Bomag BW 211 D-4 User manual

Service - Manual

Catalogue number.

008 911 45 01/2007

BW 211 D-4 / PD-4

BW 213 D-4 / PD-4

S/N 101 582 40 .....> S/N 101 582 41 .....> S/N 101 582 45 .....>

S/N 101 582 46 ....> S/N 101 582 50 ....>

Single drum roller

Table of Contents

BOMAG 3008 911 45

General 7

1.1 Introduction 8

1.2 Safety regulations 9

1.3 General repair instructions 14

1.4 Tightening torques 24

Technical data 29

2.1 Technische Daten 30

2.2 Maintenance chart 38

2.3 Table of fuels and lubricants 40

2.4 Fuels and lubricants 40

Connection overview 43

3.1 Connection overview 44

Tests and adjustments 47

4.1 Special tools, tests and adjustments 48

4.2 Checking the rotation speeds 52

4.3 Checking / adjusting the neutral positions of the travel pump 54

4.4 Pressure tests in the travel circuit 56

4.5 Checking / adjusting the vibrator shaft speeds 58

4.6 Pressure measurements in the vibration circuit 59

4.7 Check the leakage rate of the vibration motor 60

4.8 Pressure test in steering circuit 61

Flushing and bleeding 63

5.1 Special tools for flushing 64

5.2 Flushing - general 69

5.3 Flushing schematic travel circuit (distribution travel pump) 71

5.4 Flushing the travel circuit (travel pump distribution) 73

5.5 Flushing schematic travel circuit (distribution axle motor) 79

5.6 Flushing the travel circuit (axle motor distribution) 84

5.7 Flushing schematic for vibration drive 89

5.8 Flushing the vibration circuit 90

5.9 Bleeding the travel circuit 94

5.10 Bleeding the vibration circuit 96

Fundamental electrics 99

6.1 Understanding circuit diagrams 100

6.2 Terminal designations 104

6.3 Current and voltage 108

6.4 Resistance 112

6.5 Series / parallel connection 114

6.6 Ohm's law 116

6.7 Electrical energy 116

6.8 Formula diagram 117

6.9 Metrology 118

6.10 Diodes, relays, fuses 120

6.11 Batteries 123

6.12 Three-phase generator 126

6.13 Electric starter 133

Find manuals at https://best-manuals.com

Table of Contents

BOMAG4008 911 45

6.14 Telemecanique switch 136

6.15 Inductive proximity switches 139

6.16 Angle sensor with current output 140

6.17 Plug connectors 141

6.18 Deutsch plug, series DT and DTM 142

6.19 Plugs and terminals in spring clamping technology 148

Special tools, electrics 153

7.1 Special tools, electrics 154

Electronic modules 163

8.1 Seat contact module 165

Speedometer Module 173

9.1 Speedometer module 175

Service Training 177

10.1 Electrics BEM (BOMAG Evib-meter) 179

10.2 Service Training 237

Engine 299

11.1 Diesel engine, general 301

11.2 Service side 302

11.3 Starter side 303

11.4 Lubrication oil circuit 304

11.5 Oil pressure switch and low oil pressure circuitry 306

11.6 Check the engine oil level 307

11.7 Changing engine oil and oil filter cartridges 308

11.8 Coolant circuit 310

11.9 Coolant temperature switch 312

11.10 Disassembling and assembling the coolant temperature switch 313

11.11 Replacing the thermostat 314

11.12 Checking the thermostat in disassembled state 315

11.13 Check the coolant level 316

11.14 Change the coolant 316

11.15 Clean the cooling fins on engine and hydraulic oil cooler 317

11.16 Three-phase generator 318

11.17 Fuel supply 320

11.18 Injection system 323

11.19 Injection pump replacement during service 324

11.20 Injection valve replacement during service 333

11.21 Checking / repairing injection valves 336

11.22 Fuel filter 341

11.23 Check, clean the water separator 343

11.24 Change the fuel pre-filter cartridge 343

11.25 Change the fuel filter cartridge 344

11.26 Checking the compression 345

11.27 Check, adjust the valve clearance 346

11.28 Boost fuel solenoid valve 348

11.29 Engine shut-down solenoid 349

11.30 Air filter, differential pressure switch 350

11.31 Service the combustion air filter 351

Find manuals at https://best-manuals.com

Table of Contents

BOMAG 5008 911 45

11.32 Heating flange on engine 354

11.33 Checking the heating flange control 357

11.34 Electric throttle control 358

11.35 Engine monitoring 360

11.36 Engine 363

11.37 Special tools, Deutz engine (BFM 2012) 365

Air conditioning system 377

12.1 Physical basics 379

12.2 Refrigerant R134a 382

12.3 Compressor oil / refrigeration oil 383

12.4 Working principle of the air conditioning system 384

12.5 Monitoring devices 384

12.6 Description of components 385

12.7 Checking the compressor oil level 391

12.8 Checking the magnetic clutch 392

12.9 Inspection and maintenance work 393

12.10 Checking, replacing the refrigerant compressor V-belt 393

12.11 Service the air conditioning 394

12.12 Drying and evacuation 397

12.13 Emptying in case of repair 397

12.14 Leak test 398

12.15 Filling instructions 399

12.16 Trouble shooting in refrigerant circuit, basic principles 402

12.17 Trouble shooting, refrigerant circuit diagram 406

12.18 Trouble shooting procedure 407

12.19 Steam table for R134a 417

12.20 Heating control / air conditioning control 423

Replacing the cab window panes 429

13.1 Assembly of window panes 430

13.2 Special tools 431

13.3 Auxiliary materials 432

13.4 Removing and installing the window pane 434

Drum 439

14.1 Special tools, drum, single drum rollers 440

14.2 Repair overview for drum 442

14.3 Removing and installing the drum 450

14.4 Repairing the drum 456

14.5 Dismantling, assembling the change-over weights 489

14.6 Changing the rubber buffers and adjusting the pretension 492

Oscillating articulated joint 495

15.1 Special tools 496

15.2 Repair overview oscillating articulated joint 498

15.3 Removing and installing the oscillating articulated joint 501

15.4 Dismantling the oscillating articulated joint 503

15.5 Assembling the oscillating articulated joint 508

Suppliers documentation 519

16.1 Travel pump series 90R 521

