BlueChip Ultima Series User manual

Ultima X

2U Passive Industrial PC

User Manual

Document Reference Ult1ima2U Passive Manual

Document Issue Level 2.0

Blue Chip Technology Ltd.

Chowley Oak

Tattenhall

Chester

CH3 9EX

U.K.

Telephone: +44 (0)1829 772000

Facsimile: +44 (0)1829 772001

www.bluechiptechnology.co.uk

ULTIMA INDUSTRIAL PC CONTENTS

Blue Chip Technology Limited Page 2

CONTENTS

CONTENTS.................................................................................................................2

INTRODUCTION.........................................................................................................4

COMPANY PROFILE......................................................................................................................... 4

COPYRIGHT ...................................................................................................................................... 4

LIMITATIONS OF LIABILITY ............................................................................................................. 4

REGULATORY STATEMENTS ......................................................................................................... 5

RELATED PUBLICATIONS................................................................................................................ 5

TRADEMARKS................................................................................................................................... 5

PRECAUTIONS.................................................................................................................................. 6

Electro-Static Discharges.............................................................................................................................6

On-Board Battery..........................................................................................................................................6

BIOS & CMOS RAM.....................................................................................................................................6

Electromagnetic Compatibility .....................................................................................................................7

GETTING STARTED...................................................................................................8

MANUAL ORGANISATION................................................................................................................ 8

OVERVIEW ........................................................................................................................................ 9

INTRODUCTION................................................................................................................................ 9

FEATURES ........................................................................................................................................ 9

ULTIMA 2U PASSIVE INDUSTRIAL PC.......................................................................................... 10

CHASSIS FEATURES...................................................................................................................... 11

CHASSIS.......................................................................................................................................... 11

SPECIFICATION.............................................................................................................................. 11

CHASSIS LAYOUT .......................................................................................................................... 13

Rack Mount.................................................................................................................................................13

Desktop .......................................................................................................................................................14

Front panel .................................................................................................................................................15

Rear Panel ..................................................................................................................................................15

Power Supply & BBU .................................................................................................................................15

INSTALLATION.........................................................................................................16

ELECTRICAL ................................................................................................................................... 16

RACK MOUNTING........................................................................................................................... 16

MAINTENANCE.........................................................................................................22

PRECAUTIONS................................................................................................................................ 22

TOOLS.............................................................................................................................................. 22

REPLACING THE FILTER............................................................................................................... 22

REMOVING THE TOP COVER........................................................................................................ 23

REMOVING THE DRIVE CAGE ...................................................................................................... 23

ULTIMA INDUSTRIAL PC CONTENTS

Blue Chip Technology Limited Page 3

ADDING/REMOVING I/O BOARDS................................................................................................. 25

CHANGING A HDD.......................................................................................................................... 27

REPLACING THE PSU.................................................................................................................... 29

AC and DC PSU’s.......................................................................................................................................29

Dual Redundant PSU..................................................................................................................................30

TROUBLESHOOTING GUIDE ..................................................................................31

AMENDMENT HISTORY...........................................................................................32

SLIDE RAIL KIT FOR ULTIMA & DELTA PRODUCTS.............................................33

INTRODUCTION.............................................................................................................................. 33

CONVERTING THE DEFAULT 3 WAY CONFIGURATION INTO 4 WAY...................................... 33

Step 1: Remove long rear 3 hole bracket and replace with long 4 hole bracket.........................................34

Step 2: Remove smaller front 3 hole bracket and replace with smaller 4 hole bracket..............................35

ULTIMA INDUSTRIAL PC INTRODUCTION

Blue Chip Technology Limited Page 4

INTRODUCTION

COMPANY PROFILE

Blue Chip Technology is a leading specialist PC product manufacturer in Europe, providing innovation with

quality design and manufacturing from a single source.

Based in the North West of England, our purpose built complex contains both advanced research and

development facilities, and manufacturing facilities.

Specialising in the provision of industrial computing and electronic solutions for a wide range of UK and

European organisations, Blue Chip Technology has one of the UK's largest portfolios of industrial PCs,

Industrial PCs, peripherals and data acquisition cards. This extensive range of products, coupled with our

experience and expertise, enables Blue Chip Technology to offer an industrial processing solution for any

application. This is one of the products from our portfolio, providing you with a cost effective product

development and volume production tool.

A unique customisation and specialised system integration service is also available, delivering innovative

solutions to customers problems. The company's success and reputation in this area has led to a number of

large design and manufacturing projects for major companies.

British Standards Institute approval (BS EN 9001) means that all of Blue Chip Technology's design and

manufacturing procedures are strictly controlled, ensuring the highest levels of quality, reliability and

performance.

Blue Chip Technology are committed to the single European market, and continue to invest in the latest

technology and skills to provide high performance computer and electronic solutions for a world-wide

customer base.

COPYRIGHT

All rights reserved. No part of this publication may be reproduced, stored in any retrieval system, or

transmitted, in any form or by any means, electronic, mechanical, photocopied, recorded or otherwise, without

the prior permission, in writing, from the publisher. For permission in the UK please contact Blue Chip

Technology.

Information offered in this manual is believed to be correct at the time of printing. Blue Chip Technology

accepts no responsibility for any inaccuracies. The information contained herein is subject to change without

notice. There are no express or implied licences granted herein to any intellectual property rights of Blue Chip

Technology Ltd.

