HC151+ pH(Rx)-Cl(J) / HC200+ pH(Rx)

ENGLISH

INDEX

1. GENERAL RULES..................................................................................................................................... 4

1.1 INSTALLATION STANDARDS ........................................................................................................... 4

2. OPERATION .............................................................................................................................................. 5

2.1 OVERALL DIMENSIONS.................................................................................................................... 5

2.2 TECHNICAL FEATURES.................................................................................................................... 5

2.3 HYDRAULIC FEATURES ................................................................................................................... 6

2.4 PERFORMANCE GRAPHS................................................................................................................ 7

2.5 CONTENT OF THE PACKAGE (Standard version) ........................................................................... 7

3. HC151+pH(Rx)-Cl(J) / HC200+pH(Rx) .................................................................................................... 8

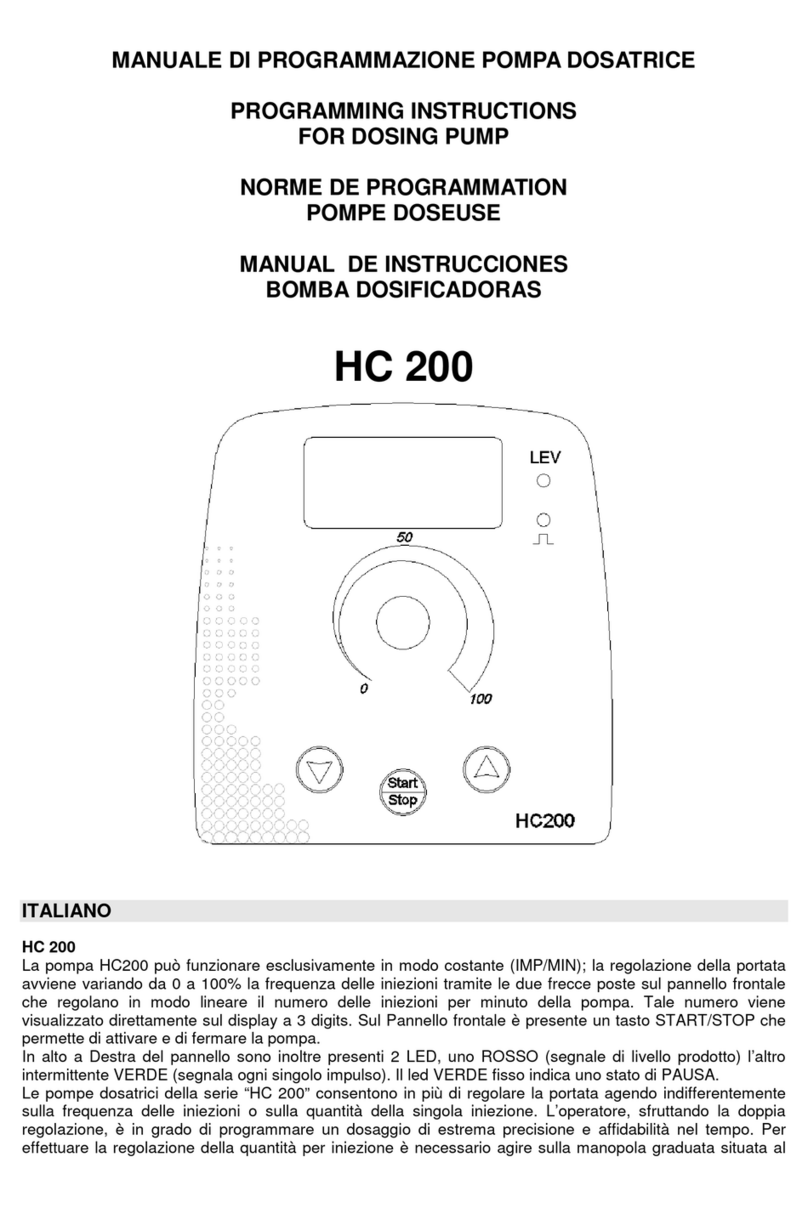

3.1 HC151+/HC200+PUMP CONTROLS................................................................................................. 8

3.2 HOW TO NAVIGATE THROUGH THE MENUS................................................................................. 9

3.3 FIRST PUMP INITIALIZATION......................................................................................................... 10

3.4 GETTING STARTED......................................................................................................................... 11

3.4.1 Priming....................................................................................................................................... 11

3.4.2 Pump calibration ........................................................................................................................ 12

3.5 PUMP SETUP................................................................................................................................... 13

3.5.1 SETPOINT menu....................................................................................................................... 13

3.5.2 CALIBRATION menu................................................................................................................. 15

3.6 CORRELATION BETWEEN FREE CHLORINE, pH e REDOX ....................................................... 18

3.7 SETTINGS ........................................................................................................................................ 19

3.7.1 General e Security ..................................................................................................................... 19

3.7.2 General > Proximity sensor ....................................................................................................... 20

3.7.3 Generals > Temperature probe ................................................................................................. 21

3.7.4 Generals > Measure startup delay............................................................................................. 22

3.7.5 General > Energy saving ........................................................................................................... 22

3.7.6 Security > Password.................................................................................................................. 23

3.7.7 Security > Level Input Polarity ................................................................................................... 23

3.7.8 Security > Low Level Delay ....................................................................................................... 24

3.7.9 Security > Over Feed Alarm (OFA)............................................................................................ 24

3.7.10 Security > Factory Settings restore............................................................................................ 25

3.8 STATISTICS...................................................................................................................................... 26

4. DOSING PUMPS INSTALLATION RULES............................................................................................. 27

5. ELECTRICAL CONNECTIONS............................................................................................................... 28

5.1 HC151+ PImA model pump .............................................................................................................. 28

6. TROUBLESHOOTING............................................................................................................................. 29

6.1 PROBLEM –CAUSE –SOLUTION.................................................................................................. 29

7. MAINTENANCE....................................................................................................................................... 29

8. WARRANTY............................................................................................................................................. 29

EXPLODED VIEWS ........................................................................................................................................ 30