Find manuals at https://best-manuals.com

Table of Contents

BOMAG6008 911 45

16.2 Travel drive series 51 611

16.3 Vibration pump 42R 041 693

16.4 Vibration motor A10FM 731

16.5 MS/MSE 02 ..... 18 755

16.6 Axle DANA 192 805

Circuit diagrams 929

17.1 Wiring diagram 931

17.2 Wiring diagram 955

17.3 Wiring diagram 985

17.4 Hydraulic diagram 1021

Find manuals at https://best-manuals.com

1.1 Introduction

BOMAG8008 911 45

1.1 Introduction

This manual is intended to support expert mechanics

in efficient repair and maintenance work. Whoever

wants to do repair work himself should have been suf-

ficiently trained and posses profound expert knowl-

edge, he should limit his work only to those parts and

components which will not affect the safety of the ve-

hicle or the passengers. It is highly recommended to

have repairs to critical systems, such as steering,

brakes and travel drive, sole carried out by a BOMAG

workshop. Untrained persons should NEVER UN-

TERTAKE SUCH REPAIR WORK.

The repair instructions describe the removal or dis-

mantling and assembly of components and assembly

groups. The repair of disassembled assembly groups

is described as far as this makes sense with respect

to available tools and spare parts supply and as far as

it can be understood by a skilled mechanic.

Documentation

For the BOMAG machines described in this training

manual the following documentation is additionally

available:

1 Operating and maintenance instructions

2 Spare parts catalogue

3 Wiring diagram*

4 Hydraulic diagram*

5 Service Information

You should only use genuine BOMAG spare parts.

Spare parts needed for repairs can be taken from the

spare parts catalogue for the machine.

This manual is not subject of any updating service; we

would therefore like to draw your

attention to the additionally published "technical serv-

ice information".

In case of a new release all necessary changes will be

included.

In the course of technical development we reserve the

right for technical modifications without prior notifica-

tion.

Information and illustrationsin this manual must not

be reproduced and distributed, nor must they be used

for the purpose of competition. All rights according to

the copyright law remain expressly reserved.

!Danger

Please observe strictly the safety regulations in

this manual, in the operating instructions as well

as the applicable accident prevention regulations.

BOMAG GmbH

Printed in Germany

Copyright by BOMAG

* The applicable documents valid at the date of print-

ing are part of this manual.

Find manuals at https://best-manuals.com

Safety regulations

BOMAG 9008 911 45

1.2

1.2 Safety regulations

Important notes

These safety regulations must be read and ap-

plied by every person involved in the repair of this

machine. The applicable accident prevention in-

structions and the safety regulations in the oper-

ating and maintenance instructions must be

additionally observed.

Repair work shall only performed by appropriately

trained personnel or by the after sales service of

BOMAG.

Any suggestions, safety precautions and warn-

ings in this section are intended as a mnemonic

aid for well trained and experienced expert me-

chanics. This manual should not be considered a

bible on workshop safety.

Workshop equipment and facilities as well as the

use and waste disposal of solvent, fluids, gases

and chemicals are subject to legal regulations,

which are intended to provide a minimum on safe-

ty. It is obviously your own responsibility to know

and adhere to these regulations.

This manual contain headers like "Note", "Attention",

"Danger" and "Environment", which must be strictly

complied with in order to avoid dangers for health and

for the environment.

!Danger

Paragraphs marked like this highlight possible

dangers for persons.

!

Caution

Paragraphs marked like this highlight possible

dangers for machines or parts of the machine.

i

Note

Paragraphs marked like this contain technical infor-

mation for the optimaleconomical use of the machine.

Environment

Paragraphs marked like this point out practices

for safe and environmental disposal of fuels and

lubricants as well as replacement parts.

Observe the regulations for the protection of the

environment.

General

lBefore starting repair work stand the machine on

level and solid ground.

lAlways secure the machine against unintended roll-

ing.

lSecure the engine reliably against unintentional

starting.

lMark a machine that is defective or being repaired

by attaching a clearly visible warning tag to the

steering wheel.

lOn machines with articulated joint keep the articu-

lated joint locked during work.

lUse protective clothes like hard hat, safety boots

and gloves.

lKeep unauthorized persons away from the machine

during repair work.

lTools, lifting gear, lifting tackle, supports and other

auxiliary equipment must be fully functional and in

safe condition.

lUse only safe and approved lifting gear of sifficient

load bearing capacity to remove and install parts or

components from and to the machine.

lBe careful with cleansing agents. Do not use easily

inflammable or harmful substances, such as gaso-

line or paint thinners for cleaning.

lCleaning or repair work on the fuel tank is very dan-

gerous. Do not smoke or allow any ignitable sparks

or open fire in the vicinity when cleaning or repairing

a tank. .

lWhen performing welding work strictly comply with

the respective welding instructions.

Precautions and codes of conduct for

welding work

Welding work should only be performed by specially

instructed expert personnel.

!Danger

Electric shock!

Sparks, fire hazard, burning of skin!

Infrared or ultraviolet radiation (arc), flashing of

eyes!

