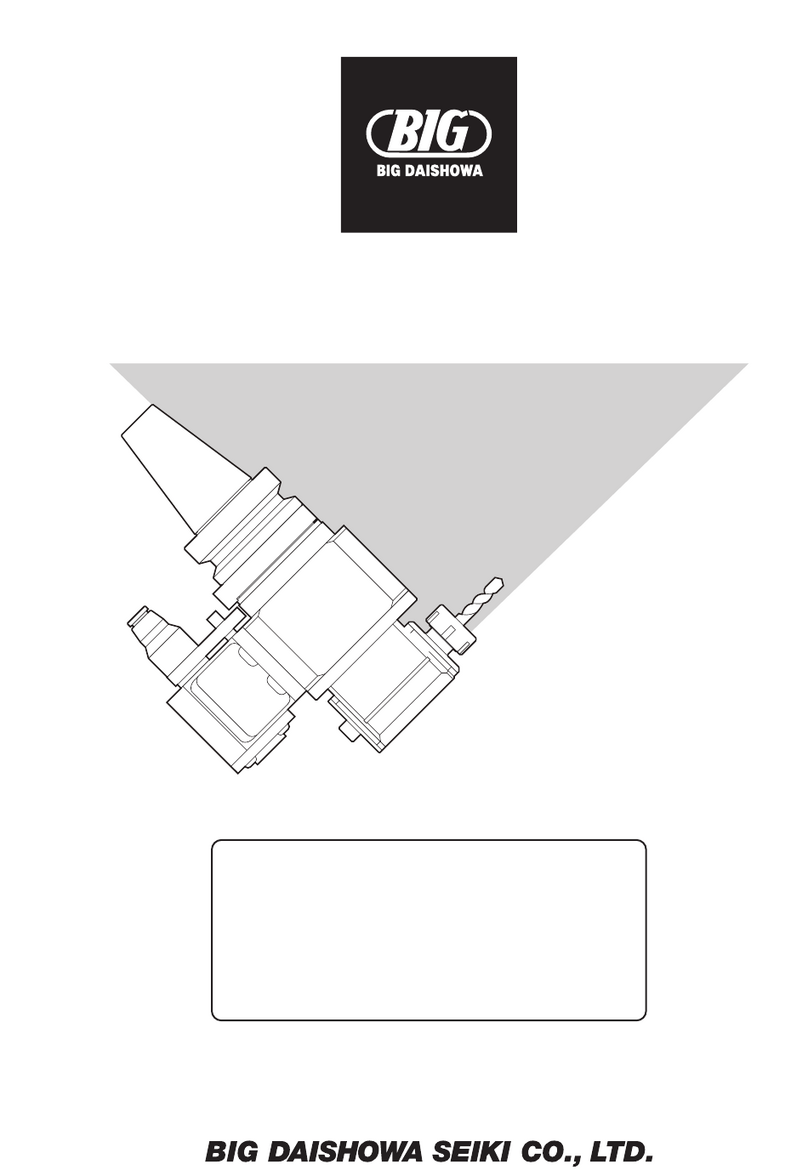

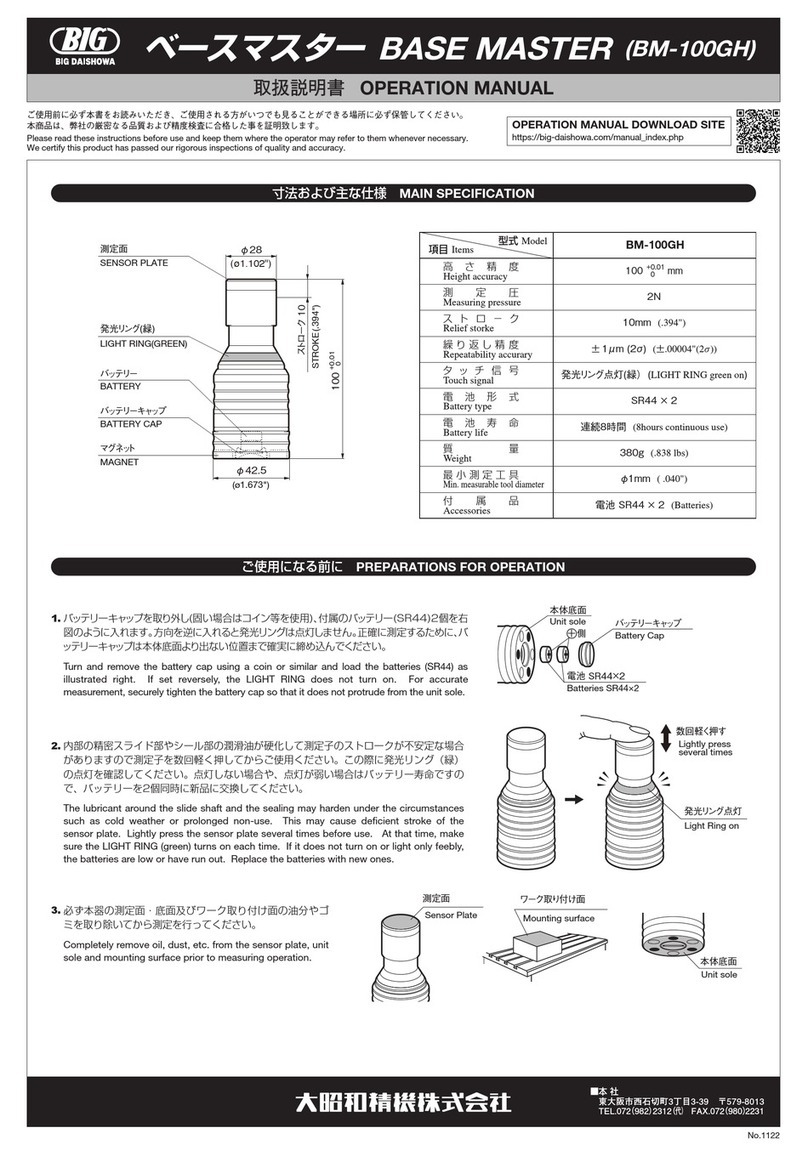

●加工物上面(Z)基準位置検出および工具長検出

Detecting position of workpiece surface on the "Z" axis and length of tool.

加工物上面にベースマスターミニ(BMM-20H)を置き、工具を測定面に接触させると同時にLEDが点灯します。この位

置が加工物上面から20mmの位置になります。工具の長さを測定する場合は、基準バーと他の工具の接触位置の差によ

り工具の長さを検出することができます。

Mount the BMM-20H on the workpiece surface. Move the spindle or "Z" axis carefully until the tool touches the sensor

plate, which will instantly light the LED lamp. This will then give you an exact reading of 20mm distance from the top

surface of the workpiece to the tool.Tool length can be measured by comparing the contact positions between the

reference bar and the actual tool.

●加工物側面(X,Y)基準位置検出および工具径検出

Detecting position of workpiece surface on the "X" and "Y" axis and diameter of tool.

加工物側面にベースマスターミニ(BMM-20H)を取り付け、工具外径部を測定子に接触させると同時にLEDが点灯しま

す。この位置が工具半径プラス20mmの位置になります。工具径を測定する場合は、基準バーで半径をプリセットして

おき、他の工具を測定した時の差により工具半径を検出することができます。

Mount BMM-20H on the side surface of workpiece and move the spindle, "X" or "Y" axis carefully until the tool touches

the sensor plate, which will instantly light the LED lamp. This will give you an exact reading of 20mm distance from the

reference surface to the tool. Then add 1/2 the diameter of the tool to give you the machine spindle center distance.

Center of

sensor plate

WORKPIECE

“Z” AXIS REFERENCE

SURFACE

WORKPIECE

本社

東大阪市西石切町3丁目3-39〒579-8013

TEL.072(982)2312(

代)

FAX.072(980)2231

・Do not immerse the BMM-20H directly into gas oil for washing.

・

Take out the batteries when not using the BMM-20H for extended periods.

・Do not disassemble the BMM-20H.

・Store the batteries in a safe place out of reach of babies to prevent

swallowing. Dispose used batteries in a prescribed way.

・Replace two batteries at the same time when voltage becomes low.

・The precision electronic parts are contained. Take care not to

splash any coolant and avoid any accidental collisions. Do not

leave it on the machine table or the jig when not in use.

・Remove coolant immediately if it is attached to the BMM-20H.

