Teikoku API-685 User manual

INSTRUCTION MANUAL

for Installation, Operation, and Maintenance

HE-10677-P June 2020

TEIKOKU

REVERSE CIRCULATION PUMP

TYPE-R (API-685 Plan 13-SE)

For Refrigeration Applications Only

Thank you for purchasing the Teikoku Type-R (Plan 13-SE) refrigeration canned motor pump.

Please carefully read this instruction manual and all Safety Warnings prior to use.

A Quick Start Guide is included in the Appendix of this manual.

Introduction

Safety Terms

Please pay close attention to these terms. When you see them

in this manual, read the information thoroughly and follow the

instructions given.

Attention!

Indicates careful attention is required. The instruction in-

cludes protective information for the device and product.

Caution!

Ignoring this warning can cause personal injury and/or

damage to the device and product.

Hazard!

Ignoring this warning can cause serious injury or even

death. It can also be used to alert against unsafe practices.

NOTE: Information included in NOTES gives additional helpful

information and recommendations.

Applicable Standards and Regulations

The Teikoku Type-R (Plan 13-SE) pump conforms to the follow-

ing standards:

1. Japanese Industrial Standard (JIS)

2. Japan Electrical Manufacturers’ Standard (JEM)

3. American Society of Mechanical Engineers (ASME) B-16.5

4. Canadian Standards Association (CSA): UL 778 CSA

22.2 No 108

5. International Institute of Ammonia Refrigeration (IIAR):

ANSI/IIAR 2-2014

Product Warranty Period

This product is warranted for two years from date of delivery.

Please refer to Teikoku USA’s Terms and Conditions of Sale for

additional warranty coverage and restrictions.

Rights

All rights on products manufactured by Teikoku, corresponding

software, and this instruction manual are registered to Teikoku

Electric Mfg Co., Ltd.

It is not permitted to reproduce or transmit any portion of this

instruction manual unless prior written consent has been ob-

tained from Teikoku USA Inc., Teikoku Electric Mfg Co., Ltd. or

its subsidiaries.

Teikoku Rotary GuardianTM and TRGTM are trademarks of

Teikoku Electric Mfg. Co., Ltd.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)1

Attention!

Do not run dry!

If the pump is allowed to run dry, the bearings, sleeves,

and other components could be damaged and serious

overheating of the motor windings can occur.

Attention!

Avoid rapid temperature changes!

Large changes in temperature must be avoided. Rapid

changes can cause leaks to occur in gaskets. Published

procedures for proper heating and cooling must be fol-

lowed. If published procedures are not available, check

with Teikoku before operating the equipment.

Caution!

Hot – Do not touch!

Motor and pump can be hot, even when pumping

cold liquids.

Caution!

If motor trips, do not restart before determining

the cause!

Restarting the motor before ascertaining the cause may

result in excessive heat, causing pump or motor failure.

Hazard!

Do not remove internal bolts in terminal box.

If it is necessary to remove the terminal box for any reason,

first loosen the bolts by 2 or 3 turns to check if any internal

pressure or liquid is present. You must take measures if the

possibility exists that the gas or liquid is toxic or hazardous

to personnel or the environment.

Hazard!

Do not remove any bolts on pump, motor, or

drain plugs!

The internal pressure can be higher than the atmosphere.

Ensure that the pump and motor are properly de-pressur-

ized and decontaminated prior to performing any work

Proper protective measures must be taken if the possibility

exists that the gas or liquid is toxic or hazardous to person-

nel or the environment.

Hazard!

Always assume that there is liquid left in the pump!

There is always the possibility that residual liquid could

remain in the pump and motor in spite of thorough de-

contamination. Pay particular attention to the clearance

between the shaft and the impeller, bearings, sleeves,

bearing housings and gaskets. You must take adequate

precautions to protect personnel and the environment if

the liquid could be considered hazardous.

Safety Warnings

Important:

Before operating the canned motor pump, read these Safety Warnings

and this entire Instruction Manual to avoid improper operation.

It is essential for your safety and to avoid disaster.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)2

Contents

Introduction 2

Overview 2

1. General Information 3

2. Installation 5

3. Operation 8

4. Maintenance 11

Appendix 16

A. Quick Start Guide ......................................................17

B. Reverse Circulation (4N-7653) .....................................18

C. Troubleshooting .........................................................19

D. Sectional View (6A-8901) ..........................................20

E. TRC-1 Information Sheet .............................................21

F. Decontamination Form ...............................................22

Figures

Figure 1-1. Reverse Circulation Type-R (Plan 13-SE) ...................3

Figure 2-1. Teikoku Type-R (Plan 13-SE) TRG ..............................7

Figure 2-2. Teikoku Type-R (Plan 13-SE) 460 Volt, 3-Phase..........7

Figure 3-1. Teikoku TRC Rotation Indicator ................................9

Figure 4-3. Bearing Wear Limits...............................................13

Figure 4-4. “g” Gap................................................................13

Figure 4-1. Front Bearing – Only Spiral Grooves ......................13

Figure 4-2. Rear Bearing – Spiral and Straight Grooves ............13

Figure 4-5. Type-R (Plan 13-SE) Model Number Indentification

Code Example .......................................................14

Tables

Table 2-1. Conditions indicated on the TRG Meter.....................6

Table 4-1. Bearing Wear Limit..................................................14

Table 4-2. Adjusting Value of Gap “g” ....................................14

Table 4-3. End Play..................................................................14

Table 4-4. Tightening Torques..................................................14

Table 4-5. Torque Values for Motor Terminal Connections –

Terminal Box and Connection Stud Size ...................14

Table 4-6. Motor Frame and Terminal Box Size.........................14

Table 4-7. Pump Ring Clearance (Standard Horizontal Pump) ...15

Overview

Teikoku Type-R (Plan 13-SE) sealless canned motor pumps are

designed for the industrial refrigeration market and offer an

advanced low probability, true secondary containment, envi-

ronmentally friendly alternative to sealed pumps and single

containment sealless pumps.

Care should be exercised upon installation, start up, removal and

maintenance of the pumps. Recommended safety equipment

should be used at all times.

This manual, containing basic instructions for installation, op-

eration and maintenance of the Teikoku Type-R (Plan 13-SE), is

designed to assist you in obtaining this service. It is important

that the persons responsible for the installation, operation, and

maintenance of the pump read and understand this manual

thoroughly.

The Teikoku Type-R (Plan 13-SE) pump is supplied with the

Teikoku Rotary Guardian (TRGTM), the radial monitoring system

of the rotating assembly of a Teikoku canned motor pump. The

TRG monitors bearing wear and gives a direct readout as to bear-

ing condition. The TRG is mounted on the electrical junction box

as standard.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)3

1.General Information

1.1 General Design and Operation

The Teikoku Type-R (Plan 13-SE) is a combined centrifugal pump

and squirrel cage induction electric motor built together into a

single hermetically-sealed unit. The pump impeller is of the closed

type, and is mounted on one end of the rotor shaft which extends

from the motor section into the pump casing. The rotor is sub-

merged in the liquid being pumped and is, therefore, “canned”

to isolate the motor rotor from contact with the liquid. The stator

winding is also canned to isolate it from the liquid being pumped.