Health hazard caused by welding work on highly

alloyed work pieces, metal coatings, paint coat-

ings, plastic coatings, oil containing dirt deposits,

grease or solvent residues, etc.!

lCheck welding equipment and cables for damage

before use (also the validity of inspection stickers).

lEnsure good conductivity between earth cable and

work piece.

lStart the extraction fan before starting work and

guide with the progressing work as required.

lAlways isolate the burner when laying it down (re-

move possible electrode residues).

lProtect cables from being damaged, use cables

with insulated couplings.

lEnsure sufficient fire protection, keep a fire extin-

guisher at hand.

Find manuals at https://best-manuals.com

1.2 Safety regulations

BOMAG10 008 911 45

lIn case of welding work in fire or explosion endan-

gered environments, you should always ask for a

welding permission.

lRemove combustible parts from the vicinity or cover

such parts.

lName a fire watch during and after welding work.

lDo not clamp the welding rod holder and the inert

gas welding gun under your arm and lay these parts

only on an insulated top.

lPlace the inert gas bottles in a safe place and se-

cure them against falling over.

lUse a protective screen or an arcing shield with

welding glass, wear welding gloves and clothes,

this applies also for assisting persons.

lSwitch the welding unit off before connecting weld-

ing cables.

Behaviour in case of faults

lCheck electrode holders and electric cables at reg-

ular intervals.

lIn case of deficiencies switch off the welding unit

and inform supervising persons.

lIn case of an extractor fan failure or any other fault

inform the supervising persons.

Maintenance; waste disposal

lReplace damaged insulating jaws and welding rod

holders immediately.

lReplace the welding wire reels only in deenergized

state.

What to do in case of accidents; First Aid

lKeep calm.

lCall first air helpers.

lReport the accident.

lIn case of an electric accident: Interrupt the power

supply and remove the injured person from the

electric circuit. If breathing and heart have stopped

apply reactivation measures and call for an emer-

gency doctor.

Old oils

Prolonged and repetitive contact with mineral oils will

remove the natural greases from the skin and causes

dryness, irritation and dermatitis. Moreover, used en-

gine oils contain potentially hazardous contaminants,

which could cause skin cancer. Appropriate skin pro-

tection agents and washing facilities must therefore

be provided.

lWear protective clothes and safety gloves, if possi-

ble.

lIf there is a risk of eye contact you should protect

your eyes appropriately, e.g. chemistry goggles or

full face visor; a facility suitable for rinsing the eyes

should also be available.

lAvoid prolonged and repetitive contact with oil, es-

pecially with old oil. In case of open incisions and in-

juries seek medical advice immediately.

lApply protective cream before starting work, so that

oil can be easier removed from the skin.

lWash with soap and water to ensure that all oil has

been removed (a skin cleaning agent and a nail

brush will help). Lanolin containing agents will re-

place natural skin oils that were lost.

lDo not use gasoline, kerosene, diesel, thinner or

solvents to wash the skin.

lDo not put oil soaked cloths into your pockets.

lAvoid clothes, especially underpants, getting soiled

by oil.

lOveralls must be washed at regular intervals.

Clothes that cannot be washed, must be disposed

of.

lIf possible degrease components before handling.

Environment

It is strictly prohibited to drain off oil into the soil,

the sewer system or into natural waters. Entrust

special companies with the waste disposal of old

oil. If in doubt you should consult your local au-

thorities.

Hydraulics

lHydraulic oil escaping under pressure can pene-

trate the skin and cause severe injury. You should

therefore relieve the pressure in the system before

disconnecting any lines.

lBefore applying pressure to the system make sure

that all line connections and ports have been prop-

erly tightened and are in perfect condition.

lHydraulic oil leaking out of a small opening can

hardly be noticed, therefore please use a piece of

cardboard or wood when checking for leaks. When

being injured by hydraulic oil consult a physician im-

mediately, as otherwise this may cause severe in-

fections.

lDo not step in front of or behind the drums/wheels/

crawler tracks when performing adjustment work in

the hydraulic system while the engine is running.

Block drums and/or wheels / crawler tracks with

wedges.

Find manuals at https://best-manuals.com

Safety regulations

BOMAG 11008 911 45

1.2

Reattach all guards and safety installations after

all work has been completed.

Environment

It is strictly prohibited to drain off hydraulic oil

into the soil, the sewer system or into natural wa-

ters. Entrust special companies with the waste

disposal of old oil. If in doubt you should consult

your local authorities.

Fuels

!Danger

Repair work on fuel systems must only be per-

formed by appropriately trained personnel.

The following notes refer to general safety precau-

tions for danger free handling of fuel. These notes are

only general instructions; in case of uncertainties you

should consult the person responsible for fire protec-

tion.

Fuel vapours not only are easily inflammable, but also

highly explosive inside closed rooms and toxic; dilu-

tion with air creates an easily inflammable mixture.

The vapours are heavier than air and therefore sink

down to the ground. Inside a workshop they may eas-

ily become distributed by draft. Even the smallest por-

tion of spilled fuel is therefore potentially dangerous.

lFire extinguishers charged with FOAM, SCHAUM,

CO2 GAS or POWDER must be available wherever

fuel is stored, filled in, drained off, or where work on

fuel systems is performed.

lThe vehicle battery must always be disconnected,

BEFORE work in the fuel system is started. While

working on the fuel system you should not discon-

nect the battery, because this could generate

sparks, which would ignite explosive fuel vapours.

lWherever fuel is stored, filled, drained off or where

work on fuel systems is carried out, all potential ig-

nition sources must be extinguished or removed.

Search lights must be fire proof and well protected

against possible contact with running out fuel.

