Quick Start

3

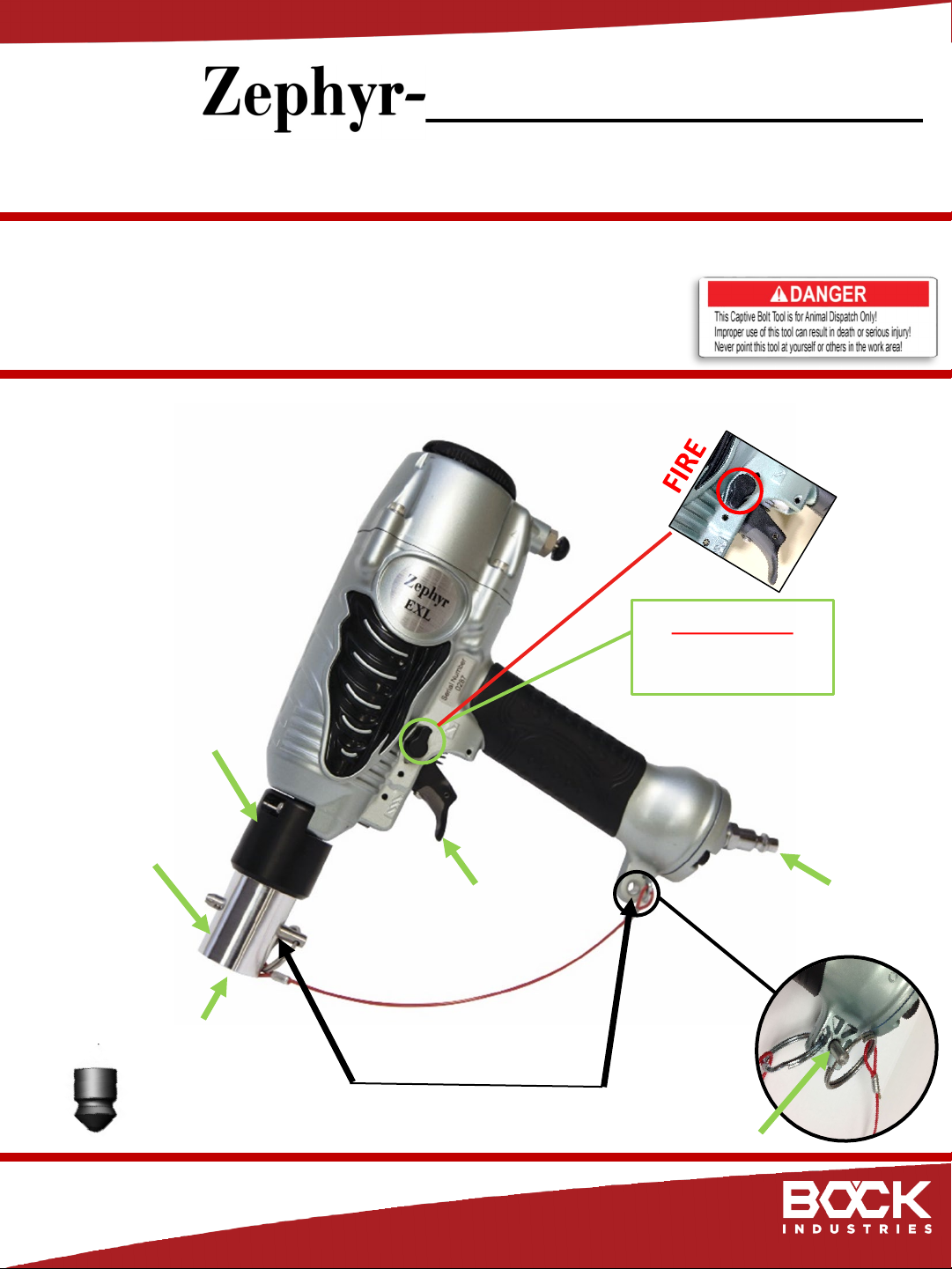

Technical Support: 814-777-3890

© 2022 Bock Industries, Incorporated.

All Rights Reserved.

