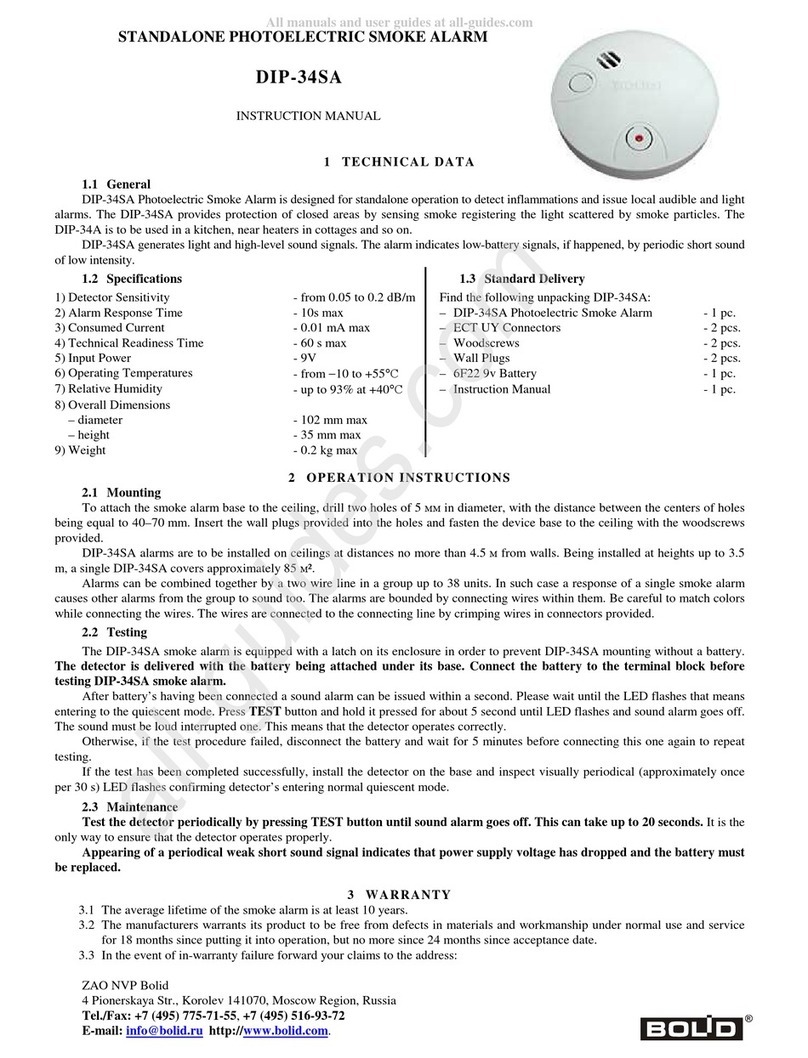

In order to program the unique DIP-34A-03 loop address connect the detector to a S2000-KDL/S2000-KDL-2I controller

which in turns is connected to a network controller (a S2000(M) panel or PC under UProg software). Then send one of

the following commands to the loop controller (for getting more information see the relevant User’s Manual):

Change the Device Address Use the Change Device Address command specifying the old detector address and the

new detector address as the parameters (see more information in the referred

Manuals). The network controller will display the messages about disconnecting the

device with the old address and then detecting the device with newly programmed

address.

Program the Device Address If the device address is unknown or two devices have the same address then use the

Program Device Address command specifying a required address as the parameter.

Then within 5 min press the detector light emitter or send the laser test tool beam into

it. The message about detecting the device with the newly assigned address shall be

displayed by a network controller (S2000(M)) or UProg Configuration Tool.

After programming write the set address of the detector on the “Address” label and stick it on the detector base.

Programming the S2000-KDL/S2000-KDL-2I to Operate the DIP-34A-03

To handle signals from a DIP-34A-03 correctly, an S2000-KDL/S2000-KDL-2I controller must be programmed with the

Zone Type parameter for this DIP-34A-03 being set to the value 1 (Smoke) or 8 (Smoke Analogue Addressable with

Variable Thresholds). To program the S2000-KDL/S2000-KDL-2I, connect it to a PC under UProg Configuration Tool and

follow the relevant programming instructions in accordance with the S2000-KDL/S2000-KDL-2I User’s Manual.

ROUTINE TESTING

Before testing the DIP-34A-03, please disconnect executive outputs of all system devices and modules that

can release an extinguishing agent. Notify the proper authorities that the system is undergoing maintenance.

After testing verify that all the detectors are ready to operate properly. Then restore operability of all the system

components disconnected before testing and notify the proper authorities that the system is back in operation.

All the equipment used in testing must be known functioning.

If the detector has failed please replace it for a healthy one and contact Technical Support. The

defective detector should be repaired by the manufacturer of in a certified repair center.

1. Turn on the network controller and the S2000-KDL controller. The light emitter of the detector shall light steady. When

the communications between the detector and S2000-KDL is established the light emitter will flash once per 4 seconds

indicating Norm status of the detector.

2. Take a can of test aerosol and spray some of the test material into the detector. The network controller shall display

Fire Alarm message for the device with the address of the DIP-34A-03. The detector’s LED shall flash twice every 4 s.

3. Alternately, you can perform a simplified test by pressing the detector light emitter or lighting it with the laser beam of a

laser test tool. This will cause solid lighting of the detector light emitter for 3 s followed by its double flashing every 4 s.

4. The network controller will display a:

−Fire Alarm message for the device with the address of the DIP-34A-03 if the version of the S2000-KDL in use is

1.35 or below, or

−Test message or Fire Alarm message (depending on the current test mode) when the version of the S2000-KDL

in use is 1.36 or higher (see the Manuals for the S2000-KDL controller and the network controller for more

information about testing)

5. When the test aerosol disappears (or light emitter is released, or laser test tool is disposed) the detector must be in the

Norm status. If the S2000M console or Orion Pro software has displayed no messages mentioned above or the

detector’s LED performs in a different way than mentioned above then the detector is unhealthy and must be replaced.

LED INDICATION

Flashing once per 4 s Norm

Four-time flashing once per 4 s Programming an address

Double flashing once per 4 s Fire Alarm or Test

Solid light Waiting for establishing a connection with the S2000-KDL

Pushing the LED or applying the laser test tool beam to the LED

Other Trouble