Hot fuels

Before draining fuel off the tank for repair work, you

must strictly apply the following measures:

lAllow the fuel to cool down, to prevent any contact

with a hot fluid.

lVent the system, by removing the filler cap in a well

ventilated area. Screw the filler cap back on, until

the tank is finally emptied.

Synthetic rubber

Many O-rings, hoses and similar parts, which are ap-

parently made of natural rubber, are actually made of

plastic material, a so-called fluoroelastomer. Under

normal operating conditions this material is safe and

does not impose any danger to health.

However, if this material becomes damaged by fire or

extreme heat, it may decompose and form highly

caustic hydrofluoric acid, which can cause severe

burns in contact with skin.

lIf the material is in such a state it must only be

touched with special protective gloves. These

gloves must be disposed of directly after use.

lIf the material has contacted the skin despite these

measures, take off the soiled clothes and seek

medical advice immediately. In the meantime wash

the affected parts of the skin for 15 to 60 minutes

with cold water or lime water.

Poisonous substances

Some of the fluids and substances used are toxic and

must under no circumstances be consumed.

Skin contact, especially with open wounds, should be

strictly avoided.

These fluids and substances are, amongst others,

anti-freeze agents, hydraulic oils, washing additives,

lubricants and various bonding agents.

Air conditioning system

!

Caution

Lines in the air conditioning system must only be

loosened by trained and explicitly instructed ex-

perts.

lWear safety goggles! Put on your safety goggles.

This will protect your eyes against coming into con-

tact with refrigerant, which could cause severe

damage by freezing.

lWear safety gloves and an apron! Refrigerant are

excellent solvents for greases and oils. In contact

with skin they will remove the protective grease film.

However, degreased skin is very sensitive against

cold temperatures and germs.

lDo not allow liquid refrigerants to come into contact

with skin! Refrigerant takes the heat required for

evaporation from the environment. Very low tem-

peratures may bereached. The results may be local

frost injuries (boiling point of R134a -26.5°C at am-

bient pressure).

lDo not inhale higher concentrations of refrigerant

vapours! Escaping refrigerant vapours will mix with

the ambient air and displace the oxygen required for

breathing.

lSmoking is strictly prohibited! Refrigerants may be

decomposed by a glowing cigarette. The resulting

substances are highly toxic and must not be in-

haled.

1.2 Safety regulations

BOMAG12 008 911 45

lWelding and soldering on refrigeration equipment!

Before starting welding or soldering work on vehi-

cles, (in the vicinity

of air conditioning components) all refrigerant must

be drawn out and the rests removed by blowing out

the system with nitrogen. The decomposition prod-

ucts created from the refrigerant under the influence

of heat not only are highly toxic, but also have a

strong corrosive effect, so that pipes and system

components may be attacked. The substance is

mainly fluorohydrogen.

lPungent smell! In case of a pungent smell the afore

mentioned decomposition products have already

been created. Extreme care must be exercised not

to inhale these substances, as otherwise the respi-

ratory system, the lungs and other organs may be

harmed.

lWhen blowing out components with compressed air

and nitrogen the gas mixture escaping from the

components must be extracted via suitable exhaust

facilities (workshop exhaust systems).

Handling pressure vessels

lSince the fluid container is pressurized, the manu-

facture and testing of these pressure vessels is gov-

erned by the pressure vessel directive. (New edition

from April 1989). Paragraph 10 of the pressure ves-

sel directive demands that these pressure contain-

ers must be periodically inspected and tested by a

specialist, according to paragraph 32. In this case

periodically recurring inspections consist of external

examinations, normally on containers in operation.

The refrigerant container must be visually inspected

two times per year, within the frame work of major

inspections. Special attention must thereby be paid

to signs of corrosion and mechanical damage. If the

container is in no good condition, it should be re-

placed for safety reasons, in order to protect the op-

erator or third parties against the dangers when

handling or operating pressure vessels.

lSecure pressure vessels against tipping over or roll-

ing away.

lDo not throw pressure vessels. Pressure vessels

may thereby be deformed to such an extent, that

theywill crack. The suddenevaporation andescape

of refrigerant releases excessive forces. This ap-

plies also when snapping off valves on bottles. Bot-

tles must therefore only be transported with the

safety caps properly installed.

lRefrigerant bottles must never be placed near heat-

ing radiators. Higher temperatures will cause higher

pressures, whereby the permissible pressure of the

vessel may be exceeded. The pressure vessel di-

rective therefore specifies that a pressure vessel

should not be warmed up to temperatures above 50

°C.

lDo not heat up refrigerant bottles with an open

flame. Excessive temperatures can damage the

material and cause the decomposition of refriger-

ant.

lDo not overfill refrigerant bottles, since any temper-

ature increase will cause enormous pressures.

Environment

In operation, during maintenance and repair work

and when taking refrigeration systems our of

service it is not permitted to let refrigerant escape

into the atmosphere, which would contradict the

current status of technology.

Battery

lWear goggles and face protection (acid).

lWear suitable clothes to protect face, hands and

body (acid).

lWork and store accumulators only well ventilated

rooms. (Development of oxyhydrogen gas).

lDo not lean over the battery while it is under load,

being charged or tested. (Danger of explosion).

lBurning cigarettes, flames or sparks can cause ex-

plosion of the accumulator

lKeep ignition sources away from the battery.

lAlways shield eyes and face towards the battery.

lDo not use battery chargers or jump leads without

following the operating instructions.

lKeep the cell plugs closed.

lAfter an accident with acid flush the skin with water

and seek medical advice.

lDo not allow children access to batteries.

lWhen mixing battery fluid always pour acid into wa-

ter, never vice-versa.