Liquid film journal bearings are submerged in system liquid and

are therefore lubricated by the process liquid.

The Teikoku Type-R (Plan 13-SE) has only one moving compo-

nent, a combined rotor-impeller assembly that is driven by the

induced magnetic field of an induction motor. A portion of the

pumped liquid is allowed to circulate through the rotor cavity to

cool the motor and lubricate the bearings. The stator windings

are protected from contact with the circulating liquid by a corro-

sion resistant, non-magnetic, alloy liner, which completely seals or

cans the stator winding.

Flow paths of the Teikoku Type-R (Plan 13-SE) reverse circulation

pumps are shown in Figure 1-1. The circulating liquid is channeled

into the motor section by holes drilled in the front bearing hous-

ing. A portion of the circulating liquid lubricates the front liquid

film journal bearing and returns to the rear of the impeller. The

remainder of the circulating liquid passes over the rotor, cools

the motor, lubricates the rear liquid film journal bearing and then

exits the rear bearing housing returning to the vapor space of the

suction tank via the reverse circulation line. The Teikoku Type-R

(Plan 13-SE) reverse circulation design avoids the heated circulat-

ing liquid returning directly to the pump suction.

The Teikoku Type-R (Plan 13-SE) offers advanced low probability

true secondary containment as a standard design feature. In the

event of a failure of the primary containment can, the stator as-

sembly in conjunction with the leak proof terminal plate assembly

provides the secondary containment. This design prevents any re-

lease of the process liquid out to the atmosphere.

A standard feature of the Teikoku Type-R (Plan 13-SE) is the pat-

ented Teikoku Rotary Guardian (TRG™). The TRG is an electrical

meter that continuously monitors the condition of the bearings.

For more information on the TRG see Section 2.3.3.

The Teikoku Type-R (Plan 13-SE) sealless pump is a precision built

unit that with proper operation and maintenance will provide

years of trouble-free, leakproof service. The entire unit is mount-

ed on a fabricated steel base cradle. Operation is unaffected by

the mounting or operating position, eliminating the need for any

costly alignment procedures.

Figure 1-1. Reverse Circulation Type-R (Plan 13-SE)

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)4

1.2 Stator Assembly

The stator assembly consists of a set of three-phase windings.

Stator laminations are of low-silicon grade steel. Laminations

and windings are mounted inside the cylindrical stator band. End

bells, welded to the stator band, close off the ends of the stator

assembly. The stator liner is, in effect, a cylindrical can placed in

the stator bore and welded to the rear end bell and front end bell

to hermetically seal off the windings from contact with the liquid

being pumped.

Terminal leads from the windings are brought into an electrical

terminal box. Motor lead wires are isolated from the users’ con-

duit line by a leakproof terminal plate assembly mounted inside

the terminal box. The design of the stator assembly in conjunction

with the leakproof terminal plate assembly provides an advanced

low probabilty true positive secondary containment.

1.3 Rotor Assembly

The rotor assembly is a squirrel cage induction rotor constructed

and machined for use in the Teikoku Type-R (Plan 13-SE). It con-

sists of a machined corrosion-resistant shaft, laminated core with

cast aluminum bars and end rings, corrosion-resistant end covers,

and a corrosion-resistant can.

The rotor end covers are welded to the shaft and also to the

rotor can which surrounds the outside of the rotor, thus her-

metically sealing off the rotor core from contact with the liquid

being pumped.

The impeller is keyed to the shaft and held in place with a bolt and

lockwasher. The shaft is fitted with replaceable shaft sleeves and

thrust collars. These parts are pinned or keyed to prevent rotation.

Axial movement is restricted by the thrust collars contacting the

face of the front and rear bearings.

1.4 Liquid Film Journal Bearings

The liquid film journal bearings for the Teikoku Type-R (Plan

13-SE) are carbon graphite as standard and are machined with

special helix grooves through the bore to assure adequate liquid

circulation at the journal area. Each liquid film journal bearing is

manufactured to close tolerances for a high degree of concentric-

ity and is held in a bearing housing by a retaining screw. Liquid

film journal bearings are easily replaced by removing the retaining

screw and sliding the bearing from its housing.

1.5 Thrust Collars and Shaft Sleeves

All Teikoku Type-R (Plan 13-SE) models are equipped with thrust

collars, providing a replaceable surface against which axial loads

can be carried during process upset conditions. The shaft is also

fitted with replaceable shaft sleeves. Both the thrust collars and

shaft sleeves are constructed of 316SS with a Stellite wear surface

for long life. These parts are pinned or keyed to prevent rotation.

1.6 Cooling Flow

Flow paths of the Teikoku Type-R (Plan 13-SE) reverse circulation

pumps are shown in Figure 1-1. The circulating liquid is chan-

neled into the motor section by holes drilled in the front bearing

housing. A portion of the circulating liquid lubricates the front

liquid film journal bearing and returns to the rear of the impeller.

The remainder of the circulating liquid passes over the rotor cools

the motor, lubricates the rear liquid film journal bearing and then

exits the rear bearing housing returning to the vapor space of the

suction tank via the reverse circulation line. The Teikoku Type-R

(Plan 13-SE) reverse circulation design avoids the heated circulat-

ing liquid returning directly to the pump suction.

1.7 Automatic Thrust Balance

Based on hydraulic principles, Teikoku Type-R (Plan 13-SE) au-

tomatic thrust balance is accomplished by the pressure of the

pumped liquid itself, operating in a balance chamber at the front

and rear of the impeller.

When a change in load shifts the position of the impeller away

from the balance condition, there is an equalizing change of

hydraulic pressure in the balance chamber, which immediately re-

turns the impeller-rotor assembly to the balanced position.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)5

2.Installation

2.1 Receipt Inspection

1. Visually inspect the shipping container for evidence of dam-

age during shipment.

2. Check unit to see that suction, discharge, and any other con-

nections are covered.

3. Inspect the suction, discharge and any other connections gas-

ket seating surface to be certain that they are clean of foreign

matter and free from nicks, gouges, and scratches.

4. Check all nameplate data against shipping papers.

5. Verify receipt of the reverse circulation line restriction orifice.

2.1.1 Storage Note

In situations where a Teikoku Type-R (Plan 13-SE) is to be stored

for a period of time prior to installation and where the climate

experiences wide temperature changes and high humidity,

the terminal box, suction and discharge flange, and any other

openings must be sealed to prevent moisture from entering the

internals of the pump. Teikoku's long term storage procedures are

available upon request.

2.2 Structural

The pump design and construction eliminates the necessity of

aligning the pump and motor. The pump should be supported

from the mountings provided. It should be mounted in such a way

as to have its weight properly supported. Suction and discharge

piping must be properly supported and aligned so that no strain

is placed on the pump casing.

1. Remove burrs and sharp edges from flanges when making

up joints.

2. When connecting flanged joints, be sure inside diameters

match within 1/16" so as not to impose a strain on the

pump casing.

3. Use pipe hangers or supports at intervals as necessary.

2.2.1 Pump Location

Locate the pump as close as possible to the liquid supply with a

positive suction head. Location of the pump and arrangement

of the system should be such that sufficient NPSH (Net Positive

Suction Head) is provided over vapor pressure of the liquid at the

pump inlet. NPSH requirements at the design point are stated on

the pump order data sheet.

