3

BEFORE OPERATING

•Read the instructions carefully. Be familiar with the controls

andproper use of the unit.

•Do not operate this unit when tired, ill or under the influ-

enceof alcohol, drugs or medication.

•Children under the age of 15 must not use the unit; teens

mayoperate the unit with adult guidance.

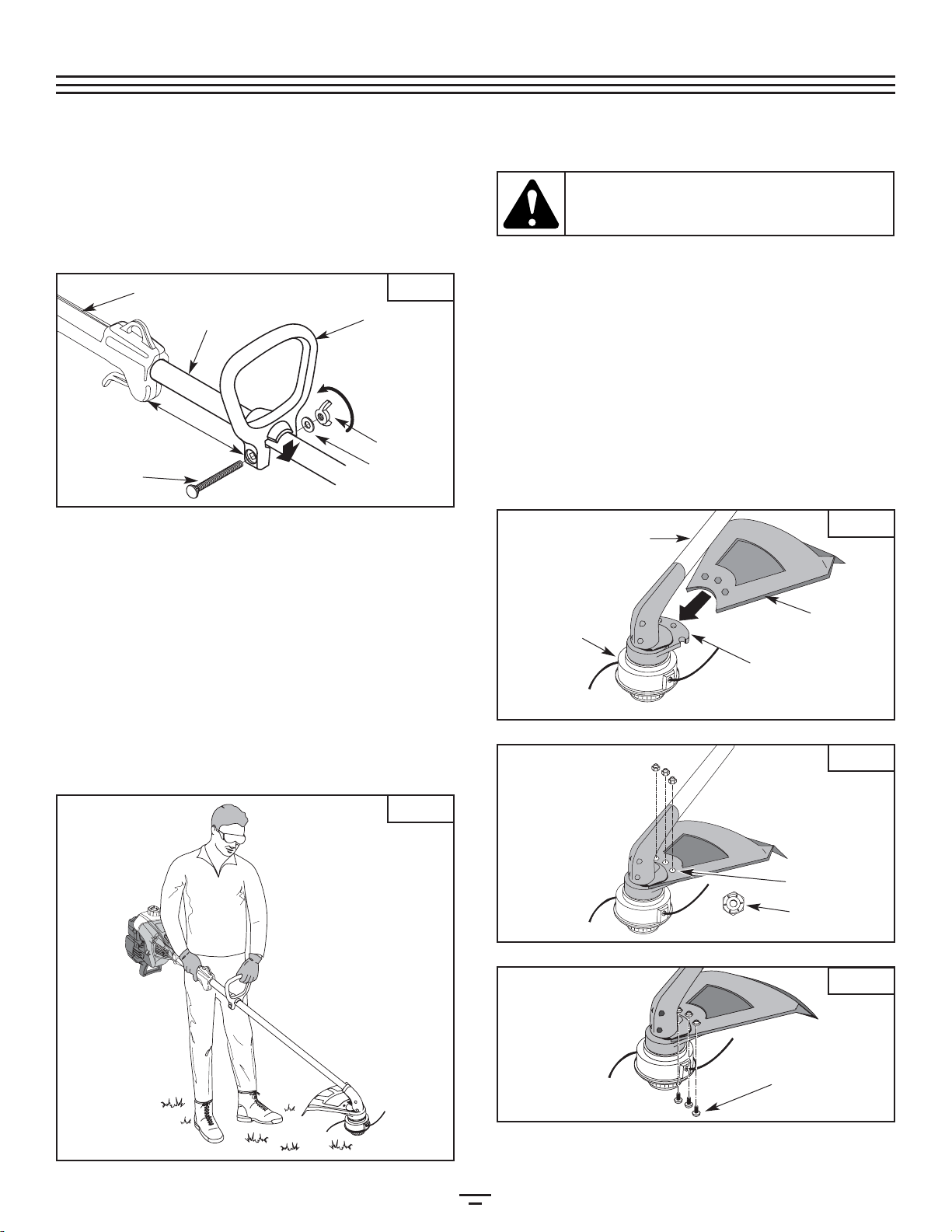

•Inspect the unit before use. Replace damaged parts. Check

for fuel leaks. Make sure all fasteners are in place and

secure. Replace cutting attachment parts that are cracked,

chipped or damaged in any way. Make sure the cutting

attachment is properly installed and securely fastened. Be

sure that the cutting attachment shield is properly

attached, and positioned as recommended. Failure to do so

can result in personal injury to the operator and

bystanders,as well as damage to the unit.

•Use only a 0.080-inch (2.03 mm) diameter Genuine Factory

Parts™ replacement line. Never use metal-reinforced line,

wire, chain or rope. These can break off and become dan-

gerousprojectiles.

•Beaware of risk of injury to the head, hands and feet.

WARNING:

When using the unit, you must follow

the safety rules. Please read these instructions

before operating the unit in order to ensure the

safety of the operator and any bystanders. Please

keepthese instructions for later use.