LIMITATIONS OF LIABILITY

In no event shall Blue Chip Technology be held liable for any loss, expenses or damages of any kind

whatsoever, whether direct, indirect, incidental or consequential, arising from the design or use of this product

or the support materials supplied with this product. If this product proves to be defective, Blue Chip

Technology is only obliged to replace or refund the purchase price at Blue Chip Technology's discretion

according to their Terms and Conditions of Sale.

ULTIMA INDUSTRIAL PC INTRODUCTION

Blue Chip Technology Limited Page 5

REGULATORY STATEMENTS

CE

This product meets the essential protection requirements of the European EMC Directive (2004/108/EC) and the

Low Voltage Directive (2006/95/EC), and is eligible to bear the CE mark.

Warning

This is a Class A product. In a domestic environment this product may cause radio

interference in which case the user may be required to take adequate measures.

FCC

NOTE:

This equipment has been designed to meet the requirements of a Class A digital device, pursuant to Part 15 of the

FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the

equipment is operated in a commercial environment. This equipment generates, uses, and can radiate radio

frequency energy and if not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the interference at their own expense.

WARNING:

Changes or modifications not expressly approved by the manufacturer could void the user's authority to operate

the equipment.

RELATED PUBLICATIONS

The following publications will provide useful information related to the Standard Personal Computer and can

be used in conjunction with this manual.

IBM Personal Computer AT Technical Reference, 1502494, IBM, 1984.

IBM Personal System/2 and Personal Computer BIOS Interface Technical Reference, 15F0306, IBM,

1987.

The Programmers PC Sourcebook, Microsoft

The Winn L. Rosch Hardware Bible, Brady

TRADEMARKS

All trademarks and registered names acknowledged.

IBM, PC, AT and PS/2 are trademarks of International Business Machines Corporation (IBM).

Phoenix BIOS is a trademark of Phoenix Technologies Inc

Intel is a registered trademark of the Intel Corporation.

All 80x86 and Pentium processors are registered trademarks of Intel Corporation.

MS-DOS and WINDOWS are registered trademarks of the Microsoft Corporation.

Linux is a registered trademark of Linus Torvalds.

ATA-Disk Chip is a trademark of Silicon Storage Technology Inc.

ULTIMA INDUSTRIAL PC INTRODUCTION

Blue Chip Technology Limited Page 6

PRECAUTIONS

Certain precautions are necessary when designing with, handling, and using circuit boards. It is imperative

that precautions are taken at all stages to avoid electro-static discharges, which will damage boards. Those

boards fitted with an on-board lithium battery must be handled carefully to avoid maltreatment of the

battery that could create a hazard.

ELECTRO-STATIC DISCHARGES

Some of the devices within the Industrial PC can be totally destroyed by static electricity. Also bear in mind

that the damage caused by static electricity may be partial and not immediately obvious. This could have an

effect on your product's reliability and warranty. Ensure that you take necessary static precautions, ideally

you should wear an approved wrist strap or if that is not possible, touch a suitable ground to discharge any

static build up. This should be repeated if the handling is for any length of time.

When carrying any boards around, please place them into the anti-static bag in which they came. This will

prevent any static electricity build up. If the board has an on-board battery, do not use black anti-static bags

because these tend to be conductive and will discharge any on-board battery.

ON-BOARD BATTERY

The ULTIMA 2U Passive Industrial PC may contain a Processor board with an on-board lithium cell

connected. To that end the following precautions apply and should be observed. If the battery is mistreated

in any way there is a very real possibility of fire, explosion, and harm. Great care should be taken with this

type of battery. Under NO circumstances should it be:

short-circuited

exposed to temperatures in excess of 100 ºC or burnt

immersed in water

unsoldered

recharged

disassembled

Expired batteries remain hazardous and must be disposed of in a safe manner.

BIOS & CMOS RAM

Please be aware that on Industrial PC products, it is possible to create configurations within the CMOS

RAM that make booting impossible. If this should happen, clear the CMOS settings, (see the description of

the Jumper Settings on the Processor board being used for details).

ULTIMA INDUSTRIAL PC INTRODUCTION

Blue Chip Technology Limited Page 7

ELECTROMAGNETIC COMPATIBILITY

This product has been assessed operating in representative, standard configurations. As with any PC product,

however, final installation & configuration can vary significantly, and so the following guidelines are offered to

help ensure that compatibility is maintained.

All components added to a system should either carry appropriate equivalent levels of compliance, or be

tested for compliance as part of the final system, and should be installed in accordance with supplier

recommendations.

The external enclosure should be securely fastened (with standard lids and covers in place) to ensure

good metal-to-metal contact around the internal electronics

Any metal back plate must be securely screwed to the chassis of the computer to ensure good metal-to-

metal (i.e. earth) contact.

Metal, screened, connector bodies should be securely connected to the enclosure.

The external cabling to boards causes most EMC problems. It is recommended that any external cabling

to the board be totally screened, and that the screen of the cable connects to the metal end bracket of the

board or the enclosure and hence to earth. Round, screened cables with a braided wire screen are used in

preference to those with a foil screen and drain wire. Wherever possible, use metal connector shells that

connect around the full circumference of the cable screen: they are far superior to those that earth the

screen by a simple “pig-tail”.

The keyboard and mouse will play an important part in the compatibility of the processor card since

they are ports into the board. Similarly, they will affect the compatibility of the complete system. Fully

compatible peripherals must be used otherwise the complete system could be degraded. They may

radiate or behave as if keys/buttons are pressed when subject to interference. Under these circumstances

it may be beneficial to add a ferrite clamp on the leads as close as possible to the connector. A suitable

type is the Chomerics type H8FE-1004-AS.