Special safety regulations

lUse only genuine BOMAG spare parts for repair

purposes. Original parts and accessories have

been specially designed for this machine.

lWe wish to make explicitly clear that we have not

tested or approved any parts or accessories not

supplied by us. The installation and/or use of such

products may therefore have an adverse effect on

the specific characteristics of the machine and

thereby impair the active and/or passive driving

safety. The manufacturer explicitly excludes any li-

ability for damage caused by the use of non-original

parts or accessories.

lUnauthorized changes to the machine are prohibit-

ed for safety reasons.

lIf tests on the articulated joint need to be performed

with the engine running, do not stand in the articu-

lation area of the machine, danger of injury!

Safety regulations

BOMAG 13008 911 45

1.2

lDo not perform cleaning work while the engine is

running.

lIf tests must be performed with the engine running

do not touch rotating parts of the engine, danger of

injury.

lExhaust gases are highly dangerous. Always en-

sure an adequate supply of fresh air when starting

the engine in closed rooms.

lRefuel only with the engineshut down. Ensure strict

cleanliness and do not spill any fuel.

lKeep used filters in a separate waste container and

dispose of environmentally.

lDispose of oils and fuel environmentally when per-

forming repair or maintenance work.

lDo not refuel in closed rooms.

lDo not heat up oil higher than 160 °C because it

may ignite.

lWipe off spilled oil and fuel.

lDo not smoke when refuelling or when checking the

acid level in the battery.

lDo not check the acid level of the battery with a na-

ked flame, danger of explosion!

lOld batteries contain lead and must be properly dis-

posed of.

lThere is a danger of scalding when draining off en-

gine or hydraulic oil at operating temperature.

lon machines with rubber tires a tire may busr if in-

correctly assembled. This can cause severe injury.

lDo not exceed the specified highest permissible tire

pressure.

1.3 General repair instructions

BOMAG14 008 911 45

1.3 General repair instructions

General

lBefore removing or disassembling and parts, hoses

or components mark these parts for easier assem-

bly.

lBefore assembly oil or grease all parts, as far as this

is necessary.

Electrics

General

The electric and electronic systems in construction

equipment are becoming more and more extensive.

Electronic elements are increasingly gaining impor-

tance in hydraulic and mechanical vehicle systems.

Diagnostics according to plan

A structured approach in trouble shooting saves time

and helps to avoid mistakes and expenses, especially

in the fields of electrics and electronics. Understand-

ing electronic controls requires the knowledge of

some basic terms concerning their general perform-

ance. In many cases error logs are just simply read

out and control units are replaced without any further

trouble shooting. This is in most cases unnecessary

and, even more important, very expensive.

Random tests have revealed that purely electronic

components or control units only very rarely are the

actual cause of failures:

lIn approx. 10 % of the examined cases the prob-

lems were caused by control units.

lIn approx. 15 % sensors and actuators were the

cause of the problems.

By far the highest proportionof all faults could be

traced back to wiring and connections (plugs, etc.).

General:

lBefore changing any expensive components, such

as control units, you should run a systematic trouble

shooting session to eliminate any other possible

fault sources. Electric signals must be checked at

the locations to which they are applied, i.e. on con-

trol unit or sensor technology. So, if the system had

been diagnosed without unplugging the control unit

and checking the wiring, one should be alerted.

lCheck for good cable and ground contacts, there-

fore keep all mechanical transition points between

electric conductors (terminals, plugs) free of oxide

and dirt, as far as this is possible.

lPerform trouble shooting in a systematic way. Do

not become confused by the high number and vari-

ety of electric cables, current can only flow in a

closed circuit. You should first become acquainted

with the function of the corresponding electric circuit

by following the correct wiring diagram. Detected

faults should be rectified immediately. If the system

still does not work correctly after this measure, trou-

ble shooting must be continued. Several faults very

rarely occur at the same time, but it is not impossi-

ble.

lDo not disconnect or connect battery or generator

while the engine is running.

lDo not operate the main battery switch under load.

General repair instructions

BOMAG 15008 911 45

1.3

lDo not use jump leads after the battery has been re-

moved.

lSensors and electric actuators on control units must

never be connected individually or between exter-

nal power sources for the purpose of testing, but

only in connection with the control unit in question,

as otherwise there may be a risk of destruction

(damage)!

lDisconnecting the control unit plug connectors with

the control unit switched on, i.e. with the power sup-

ply (terminal 15 "On"), is not permitted. Switch the

voltage supply "off" first - then pull out the plug.

lEven with an existing polarity reversal protection in-

correct polarity must be strictly avoided. Incorrect

polarity can cause damage to control units!

lPlug-in connectors on control units are only dust

and water tight if the mating connector is plugged

on! Control units must be protected against spray

water, until the mating connector is finally plugged

on!

lUnauthorized opening of the control electronics (mi-

cro controller MC) as well as changes or repairs on

the wiring can lead to dangerous malfunctions.

lDo not use any radio equipment or mobile phones

inside the driver's cab without an appropriate out-

side antenna or in the vicinity of the control electron-

ics!

Electrical system and welding work

lSurge voltages in the electric system must be strict-

ly avoided:

lWhen performing welding work always fasten the

earth clamp of the welding unit in the immediate vi-

cinity of the welding location.

!

Caution

Switch off the main battery switch, doisconnect

the generator and pull the plug out on the control

unit before starting welding work.

Battery

Rules for the handling of batteries

Even though it may be conveniently installed in the

engine compartment, it should never be used as a rest

for tools. When connecting the poles, e.g. by means

of a spanner, the battery will become an "electric

welder".

As a measure to avoid short circuits you should first

disconnect the negative pole during disassembly and

reconnect the negative pole last during assembly.

