Bohle VMA 70 V Ex WIP User manual

Maschinen + Verfahren GmbH

Operating instructions

Serial number: 0715940 001

Issue: 11 / 2007

Type: VMA 70 V Ex WIP

Maschinen + Verfahren GmbH

Revision Index

Version 1.0 Initial Version

Version 2.0 Error Messages added

Vaccum screen changed

Version 2.1 Error Messages added

Analog screen changed

Vaccum screen changed

Author: Dirk Netzlaw

Print date: 20.11.2007

Denomination: V_VMA_EN_15940_V2.1.doc

© 2007 (L.B.Bohle Maschinen + Verfahren GmbH, D-59320 Ennigerloh)

This document and all its components are copyright protected!

It is only to be used for the agreed purpose. Copies or other reproduction methods, including saving,

editing and distribution using electronic systems may only be made for the agreed purpose. Originals or

reproductions must not be made available or accessible to third parties in any way.

Printed in Germany

Maschinen + Verfahren GmbH

Content I

Table of contents

1Introduction 1-1

1.1 User guidance..................................................................................... 1-3

1.2 Explanation of the instructions used ..................................................... 1-4

1.3 Definitions........................................................................................... 1-5

1.4 Company address and contact............................................................. 1-6

1.5 Product description.............................................................................. 1-7

1.6 Guidelines, legislation, standards ......................................................... 1-9

1.7 Warranty conditions............................................................................. 1-9

1.8 Technical data .................................................................................. 1-10

2Safety instructions 2-1

2.1 General .............................................................................................. 2-3

2.2 Duty of care by the operator................................................................. 2-3

2.3 Instructions regarding personnel .......................................................... 2-4

2.4 Transport ............................................................................................ 2-5

2.5 Installation, commissioning .................................................................. 2-6

2.6 Feeding and discharging...................................................................... 2-7

2.7 Operation ........................................................................................... 2-8

2.8 Cleaning........................................................................................... 2-10

2.9 De-commissioning............................................................................. 2-11

2.10 Safety instructions regarding the use of the sampling lance ................. 2-15

2.11 Safety instructions for explosion protected system operation................ 2-15

3Switching the system on/off 3-1

3.1 General .............................................................................................. 3-3

3.2 Switching on....................................................................................... 3-4

3.3 Switching the system off...................................................................... 3-5

4Control elements 4-1

4.1 Operator panel.................................................................................... 4-3

4.2 EMERGENCY STOP........................................................................... 4-3

4.3 ON/OFF.............................................................................................. 4-4

4.4 ERROR .............................................................................................. 4-4

4.5 OPEN/CLOSE .................................................................................... 4-5

4.6 DISCHARGE VALVE CLOSE OPEN.................................................... 4-7

4.7 DISCHARGING................................................................................... 4-8

4.8 Sampling device.................................................................................. 4-9

4.9 Key-switch EX-OPERATION OFF / ON .............................................. 4-11

4.10 Dosing system.................................................................................. 4-12

Maschinen + Verfahren GmbH

Contents II

5Operating the control system software 5-1

5.1 General .............................................................................................. 5-3

5.2 Screen layout...................................................................................... 5-4

5.3 Operator........................................................................................... 5-10

5.4 Keyboard/Mouse............................................................................... 5-17

5.5 Print preview..................................................................................... 5-18

6Manual operation 6-1

6.1 General .............................................................................................. 6-3

6.2 <F2> Feeding ..................................................................................... 6-4

6.3 <F3> Blending .................................................................................... 6-6

6.4 <F5> Dosing pump............................................................................ 6-11

6.5 Drying .............................................................................................. 6-12

6.6 Temperatures ................................................................................... 6-20

6.7 <CF8> Clean video ........................................................................... 6-21

