Blue Sky Energy –Solar Boost 3000i

1Blue Sky Energy | USA | www.blueskyenergyinc.com

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .................................................................................................................. 2

PRODUCT DESCRIPTION...................................................................................................................................... 2

Part Numbers and Options................................................................................................................... 3

OPERATION ....................................................................................................................................................... 3

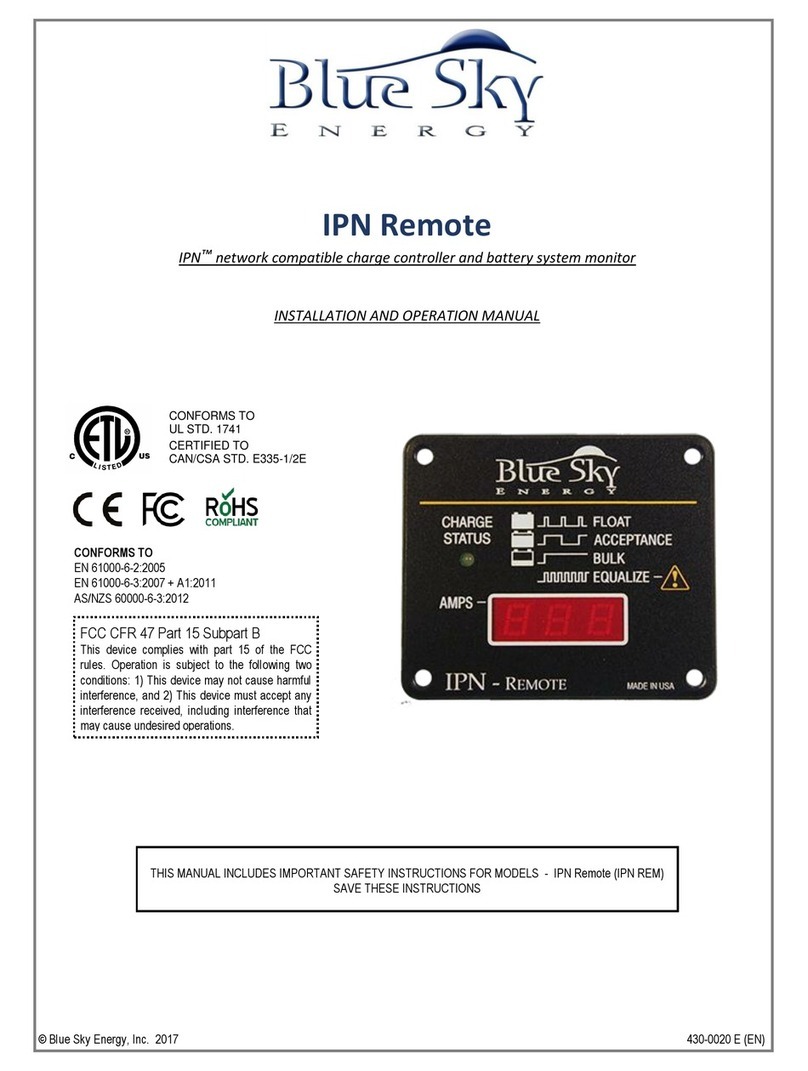

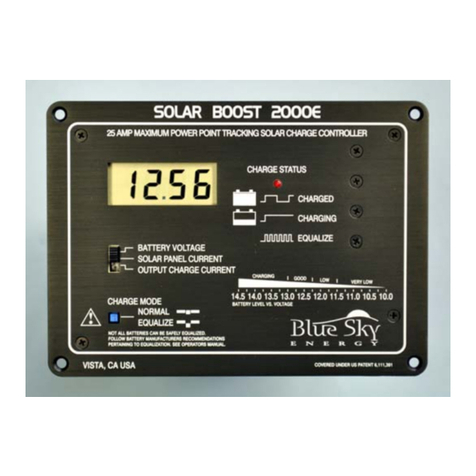

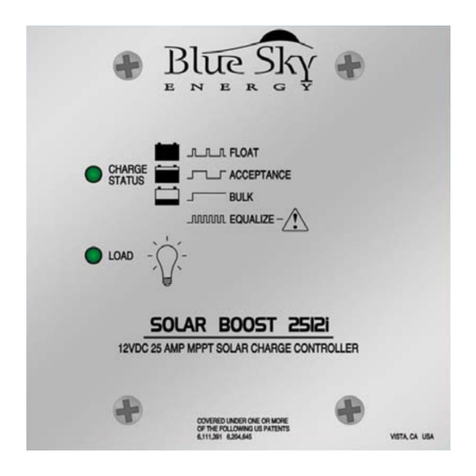

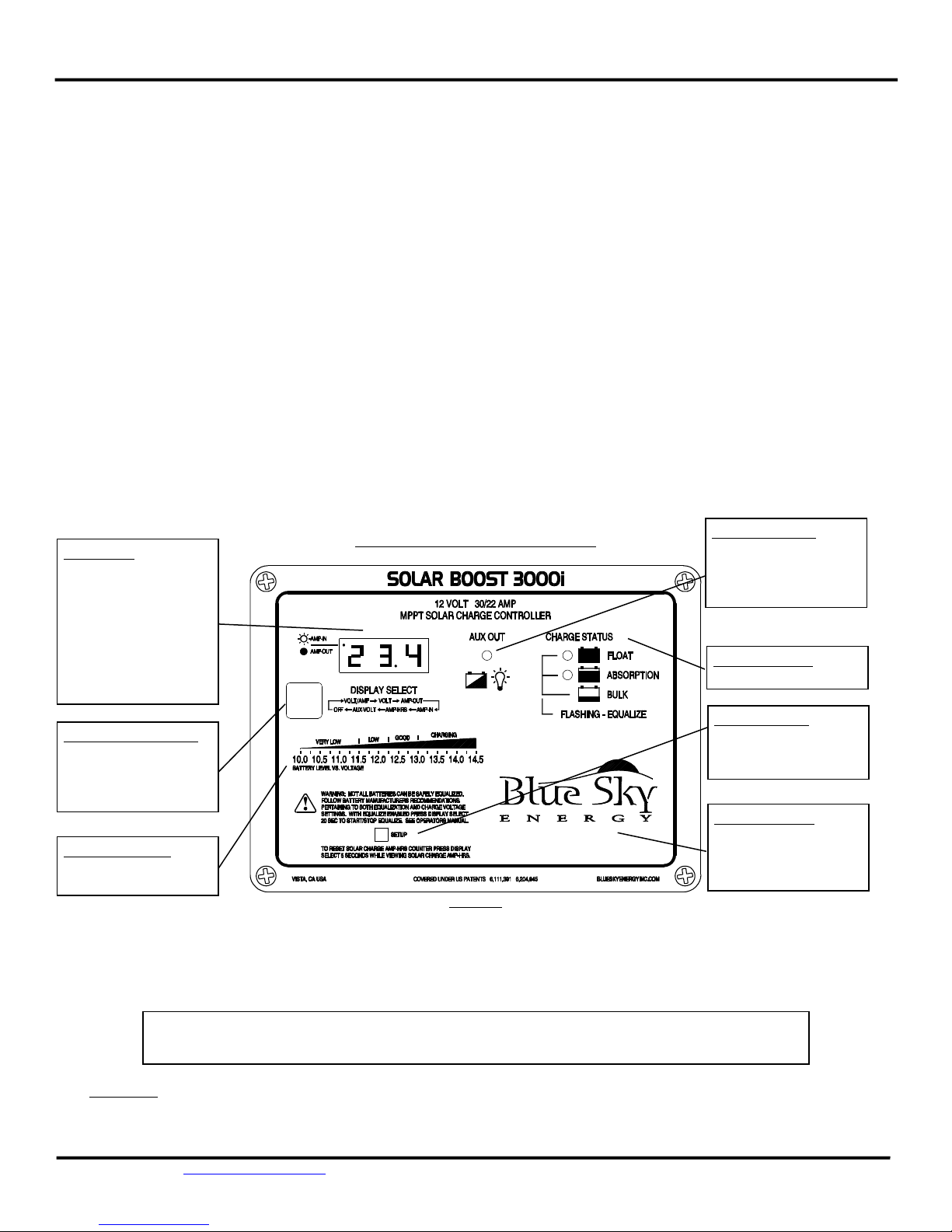

Charge Status Indication ...................................................................................................................... 3

Digital Display....................................................................................................................................... 3

Solar Charge Amp-Hour Counter.......................................................................................................... 3

Battery Level Graphic........................................................................................................................... 4

3-Stage Charge Control ........................................................................................................................ 4

Bulk Charge .................................................................................................................... 4

Absorption Charge.......................................................................................................... 4

Float Charge .....................................................................................................................4

Two Stage Charge Control.................................................................................................................... 5

Output Current Limit............................................................................................................................ 5

Optional Temperature Compensation ................................................................................................. 5

Equalization.......................................................................................................................................... 5

Maximum Setpoint Voltage Limit......................................................................................................... 5

Maximum Power Point Tracking.......................................................................................................... 6

Panel Temperature and Thermal Protection........................................................................................ 6

Multiple Charge Controllers On The IPN Network ............................................................................... 6

INSTALLATION ..................................................................................................................................................... 6

Charge And Load Control Settings........................................................................................................ 6

As Shipped Factory Default Settings............................................................................... 6

Restoring As Shipped Factory Default Settings............................................................... 7

Changing Charge And Load Control Settings .................................................................. 7

Selecting PV Modules........................................................................................................................... 8