NOTE: Experience has proven that most pump troubles result

from poor suction conditions including insufficient NPSH. The

suction line must have as few pressure drops as possible and avail-

able NPSH MUST be greater than required NPSH.

Depending on job conditions, available NPSH can sometimes be

increased to meet the NPSH required by the pump for satisfac-

tory operation. NPSH can be tailored by changes in the piping, in

liquid supply level, and by several other methods. Refer to Appx.

C. Troubleshooting.

2.2.2 Mounting and Alignment

Base plate assemblies are offered on all models. Simply set the

pump on a foundation strong enough to support its weight. There

is no need to bolt down or grout a Teikoku Type-R (Plan 13-SE).

Be sure that the suction and discharge piping is properly aligned so

that no strain is placed on the pump casing by out-of-line piping.

2.2.3 Piping Data

Observe the standards of the Hydraulic Institute and International

Institute of Ammonia Refrigeration when sizing and making up

suction and discharge piping. Follow these procedures:

1. Remove burrs and sharp edges when making up joints.

2. When using flanged joints, be sure inside diameters match

properly. When gasketing flanged joints, do not cut flow hole

smaller than flange opening.

3. Use pipe hangers or supports at necessary intervals.

4. Provide for pipe expansion when required by liquid

temperature.

5. When welding joints, avoid possibility of welding shot entering

the suction or discharge line, and thereby entering the pump.

Caution!

Do not weld pipe when it is connected to pump.

6. Do not spring piping when making up any connections.

7. Make suction piping as straight as possible, avoiding unneces-

sary elbows. Where necessary, use 45-degree or long-sweep

90-degree fittings.

8. Make suction piping short, direct, and never smaller in diam-

eter than suction opening of pump. Suction piping should

be equal to or larger than pump suction port, depending on

pipe length.

9. Ensure that all joints in suction piping are airtight.

10. When installing valves and other fittings, position them to

avoid formation of air pockets.

11. Permanently mounted suction filters are not recommended.

It is extremely important to design and size the suction system to

minimize pressure losses and to be sure that the pump will not be

starved for liquid during operation. NPSH problems are a result of

improper suction systems.

The suction pipe should be one or two sizes larger than pump

suction port, depending on piping length. Use the largest pipe

size practical on suction piping and keep piping short and free

from elbows, tees or other sources of pressure drop.

If elbows, tees or valves must be used, locate them from 5 to 10

pipe diameters upstream from suction. When reducing to pump

suction port diameter, use eccentric reducers with flat side on top

to avoid air pockets.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)6

On most Type R (Plane 13-SE) pumps there is a restriction orifice

that must be installed on the reverse circulation flange of the rear

bearing housing.

The design and installation of the reverse circulation line must be

in accordance with reverse piping layout drawing shown it Appx.

B. Reverse Circulation (4N-7653).

When it is necessary to connect two or more pumps to the same

suction and discharge lines, provide gate valves so that any

pump can be isolated from the line. Install gate valves with stems

horizontal to avoid air pockets. Globe valves should be avoided,

particularly where NPSH is critical.

A vent line back to the suction vessel is required in the discharge

pipe. The connection for the vent line in the discharge pipe must

be between the pump discharge flange and the first block valve

and/or check valve. The vent line can also be used as the mini-

mum flow line.

If discharge pipe length is normal, pipe diameter can be the same

size as the pump discharge port diameter. If discharge piping is

of considerable length, use one or two size larger diameter pipe.

If the pump is to discharge into a closed system, an elevated tank

or if there are multiple pumps connected together, place a check

valve in the discharge line close to the pump.

NOTE: Install properly sized pressure gauges in suction and dis-

charge lines between the pump and the first block and/or check

valve so that operation of the pump and system can be easily

observed. Should cavitation, vapor lock, or unstable operation oc-

cur, widely fluctuating discharge pressures will be observed. Such

gauges provide a positive means of determining actual system

conditions and can be used to great advantage in evaluating sys-

tem problems.

2.3 Electrical

2.3.1 General

Except where indicated, all Teikoku Type-R (Plan 13-SE) are started

with full line voltage. Refer to Section 3.2.3 for checking direction

of rotation. Also see Figure 2-2 for proper wiring connections.

2.3.2 Starting Equipment

Motor starters (normally not supplied with Teikoku Type-R (Plan

13-SE)) should be sized to handle the load required. The full load

amps and start KVA data is listed on the nameplate.

The thermal overload protective devices in the starters should

be sized for the amperage shown on the Teikoku Type-R (Plan

13-SE) nameplate. Do not size thermal overload protective de-

vices in excess of 10% of full load amp rating. In order to provide

complete protection for Teikoku Type-R (Plan 13-SE) motors under

all conditions, it is recommended that quick-trip (Class 10) type

thermal overload protective devices be used in the starters where

available. Standard thermal overload protective devices provide

adequate protection for Teikoku Type-R (Plan 13-SE) motors un-

der starting or normal running conditions, but require a greater

length of time than quick-trip-type thermal overload protective

devices to cut out if the motor is subject to locked rotor or over-

load conditions.

2.3.3 TRG Bearing Wear Monitor

The TRG is an electrical meter that continuously monitors the

condition of the bearings. The TRG is mounted on the electrical

junction box as standard.

The TRG meter operates on the principle of induced voltage.

There are two TRG coils located inside the stator 180° apart. A

magnetic field is created in the stator by current flowing through

the stator windings. When the rotor is perfectly centered in the

stator, the two magnetic fields are essentially balanced. When

bearing wear occurs and the gap between the rotor and stator

decreases, an imbalance in the magnetic fields causes a differen-

tial induced voltage in the TRG coils. This differential voltage is

indicated on the TRG voltmeter.

The initial indication of the TRG meter is not constant because it

is influenced by the operating load. Initial indication of up to 0.4

should be allowed.

Keeping records of the TRG meter reading in conjunction with

motor amp readings will provide a good indication of when the

pump will require maintenance.

Table 2-1. Conditions indicated on the TRG Meter

The TRG meter has a colored scale which is divided into three zones: Green (0 to 0.5), Yellow (0.5 to 0.75), Red (0.75 to 1)

AT TRIAL OPERATION DURING OPERATION

Indication Condition Solution Indication Diagnosis User Actions

Full scale or 1-Volt reverse rotation change power cable

connection Green Good No action

Yellow to Red phase failure check connection of

cables

Yellow or voltage increase of

> 0.3 V from initial indication

Bearings worn to

caution level

Plan routine

maintenance

Green normal connection is correct Red or voltage increased of

> 0.5 V from initial indication

Immediate

maintenance required

Shutdown immediately

and replace worn parts

Hazard! Do not operate if TRG meter condition is RED.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)7

Figure 2-1. Teikoku Type-R (Plan 13-SE) TRG

Figure 2-2. Teikoku Type-R (Plan 13-SE) 460 Volt, 3-Phase

R TS

U WV

MAGNETIC CONTACTOR

THERMAL OVERLOAD

PROTECTIVE DEVICE

TRG

MAGNETIC CONTACTOR

TEIKOKU SUPPLY

G1 G2

OFF

ON

X

NOTE: Teikoku Type R motors manufactured for the

industrial refrigeration market do not include

Thermal Cut-Outs (TCOs). For electrical data refer to

the pump-specic Motor/Pump Data Sheet.

