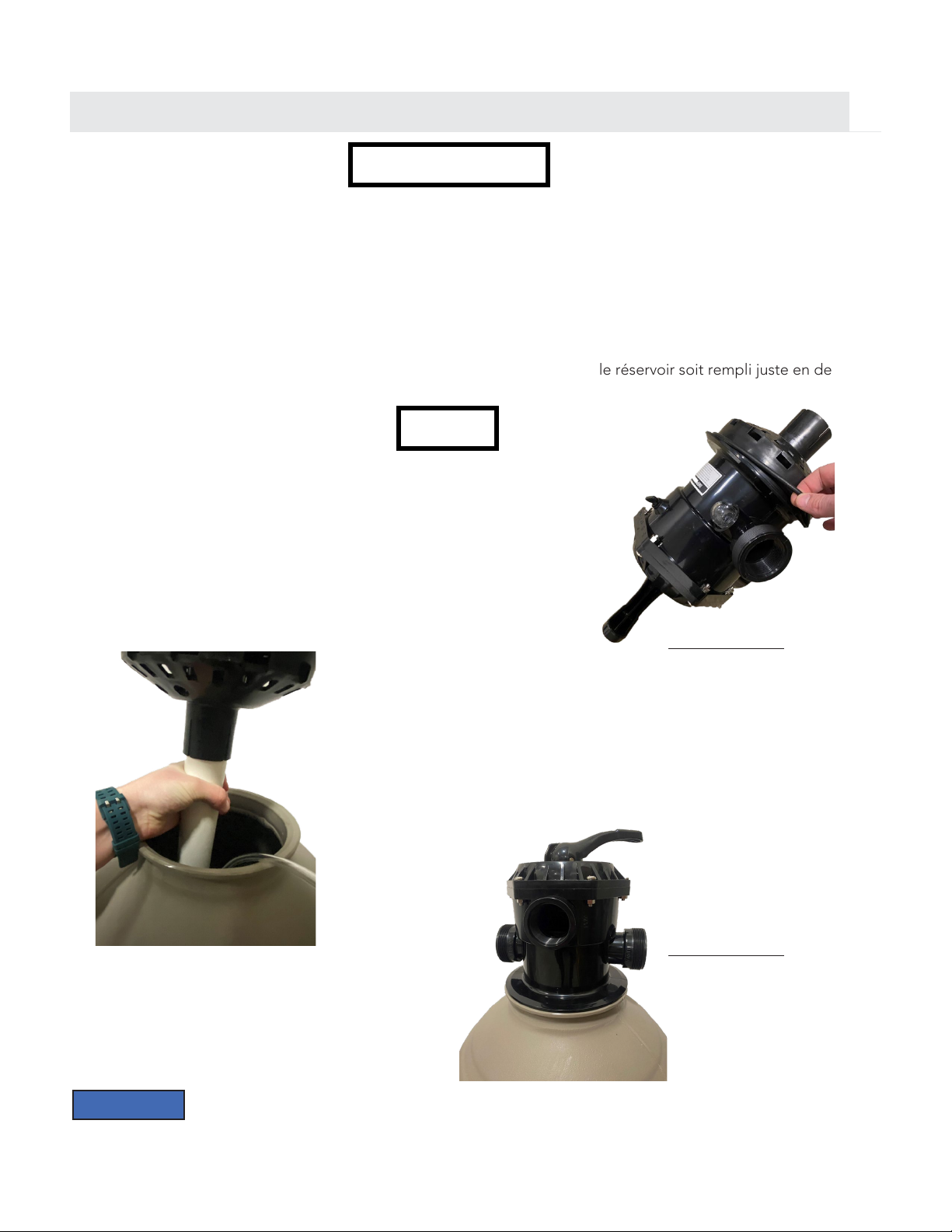

• Push down the selector handle on the valve and turn it to the notch labeled BACKWASH. Let go of the

handle and the valve is now in the correct backwash position. Make sure the backwash hose (sold separately)

is attached to the waste port so water will not spray all over you once the pump is started.

• Remove the lid of the strainer basket on the pump (if applicable) and ll with water. These skimmer and

return lines should be lled with water as well (when the water level is in a proper place in the pool, this will

happen naturally).

• Place the cover back on the basket and plug in/switch on the pump. When the pump starts up, water will

come out through the backwash hose. If the pump is properly primed, the water in the strainer basket will ll

completely and the air pockets will be eliminated.

• Repeat above steps until all air is purged from the system then turn OFF the pump. If this does not get the

air out of the system, double check all connections to make sure they are properly tightened and try again.

• To use the lter, with the pump OFF, push down the selector handle on the valve and turn to the notch

labeled FILTER.

• Connect your pump to power to start the lter operation.

• Note the pressure gauge reading at this time.

• When pressure through the return fades and pressure gauge reads 5 psi above the starting pressure,

you will need to backwash the lter system to remove debris.

• Turn the pump off before moving the selector to the BACKWASH position. Once in this position, turn your

pump back on.

• Water will then come out through the waste port, so position the backwash hose where you would like the

water to run out.

• NEVER backwash for longer than ONE MINUTE at a time! Backwashing longer than one minute will cause

sandblasting of internal components and can lead to damage of the standpipe and/or laterals and will thus

VOID WARRANTY.

• Turn the pump off and move the selector to RINSE position. Rinse will allow water to ow through the

pump to clear out the lines and prevent a puff of sand or debris back into the pool after backwashing .

• Rinse for approximately 15 SECONDS and turn off the pump once again. Move the selector back to the

FILTER position and turn the pump back ON. You are now ltering the pools water.

• The WASTE position does NOT allow water to pass through the lter.

• If there is a point where you would like to take water directly out of the pool, this is the option that allows

you to do so.

• You may also vacuum waste to take serious debris straight out of the pool if/when necessary.

• Remember, this is taking water out of the pool so watch the water level to protect your pump and lter. If

the water drops below the skimmer level you MUST turn the pump off.

• RECIRCULATE selector position allows you to move water in the pool WITHOUT ltering the water. This is

usually used when adding chemicals to the pool, during pool opening, or regular maintenance.

NOTICE

NOTICE Your lter CANNOT be run if the water is not at the proper level in the pool. Running the lter

without water can cause serious damage to your pump and lter.

NEVER move selector handle while pump is on. Pump MUST be switched off to change the

position of the valve. Failure to comply will cause damage to your valve and is not covered by

WARRANTY.