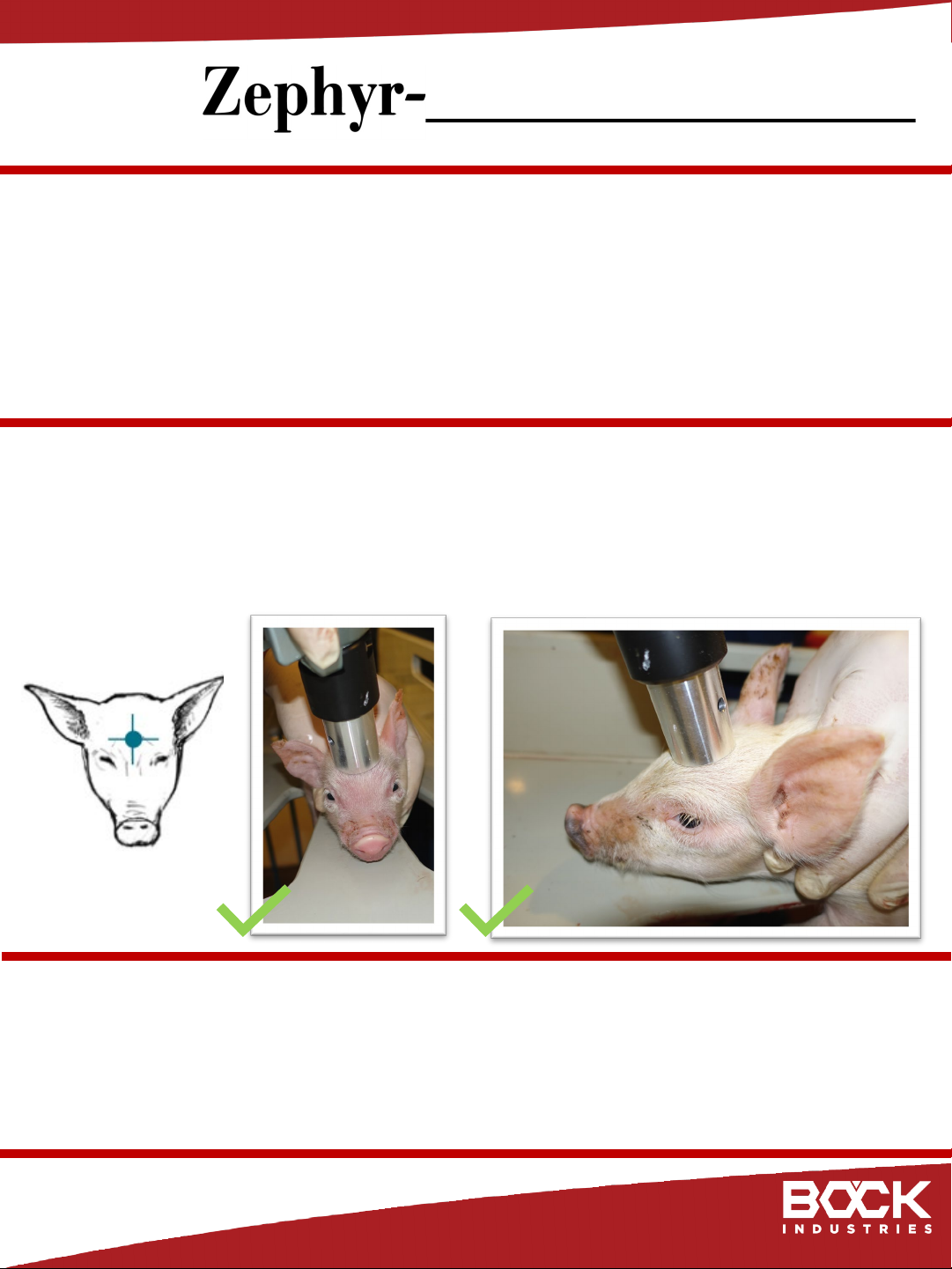

1. Specific requirements for non-penetrating captive bolt use. A non-penetrative captive bolt device

can be used for slaughter, depopulation and other situations for killing piglet, within certain

specified parameters:

1.1 Species: Piglets of less than 10 kg of live weight.

Refer to page 4.

1.2 Parameters: The device must deliver a minimum kinetic energy of 27.7 Joules.

Refer to page 1.

1.3 Monitor Efficacy: Confirm the physical signs of insensibility & death.

e.g., no rhythmic breathing, no corneal reflex and no response to nose prick.

1.4 Recommended Maintenance: To ensure consistent device minimum kinetic energy.

Refer to pages 5 -7.

2. General requirements of legislation for non-penetrating captive bolt use.

2.1 Piglets of less than 10 kg of live weight. Minimum kinetic energy 27.7 Joules.

2.2 Kids of less than 4 kg of live weight. Minimum kinetic energy 27.8 Joules.

2.3 The non-penetrative captive bolt device remains a permitted method for simple stunning

for cattle, sheep and goats (ruminants) under 10kg live weight, as well as poultry, rabbits

and hares. It can be used for slaughter, depopulation and other situations of poultry,

rabbits, hares and lambs of less than 10kg live weight and kids of less than 10kg live

weight and slaughter only for other ruminants.

2.4 The operator must apply the device in the proper position and use the correct strength of

cartridge or other propellant in accordance with the manufacturer’s instructions to

produce an effective stun or kill, as appropriate.

Legislation 1/1

EXL

Video Training

bock-industries.com

Complies with the requirement of The Protection of Animals at the Time of Killing

(Amendment) (England) Regulations 2022 (Legislation.gov.uk) for piglets under 10 kg.