7Batch mode 7-1

7.1 General .............................................................................................. 7-3

7.2 Batch handling .................................................................................. 7-13

8Recipe creation 8-1

8.1 Definition, general information.............................................................. 8-4

8.2 Start the “Recipe program”................................................................... 8-4

8.3 Start R & D programs .......................................................................... 8-5

8.4 Leaving the recipe program.................................................................. 8-6

8.5 Login.................................................................................................. 8-6

8.6 Create new recipe ............................................................................... 8-6

8.7 Copy recipe ........................................................................................ 8-7

8.8 Delete recipe ...................................................................................... 8-7

8.9 Print recipe ......................................................................................... 8-7

8.10 Edit recipe .......................................................................................... 8-7

8.11 Cycles................................................................................................ 8-9

8.12 Import/export recipe.......................................................................... 8-11

8.13 Recipe cycles ................................................................................... 8-12

8.14 Cleaning cycles................................................................................. 8-17

9Process information 9-1

9.1 Illustrations ......................................................................................... 9-3

9.2 Trend charts ....................................................................................... 9-5

10 Configuration and settings 10-1

10.1 Special functions............................................................................... 10-3

Maschinen + Verfahren GmbH

Content III

10.2 Analog values ................................................................................... 10-6

10.3 Calibration........................................................................................ 10-7

10.4 Machine parameters ......................................................................... 10-8

10.5 Extended machine parameters .........................................................10-10

10.6 Error parameters (option) .................................................................10-12

10.7 Controller ........................................................................................10-13

10.8 Operating hours ...............................................................................10-13

11 Errors and messages 11-1

11.1 Software messages........................................................................... 11-3

11.2 System messages............................................................................. 11-6

11.3 Control messages ............................................................................. 11-6

Maschinen + Verfahren GmbH

Contents IV

Maschinen + Verfahren GmbH

1-1

1Introduction

Maschinen + Verfahren GmbH

1-2

Contents

1Introduction 1-1

1.1 User guidance..................................................................................... 1-3

1.2 Explanation of the instructions used ..................................................... 1-4

1.3 Definitions........................................................................................... 1-5

1.4 Company address and contact............................................................. 1-6

1.5 Product description.............................................................................. 1-7

1.5.1 Intended use.................................................................................... 1-7

1.5.2 Spatial borders................................................................................. 1-8

1.5.3 Configuration ................................................................................... 1-8

1.6 Guidelines, legislation, standards ......................................................... 1-9

1.7 Warranty conditions............................................................................. 1-9

1.8 Technical data .................................................................................. 1-10

Maschinen + Verfahren GmbH

1-3

1.1 User guidance

The operating instructions and all other operating instructions for individ-

ual components must be legible and complete, and always available at

the operating location.

The complete documentation for the system consists of:

•the operating instructions,

•the maintenance instruction,

•the circuit diagrams,

•the binder Software,

•the documentation for components and supplier components,

The operating instructions are intended to introduce the operation of the

system and enable the intended use. They contain important information

on how to safely, correctly and economically use the system. Compliance

with these instructions will aid in avoiding dangers, reduce shutdowns

and repair costs and increase reliability and service life.

The descriptions are written in the assumption that only sufficiently trai-

ned personnel will be used.

For standardization reasons it is possible that individual designations and

texts in screenshot graphics may differ from the applicable national lan-

guage concerned.

The content of these operating instructions can be modified without pre-

vious notification. This manual must not be used to implement modifica-

tions.

Note!

This manual must not be used to implement modifications.

Maschinen + Verfahren GmbH

1-4

1.2 Explanation of the instructions used

The following signs are used for particularly important information in the-

se operating instructions:

Read and comply with text in boxes! Continue reading the text and oper-

ating the system after you have done so.

Danger!

Direct danger to life and limb that could lead to serious physical injury or

death.

Attention!

Special information about provisions/prohibitions regarding damage pre-

vention for machines or systems.

Sign giving orders

Actions necessary for ensuring safety. Contains symbol or pictogram.

Warning sign

Contains symbol or pictogram.

Note!

Information for particularly efficient use of the machine or system.

Information!

Recommendations and references to other information sources.

Maschinen + Verfahren GmbH

1-5

1.3 Definitions

right to the right from the viewpoint of the operator

left to the left from the viewpoint of the operator

→Operating instructions (in this sequence)

9Result after operating instruction has been carried out

—Listing in text

/or

<...> Button (keyboard)

[ ] Control element (control panel)

» « Function button on screen

Maschinen + Verfahren GmbH

1-6

1.4 Company address and contact

*L. B. Bohle

Maschinen + Verfahren GmbH

Industriestraße 18

59320 Ennigerloh

Germany

Internet Internet: www.lbbohle.com

or www.lbbohle.de

e-Mail: [email protected]

Contact person

Electro / Electronic / Software:

L.B.Bohle EE department

(++49 2524 / 9323-0

Fax:++49 2524 / 9323-399

Contact person

Process engineering:

L.B.Bohle VT-department

(++49 2524 / 9323-0

Fax:++49 2524 / 9323-79

Maschinen + Verfahren GmbH

1-7

1.5 Product description

1.5.1 Intended use

The system is for blending and granulating powdery, fluid pharmaceutical

substances. Because of the filter-mesh size the powder-grain size should

not smaller than Ø 10 µm.

The solvents water, isopropanol, and ethanol are admissible for granula-

tion and drying.

It is not allowed to process explosive substances or pyrotechnical sub-

stances tending to deflagration.

It is allowed to process substances with high hazardous potential like

hormones, carcinogen substances, antibiotics if the operator provides

adequate operator safety (safety cloth, dust protection) (See also “spatial

borders”).