Terminal clamps should be assembled with as little

force as possible.

Poles and terminal clamps should always be kept

clean to avoid transition resistances during starting

and the related development of heat.

You should obviously also pay attention to secure fas-

tening of the battery in the vehicle.

1.3 General repair instructions

BOMAG16 008 911 45

Hydraulic system

!

Caution

Do not open any hydraulic components if you

have not been properly trained and without exact

knowledge.

Please note

Cleanliness is of utmost importance. Make sure that

no dirt or other contaminating substances can enter

into the system.

lClean fittings, filler covers and the area around such

parts before disassembly to avoid entering of dirt.

lBefore disconnecting hoses, pipes or similar relieve

the system pressure with the engine shut down.

lDuring repair work keep all openings closed with

clean plastic plugs and caps.

lDo not run pumps and motors without oil.

lWhen cleaning hydraulic components take care not

to damage any fine machine surfaces.

lChemical and rubber soluble cleansing agents may

only be used to clean metal parts. Do not let such

substances come in contact with sealing material.

lRinse of cleaned parts thoroughly, dry them with

compressed air and apply anti-corrosion oil immedi-

ately. Do not install parts that show traces of corro-

sion.

lAvoid the formation of rust on fine machined caused

by hand sweat.

lGrease must not used as a sliding agent for assem-

bly work. Use hydraulic oil.

lDo not start the engine after the hydraulic oil has

been drained off.

lUse only the specified pressure gauges. Risk of

damaging the pressure gauges under too high pres-

sure.

lClean ports and fittings before removal so that no

dirt can enter into the hydraulic system.

lCheck the hydraulic oil level before and after the

work.

lUse only clean oil according to specification.

lCheck the hydraulic system for leaks, find and rec-

tify the cause.

lFill new hydraulic units with hydraulic oil before

starting operation.

lAfter changing a component thoroughly flush and

bleed the entire hydraulic system.

lPerform measurements at operating temperature of

the hydraulic oil (approx. 40 ¯C).

lAfter changing a component perform a high and

charge pressure test, if necessary check the speed

of the exciter shaft.

lThe operating pressure of the exciter shaft to a

great extent depends on the base under the vibrat-

ing drum. If the soil is too hard place the drums on

old rubber tires. Do not activate the vibration on a

hard, concreted base, danger of bearing damage.

lAfter the completion of all tests perform a test run

and then check all connections and fittings for leaks

with the engine still stopped and the hydraulic sys-

tem depressurized.

Before commissioning

lAfter changing a component clean the hydraulic oil

tank thoroughly.

lFill the housings of hydraulic pumps and motors

with hydraulic oil.

lUse only hydraulic oils according to the specifica-

tion in the maintenance instructions.

lAfter changing a component clean the hydraulic

system as described in the flushing instructions in

order to prevent all other components from being

damaged by abrasion and metal chips remaining in

the system.

lChange the hydraulic oil filter.

Commissioning

lBleed the hydraulic circuits.

lStart up the system without load.

lCheck the hydraulic oil level in the tank, fill up oil if

necessary.

After commissioning

lCheck system pressures and speeds.

lCheck fittings and flanges for leaks.

lAfter each repair check all adjustment data, rota-

tional speeds and nominal values in the hydraulic

system, adjust if necessary.

lDo not adjust pressure relief valves and control

valves to values above their specified values.

General repair instructions

BOMAG 17008 911 45

1.3

Air conditioning system

CFC - halon prohibition

The CFC - halon prohibition from May 06, 1991 regu-

lates the withdrawal from the use of CFC and the han-

dling of these refrigerants.

Contents:

Since 1995 CFC (R12) is no longer permitted for use

in new systems.

In operation, during maintenance and repair work and

when taking refrigeration systems our of service it is

not permitted to let refrigerant escape into the atmos-

phere, which would contradict the current status of

technology.

Work on refrigeration systems must only be carried

out by persons with well founded knowledge about

such systems and who have the necessary technical

equipment available.

The use of refrigerant must be documented.

Old systems should be converted to refrigerants

harmless to ozone (refrigerant substitutes).

For this reason the Federal Environmental Agency at

the end of 1995 published suitable replacement refrig-

erants for R 12. As a consequence old systems must

no longer be filled with R12. As soon as such a system

is opened for service, the system must be converted

to a suitable replacement or service refrigerant. Old

systems may still be used, as long as they are leak

tight. R 134a was nominated as replacement for R 12.

Inside the European Union the "EU-Directive 2037/

2000 on substances causing decomposition of the

ozone layer" regulates the production, use and avail-

ability of CFC and H-CFC.

lIn case of a repair on the refrigeration system you

should first evacuate the air conditioning system for

at least 45 minutes to remove any moisture from the

system, before you start to refill. Moisture bonded in

the compressor oil / refrigeration oil (PAG oil) can

only be removed from the system by changing the

oil.

lDuring repair work on refrigerant lines and compo-

nents, these must be kept closed as far as possible,

in order to prevent the invasion of air, moisture and

dirt,becausetheoperational reliability of the system

can only be assured if all components in the refrig-

erant circuit are clean and dry from inside.

lMake sure that no dirt or foreign parts can enter into

the compressor or the air conditioning system. The

area around the refrigerant hoses should be

cleaned with a gasoline free solvent.

lAll parts to be reused should be cleaned with a

gasoline free solvent and blow-dried with clean

compressed air or dried with a lint-free cloth.

lBefore opening all components should have

warmed up to ambient temperature, to avoid that

damp air is drawn into the component by the differ-

ence in temperatures.

lDamaged or leaking parts of the air conditioning

must not be repaired by welding or soldering, but

must generally be replaced.

lDo not fill up refrigerant, but extract existing refrig-

erant and refill the system.

lDifferent types of refrigerant must not be mixed.