USB cables should be high quality screened types.

Ensure that the screens of any external cables are bonded to a good RF earth at the remote end of the

cable.

An earth stud is available on the back of the unit to improve grounding in extreme environments

Failure to observe these recommendations may invalidate the EMC compliance.

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 8

GETTING STARTED

MANUAL ORGANISATION

This manual describes in detail the Blue Chip Technology ULTIMA 2U Passive Industrial PC.

We have tried to include as much information as possible but we have not duplicated information that is

provided in the standard IBM Technical References, unless it proved to be necessary to aid in the

understanding of the ULTIMA Industrial PC.

The manual is sectioned as follows:

Overview, listing the Chassis’s features and specification;

Layout, and dimensional details;

Installation, and associated issues;

Troubleshooting guide;

We strongly recommend that you study this manual carefully before attempting to interface with the ULTIMA

Industrial PC or change the standard configurations. Whilst all the necessary information is available in this

manual we would recommend that unless you are confident, you contact your supplier for guidance. IT IS

PARTICULARLY IMPORTANT THAT YOU READ THE SECTION 'PRECAUTIONS' BEFORE

HANDLING ANY BOARDS.

If you have any suggestions or find any errors concerning this manual and want to inform us of these, please

contact our Technical Services department with the relevant details.

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 9

OVERVIEW

INTRODUCTION

The ULTIMA 2U PASSIVE is a ruggedised PC compatible microcomputer designed for reliable operation in

adverse environments. It is available as a 19" rack mountable unit, and as a desktop unit. Both units use a

common chassis and layout. System controls and disk drives are protected behind a sealed lockable steel door.

The machine is cooled internally by filtered air, which enters through a removable filter at the front panel and

exits at the rear. Access to boards is by a removable top cover. Connections to the boards are made at the rear of

the chassis and behind the front door.

FEATURES

Robust polished stainless steel chassis using recognised electromagnetic compatible (EMC) emission and

immunity design techniques.

Front panel with lockable door security for system controls.

ATX compliant.

Various switch mode AC power supply units

Optional Dual Redundant AC power supply unit

Optional 24V DC/DC power supply unit

Shock and vibration protected drive cage

supports addition of up to 4 PCI cards or 3 PCI cards and 1 ISA card (Note: only ONE card may be full

length, the others must be short length)

Filtered air through two 80 x 25 mm, 12V DC fans mounted behind the filter panel.

Quick access to the air filter. The filter is a coated polyester material of 30 PPI porosity having flammability

rating to UL94 Class V0.

Optional telescopic slide rail fittings.

Each system is supplied configured to order. The System Release Documentation details each particular

system's configuration

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 10

ULTIMA 2U PASSIVE INDUSTRIAL PC

Above 2004 Model

Below 2012 Model

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 11

CHASSIS FEATURES

CHASSIS

The basic chassis is common to both types of assembly (rack mounting and desktop), and comprises several sub-

assemblies:

Chassis body including the cooling fan assembly

Chassis front panel

Chassis cover

Internal drive cage assembly

Internal HDD cage assembly

Internal I/O Expansion assembly

Power supply unit

The common metalwork is of stainless steel construction with riveted fitments. Removable items are fixed by

screws.

Fitted internally are two cooling fans, the passive back plane and drives.

The front panel has two hinged doors. The left hand one has a slotted front to allow air through to the filter. The

right hand door, which is lockable, gives access to the drive bays, the power on/off switch and two USB ports.

SPECIFICATION

Chassis 19" Rack mountable polished stainless steel chassis

Shock mounting for drives

Front panel handles

Optional fully extending heavy duty slide rails

High capacity fans

Air filter approved to UL94 V-0

Locking door, covering drives, power and reset switch.

Nitrile/PVC seals - Approved to FMVSS302

Temperature Non-Operating -20 ºC to +70 ºC

Operating +0 ºC to +50 ºC

(Note1: Unit should not be started at temperatures less than 5ºC as items

with mechanical parts, such as the HDD, may not operate correctly at such low

temperatures resulting in damage

Note2: Max Temperature changes are restricted to 20ºC per hour

as damage to HDD’s resulting in data loss may occur above this

rate of change

Humidity 0-90 %RH non-condensing

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 12

Shock: (IEC 68-2-27)

Operating 5G 11 ms, ½sine wave

Non-operating 15G 11ms, ½ sine wave

Vibration: (IEC 68-2-6)

