Architect &

Engineer

Specifications

Technical

Specifications

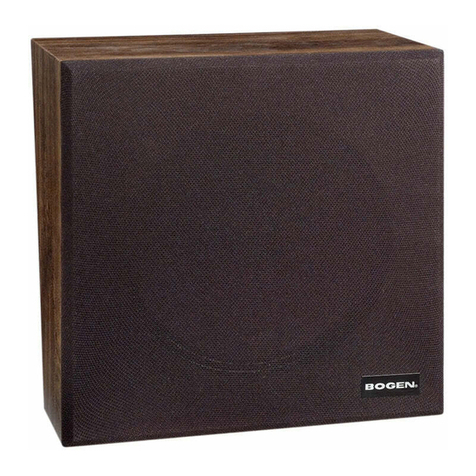

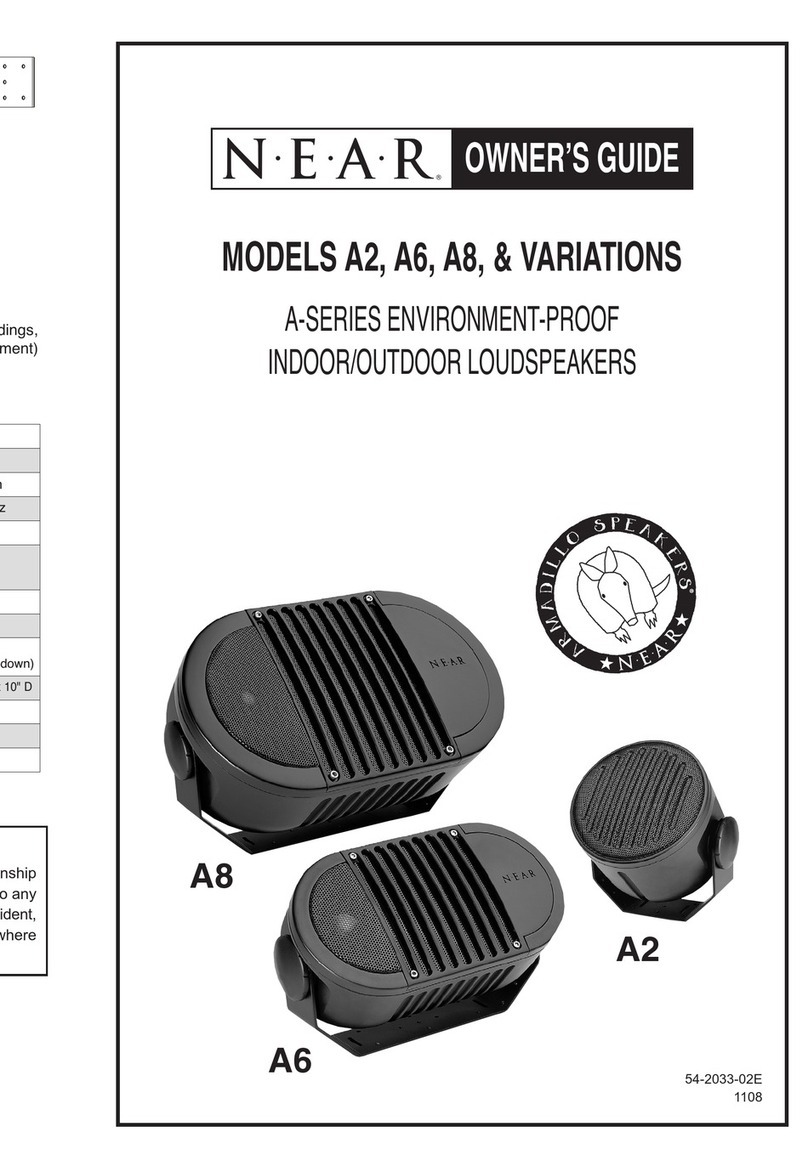

The loudspeaker shall be a NEAR Model A12 with a

power handling capacity of 225W (16-ohm) or 128W

(70V) or approved equivalent. The loudspeaker shall

consist of two 6.5" nominal low-frequency transducers

and one 1.9" nominal mylar high-frequency transducer

with a filter network for dividing and smoothing fre-

quencies between the transducers. A mathematically-

aligned, vented enclosure shall house all components.All

vents shall be further protected from water ingress by

acoustically transparent fabric designed to shed water.

The enclosure shall be constructed from an injection-

molded, high-density (30% or greater) mineral-filled

polypropylene material compounded with UV

inhibitors.

Enclosure shall be molded in black. Surface shall be able

to accept paint. Perforated speaker grilles shall be made

from color-matched perforated polypropylene, also able

to accept paint if required.

The low-frequency drivers shall utilize a metal-alloy

cone with deep-anodized surface treatment for rigidity

and corrosion resistance.The cone shall provide a heat

transfer thermal path for the voice coil under high-

power inputs. Compounded rubber cone surrounds

shall be formulated to withstand all-environment instal-

lations, including salt spray, ultraviolet light (UV), chlo-

rine exposure, heat, cold, and constant humidity. The

voice coil will be centered via a high-gauss, low-viscosi-

ty magnetic fluid (Ferrofluid), which increases the heat

transfer rate from the voice coil under long-term high-

power use. The magnetic fluid shall prevent corrosion

from occurring in the magnet gap.

The high-frequency driver shall utilize an environmen-

tally stable Mylar diaphragm. An integrated horn and

phase compensation device shall provide increased out-

put sensitivity and controlled coverage of the output.

The mounting yoke provided with the speaker shall be

designed with a built-in angle to facilitate installation

when downward angulation is required, as well as 180-

degree left-to-right adjustment. The yoke shall be

formed from heavy-gauge stainless steel (minimum

3mm thick), and finished with a scratch-resistant paint.

In addition, an optional Adjustable Tilt-Mount Adapter

(Model TMA812) shall be available which provides addi-

tional angles for precise orientation vertically over 18

specified points.

The input connectors for 16-ohm and 70-volt systems

shall be gold-plated, rust-proof screws with integral

clamping washers.

Dimensions of the loudspeaker shall not exceed

10-1/4" W x 17-7/8" H x 11-3/4" D. Weight shall not

exceed 22 lb.

SPECIFICATIONS A12

Frequency Response (-10 dB)*55 Hz to 17.5 kHz

LF Driver Dual Metal-Composite 6.5" Cone Woofers,

Patented MLS Voice Coil Guidance System

HF Driver Weatherproof 1.9"Mylar Diaphragm

Constant Directivity Horn, 1" Exit

Sensitivity (1W/1M) 94.5 dBspl

Dispersion 90° Horizontal, 45° Vertical

Impedance Ratings Low (16 ohms) / High (70V)

Power Input (Max.) 225W @ 16 ohms; 128W @ 70V

Power Settings (in watts) 70V: 128, 64, 32, 16, 8

Grille Material Perforated Polypropylene

Cabinet Material Black, Mineral-filled Polypropylene, with UV Inhibitor

Terminations Dual 4-Terminal Barrier Strips with Gold-plated,

Rust-proof Screws

Product Weight 22 lb.

Speaker Dimensions 10-1/4"Wx17-7/8" H x 11-3/4" D

Included Accessories Color-matched, Stainless Steel Mounting Bracket

Optional Accessories Adjustable Tilt-Mount Adapter (Model TMA812)

* Half-space response,

16-ohm input