FOR TRG WIRES ONLY

THERMAL OVERLOAD

PROTECTIVE DEVICE

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)8

3.Operation

3.1 Procedure Before Initial Start

Attention!

Before starting the pump for the first time, make sure suc-

tion and discharge piping are free of tools, nuts, bolts, or

other foreign matter. Save time and money by checking

before start-up.

3.2 Preparation and Trial Operation

The following procedures are recommended for protection of

canned motor pumps in industrial refrigeration services.

Teikoku USA recommends monitoring the differential pressure

and the power monitor for total protection of the pumps. Teikoku

recommends using both as differential pressure works best for

cavitation protection and the power monitor works best for

no flow, loss of flow and excessive flow. If only one method is

going to be applied then differential pressure would be the pre-

ferred method.

The preferred method for differential pressure monitoring is to

install pressure transducers in the suction line between the pump

and the block valve and in the discharge line between the pump

and the first valve (either check or block). The signals from the

pressure transducers are then sent to the control system and the

pressure and time delay limits can be set within the control system

program. Calibration of the transducers should always be checked

as part of the installation process and startup of the system.

Recommended set points are:

• Differential Pressure (DP): 15 to 20 PSI below normal op-

erating differential pressure

• Time Delay (TD): 20 seconds or less

When using an automatic control system, the following param-

eters are recommended:

A. Single pump:

• 20 Second Delay: Low differential pressure trip

• 60 Second Delay: Pump Restart

Repeat above timing sequence for a maximum of 3 starts. If

low differential continues after 3 starts a manual reset of the

process controller is required.

B. Dual pumps:

• 20 Second Delay: “A” Pump low differential pressure trip

• 60 Second Delay: “B” Pump start

• 20 Second Delay: “B” Pump low differential pressure trip

• 60 Second Delay: “A” Pump start

Repeat above timing sequence for a maximum of 3 starts per

pump (6 starts combined total). If low differential continues

after 3 starts per pump (6 starts combined total) a manual

reset of the process controller is required.

Commercially available differential pressure switches are provided

with little to no adjustment. These switches will work but with no

adjustment in the time frame or differential pressure set points

they typically will not meet Teikoku’s pressure and time delay

recommendations.

The preferred method to monitor the input power to the pump

would be to use a power monitor like the Load Controls PMP-25.

The power monitor prevents failures due to loss of prime, no flow

and excessive flow. The performance curve of the pump is used

to set the low power and high power warnings and trip set point.

Actual operating data can be used to make the final adjustments

to the initial set points.

3.2.1 Setting of Thermal Overload Protective Device

Set the thermal overload protective device at the rated current

indicated on the nameplate. It is effective as a protecting device

for canned motors to set the thermal overload protective device

at as low current as possible. When operating current is far lower

than rated current, set the thermal overload protective device on

the operating current not the rated current. Generally, it is rec-

ommended to set the thermal overload protective device at the

following values:

• Variation of voltage and load is small: operating current

times 1.1

• Variation of voltage and load is big: operating current

times 1.25

Attention!

Do not set the thermal overload protective device at more

than the full load amps (FLA) listed on the name tag.

3.2.2 Priming and Venting

Complete priming should be carried out in the following order:

1. Open suction valve 100%

2. Open discharge valve 100%

3. Open reverse circulation line valve 100%

4. Open discharge pipe vent valve 100%

5. Open minimum flow valve (if required)

6. Wait until frost or condensation forms over the entire

pump and motor

Caution!

All valves in the reverse circulation line must remain fully

open while the pump is in operation. Verify that the cor-

rect restriction orifice is properly installed in the reverse

circulation line.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)9

3.2.3 Rotation Check

Centrifugal pump impellers must rotate in the proper direction to

deliver rated head and capacity. The impeller must rotate in the

same direction as the arrow cast on the pump casing.

Caution!

Pump and motor must be fully primed, vented, and liquid

full prior to checking direction of rotation.

3.2.3.a Rotation Check using Type-M TRG Meter AM-45

The Type-M TRG Meter AM-45 is designed to provide a verifica-

tion of direction of rotation. If the TRG Meter immediately pegs

full scale the direction of rotation is not correct.

1. Verify suction valve is 100% open.

2. Set discharge valve 10% to 20% open.

3. Check that valves in reverse circulation piping are open. Verify

that the correct restriction orifice is installed in the reverse

circulation line.

4. Switch on the pump for 3 to 5 seconds.

5. Check indication of TRG meter. If TRG meter is pegged full

scale red, the pump is rotating in the reverse direction. See

Section 2.3.3 and Table 2-1.

6. If direction of rotation is not correct, swap any two of the

electrical supply leads and repeat rotation check.

7. Once direction of rotation has been verified, stop the pump

and leave it for several minutes.

8. Once you have determined correct rotation, tag correctly

connected main power leads, in accordance with motor

lead markings.

3.2.3.b Rotation Check using Hand-held TRC-1 Indicator

The Type-L TRG Meter A45 C does not provide direction of

rotation. The Teikoku TRC-1 hand-held direction of rotation in-

dicator is available from Teikoku USA. This portable device can

be used to confirm the rotation of any motor. See Appx. F.

Decontamination Form

1. Verify suction valve is 100% open.

2. Set discharge valve 10% to 20% open.

3. Check that valves in reverse circulation piping are open. Verify

that the correct restriction orifice is installed in the reverse

circulation line.

4. Switch on the pump for 3 to 5 seconds.

5. Check indication of TRC-1 hand-held rotation indicator. See

Figure 3-1.

6. If direction of rotation is not correct, swap any two of the

electrical supply leads and repeat rotation check.

7. Once direction of rotation has been verified, stop the pump

and leave it for several minutes.

8. Once you have determined correct rotation, tag correctly

connected main power leads, in accordance with motor

lead markings.

3.2.3.c Rotation Check using Pressure & Amps

1. Open suction valve 100%.

2. Set discharge valve 10% to 20% open.

3. Check that valves in reverse circulation piping are open. Verify

that the correct restriction orifice is installed in the reverse

circulation line.

4. Switch on the pump for 3 to 5 seconds.

5. Note the motor amps and the discharge pressure at a pressure

gauge, which should be installed between the pump casing

and discharge valve.

6. Reverse any two of the three power leads and read the amps

and the pressure gauge again. The higher amps and pressure

is the correct direction of rotation.

7. Once direction of rotation has been verified, stop the pump

and leave it for several minutes.

8. Once you have determined correct rotation, tag correctly

connected main power leads, in accordance with motor

lead markings.

Attention!

It is recommended that the unit be run as little as possible

with a closed discharge valve in order to prevent excessive

overheating of the liquid circulating within the unit.

Figure 3-1. Teikoku TRC Rotation Indicator

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)10

3.3 Starting Procedure

Caution!

Do not start or operate pump unless fully primed and

liquid full.

Caution!

Do not continuously cavitate the pump.

Attention!

The pump should not be allowed to run for more than one

minute with the discharge valve fully closed.

Attention!

Wait a minimum of five minutes between starts.