Operating 5 to 500 Hz, 0.5G

Non-operating 5 to 500 Hz, 2.0G

Safety Designed to meet EN 60950

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 13

CHASSIS LAYOUT

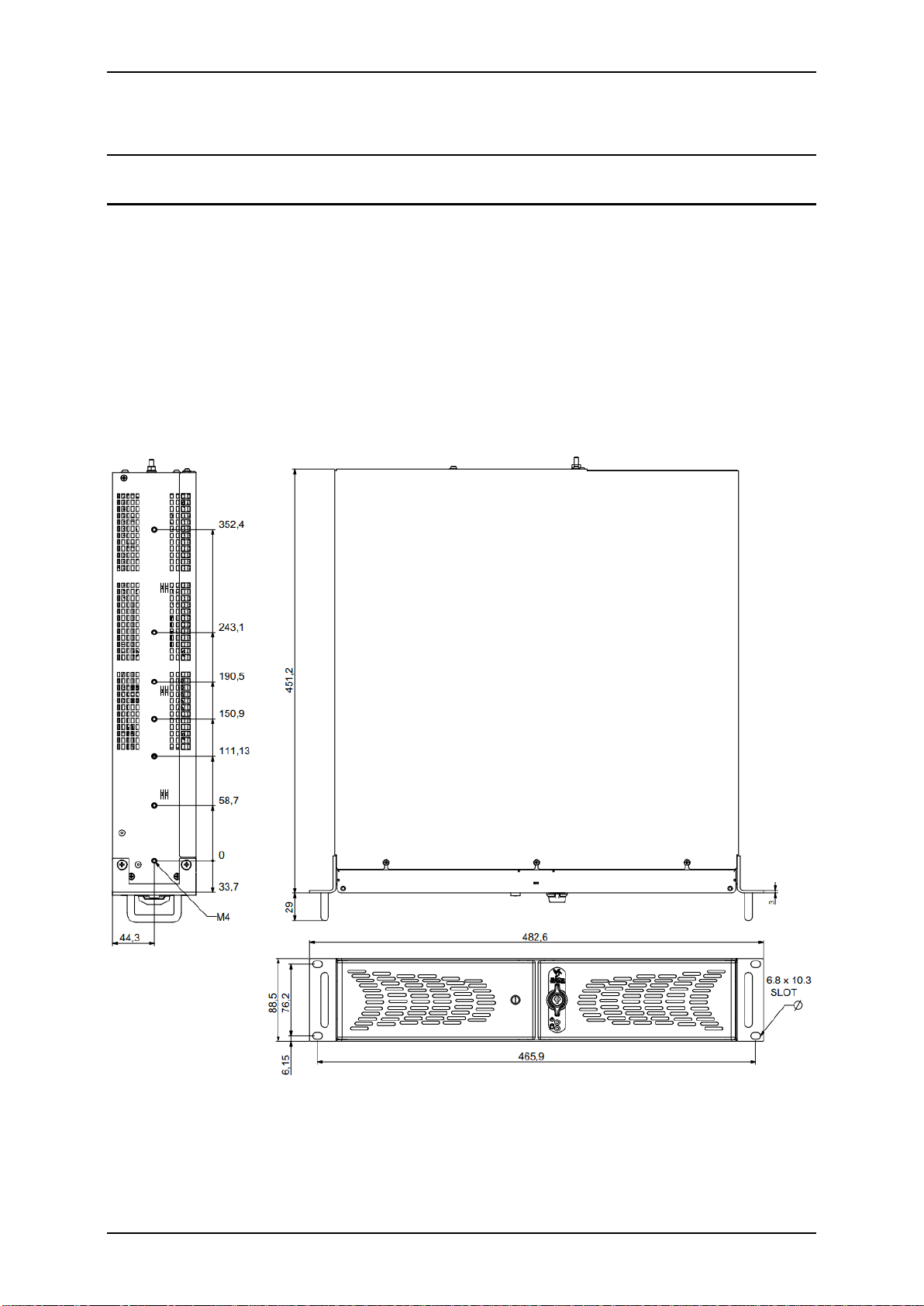

RACK MOUNT

The rack mounting chassis is made of polished stainless steel and is shown in Figure 1. It comprises the same

chassis as the bench mount, but has mounting ears. A polished stainless steel lid held in place by five screws

completes the chassis.

The front panel is a 2U high, full 19” racking width panel. The front panel secures the unit to the rack ladder by

four fixing screws. To permit withdrawal from the racking, handles are fitted to the front panel.

The rack mount unit has tapped holes along each side to facilitate the mounting of the slide rails. Take care not to

insert longer screws than those provided in the side (M4 x 6 maximum). Overly long screws may cause internal

damage.

