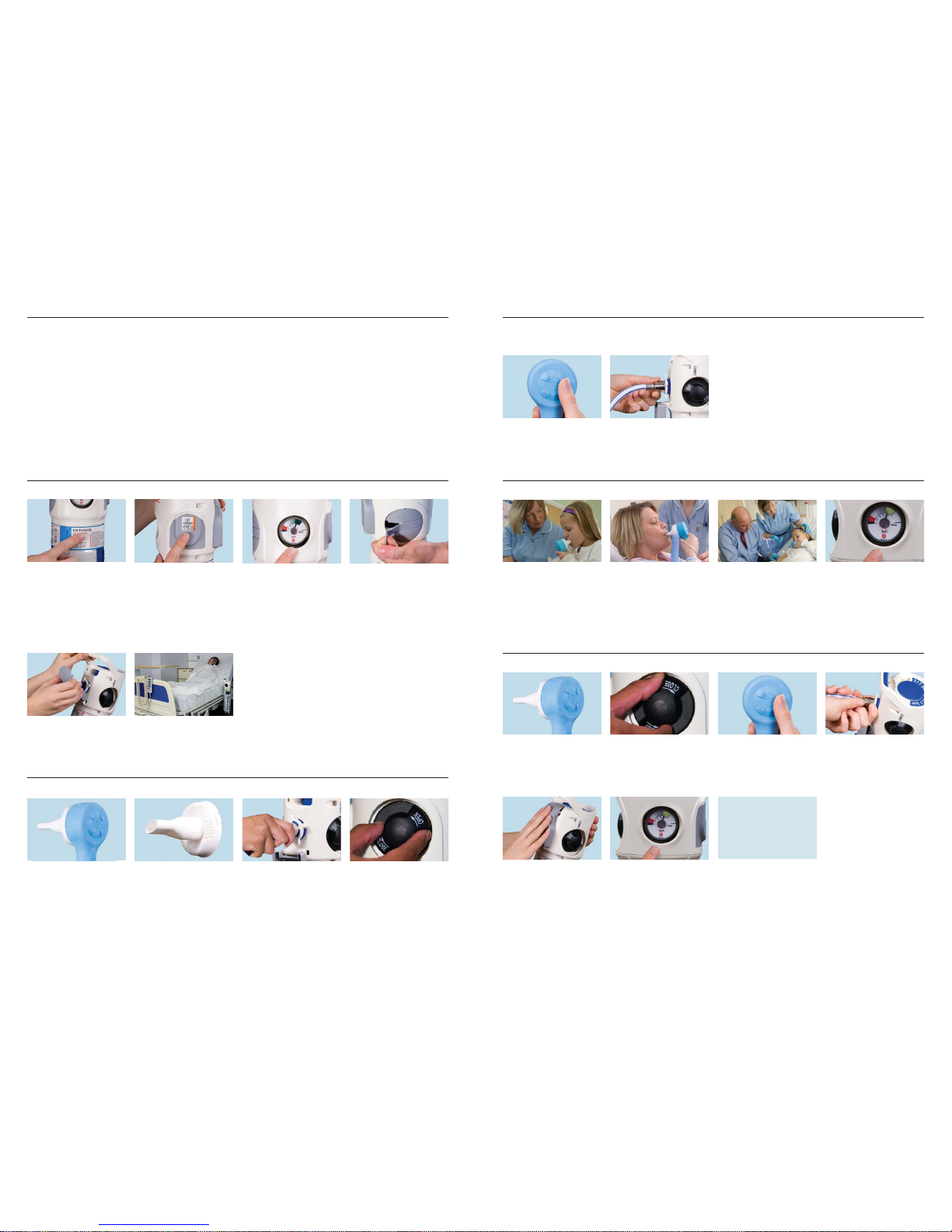

03Cylinder instructions

5.5 Replace the outlet cover by

pulling up the hinged grey cover.

5.1 Remove the demand valve

from the patient. If the treatment

is fi nished safely dispose of the

fi lter and mouthpiece or mask.

4.1 Instruct the patient on how to

use the demand valve correctly

before commencing therapy.

The gas should be inhaled for

at least 2 minutes prior to

starting any procedure for

optimum pain relief.

3.5 Check the demand valve is

operating by pushing the “test

button”. Ensure you can hear the

gas fl owing.

3.1 Ensure the demand valve

is clean and ready for use. You

will need a single patient use

mouthpiece or face mask.

5.3 Vent any residual gas in the

hose by pressing test button on

the demand valve. Wait for the

gas to stop venting.

4.3 Ensure the clinical condition

of the patient remains satisfactory

throughout the therapy.

If the patient experiences

complications ask them to stop

inhaling the gas.

4.4 Check the contents gauge at

regular intervals (as described

in 2.3), to make sure there is

enough gas to continue the

therapy.

3.3 Insert the probe on the hose

connected to the demand valve

into the Schrader outlet. Push

fi rmly to ensure the probe clicks

securely into place.

3.4 Slowly turn on the

cylinder by rotating the hand

wheel anti-clockwise until it

comes to a stop. Do not use

excessive force.

5.6 Check the cylinder gauge, for

content level (refer to nominal

duration chart). Return the

cylinder to a designated ‘in use’

or empty storage area.

5.2 Turn off the cylinder by

rotating the hand wheel clockwise

until it comes to a stop. Do not

use excessive force.

4.2 Use scavenging equipment

whenever possible, to avoid a

build up of nitrous oxide in the

environment. If scavenging is

not possible, use in a well

ventilated area.