After priming, venting, and checking the direction of rotation, put

the pump in operation as follows:

1. Set the valve in the suction line to 100% open.

2. Set the valve in the discharge line to 20% open.

3. Set the valve in the reverse circulation line valve to 100% open.

4. Set the valve in the discharge vent line to 100% open.

5. Set the valve in the by-pass line at required percent. To accu-

rately set the valve position in the by-pass line for the correct

minimum flow amount, the valve in the discharge line must

be fully closed.

6. Start the pump. Pump should operate with very low noise and

vibrations. Excessive or abnormal noise or vibrations should

be corrected immediately.

7. When the pump is running at full speed, slowly open the

valve in the discharge line to the desired setting.

8. Once pump is operational, check the reading of the TRG me-

ter. Record initial reading for comparison to future readings.

Check indication of TRG meter. See Table 2-1.

9. If the suction and discharge lines are completely filled with

system liquid and adequate suction head is available, the

pump can be started without closing the discharge valve.

During any start up sequence, caution must be exercised not

to exceed full load ampere rating indicated on the nameplate.

10. If the unit has not been run for a period of two weeks or

more, the following inspections should precede its operation:

A. Check terminal box for moisture.

B. Upon starting, check for excessive noise, vibration, erratic

speeds or excessive amp draw.

Caution!

If the pump appears to be air bound as a result of the

unit not being properly primed, do not continue opera-

tion. Locate and correct the conditions that prevent proper

priming before attempting to start the unit.

3.4 Operation Details

TRG meter should be checked periodically during operation. If

the initial reading (TRG) was not recorded, then the color coding

system shown in Section 2.3.3 may be used to determine bearing

changing intervals.

Hazard!

Do not operate if TRG meter condition is RED.

Discharge pressure should be checked frequently during op-

eration. Pressure should be stable in a non-variable closed loop

although the discharge pressure gauge needle may show small

fluctuations.

Check motor amps at normal operations. Verify motor amps

are within the expected range. Pump should never be operating

above the rated full load amps listed on the name tag.

In some cases, the liquid supply may contain an excessive amount

of air or gas, which will tend to separate from the liquid and re-

main in the passages of the pump. This results in the pump losing

its prime and becoming air bound with a marked reduction in

capacity. The discharge pressure gauge will show large fluctua-

tions if this occurs.

If any abnormal noise or vibration is observed, stop the pump and

check for possible causes, see Appx. C. Troubleshooting

3.5 Shutdown Procedure

Shutdown as follows:

1. Close the valve in the discharge line.

Attention!

The pump should not be allowed to run for more than

one minute with the discharge valve fully closed.

2. Stop the pump (de-energize the motor).

3. Close reverse circulation, by-pass and suction valves if pump is

to be removed from service.

Attention!

If the pump is to be shut down for a long period of

time or if there is danger of freezing, after stopping

the pump, shut all valves, and drain the entire pump

and connected piping.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)11

4.Maintenance

4.1 Recommended Tools for Disassembly,

Reassembly, and Inspection

Size Description

Metric socket wrenches For pump casing, rear bearing housing

bolts, rear shaft sleeve retaining bolt, and

impeller retaining bolt.

Metric hex wrenches For bearing retaining screws.

For front bearing housing retaining bolts.

.200" or greater

travel dial indicator

To measure endplay.

Dial calipers To measure bearing wear.

Feeler gauges To measure “g” gap.

Torque wrench To measure bolt tightness.

Channel-lock pliers To bend up tabs on lock washers.

4.2 Disassembly

Caution!

Observe and adhere to the end user specific lock out tag

out procedures.

1. Fully close valves in discharge, suction, reverse circulation and

utility piping.

2. Disconnect the power cables from the connection box prior

to disassembly.

Hazard!

Safety hazard to personnel will exist if power cables

are not disconnected.

3. Drain pump per end user specific procedures.

4. Since piping loads may exist, insert bracing under piping.

5. Remove discharge, suction and reverse circulation flange bolting.

Hazard!

Always assume that there is liquid left in the pump.

6. Remove anchor bolting in order to slide pump out of piping.

7. Remove casing bolts and slide casing off. Be careful not to

allow the casing to bind to or drop onto the impeller and

inducer. Be careful not to spill any remaining liquid that may

have been trapped in casing. Remove casing gasket.

8. Measure and record the end play and the “g” gap before

further disassembly. See Figure 4-4.

9. To remove impeller, extend tabs of lock washer and remove

impeller bolt, Slide impeller and, if supplied, inducer off rotor

shaft. Be careful of small parts that can be lost.

10. Remover impeller key.

11. Remove socket head cap screws and remove front bearing

housing from stator assembly.

Hazard!

Exercise care while removing this housing because of

liquids which may be contained in the stator assembly.

12. Remove impeller adjusting washer(s). Record quantity and

thickness. The adjusting washer(s) may come off the shaft

with the front bearing housing.

13. Remove rear bearing housing bolts and remove rear

bearing housing from stator assembly. Remove rear bearing

housing gasket.

Hazard!

Exercise care while removing this housing because of

liquids which may be contained in the stator assembly.

14. Remove rotor assembly. Place on a clean cloth to avoid dam-

age. During the removal of the rotor, take care in handling to

prevent damage to the rotor or stator because the rotor will

drop once the armature clears the stator assembly and the

rotor shaft may hit the stator liner if not properly supported.

15. Remove front shaft sleeve and front thrust collar. Remove

anti-rotation pin/key.

Caution!

Do not forcibly remove shaft sleeve. If shaft sleeve does

not slide off easily it may be required to machine or cut

the shaft sleeve off the rotor shaft.

16. To remove rear shaft sleeve and thrust collar, bend tabs up on

lock washer and unscrew bolt. This bolt has left hand threads.

17. Remove rear shaft sleeve and rear thrust collar. Remove anti-

rotation pin/key.

18. To remove bearing, remove set screw, slide out bearing, and

remove flat washer.

19. Remove bearing adjusting washer(s) from rear bearing hous-

ing. Note quantity and measure thickness.

4.3 Inspection

4.3.1 Bearings

Check the following points:

1. Thrust face for scratches and chips. Refer to Figure 4-3 (L),

for excess wear on thrust surface. (Check this dimension after

bearing has been removed.)

2. Wear inside of bearing bore. Refer to Figure 4-3 (A-B).

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)12

4.3.2 Shaft Sleeves and Thrust Collars

The rotor assembly shaft sleeves and thrust surfaces should also

be visually inspected at the bearing contact area for general ap-

pearance and uniform wear.

Excessive undercutting, pitting, or scoring is cause for replacement.

Check the following points:

1. Corrosion

2. Contact marks and wear.

4.3.3 Rotor Assembly Inspection

The complete rotor assembly should be visually inspected for

cracks, breaks, pitting, or corrosion which might destroy the ef-

fectiveness of the hermetically sealed rotor end covers and sleeve.

Check rotor assembly shafts for straightness.

4.3.4 Stator Assembly Inspection

The complete stator assembly should be visually inspected for

cracks, breaks, pitting, or corrosion of the stator liner which

may destroy the effectiveness of the barrier. Inspect the inside

of the electrical junction box for corrosion and moisture. Teikoku

recommends performing a megger and resistance check on the

motor winding.