Figure 1 Rack Mount Dimensions

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 14

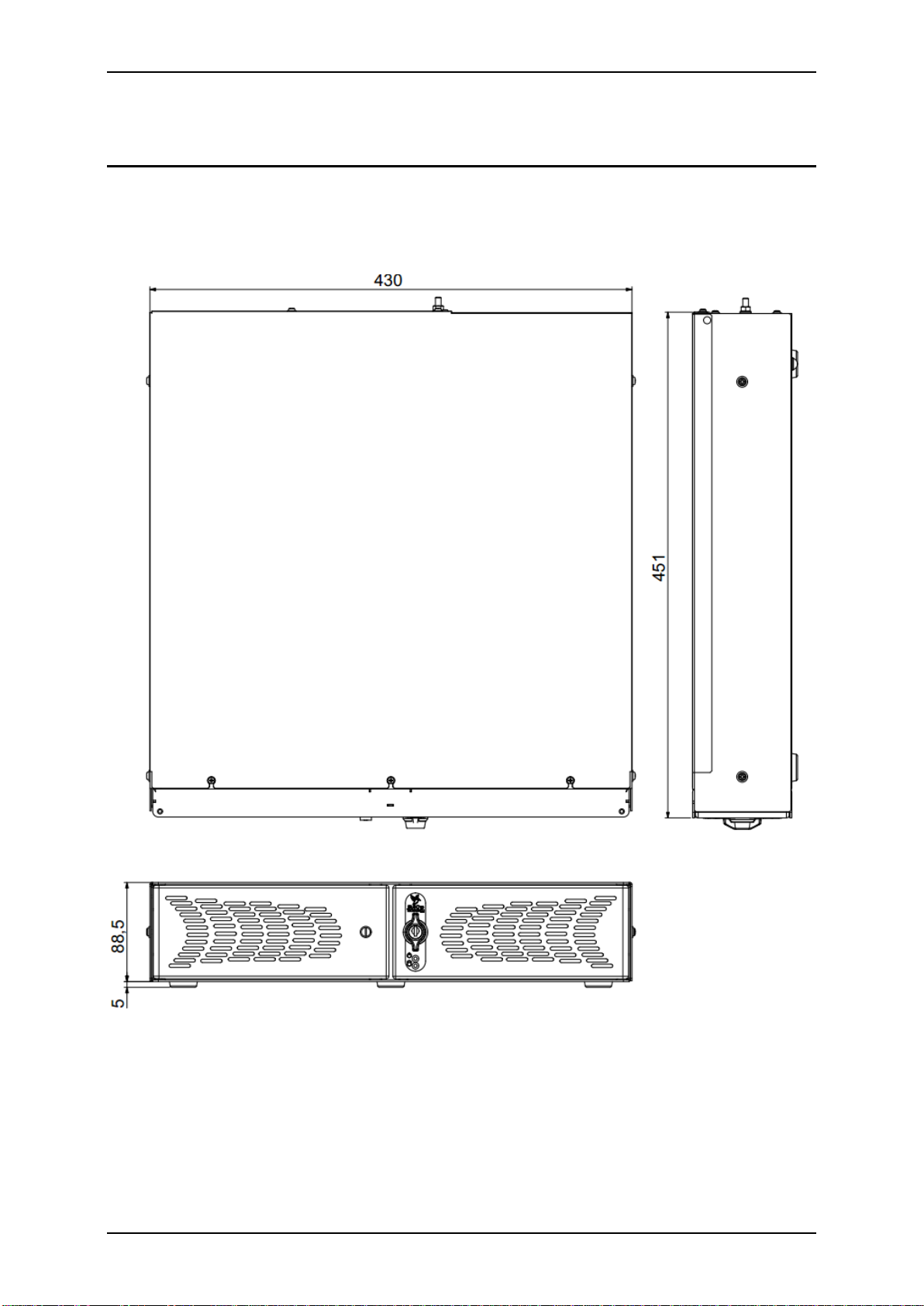

DESKTOP

The desktop unit is shown in Figure 2. It comprises the same chassis as the rack unit, but without the mounting

ears.

Figure 2 Desktop Dimensions

ULTIMA INDUSTRIAL PC GETTING STARTED

Blue Chip Technology Limited Page 15

FRONT PANEL

Operator controls and the air filter are located on the front panel behind sealed doors. The operator controls are

behind a key-lockable door, on the right hand side. The filter is held in place behind the left-hand door. A ¾ turn

fastener allows access to the filter.

REAR PANEL

All electrical connections to the ULTIMA are made at the rear of the unit. Units are configured individually to

requirements. Refer to the System Release Documentation for details of a particular PC configuration.

To ensure the integrity of the system EMC, it is important that the chassis earth stud is connected direct to the

best available cabinet earth in rack mounted installations, because of the proximity of other electrical equipment.

POWER SUPPLY & BBU

The chassis can be fitted with a variety of ATX style PSUs, as well as Dual Redundant and DC power supplies.

An optional Battery Backup Unit can also be provided to ensure operational integrity in mission critical

applications.

Some PSUs may have switchable input voltage range. In these cases the following warning should be observed.

WARNING

Selection of the wrong voltage may cause permanent damage to the unit. Ensure that the switch is

correctly set for the installation supply before connecting to the supply. If the wrong voltage is

applied to the unit the internal fuse may protect the ULTIMA. However, this cannot be

guaranteed. Blue Chip Technology accept no responsibility for the consequences of operating the

unit on the wrong supply.

Some Power Supply variants do not offer –5Volts. If this voltage rail is required, or if other specific voltage rails

and power needs are required, then please contact Blue Chip Technology in order to identify a suitable power

supply option to match your requirements.