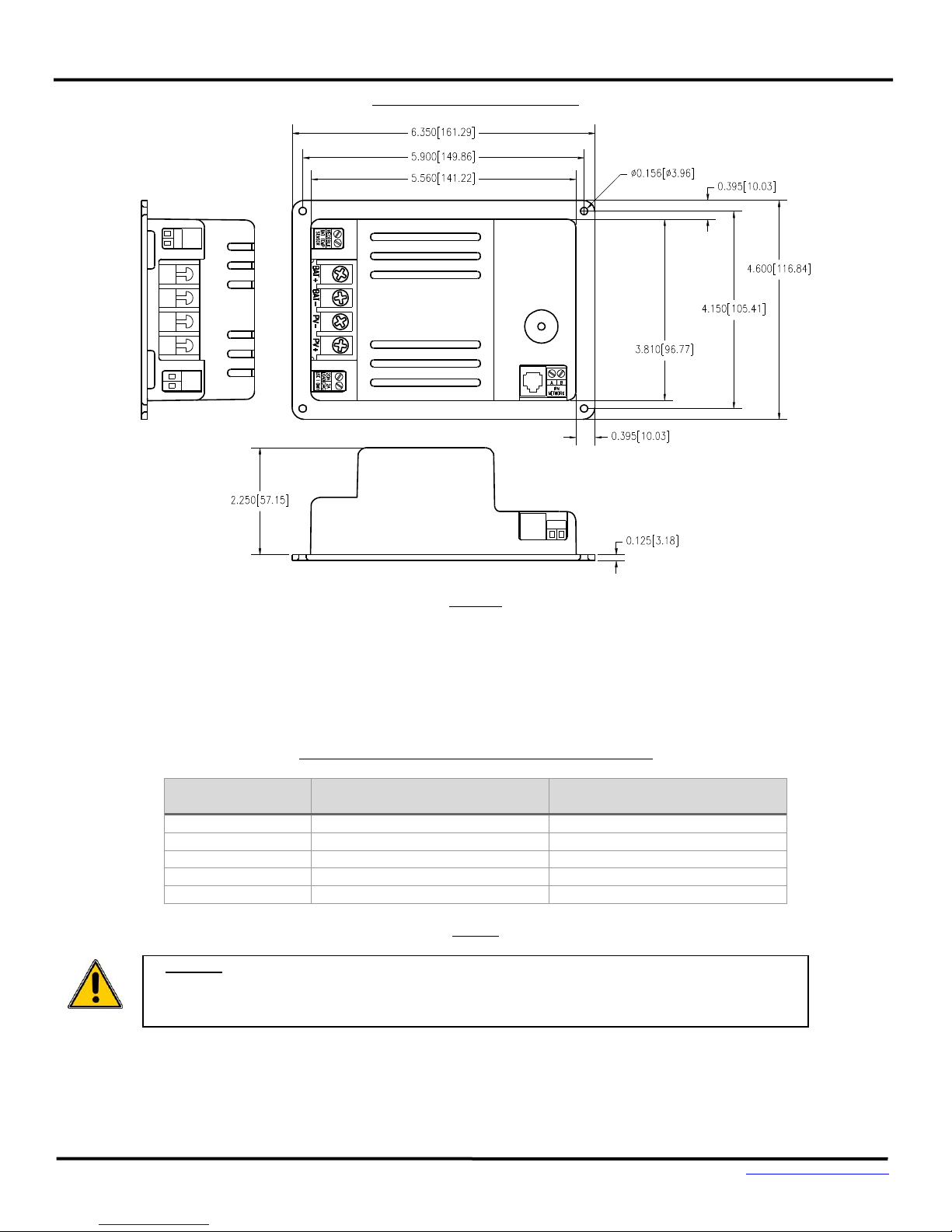

Mounting ............................................................................................................................................. 8

Battery and PV Wiring.......................................................................................................................... 9

Optional Battery Temperature Sensor ................................................................................................. 9

Auxiliary Output ...................................................................................................................................10

Auxiliary Battery Charge.................................................................................................10

Load Controller...............................................................................................................10

Dusk–To–Dawn Lighting Control ....................................................................................11

Battery & PV Power Connect/Disconnect Order..................................................................................11

Connecting The Battery..................................................................................................11

Connecting PV Modules .................................................................................................11

Installing A Multi-Controller System Using The IPN Network...............................................................11

Multi-Controller Wiring And Setup.................................................................................12

TROUBLESHOOTING GUIDE ................................................................................................................................12

SPECIFICATIONS ..................................................................................................................................................15

FIVE YEAR LIMITED WARRANTY..........................................................................................................................15

TABLES AND FIGURES

Table 1 Charge Status ................................................................................................................. 3

Table 2 Charge And Load Control Settings.................................................................................. 7

Table 3 Maximum Conductor Pair Length –3% Voltage Drop.................................................... 9

Figure 1 Front Panel Operation & Indicators................................................................................ 4

Figure 2 Factory Charge Voltage Setpoints -vs.- Battery Temperature........................................ 5

Figure 3 Detailed Dimensional Drawing ....................................................................................... 8

Figure 4 Wiring Diagram .............................................................................................................. 9

Figure 5 Auxiliary Output Wiring Diagram....................................................................................10

Figure 6 IPN Network Wiring........................................................................................................12