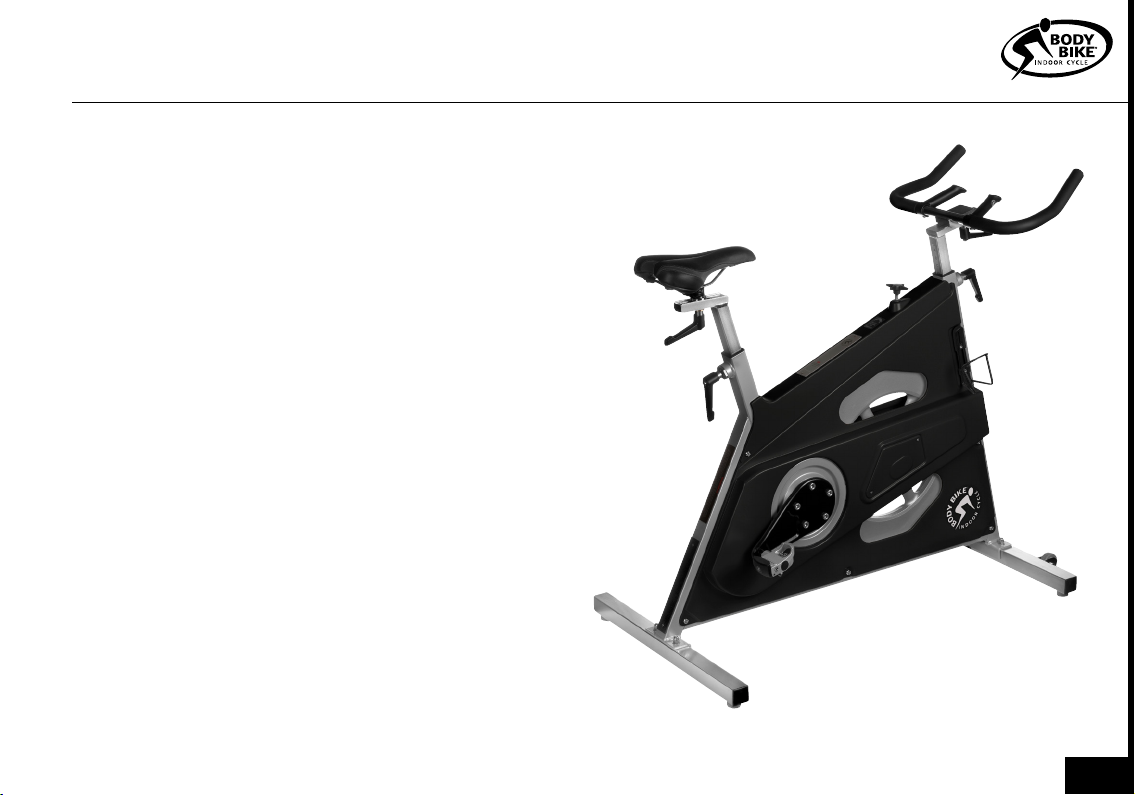

BODY BIKE Classic User manual

Other BODY BIKE Exercise Bike manuals

BODY BIKE

BODY BIKE Indoor Cycle User manual

BODY BIKE

BODY BIKE CONNECT User manual

BODY BIKE

BODY BIKE SMART+ User manual

BODY BIKE

BODY BIKE Basic User manual

BODY BIKE

BODY BIKE Classic Supreme User manual

BODY BIKE

BODY BIKE Basic User manual

BODY BIKE

BODY BIKE SUPREME User manual

BODY BIKE

BODY BIKE Indoor Cycle User manual

BODY BIKE

BODY BIKE Smart Programming manual

BODY BIKE

BODY BIKE SMART+ User manual

Popular Exercise Bike manuals by other brands

Sunny Health & Fitness

Sunny Health & Fitness SF-B121021 user manual

Monark

Monark 827E instruction manual

Stamina

Stamina 1310 owner's manual

American Fitness

American Fitness SPR-BK1072A owner's manual

Cateye

Cateye CS-1000 (CYCLO SIMULATOR) Service manual

BH FITNESS

BH FITNESS H9158H Instructions for assembly and use