Other bulks (powder and solvents) are to be brought to agreement with

LBB.

Any other use is not the intended use.

Any damage to persons or property caused by non-intended use is

the responsibility of the machine or system operator and not that of

the manufacturer!

Written permission from L. B. Bohle Maschinen + Verfahren GmbH must

therefore be obtained before any intended deviation from the agreed op-

erating procedure can be implemented.

To avoid sources of ignition:

All materials being processed must be pure in form, i.e. the operator must

ensure that

•no sparking particles enter the system (through suitable control

steps, e.g. sieving),

•the ignition temperatures of the materials used are not exceeded,

e.g. through chemical reactions, etc.

Only substances that meet these requirements may be processed. Other

substances that deviate from these requirements require written authori-

zation from L. B. Bohle.

Maschinen + Verfahren GmbH

1-8

1.5.2 Spatial borders

The process-unit is suitable for the use in rooms of the Ex-area Zone 2.

The technique module control cabinet, tempering units and the pump

stand are located in the non-Ex technical area.

Protection class production area: IP 65, Protection class technique area:

IP 20.

The ambient temperature in the production-and technique area is be-

tween 5°C to 30°C max. The ambient pressure is 1013 mbar +/-50 mbar.

The erection height must be < 2000 meter above sea level. The ambient

humidity is 65 % +/-15 % (non condensing).

The operator protection against contamination shall be provided by the

customer.

1.5.3 Configuration

The system VAGUMATOR VMA 70 V Ex WIP consist of the frame, proc-

ess bowl and head. The process bowl can be moved.

The head of the unit is equipped with the impeller, chopper, product filter

of the vacuum system, the measuring sensors and the video camera. The

entire head is also smoothly clad.

The system is operated from the control panel. The control panel is e-

quipped with buttons for the safety operation functions and a PC key-

board for all other functions. The process is monitored on the PC monitor

and on the video monitor. The batch documentation can be printed out on

the printer.

The switch cabinet of the unit, the vacuum system with condensers, the

temperature balancing units for bowl and lid are located in the technical

area.

Maschinen + Verfahren GmbH

1-9

1.6 Guidelines, legislation, standards

The following guidelines and legislation were referred to in the design and

construction of this machine or system:

EC-directives:

•98/37/EEC Machinery directive

•2006/95/EC Low voltage guideline

•89/336/EEC EMC directive

•94/9/EC ATEX Directive

harmonized standards:

•EN 60204-1 Safety of machinery –electrical equipment of machines

•EN 50081-1 EMC, Electromagnetic compatibility: Generic Emission

Standard

•EN 50082-2 EMC, Electromagnetic compatibility: Generic Immunity

Standard

•DIN EN ISO 12100-1 and 2 Safety of machinery: Basic concepts,

general principles for design, Part 1 and Part 2

•DIN EN ISO 13849-1 Safety of machinery -Safety related parts of

control systems

1.7 Warranty conditions

The applicable warranty conditions are specified in the delivery condi-

tions.

The warranty is voided, if

•damage is caused by malfunctions due to unauthorized use and in-

correct operation,

•repairs or manipulations are implemented by persons without au-

thorization or training,

•damage is caused by accessories or replacement parts used without

permission from L.B. Bohle

•See also 2.13 “Modifications, replacement parts, accessories”.

Maschinen + Verfahren GmbH

1-10

1.8 Technical data

Serial-no.: 0715940 001

Model: VMA 70 V Ex WIP

Customer: Lek S.A.

Year of construction: 2007

Bowl volume: 70 l

Capacity per batch (depending on

the density): 5 -40 kg

Power supply: 3x400 V/ PE / 50 Hz

Control voltage: 24 V DC

Rated power: 43.5 kW

Fuses: 125 A

Full load current: 107

Rated current: 25,9 A

Video Monitor: 10 inch

Impeller drive From above (top drive)

Speed range 15 -400 rpm

Driving power 7.5 kW

Chopper drive From above (top drive)