4.3.5 General Inspection

1. Inspect the threads on both ends of the rotor shaft to en-

sure they are not damaged. Teikoku Type-R (Plan 13-SE) have

right-hand threads, except the rear rotor bolt which has left-

hand threads.

2. Be sure that all mating faces are free of nicks and burrs so that

they will have a smooth face ensuring a good seal. Clean off

any trace of old gasket material.

3. Make sure all parts are clean. Inaccessible area may be cleaned

with a small brush or pointed tool.

4. The impeller, casing, and front bearing housing should be in-

spected for wear. If excessive grooving or scoring of the rings

areas, hubs, and bores is evident, these components must be

repaired or replaced.

5. On the rear bearing housing, inspect the ports for reverse cir-

culation line to ensure that the ports are clear and free of

obstructions.

4.4 Reassembly

1. Clean and dry all parts. Reassemble in the reverse manner of

disassembly.

2. Install adjusting washer(s) into rear bearing housing. Quantity

and thickness of adjusting washers is as required for proper

rotor end play.

Attention!

The front bearing has only spiral grooves, the rear

bearing has spiral and straight grooves. Figure 4-1 and

Figure 4-2.

3. Insert bearing with flat washer into front and rear bearing

housings. Position flat washer side of bearing in line with set

screw hole. While holding bearing down, tighten set screw.

Caution!

Do not over-tighten set screw as damage to bearing

may occur.

4. Install anti-rotation pin/key. Slide on rear thrust collar, verify-

ing that the thrust collar is installed correctly. The coated side

of the thrust collar should be positioned facing outboard with

the chamfer side facing inboard. Slide on the rear shaft sleeve,

ensuring that the shaft sleeve is tight against the thrust collar

and is engaged in the anti-rotational key or pin. Install the

flat washer, lock washer, and lock bolt, ensuring that the lock

washer tab is engaged in the slot in the shaft sleeve. Torque

lock bolt per Table 4-4. This bolt has left hand threads. Bend

up tabs on lock washer.

5. Install anti-rotation pin/key. Slide on front thrust collar, veri-

fying that the thrust collar is installed correctly. The coated

side of the thrust collar should be positioned facing outboard

with the chamfer side facing inboard. Slide on the front shaft

sleeve ensuring that the shaft sleeve is tight against the thrust

collar and is engaged in the anti-rotational key or pin. Slide

assembled rotor into stator with rear end of rotor extending

out of the stator.

6. Install the rear stator gasket. Slide the rear bearing housing

onto the rotor and slide the rear bearing housing and rotor

into the stator. Take care to tighten bolting evenly using a star

or cross pattern. Torque bolts per Table 4-4.

7. Slide front bearing housing onto rotor and into stator. Take

care to tighten bolting evenly. Ensure that the shaft sleeve

is tight against the thrust collar and is engaged in the anti-

rotational key or pin. Verify that the rotating assembly rotates

freely by hand with no binding or rubs.

8. Install adjusting washers onto rotor shaft. Quantity and thick-

ness is as required for proper “g”gap.

9. Install impeller key.

10. Slide impeller and inducer, if required, onto rotor shaft, install

the flat washer, lock washer and lock bolt ensuring that the

lock washer tab is engaged in the impeller key slot. Check

rotor assembly end play. End play should be within the range

indicated in Table 4-3. If the rotor assembly does not fall

within this range, remove rear bearing housing, remove rear

bearing and increase or decrease the adjusting washer quan-

titiy and thickness as required.

11. Measure the “g”gap by pulling impeller forward shown in

Figure 4-4. The “g”gap should be within indicated ranges

shown in Table 4-3. If gap is not within specified range, use

adjusting washers behind impeller to make adjustments.

12. Make sure impeller bolt is tight (see Table 4-4 for correct

torque values) and lock washer locking tabs are bent over.

13. Assembled pump should rotate freely by hand with no metal

to metal contact.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)13

14. Install pump casing gasket. Slide pump back into casing and

tighten all bolts. Add new Teflon tape to plugs where needed.

Torque bolts per Table 4-4.

4.5 Service Policy

Any Teikoku USA product, damaged or inoperative for any rea-

son, can be repaired at the Teikoku service centers at minimal cost

and returned to the customer as quickly as possible. Refer to the

Pump Repair Receipt Policy in the Appendix.

Caution!

Before returning units to the factory for examination

or repair, clean and decontaminate the pump and/

or parts thoroughly to prevent corrosive attack dur-

ing shipment or injury to personnel handling returned

equipment. tag pump with information regarding the

fluid it was handling and operating conditions at the

time of failure.

Proper service will be facilitated with the proper submittal of a

Teikoku USA Decontamination Form. The Decontamination Form

and the Pump Repair Receipt Policy are available from the fac-

tory, from the Teikoku USA field representatives, and from the

Appendix of this instruction manual.

4.6 Spare Parts

Teikoku USA recommends to have on hand at least one com-

plete repair kit for each pump model. The repair kit includes the

bearings, sleeves, thrust collars, gaskets and lock washers. When

ordering spare parts, provide the serial number and model num-

ber; then give the part name which is noted on the sectional

drawing, Appx. D. Sectional View (6A-8901). When ordering

an impeller, include the diameter, which can be noted from the

pump order acknowledgment or from the pump nameplate.

Figure 4-3. Bearing Wear Limits

SHAFT SLEEVE

BEARING

THRUST COLLAR

SHAFT

KEY OR PIN

L

ØB

ØA

Figure 4-4. “g” Gap

FRONT

BEARING

HOUSING

ADJUSTING

WASHER

IMPELLER

g± 0.004"(0.1 mm)

Pull Impeller

forward all the way

Figure 4-1. Front Bearing – Only Spiral Grooves Figure 4-2. Rear Bearing – Spiral and Straight Grooves

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)14

Figure 4-5. Type-R (Plan 13-SE) Model Number Indentification

Code Example

R42-316F4AM-0506T1-E

MOTOR FRAME IMPELLER SIZE

Table 4-1. Bearing Wear Limit

Motor

Frame Number*

øA – øB L

Inch mm Inch mm

119 0.012 0.3 1.746 44.2

215, 216, 217

0.016 0.4

1.937 49.2

316, 317 2.331 59.2

416, 417 2.724 69.2

426, 516, 518 0.020 0.5 3.079 78.2

526, 529 4.449 113

NOTE: For F, H, N, C, and U Insulations (Standard Carbon Bearings)

* See Figure 4-5

Table 4-2. Adjusting Value of Gap “g”

Motor

Frame Number*

Impeller

Size

“g” gap (rotor pulled)

Inch mm

119 R

.154 to .161 3.9 to 4.1215, 216, 217 S

316, 317 TS (S)

T.161 to .169 4.1 to 4.3

416, 417 T.173 to .181 4.4 to 4.6

426, 516, 518 U.193 to .201 4.9 to 5.1

526, 529

U

V.232 to .240 5.9 to 6.1

W.248 to .256 6.3 to 6.5

* See Figure 4-5

Table 4-3. End Play

Motor Frame Number* End-Play

Inch mm

119 .039 to .063 1.0 to 1.6

215, 216, 217 .043 to .067 1.1 to 1.7

316, 317

416, 417 .055 to .079 1.4 to 2.0

426, 516, 518 .067 to .091 1.7 to 2.3

526, 529 .071 to .094 1.8 to 2.4

* See Figure 4-5

Table 4-4. Tightening Torques

Bolt Size Torque

(ft.lb.) Bolt Size Torque

(ft.lb.)

