reflector, for example to put the transceiver on a table with the lens facing up using the ceiling

as a reflector.

5.1.3 For testing operability, power up the control panel or PC and the polling loop controller

with the detector connected to the last one.

5.1.4 Activate the alignment mode by sliding the DIP switch “1” to the ON position. Visually

inspect fast pulsing (faster than five flashes per second) in red (which means selecting an

optimal gain with rewriting the maximum achieved level of received signal) followed by pulsing

most of the time in blue (Very Close) with normal frequency (approximately twice per second).

In particular, there can be rare flashes with amber (Less) or red (More). Having achieved such

condition, you can terminate the alignment by sliding the DIP switch “1” to the OFF position and

waiting for approximately one minute until the detector automatically quits this mode having

rewritten new values of installation parameters into the non-volatile memory.

After detector’s having entered to the alignment mode the control panel or PC shall

receive a Test of Fire Alarm event depending on the current settings

5.1.5 If the alignment mode has established but the LED rapidly flashes with white (Too Low) or

blue (Two High) then take measures to increase the reflected signal in the first case or to

reduce the reflected signal in the second one. If you failed to alter this performance then with

great probability the detector is improper.

5.1.6 If the detector exits the alignment mode normally it shall enter in the Norm state indicating

this by red flashing once per four seconds.

5.1.7 Arm the detector.

5.1.8 Press the TROUBLE button on the detector’s board and observe fast flashing with amber

(“Trouble in Progress”) followed by flashing in red with the trouble pattern. After releasing the

button the detector will enter normal state in some time.

5.1.9 Press the TEST button on the detector’s board and observe fast green pulsing at first

(“Test in Progress”) followed by solid illuminating with red. The full-range verification of the

operability of the detector is completed now. If any problems were detected during verification

the detector should be sent to the manufacturer for repair, however, it is recommended to

contact preliminary the technical support service in order to verify the validity of the checks

performed. 5.2 Testing Performance of the Detectors

5.2.1 General Guidelines for Testing

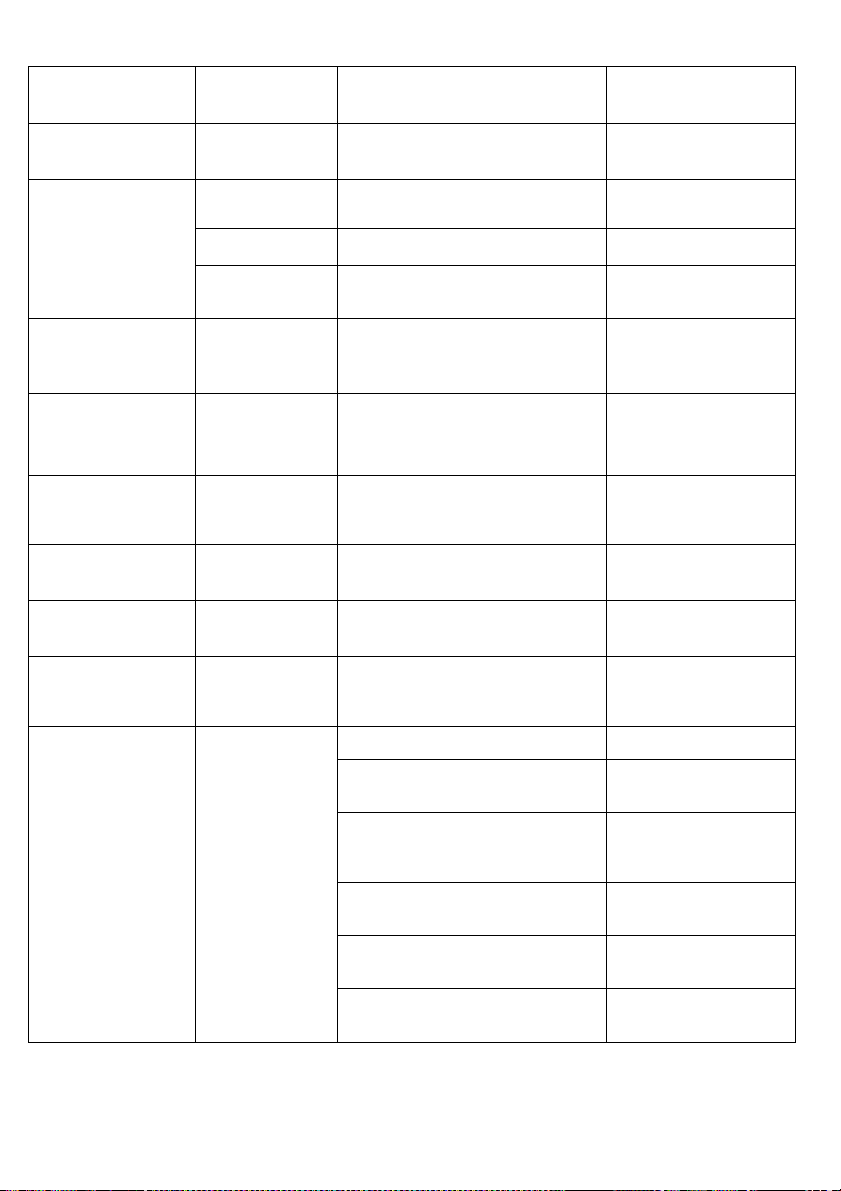

5.2.1.1. Performance of visual indication when the detector displays its conditions in the

operation mode and in the alignment mode is crucially different. Table 1 contains descriptions

of various conditions of the detector for the operation mode, their textual names, and the

ways to display these conditions by means of detector’s indication and on the LCD of an

IPDL-152 test station.

5.2.1.2. Prior to testing the detector please read and understand the information from

Table 1.