•Squeeze the throttle control and check that it returns auto-

matically to the idle position. Make all adjustments or

repairsbefore using the unit.

•Clear the area to be cut before each use. Remove rocks,

broken glass, nails, wire, string and other objects which

may be thrown or become entangled in the cutting attach-

ment. Clear the area of children, bystanders and pets; keep

them outside a 50-foot (15 m.) radius, at a minimum. Even

then, they are still at risk from thrown objects. Encourage

bystanders to wear eye protection. If you are approached,

stopthe unit immediately.

•This unit was not designed to be used as a brushcutter. Do

not attach or operate this unit with any type of brushcut-

tingblade or brushcutting attachment.

SAFETYWARNINGS FOR GAS TRIMMERS

•Store fuel only in containers specifically designed and

approvedfor the storage of such materials.

•Always stop the engine and allow it to cool before filling

the fuel tank. Never remove the fuel tank cap or add fuel

when the engine is hot. Never operate the unit without the

fuel cap securely in place. Loosen the fuel tank cap slowly

torelieve any pressure in the tank.

WARNING: Gasoline is highly flammable and its

vapors can explode if ignited. Follow the ensu-

ingprecautions.

RULESFORSAFEOPERATION

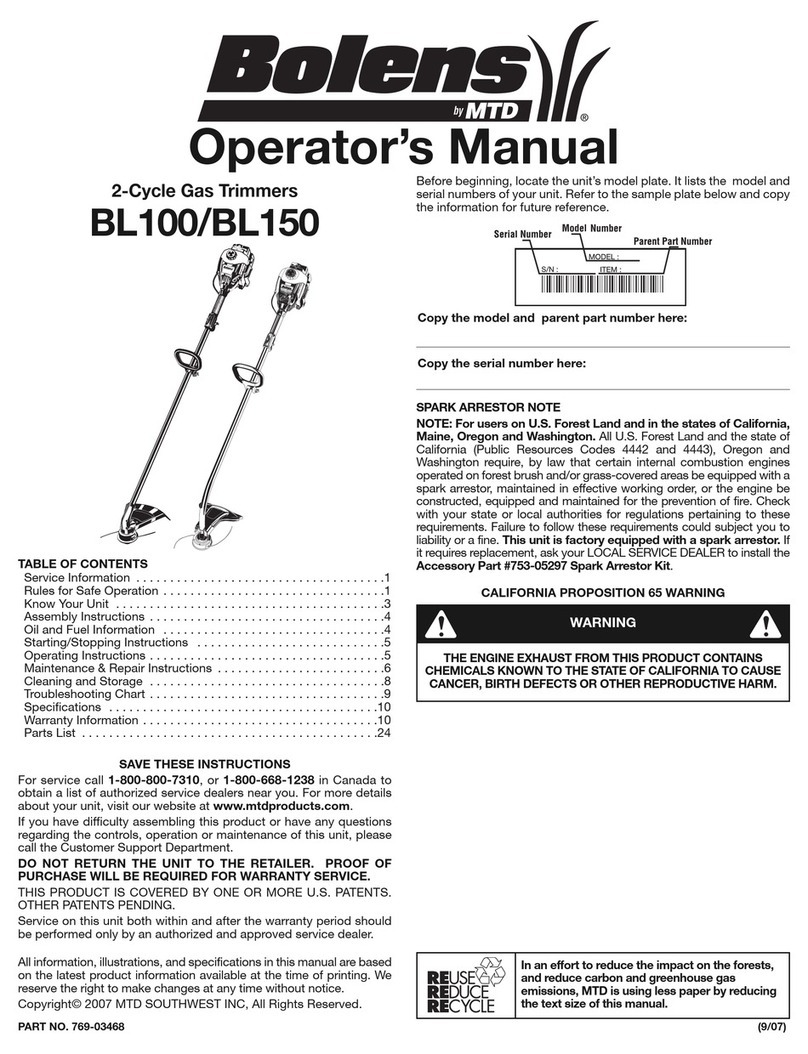

NOTE: For users on U.S. Forest Land and in the states of California, Maine, Oregon, and Washington. All U.S. Forest Land and

the state of California (Public Resources Codes 4442 and 4443), Oregon, and Washington require by law that certain internal com-

bustion engines operated on forest brush and/or grass-covered areas be equipped with a spark arrestor, maintained in effective

working order, or the engine be constructed, equipped, and maintained for the prevention of fire. Check with your state or local

authorities for regulations pertaining to these requirements. Failure to follow these requirements could subject you to liability or a

fine. This unit is factory equipped with a spark arrestor. If it requires replacement, ask your LOCAL SERVICE DEALER to install

theAccessory Part #182747 Spark Arrestor.

Read the Operator’s Manual(s) and follow all warnings and safety instructions.

Failure to do so can result in serious injury to the operator and/or bystanders.