Rotor (304SS, 304LSS, 316SS, 316LSS)

Note: Rear rotor bolts have left-hand threads

M10 13 M18 73

M12 22 M20 109

M14 34 M22 145

M16 55 M24 181

Front Bearing Housing (304SS, 304LSS, 316SS, 316LSS)

M6 3.0 M12 22

M8 6.0 M14 34

M10 13 M16 55

Set Screw (316SS, 316LSS)

M6 1.3 M8 4.4

Pump Casing for Flat Gasket (304SS)

M6 3.0 M12 22

M8 6.0 M14 34

M10 13 M16 55

Pump Casing for Spiral Wound Gasket (SCM435)

M10 42 M14 116

M12 73 M16 181

Table 4-5. Torque Values for Motor Terminal Connections –

Terminal Box and Connection Stud Size

Terminal Box

Size*

Connection Stud Size** Torque Values

U, V, W X, Y, Z ft.lb Nm

Small (S) M6 —2.9 4

Medium (M) M8 —7.4 10

M10 —11 15

Large (L) M12 M12 21 29

* Refer to Table 4.6

** The number after the “M” represents the nominal threads OD (mm)

Table 4-6. Motor Frame and Terminal Box Size

Motor Frame Number* Terminal Box Size

118, 119

S

215, 216, 217

315, 316, 317, 325, 326

416, 425, 426

417

M515, 516, 517, 525, 526

625, 626

518, 615, 616, 617

L715, 716, 717, 718

725, 726, 727

* See Figure 4-5

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)15

Table 4-7. Pump Ring Clearance (Standard Horizontal Pump)

IMPELLER

CASING

FRONT BEARING

HOUSING ADAPTOR

ØX3 ØC2ØC3 ØX2 ØX1 ØC1

Casing Size C1 – X1 X2 – C2 C3 – X3––

Inch mm Inch mm Inch mm

0204 R

0.030 - 0.034 0.78 - 0.88 0.030 - 0.042 0.78 - 1.08 0.028 - 0.032 0.70 - 0.800204 S

0204 T

0405 R

0.030 - 0.034 0.78 - 0.88 0.030 - 0.042 0.78 - 1.08 0.028 - 0.032 0.70 - 0.80

0405 S

0405 T

0405 U 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22

0408 S 0.032 - 0.038 0.84 - 0.96 0.032 - 0.046 0.84 - 1.16 0.028 - 0.032 0.70 - 0.80

0408 T

0506 R 0.030 - 0.034 0.78 - 0.88 0.030 - 0.042 0.78 - 1.08

0.028 - 0.032 0.70 - 0.80

0506 S 0.032 - 0.038 0.84 - 0.96 0.032 - 0.046 0.84 - 1.16

0506 T

0506 U 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22

0508 S 0.032 - 0.038 0.84 - 0.96 0.032 - 0.046 0.84 - 1.16 0.028 - 0.032 0.70 - 0.80

0508 T 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22 0.030 - 0.034 0.76 - 0.86

0510 T 0.032 - 0.038 0.84 - 0.96 0.032 - 0.046 0.84 - 1.16 0.030 - 0.034 0.76 - 0.86

0608 R 0.030 - 0.034 0.78 - 0.88 0.030 - 0.042 0.78 - 1.08

0.030 - 0.034 0.76 - 0.86

0608 S 0.032 - 0.038 0.84 - 0.96 0.032 - 0.046 0.84 - 1.16

0608 T 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22

0608 U

0810 S 0.032 - 0.038 0.84 - 0.96 0.032 - 0.046 0.84 - 1.16

0.030 - 0.034 0.76 - 0.860810 T 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22

0810 U

1012 T 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22 0.032 - 0.036 0.80 - 0.921012 U

1012 V 0.036 - 0.044 0.94 - 1.10 0.036 - 0.052 0.94 - 1.30

1015 T 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22 0.032 - 0.036 0.80 - 0.921015 U

1015 V 0.036 - 0.044 0.94 - 1.10 0.036 - 0.052 0.94 - 1.30

1215 U 0.034 - 0.040 0.88 - 1.02 0.034 - 0.048 0.88 - 1.22 0.032 - 0.036 0.40 - 0.46

1215 V 0.036 - 0.044 0.94 - 1.10 0.036 - 0.052 0.94 - 1.30

1520 W 0.036 - 0.044 0.94 - 1.10 0.036 - 0.052 0.94 - 1.30 0.034 - 0.040 0.86 - 1.00

NOTE: All clearances are values in diameter.

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)17

A. Quick Start Guide

Teikoku Type-R (Plan 13-SE) Refrigeration Pump

Prior to Priming the Pump

Attention!

Do not operate the pump if the TRG bearing wear monitor

reading is in the red. Doing so will void the warranty.

1. Verify that the vessel contains enough liquid as to not cause

cavitation or dry running

2. Verify the restriction orifice in the reverse circulation line is

installed between the flange at the rear of the motor and the

reverse circulation piping

3. Verify the reverse circulation piping is per the Teikoku recom-

mendations as shown in Appendix B.

4. Allow compressor to pull down system temperature to normal

operating temperature

Priming and Venting

1. Inspect installation

2. Open suction valve 100%

3. Open discharge valve 100%

4. Open reverse circulation valve 100%

5. Set discharge line vent valve to 100% open

6. * Open minimum flow valve 100% (If required)

7. Let pump fill with liquid until a frost layer develops on the

motor body

Rotation Check

with Type-M TRG Meter AM-45

1. Pump must be primed

2. Set suction valve to 100% open

3. Set discharge valve to 20% open

4. Set reverse circulation valve to 100% open

5. * Set minimum flow valve to required % open (if required)

6. Set discharge line vent valve to 100% open

7. Start pump for 3 to 5 seconds and observe TRG

8. If TRG is in the GREEN the rotation is correct

9. If TRG is pegged RED the rotation is reverse, swap two leads

and repeat rotation check

Rotation Check

with TRC-1 Hand-Held Rotation Checker

Use TRC-1 on Type-L TRG Meter A-45 C

1. Pump must be primed

2. Set suction valve to 100% open

3. Set discharge valve to 20% open

4. Set reverse circulation valve to 100% open

5. Set discharge line vent valve to 100% open

6. * Set minimum flow valve to required % open (if required)

7. Place TRC-1 on motor as per instructions in Appx. F.

Decontamination Form.