Only the refrigerant specified for the corresponding

air conditioning system must be used.

lRefrigerant circuits with refrigerant type R134a

must only be operated with the compressor oil / re-

frigeration oil approved for the compressor.

lUsed compressor oil / refrigeration oil must be dis-

posed of as hazardous waste.

lDue to its chemical properties compressor oil / re-

frigeration oil must never be disposed of together

with engine or transmission oil.

lCompressor oil / refrigeration oil is highly hydro-

scopic. Oil cans must strictly be kept closed until

use. Oil rests should not be used, if the can had

been opened over a longer period of time.

lAll O-rings as well as pipe and hose fittings must be

oiled with compressor/refrigeration oil be-

foreiassembly.

lWhen replacing a heat exchanger, e.g. evaporator

or condenser, any compressor oil / refrigeration oil

lost by exchanging the components, must be re-

placed with fresh oil.

lA too high compressor oil / refrigeration oil level ad-

versely affects the cooling performance and a too

low oil level has a negative effect on the lifetime of

the compressor.

lIf a air conditioning unit needs to be opened, the

dryer must be replaced in any case.

lAlways use new O-rings when reassembling the

unit.

lAlways use two spanners when connecting pipes or

hoses, to prevent the pipe end from being damaged

.

lTighten screw fittings with the specified torque.

lCheck the connections of pipes, fittings or compo-

nents thoroughly; do not use if damaged.

lDo not leave the refrigerant circuit unnecessarily

open to the atmosphere. Do not attempt to repair

bent or burst pipes.

lCompressor valves must only be opened after the

system has been properly sealed.

lThe use of leak detection colouring matter is not

permitted, because its chemical composition is un-

known and its effect on compressor oil and rubber

elements is not predictable. The use of leak detec-

1.3 General repair instructions

BOMAG18 008 911 45

tion colouring matter makes any warranty claims

null and void.

lTools used on refrigeration circuits must be of ex-

cellent condition, thus to avoid the damage of any

connections.

lThe dryer is to be installed last, after all connections

in the refrigerant circuit have been tightened.

lAfter completion of repair work screw locking caps

(with seals) on all connections with valves and on

the service connections. Start up of the air condi-

tioning system. Observe the filling capacity.

lBefore start up of the air conditioning system after a

new filling: - Turn the compressor approx. 10 revo-

lutions by hand using the clutch or V-belt pulley of

the magnetic clutch. - Start the engine with the com-

pressor/control valve switched off. - Once the idle

speed of the engine has stabilized switch on the

compressor and run it for at least 10 minutes at idle

speed and maximum cooling power.

lNever operate the compressor over longer periods

of time with high engine speeds without a sufficient

amount of refrigerant in the system. This could

probably cause overheating and internal damage.

Fuel hoses

Fig. 1

!

Caution

All fuel hoses have two layers of material, a rein-

forced rubber coating outside and an internal Vi-

ton hose. If a fuel hose has come loose one must

make absolutely sure that the internal Viton layer

has not been separated from the reinforced outer

layer. In case of a separation the hose needs to be

replaced.

General repair instructions

BOMAG 19008 911 45

1.3

Gaskets and mating surfaces

Leaking or failing seals and gaskets can in most cases

be tracked down to careless assembly, causing dam-

age not only to the seal or gasket, but also to the mat-

ing surfaces. Careful assembly work is mandatory if

good results are to be achieved.

lBefore assembling replacement seals make sure

that the running surface is free of pitting, flutes, cor-

rosion or other damage.

lInappropriately stored or handled seals (e.g. hang-

ing from hooks or nails) must under no circumstanc-

es be used.

lSealing compound should only be used if specially

requested in the instructions. In all other cases

these joints should be assembled in dry condition.

lSealing compound must be applied thin and evenly

on the corresponding surfaces; take care that the

compound does not enter into oil galleries or blind

threaded bores.

lBefore assembly remove any residues of old seal-

ing compound. Do not use any tools that could dam-

age the sealing surfaces.

lExamine the contact faces for scratches and burrs,

remove these with a fine file or an oilstone; take

care that no grinding dust and dirt enters into

tapped bores or enclosed components.

lBlow lines, ducts and gapsout with compressed air,

replace any O-rings and seals that have been dis-

lodged by the compressed air.