FOR QUESTIONS,CALL 1-330-558-7720 or 1-866-840-6483

SAFETY ALERT SYMBOL

:Indicates danger, warn-

ing or caution. Attention is required in order to

avoid serious personal injury. May be used in

conjunctionwith other symbols or pictographs.

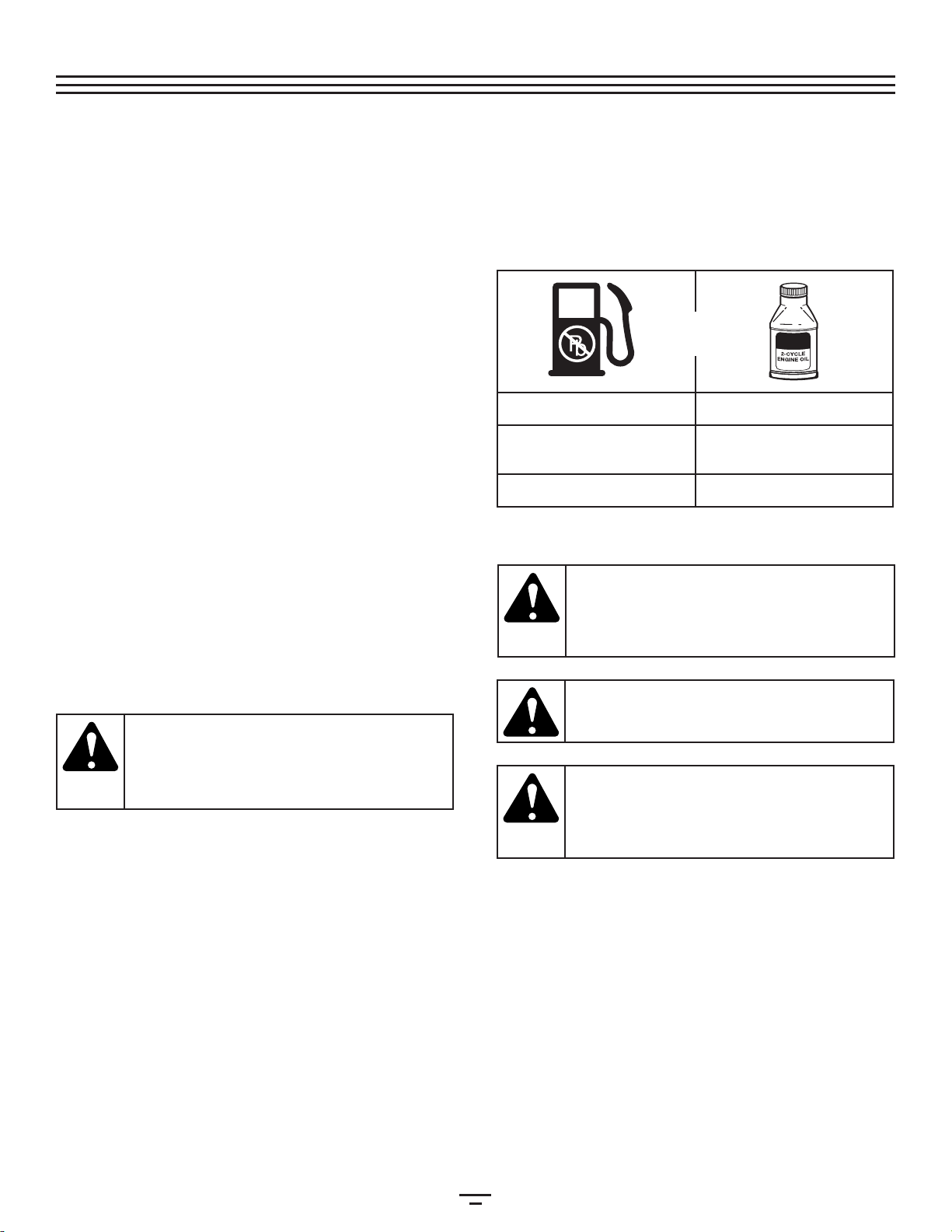

• SAFETY SYMBOLS •

• IMPORTANT SAFETY INFORMATION •

READ ALL INSTRUCTIONS

The purpose of safety symbols is to attract your attention to possible dangers. The safety symbols, and their explanations, deserve

your careful attention and understanding. The safety warnings do not by themselves eliminate any danger. The instructions or

warningsthey give are not substitutes for proper accident prevention measures.

SYMBOL MEANING

DANGER: Failure to obey a safety warning will

result in serious injury to yourself or to others.

Always follow the safety precautions to reduce

therisk of fire, electric shock and personal injury.

WARNING: Failure to obey a safety warning can

result in injury to yourself and others. Always fol-

low the safety precautions to reduce the risk of

fire,electric shock, and personal injury.

CAUTION: Failure to obey a safety warning may

result in property damage or personal injury to

yourself or to others. Always follow the safety

precautions to reduce the risk of fire, electric

shock,and personal injury.

SYMBOL MEANING

NOTE: Advises you of information or instructions vital to the operation or maintenance of the equipment.