Speed range 150 -1500 rpm

Driving power 5.5 kW

Maschinen + Verfahren GmbH

1-11

Bowl / lid tempering

Temperature range 5 -80°C

Heating power bowl 12 KW

Heating power lid 6 KW

max. Cooling power bowl 85 KW

max. Cooling power lid 85 kW

VAGAS

Range 0-4 nm3/min

Vacuum system

Vacuum pump Rotary vane pump 305m3/h

Maschinen + Verfahren GmbH

1-12

Maschinen + Verfahren GmbH

2-1

2Safety instructions

Maschinen + Verfahren GmbH

2-2

Contents

2Safety instructions 2-1

2.1 General .............................................................................................. 2-3

2.2 Duty of care by the operator................................................................. 2-3

2.3 Instructions regarding personnel .......................................................... 2-4

2.4 Transport ............................................................................................ 2-5

2.4.1 General ........................................................................................... 2-5

2.4.2 Dimensions and weights................................................................... 2-6

2.5 Installation, commissioning .................................................................. 2-6

2.5.1 General ........................................................................................... 2-6

2.5.2 Implementing the supply connections ................................................ 2-7

2.6 Feeding and discharging...................................................................... 2-7

2.7 Operation ........................................................................................... 2-8

2.7.1 Safety of the operator and persons in the working area of the system.. 2-8

2.8 Cleaning........................................................................................... 2-10

2.9 De-commissioning............................................................................. 2-11

2.9.1 General ......................................................................................... 2-11

2.9.2 Safety instructions .......................................................................... 2-12

2.9.3 Waste disposal............................................................................... 2-13

2.9.4 Temporary decommissioning .......................................................... 2-14

2.9.5 Re-commissioning.......................................................................... 2-14

2.10 Safety instructions regarding the use of the sampling lance ................. 2-15

2.11 Safety instructions for explosion protected system operation................ 2-15

Table of contents

Popular Industrial Equipment manuals by other brands

Rothenberger

Rothenberger Rofrost Turbo II operating instructions

IFM

IFM Efectol 600 E34110 installation instructions

Baileigh Industrial

Baileigh Industrial SR-5016E Operator's manual

Big Daishowa

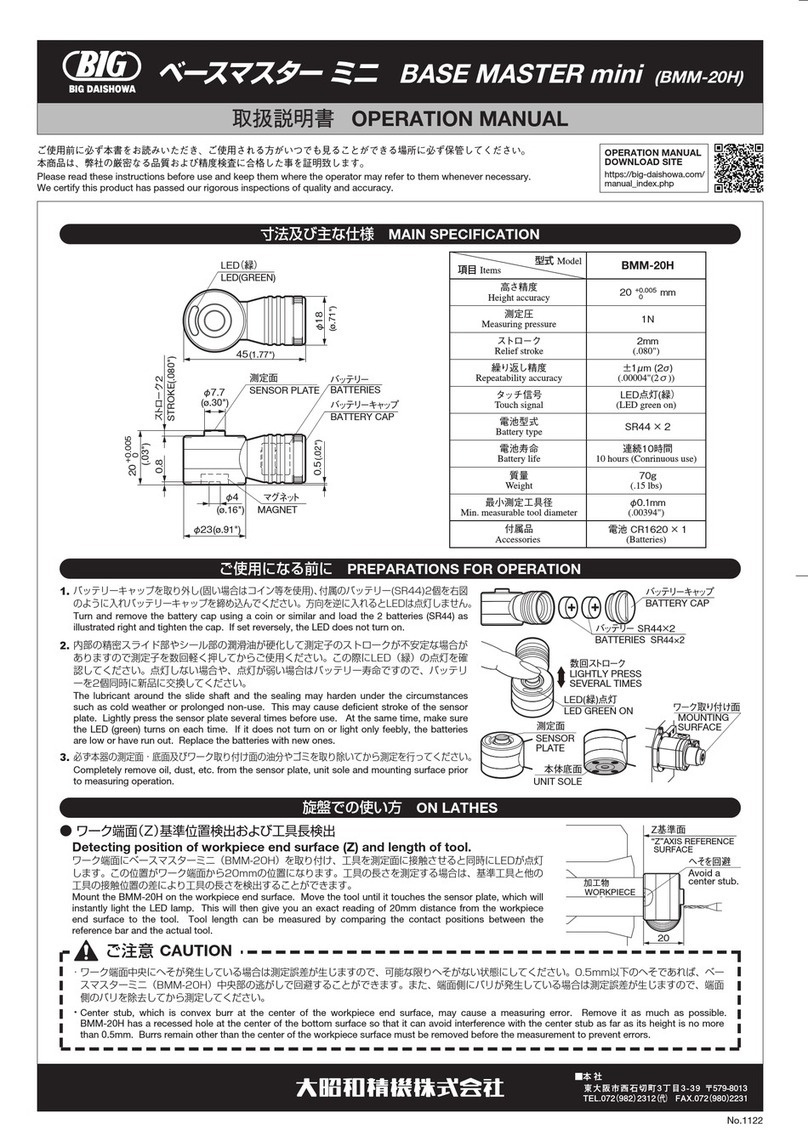

Big Daishowa BASE MASTER mini Operation manual

VariProp

VariProp DF-160 manual

Geovent

Geovent GEOFILTER DUST instruction manual