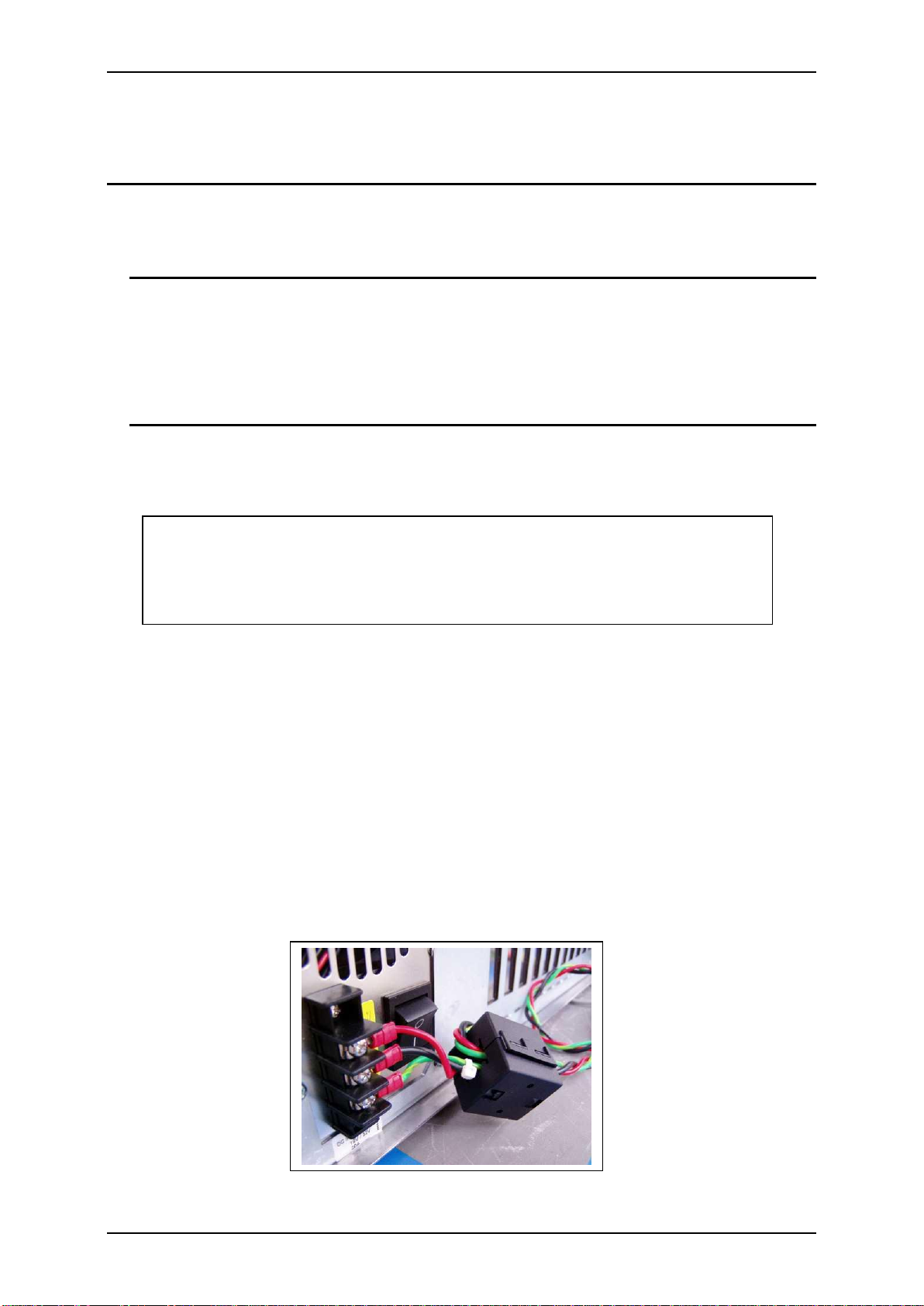

If a DC/DC power supply is being used, in order to maintain full Electro-Magnetic Compatibility under all

conditions, the cable connecting the DC source to the Ultima power supply should be well-screened. The braid

should be connected to the earthing stud on the Ultima and a good earth at the power source end. The exposed

cable and the braid ends should be kept as short as possible.

Where this is not possible, a clip-on Ferrite suppressor (supplied) should be fitted to the DC cable as close as

possible to the Ultima power supply terminal block. The cable should loop through the Ferrite clamp twice, as

shown below

For DC powered units which are not provided with a physical 'on/off' switch at the power supply inlet, it

is recommended that a suitable isolation switch be provided in the DC feed to the unit to enable isolation

from power during maintenance activities.

ULTIMA INDUSTRIAL PC INSTALLATION

Blue Chip Technology Limited Page 16

INSTALLATION

ELECTRICAL

This item must be connected to an earthed socket. A stud is fitted to the rear panel of the chassis. It is

recommended that this is also connected to a good earth within the racking system. Cutting washers must be

used in order to maintain a good connection.

The plug on the power supply cord is intended to serve as the power disconnect device. The socket outlet into

which this is plugged should be near the equipment, and should remain readily accessible when all items are

mounted in the racking enclosure. It is good practice to identify the socket.

If the plug fitted to the power supply cord is removed, the cord should be connected to a suitably installed power

disconnect device, by qualified personnel.

RACK MOUNTING

If the ULTIMA is to be installed in a 19" rack unit, it is recommended that telescopic slide rails are used. A slide

rail kit is available from Blue Chip Technology Ltd.

WARNING

Under no circumstances must the ULTIMA be mounted in a 19” rack solely by its front panel

fixings. Slide rails or a rear support must be used.

Before installation carefully assess the space available. Figure 1 gives outline dimensions of the chassis. Ensure

there is enough room at the rear of the unit for cables. DO NOT mount the unit in such a way that air inlet or

outlet vents are covered or blocked.

The slide rail kit will accommodate cabinets with front to rear ladder depths from 540mm to 790mm. The slide

rail kit comprises:

M6 cage nut

12

M6 x 10 Pan Head screw

4

10/32 UNF Fillister Head Screw

8

Bar Nut

4

Large extension bracket (Rear)

2

Small extension bracket (Front)

2

Telescopic slide rail

2

M4 Screw & washers

8

The following procedure describes the installation for one slide rail. Both sets of slides will need to be installed

to mount the ULTIMA within a cabinet.