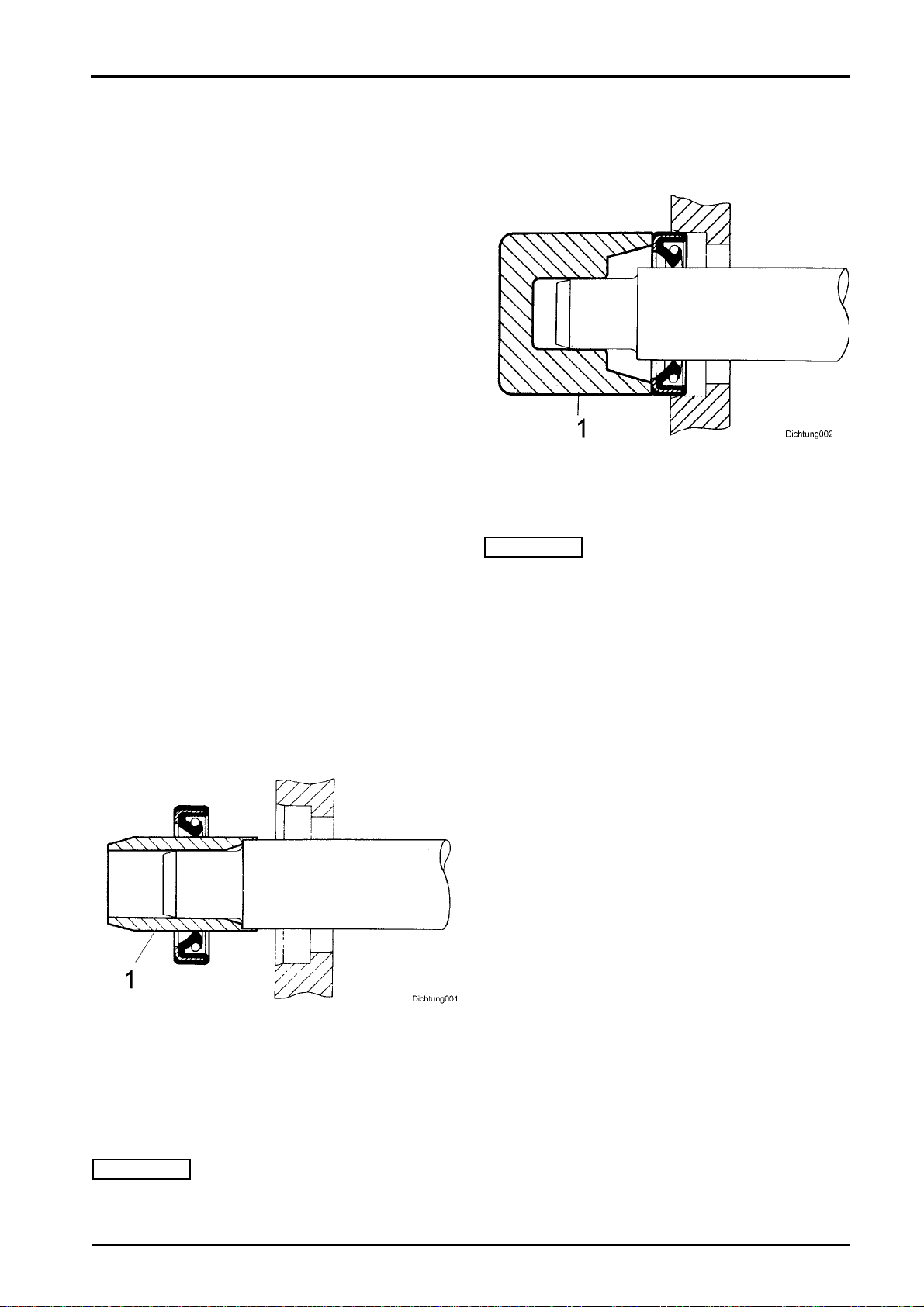

Assembly of radial seals

Fig. 2

lLubricate sealing lips1 (Fig. 2) with clean grease; in

case of double seals fill the space between the seal-

ing lips with a generous amount of grease.

lSlide the seal over the shaft, with the lip facing to-

wards the fluid to be sealed.

i

Note

If possible, use an assembly sleeve 1 (Fig. 2), to pro-

tect the lip from being damaged by sharp edges,

threads or splines. If no assembly sleeve is availa-

ble, you should use a plastic tube or adhesive tape to

prevent the sealing lip from being damaged.

Fig. 3

lLubricate the outer rim 1 (Fig. 3) of the seal and

press it flat on the housing seat.

i

Note

If possible, use a "bell" 1 (Fig. 3), to make sure that

the seal will not skew. In some cases it may be ad-

visable to assemble the seal into the housing first, be-

fore sliding it over the shaft. Under no circumstances

should the full weight of the shaft rest on the seal.

If you have no proper service tools at hand, use a suit-

able drift punch with a diameter which is about 0.4mm

smaller than the outer diameter of the seal. Use VERY

LIGHT blows with the hammer if no press is available.

lPress or knock the seal into the housing, until it is

flush with the housing surface.

1.3 General repair instructions

BOMAG20 008 911 45

Feather keys and keyways

!

Caution

Feather keys must only be reused if they show no

differences to new feather keys, any notches must

be considered as initial signs of wear.

Fig. 4

lClean and thoroughly examine the feather key.

lDebur and thoroughly clean the edges of the key-

way with a fine file before reassembling.

Ball and roller bearings

!

Caution

Ball and roller bearings must only be reinstalled

after it has been assured that they are in perfect

condition.

Fig. 5

lRemove any lubricant residues from the bearing to

be examined by washing it with gasoline or any oth-

er appropriate degreasing agent. Cleanliness is of

utmost importance for all related work.

lCheck balls or rollers, running surfaces, outer faces

of outer races and inner faces of inner races for vis-

ible damage. If necessary replace the bearing with

a new one, since these symptoms are first signs of

wear.

lHold the bearing with you thumb and the index fin-

ger by the inner race, rotate the outer race and

make sure that it runs without friction. Hold the

bearing by the outer race and repeat this test with

the inner race.

lMove the outer race gently to and fro while holding

it by the inner race; check for resistance while rotat-

ing and replace the bearing if it does not work cor-

rectly.

lLubricate the bearing with an appropriate lubricant

before reinstalling.

This manual suits for next models

3

Table of contents

Other Bomag Construction Equipment manuals

Bomag

Bomag BW 154 AP-4 User manual

Bomag

Bomag BW 156 D-3 User manual

Bomag

Bomag BW 213 D-4 Instructions for use

Bomag

Bomag BVP 10/36 User manual

Bomag

Bomag BW 900-2 User manual

Bomag

Bomag BT 60/4 User manual

Bomag

Bomag BW 100 AD-5 Installation and operation manual

Bomag

Bomag BW 177 D-4 User manual

Bomag

Bomag BW 211 D-40 User manual

Bomag

Bomag BW 100 AD-4 User manual