3.6 Check for leaks which maybe

indicated by a hissing sound.(1)

3.2 Fit a new microbial fi lter to the

demand valve. Fit a new fi lter/

mouthpiece for each patient to

prevent cross contamination.

5.4 Disconnect the probe from

the cylinder outlet. Holding the

probe twist the capstan and

withdraw it from the outlet.

5. After use

4. Monitoring during use

Note:

(1) If you suspect that you have a leak, turn off the cylinder and check

the equipment is properly connected. Turn on the cylinder and re-check

for leaks. If the leak continues, turn off and quarantine the cylinder and

contact BOC Healthcare.

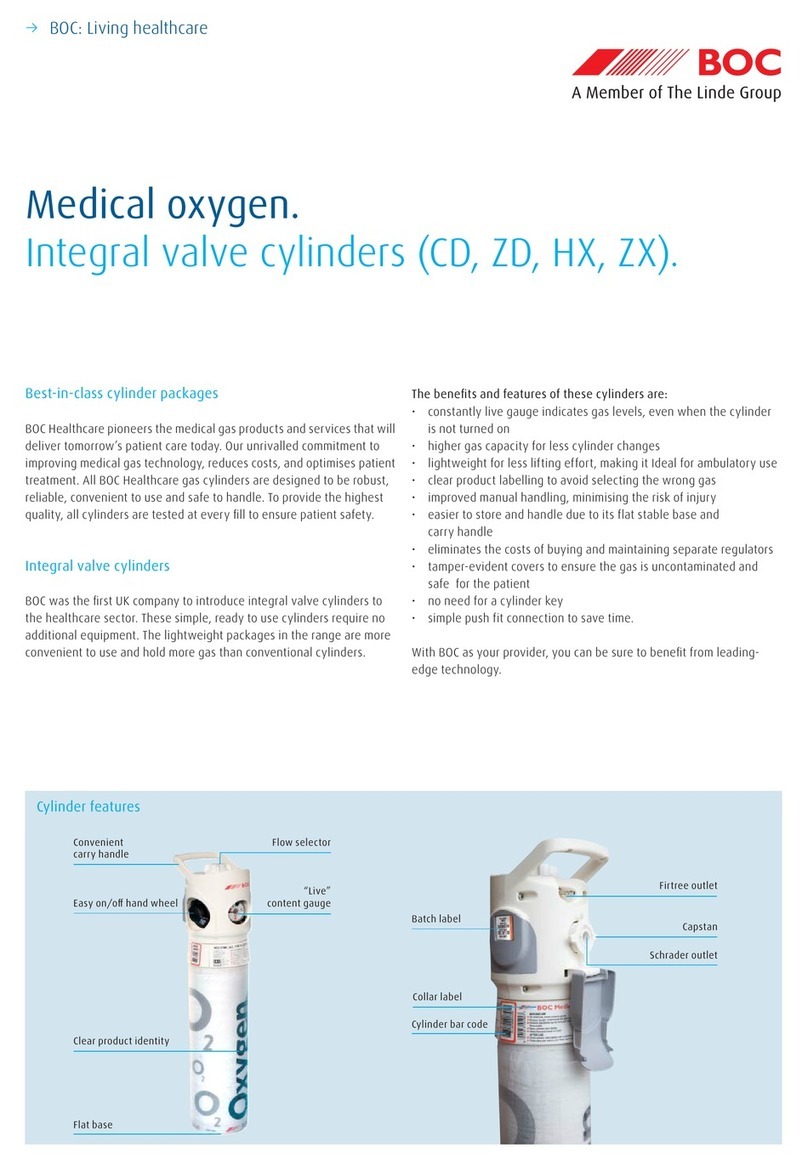

02 Cylinder instructions

Instructions for use.

1. Initial safety checks

Before handling cylinders ensure your hands are clean. If you have

been using alcohol based gel or liquids to decontaminate your hands

make sure the alcohol has totally evaporated.

2.1 Ensure you have the correct

medical gas by checking the

cylinder label.

2.5 Open the valve outlet cover.

The hinged grey cover is pulled

down. Do not remove the grey

cover and refi t after use.

When selecting the cylinder for use, check that the cylinder is free from

oil and grease, particularly around the Schrader outlet. Check that the

cylinder is not damaged in any way, if it is contact BOC.

2.3 Make sure the contents gauge

is in the green zone. This indicates

that the cylinder is FULL.

2.2 Check the expiry date on the

batch label. Use cylinders with

the nearest expiry date.

2.4 Remove the tamper evident

handwheel cover by pulling the

tear ring. Discard the cover into

the recycle bin. If the cylinder

has been used before this cover

will not be present.

2. Preparing a new cylinder for use

3. Connecting a demand valve to the Schrader outlet

If the cylinder has been used before make sure you have suffi cient gas for treatment by inspecting the

contents gauge. If the needle is in the red zone there is limited capacity and you may need to change

the cylinder (see nominal duration chart overleaf).

In the event of an emergency,

or if you suspect your cylinder

is leaking, contact BOC

Healthcare on 0800 111 333.

2.6 Place the cylinder in a

safe location, preferably in an

appropriately designed cylinder

holder fi tted to the patient‘s bed.

Note:

Ideally the cylinder should not be placed on the bed next to the patient.

If there is no alternative; before placing on the patient‘s bed make

sure that:

• the equipment is connected

• the cylinder is turned on and not leaking (see 3.1 to 3.6)

• check there is a gas fl ow by pressing the test button.