・Specications and height are the gures under measurement

environment at a temperature of 20℃±0.5℃(equivalent to 68°F)

and at a humidity of 55%±5%. For precise measurement under

different environment, compare the height with a block gage and

compensate the difference.

・Use under low temperature below 5℃may worsen movement of the

sensor plate.

・If an accuracy problem or any malfunctions occur, immediately stop

using the device and contact us through distributors.

・測定面や本体底面の汚れた本器を使用して測定した場合、測定誤差が生じます。

そのまま加工に入ると刃具、加工物、機械等を破損する恐れがあり、また、そ

の破片で人体に危険を及ぼす恐れがあります。

・本器測定面に工具を早送りで近づけるときは余裕のある位置で止め、残りはゆ

っくりハンドルで送ってください。万一、早送りのままで本器にぶつかった場

合、本器や刃具、加工物、機械等を破損する恐れがあり、また、その破片で人

体に危険を及ぼす恐れがあります。

・Measurement may be in error, if the sensor plate or sole plane is

soiled. Any attempt to commence machining after a false reading

may lead to damage of the tool, workpiece, machine, etc. and

broken parts could endanger persons in the area.

・When any tool approaches the sensor plate at a high feed rate, then

it should be arrested at a sufcient safe distance to allow the nal

approach at ne feed by hand. Should the tool collied with the

BMM-10H at a high feed then damage may be caused and broken

parts could endanger persons in the area.

Class and Group Description

This product is a CISPR11 Group 1, Class A product in accordance with EN61326-1 and EN61326-2-3. This means that this product does not generate

and/or use intentionally radio-frequency energy, in the form of electromagnetic radiation, inductive and/or capacitive coupling, for the treatment of

material or inspection / analysis purpose and is intended for use in an industrial environment.

Note: Since this product is battery operated, this product is not connected to this low voltage power supply network.

・Manufacturer : BIG DAISHOWA SEIKI CO., LTD. Address : Nishiishikiricho 3-3-39, Higashiosakashi, Osaka, JAPAN

・Authorized Representative in EU : BIG KAISER PRECISION TOOLING LTD. Address : Glattalstrasse 516, 8153 Rümlang, Switzerland

使用上の注意 CAUTION IN USE

EMC INFORMATION

ご注意 CAUTION

ご注意 CAUTION

・軽油等へ漬けての丸洗いはしないでください。

・長期保存の場合は電池を取り外してください。

・本器の分解はできません。

・電池は幼児の手の届かない場所に保存し、不要になった電池は所定の方法で処

分してください。

・電池の電圧が低下した時は、2個同時に交換してください。

・精密電子部品を使用しておりますので、クーラントをかけたり衝撃を与えたりしな

いでください。また、ご使用後は機械テーブル上や治具上に放置しないでください。

・ご使用時にクーラントが本器に付着した場合は、放置しないで必ずクーラント

を拭き取ってください。

・仕様および高さは測定環境が温度20℃±0.5℃、湿度55%±5%の値です。

前環境以外でより正確な測定を行う場合は、ゲージブロックと比較測定し、高

さを補正してください。

・

低温下でのご使用は、測定子の動きに影響を及ぼす恐れがあります。(低温下:5℃以下)

・精度の異常や不具合が発生した場合は直ちに使用を中止し、ご購入先を通じて

弊社支店へご連絡ください。

危険 DANGER

マシニングセンタ・汎用フライス盤等での使い方 ON MACHINING CENTERS AND MILLING MACHINES (CNC AND STANDARD)

・工具の先端部を測定面の中心に合わせて、測定を行ってください。中心よりズレますと、工具の破損や測定

が正確に行われない恐れがあります。

・工具を測定面にタッチさせる時は、タッチスピ−ドが速いと工具破損する恐れがありますので、ゆっくりと

慎重にアプロ−チを行ってください。

・測定子は2mm以上押し込まないでください。

・

The tool edge should be centered in the sensor plate. Otherwise, the tool may be damaged or precise measurement may be in error.

・When the tool approaches the sensor plate, it should be arrested at a sufciently safe distance to allow the nal approach at ne

feed by hand. Should the tool edge collide with the sensor plate at a high feed then damage may be caused.

・Do not press the sensor plate beyond 2mm(.080").