Drucker Diagnostics – Customer Service: +1-814-692-7661 – CustomerService@DruckerDiagnostics.com | Page 8

ROTOR REMOVAL AND INSTALLATION

TO REMOVE THE ROTOR

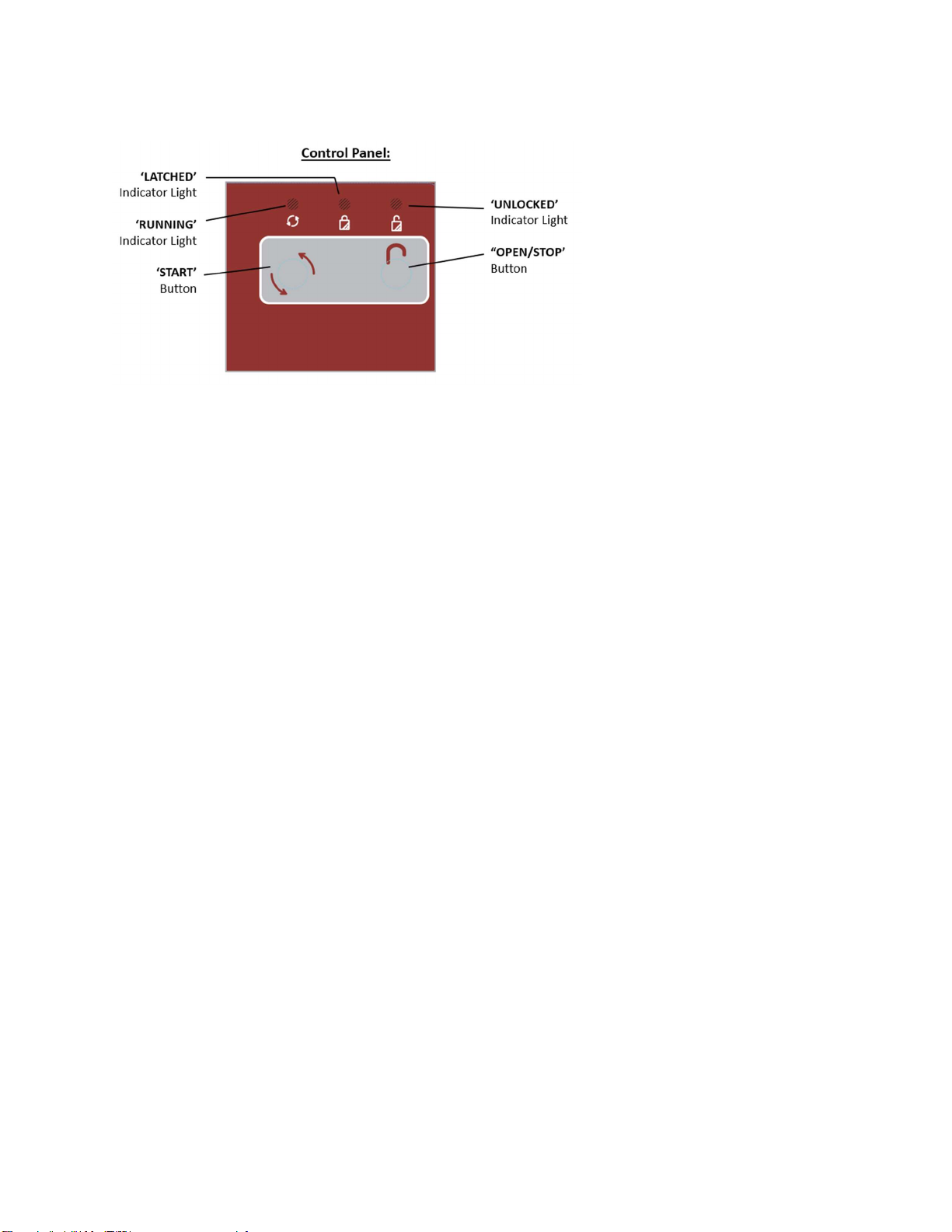

1. Unlock the centrifuge by pushing the ‘OPEN / STOP’ button and unlatch and open the lid.

CAUTION: Unplug the centrifuge from the electrical outlet to eliminate the possibility of electrical shock

or other injury.

2. Remove the test tube holders.

3. Remove the nut in the center of the rotor by turning it counterclockwise (a tool may be required).

4. The rotor is sitting on a cone-shaped adapter. Pull the rotor up and off of this adapter.

TO INSTALL THE ROTOR

1. Place the rotor back onto the cone-shaped adapter. You may need to turn the rotor slightly to line it up

properly.

2. The rotor should slide onto the rotor cone freely.

3. Once a proper fit has been achieved, replace the nut and turn it until it is hand-tight, (a tool may be

required).

4. Replace the tube holders and verify that they are seated properly.

5. It is recommended that the initial setup procedures be performed to ensure that the rotor has been

installed correctly and that no damage has been done to the centrifuge during either the rotor installation

or possible rotor chamber cleaning. See page 6 for this procedure.

CARE AND PREVENTATIVE MAINTENANCE

With proper care and maintenance your centrifuge will provide years of laboratory service. For proper care, the

following steps should be taken:

1. Provide Adequate Ventilation: For cooling purposes, the Model 642E draws in ambient air through the air

intake cover on the top of the lid and exhausts this air in the rear of the base. The centrifuge should be

placed on a hard smooth surface for good air circulation.

2. Always Spin Balanced Loads: Make certain that you are always spinning a balanced load. The Model 642E

has a unique counter balanced motor mounting design which, along with its rubber suction feet, produces

excellent vibration dampening. However, out–of–balance loads may break glass test tubes and may

produce unsatisfactory separation results. Proper load balancing will improve sample separation and

extend the life of the centrifuge. Refer to page 10 on balanced loads for additional information on

balancing the load.

3. Keep the Tube Holders Clean: NOTE: Always follow the safety guidelines of your laboratory to properly

clean up and/or dispose of materials in the event that a substance known to be potentially toxic,

radioactive or contaminated with a pathogenic microorganism is spilt in or on the centrifuge. Small glass

fragments left in the tube holder after a tube breakage may adhere to the next test tube inserted in that

holder. When this tube is handled, these fragments may puncture protective gloves and lacerate the

operator’s fingers or hand. Remaining fragments may provide stress points on subsequent tubes and

result in additional breakage. If a tube breakage occurs, carefully remove the tube holder. Properly

dispose of the sample and tube fragments and thoroughly clean both the inside and outside of the tube

holder.

4. Motor and Electrical Maintenance: The Model 642E uses a brushless permanent split capacitor AC motor.

It should not need routine servicing for the life of the centrifuge. The electrical components are selected

for high reliability and should not need routine service.

5. Tube Holder Replacement: It is recommended that the tube holders be replaced after 24 months of use.

Inspect tube holders regularly for cracks. If cracks are discovered, replace immediately.

6. Remove Accessories Before Moving: All tube holders, samples, and caps must be removed from the rotor

chamber before transporting or storing the centrifuge to prevent damage and injury.