8. Start pump for 3 to 5 seconds and observe TRC-1

9. The illuminated arrow on the TRC-1 indicates the direction

of rotation

10. If the TRC-1 indicates the incorrect direction of rotation, swap

two leads and repeat rotation check

Standard Start up

1. Pump must be primed and rotation checked

2. Open suction valve 100%

3. Set discharge valve to 20% open

4. Set reverse circulation valve to 100% open

5. Set discharge line vent valve to 100% open

6. * Set minimum flow valve to required % open (if required)

7. Start pump

8. Gradually open discharge valve until specified capacity

is reached

Check Points

• TRG meter indicates low GREEN – check regularly

• Report when TRG meter goes into the yellow zone

• Verify motor amps are correct

• Verify differential pressure is correct

• Verify pump is operating without excessive or abnormal

noise or vibrations

Teikoku USA | Chempump Instruction Manual HE-10677-P (1018)18

Teikoku Type-R (Plan 13-SE) Refrigeration Pump

These instructions describe the recommended method for installation of the reverse circulation piping on

Teikoku Type-R (Plan 13-SE) pumps, which are specifically designed to handle highly volatile fluids. These

instructions also include recommendations for the suction pipe and the bypass pipe.

1. Reverse Circulation Piping

The purpose of these recommendations

is to vent any vapors that form inside the

reverse circulation pipe. Trapped vapors

in the reverse circulation line will cause

the flow through the line to stop. In the

event that the flow stops, the pump

will be damaged from liquid vaporiza-

tion and/or overheating. Following these

recommendations will allow both the

vapor and liquid to flow freely back to the

suction tank.

a. This line must be connected to the

vapor zone in the suction tank.

b. Never install a check valve on this line.

c. This line must be continuously rising

to the suction tank.

d. This line must never be down-slope

at any point, as this will create

vapor traps.

e. The Teikoku supplied reverse circula-

tion line orifice must be installed in

this line. Controlling the required re-

verse circulation flow rate using a flow

meter and a control valve is an option.

f. Install a block valve in this line. This

block valve must be 100% open at

all times.

g. To prevent vapor traps, use of a full

port ball type valve is recommended.

h. The orifice plate must be installed in

vertical line.

i. This line must be individual for each

pump. Never combine these lines.

j. Never connect this line to the suction,

discharge or minimum flow lines.

k. The total head of this line (HR) must

never exceed the value specified on

the data sheet of the pump.

2. Suction Pipe

a. Suction pipe shall be constantly falling

until it reaches the pump suction.

b. If any reducer is installed in the

suction line, the reducer must be ec-

centric and must be installed with the

flat side on top.

3. Bypass Pipe for Venting and

Minimum Flow

a. This line must be continuously rising

back up to the suction tank.

b. If incorporated, the orifice plate shall

be installed in vertical line.

c. Never combine these lines.

d. A block valve shall be installed in the

bypass line.

B. Reverse Circulation (4N-7653)

Figure B-1. Reverse Circulation Piping

LOWEST LIQUID LEVEL

HIGHEST LIQUID LEVEL

REVERSE PIPE

BYPASS PIPE

SUCTION

DISCHARGE

QS

QD

QR

QM

HRS

QS

QD

QM

QR

Table of contents

Other Teikoku Water Pump manuals

Popular Water Pump manuals by other brands

GORMAN-RUPP

GORMAN-RUPP PA4A60-4024T-ESP Installation, operation and maintenance manual

Homa

Homa TP 28 Original instruction manual

Productos McLand

Productos McLand GARLAND GEISER 401 Q instruction manual

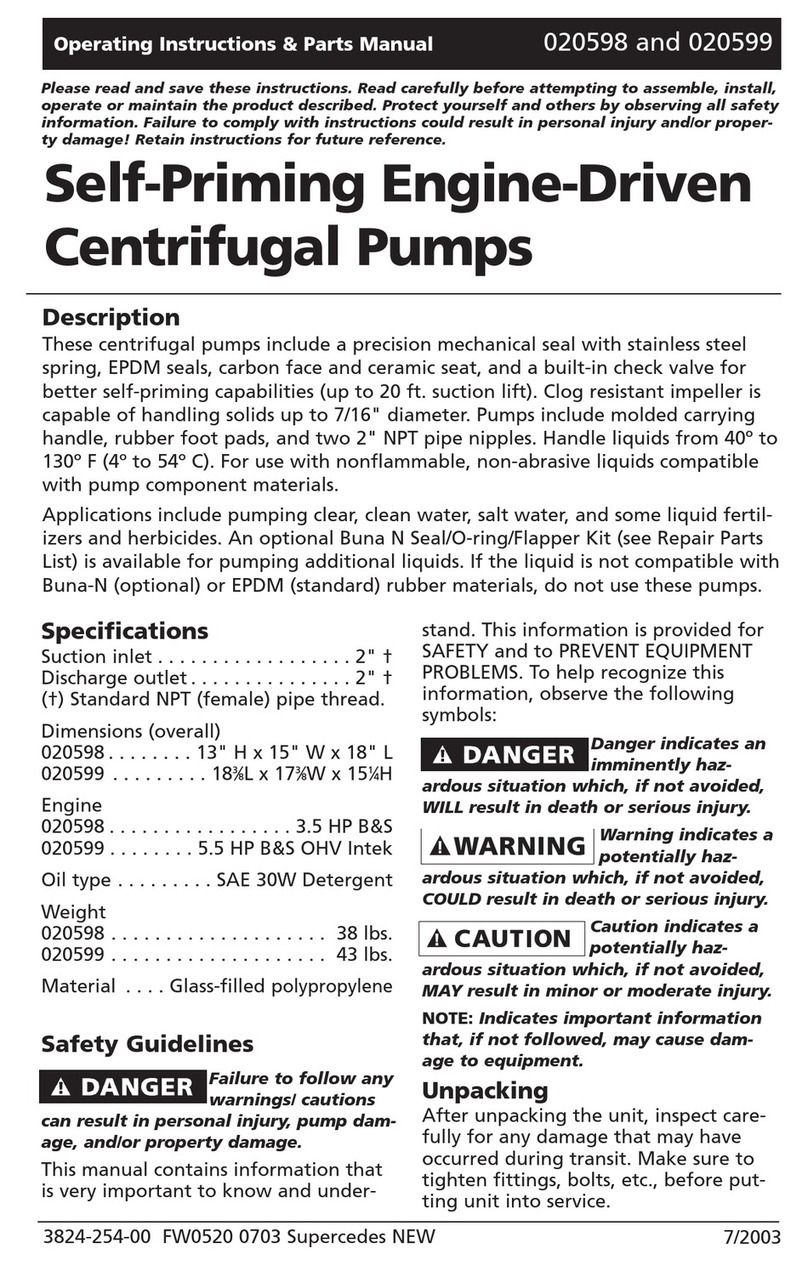

HP

HP 20598 Operating instructions and parts manual

maxwatt

maxwatt MXWP20 Operator's manual

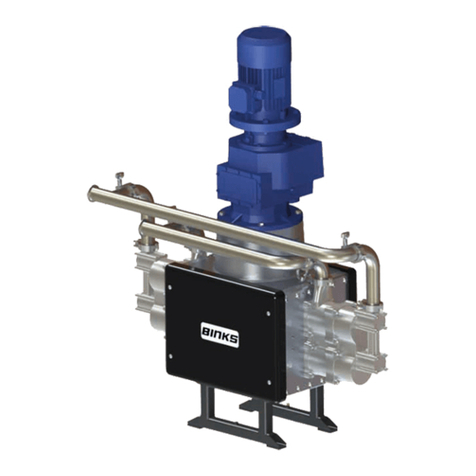

Binks

Binks E4-60 Service manual