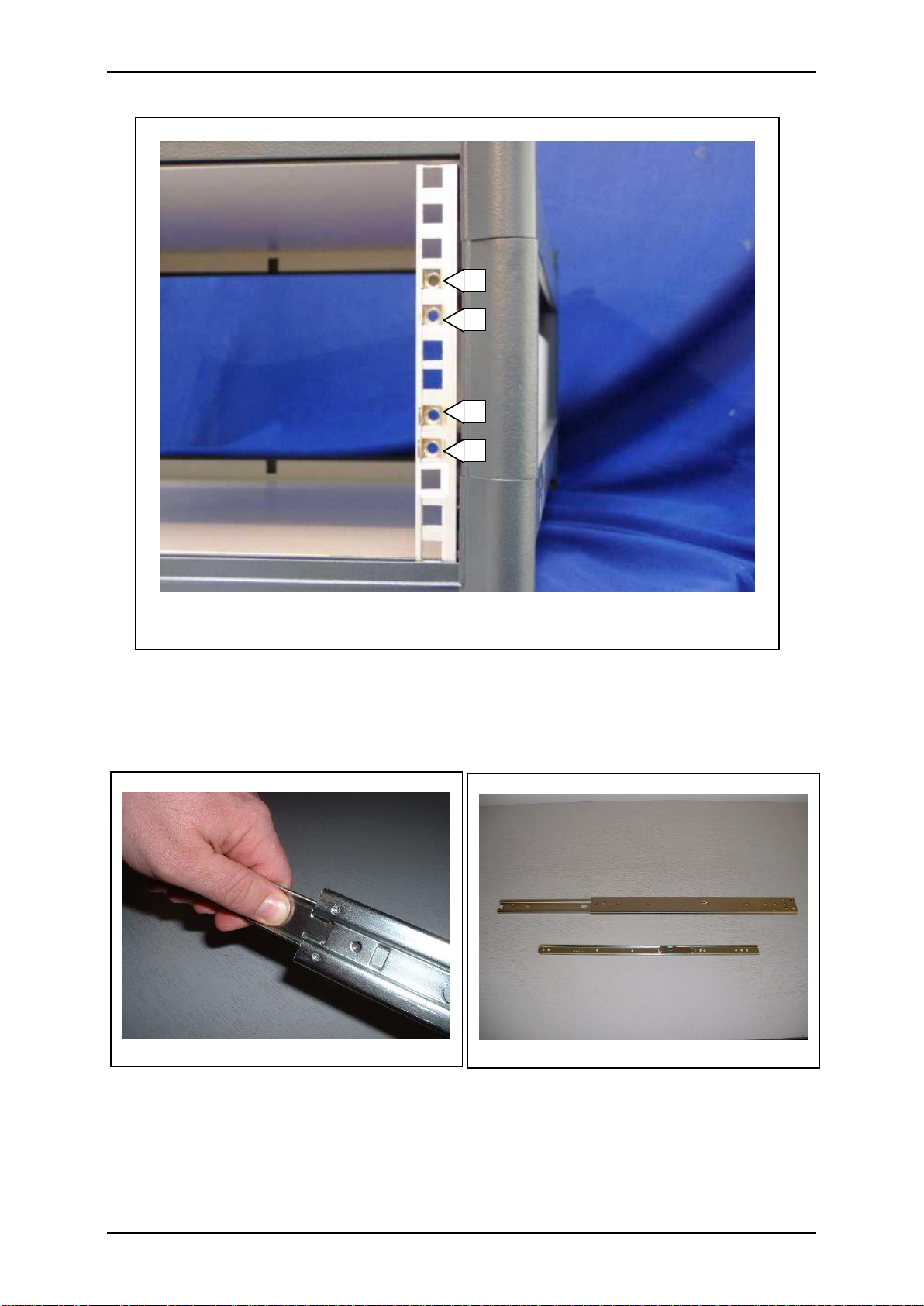

CAGE NUT INSTALLATION

Refer to Figure 5 to identify the pattern of the ladder holes. Holes A, hold cage nuts to which the front panel will

eventually be secured. Holes B hold cage nuts and clamp the front and rear ends of the fixed section of the slide

rails.

Clip M6 cage nuts into front ladder sections in positions A and B. Repeat on the right hand side. A total of 8 cage

nuts will be fitted to the front of the 19in cabinet.

Clip M6 cage nuts into rear ladder sections in positions B only. Repeat on the right hand side. A total of 4 cage

nuts will be fitted to the rear of the 19in cabinet.

ULTIMA INDUSTRIAL PC INSTALLATION

Blue Chip Technology Limited Page 17

SLIDE RAIL AND BRACKET ASSEMBLY

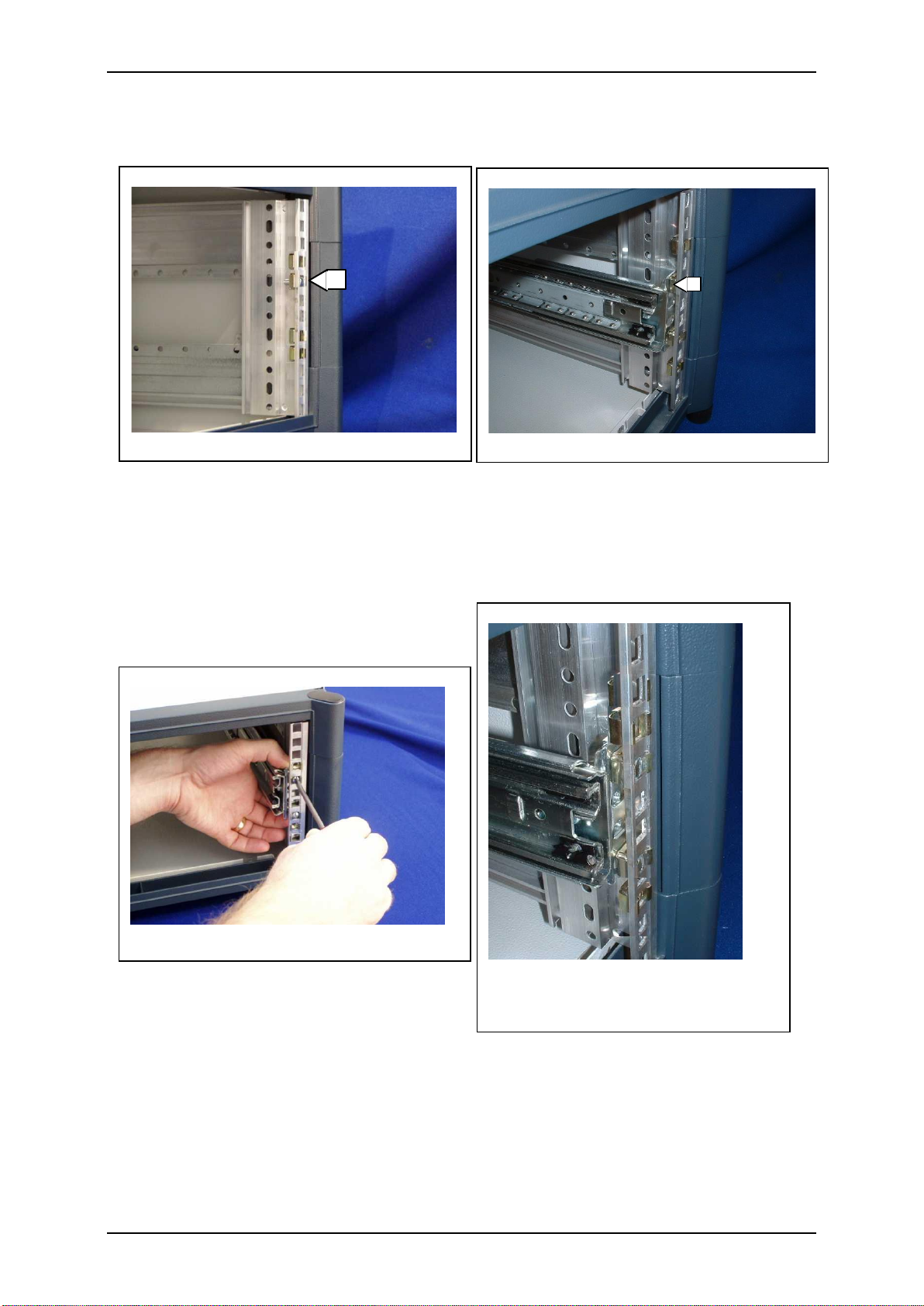

Referring to Figure 6.1, withdraw the inner slide section and disconnect by depressing the spring catch. Figure

6.2 shows outer and inner slide rail sections disconnected, top and bottom respectively.

A

A

B

B

Figure 5 2U Ladder Holes (left hand side)

Figure 6.1

Figure 6.2

ULTIMA INDUSTRIAL PC INSTALLATION

Blue Chip Technology Limited Page 18

Figure 6.3, shows the relationship between the brackets and slide rail outer section. The small bracket fits to the

front of the cabinet, the larger to the rear. Note the rail orientation, with middle slide visible at the front.

Referring to Figure 6.4 and 6.5, attach the front bracket to the slide rail outer section. For most installations the

first attachment hole on both the slide and bracket is recommended. For assembly an access hole on the middle

slide is provided. In this position the slide rail outer will sit flush to the front of the bracket slot face.

Referring to Figure 6.6 and 6.7, loosely attach the rear bracket to the slide rail outer section. The bracket position

indicated is typically suitable for a 600mm deep cabinet. It is recommended that at least two screws, per bracket

be used. The screws will be tightened once the slides are installed in the 19in cabinet.

Figure 6.3

Figure 6.4

Figure 6.5

Figure 6.6

Figure 6.7

ULTIMA INDUSTRIAL PC INSTALLATION

Blue Chip Technology Limited Page 19

SLIDE RAIL INSTALLATION

Referring to Figure 6.8, insert fillister head screws through cage nut B at front and rear.

Referring to Figure 6.9, carefully position slide rail and bracket assembly on to fillister screws B at front and

rear.

Referring to Figure 6.10, carefully slide bar nut behind front bracket and turn fillister screw to engage thread and

loosely clamp the bracket. Insert fillister screw into lower cage nut B position (Figure 5) and loosely tighten. The

installation will look like Figure 6.11.

Repeat this procedure at the rear.

B

Figure 6.8

B

Figure 6.9

Figure 6.10

Figure 6.11

ULTIMA INDUSTRIAL PC INSTALLATION

Blue Chip Technology Limited Page 20

Referring to 6.12, withdraw the middle slide until it locks into the extended position.

UTLIMA INSTALLATION

The following pictures show a 4U chassis. The assembly for the 2U chassis is exactly the same. Referring to

Figure 7.1 and 7.2, attach the inner slide rails to ULTIMA sides using 4 off M4 x 6 screws.

WARNING

Do not use longer screws (M4 x 6 maximum). Longer screws may damage

the electronics within the unit.

Referring to Figure 7.2, note the second hole position on the inner slide.

Figure 6.12

Figure 7.1

Figure 7.2

WARNING:

Depending on the configuration and equipping levels the Ultima chassis may exceed 20Kg in

weight. Assistance may be required in installing the unit into a rack/cabinet.

This manual suits for next models

1

Table of contents