Bonart ART-SP2 User manual

ART-SP2 Scaler /Polisher Combo Unit

Instruction Manual

Bonart Co., Ltd.

Jorgen Kruuse A/S

No.80, Wuxun St., Anle Dist.,

Keelung City, 20446, Taiwan, R.O.C.

Tel: 886-2-22983980

Fax:886-2-22983981

Email:[email protected]

Havretoften 4, DK-5550 Langeskov,

Denmark

2460

COPYRIGHT© 2018 BONART CO., LTD.

- 1 -

BONART Co., Ltd. owns all rights to this publication. This publication shall be used solely as a

reference for operation, maintenance, and repair on BONART equipment. No part of this document

may be reproduced or distributed in any form for any other purpose.

In the event of inadvertent or deliberate publication, BONART intends to enforce its rights to this

manual under the copyright law. Reproduction of the materials presented in this manual without the

express written permission of BONART Co., Ltd. is prohibited.

The contents of this manual are subject to change without prior notice.

PROPERTY OF BONART CO., LTD.

ALL RIGHTS RESERVED

ART is a registered trademark of BONART Co., Ltd. & its affiliates.

Document No. RD-02-14-05 Rev.1.1 (2018/03)

Printed in Taiwan, R.O.C.

- 2 -

Operator Safety

Please read the entire manual thoroughly before operating the unit.

ART-SP2 Scaler /Polisher Combo Unit

The dental equipment described in this manual should be used only by properly trained

personnel. Only qualified personnel shall perform any adjustments, maintenance and repair of

the equipment.

NOTE, CAUTION, AND WARNING STATEMENTS

NOTE:Provide tips and advice.

CAUTION:Provide correct operating or maintenance procedures.

WARNING:Alert user of danger of injury or damage.

SYMBOLS

Complies with MDD 93/42/EEC

BF equipment

Grounding terminal

Attention! Please read instructions

- 3 -

Warnings

Important!

The ART-SP2 should be operated solely by qualified personnel (trained doctors,

dentist, and hygienists, etc.).

Patients with pacemakers should not be treated with the ART-SP2

Do not immerse the ART-SP2 in water!

If the patient or operator is pregnant, consult a physician prior to performing

dental scaling for safety purposes.

The ART-SP2 requires a shielded AC power cord.

Plug the power cord into a well-grounded outlet.

Attention to users with cardiac pacemakers!

Patients with pacemakers should avoid treatment with the ART-SP2. Studies have shown

that electronic appliances including razors, hair dryers, microwave ovens, TV receptors, and

other medical equipment, such as the ART-SP2, may interfere with the performance of

pacemakers.

For more information on this subject, please refer to the following articles:

"Advances in Cardiac Pacemaker", The New York Academy of Sciences, Vol. 167,

Article 2, pp. 515-1075

"Electromagnetic Radiation Interference with Cardiac Pacemaker", U. S. Department of

Health, Education and Welfare

"The Individual with a Pacemaker in the Dental Environment", Journal of the American

Dental Association, Vol. 91, No. 6, pp. 1224-1229

- 4 -

Please Read Before Operating:

Make sure the device is connected to a grounded outlet. Failure to

meet this requirement may severely damage the user and device.

Place the device on a flat and stable surface. Placing the device

on a tilted or unstable surface may degrade performance or damage

the device.

Do not modify the device. Modifications to the device will violate

safety codes and invalidate the warranty while endangering the

patient and operator.

Do not place heavy objects on top of the power cord and keep the

power cord away from intense heat.

Unplug the device and call Bonart for service and instructions if

you observe any abnormalities while operating the device.

- 5 -

Preface

About the ART-SP2 Scaler/Polisher Combo Unit

The ART-SP2 is CE 2460 certified in compliance with the applicable requirements of the Council

Directive 93/42/EEC. The reviewing council also classifies the ART-SP2 in accordance with

EN60601-1 and EN60601-1-2 safety requirements.

How it works

The ART-SP2 Piezoelectric Ultrasonic Scaler generates ultrasonic waves in the hand piece to

vibrate the tip, which allows the ART-SP2 to remove calculus and tartar easily. These ultrasonic

waves are created by 4 ceramic piezoelectric plates subjected to high frequency alternating

currents.

The piezoelectric transducer operates at a frequency of 29khz with minimal noise and heat, and

efficiently reduces the amount of cooling water required during treatment. This

electric-mechanical feature provides greater efficiency than traditional magnetostrictive systems.

Features:

Scaler and polisher in one system

Automatic phase lock and power control

Automatic feedback control

Micro-motor speed control of 2,000 to 30,000 RPMS

Supplies & Replacement Part

To order supplies or replacement parts in the U.S., please contact one of our authorized

distributors listed on www.askmagpie.com . For outside of U.S., please email to

CAUTION:Since the scaling tip is made of stainless steel, avoid direct contact with teeth.

Direct contact will cause damage to teeth enamel. For optimum performance, we suggest

practicing on a model or aluminum plates to become more familiar with the scaling tips before

performing on patients.

- 6 -

Table of Contents

Copyrights ……………………………...

1

Operator Safety ..........……………………….

2

Warnings ......………………………….

3

Preface ……..……………………….

5

Contents ..…………………………….

6

Section I. Indications for Use ..…………………………….

7

Section II. Contraindications and Warnings ……………………..

7

Section III. Precautions .……………………………..

7

Section IV. Infection Control ……………………………...

9

Section V. Installation …..………………………………………….

11

Section VI. General Description and Information of Parts…………….

16

Section VII. Techniques ……………………………….

18

Section VIII. System Maintenance …………………………..…

19

Section IX. Troubleshooting ……………………………….

20

Section X. Specifications ……………………………….

21

Section XI. Disposal ..……………………………..

21

- 7 -

Section Ⅰ: Indications for Use

1-A Ultrasonic scaling procedures:

Removal of calculus and plaque during dental prophylaxis.

General supra and sub-gingival scaling applications.

Periodontal debridement for all types of periodontal diseases.

Endodontic procedures.

1-B Polishing procedures:

For removal of calculus and plaque during dental polishing.

All general supra and subgingival polishing applications.

Periodontal debridement for all types of periodontal diseases.

Endodontic procedures with optional bur tools.

Section Ⅱ: Contraindications and Warnings

Do not use the ART -SP2 for amalgam restorative dental procedures.

Do not use the ART-SP2 if the patient or operator is wearing a pacemaker.

Do not immerse the ART-SP2 in water or liquid. If the ART-SP2 has water damage, return

the machine to Bonart for servicing.

Do not modify the ART-SP2. Modifications will invalidate the warranty on the machine,

violate safety codes, and endanger the patient and operator.

Section Ⅲ: Precautions

3-A Precautions for the ART-SP2 and all Ultrasonic Scaler Systems

Ensure that an adequate amount of water flows to the piezo tip during use in order to cool

the hand piece and tip.

Take precaution to prevent transmission of contagious diseases as all ultrasonic scalers

produce aerosols.

Use tips manufactured by Bonart for optimal performance.

Keep the ART-SP2 away from heat sources to prevent overheating and damaging of

electrical components.

Ensure that the water valve is closed when the ART-SP2 is not in use.

Avoid treating patients with pacemakers due to the magnetic field produced by the ART-SP2.

- 8 -

3-B:Precautions for Ultrasonic Prophylaxis Procedures

Discard and replace piezo tips as needed. Scaling tips wear out with use and should be

replaced after 2mm of wear (approximately 3 to 4 months) to maintain optimal performance

Discard and replace piezo tips that are bent, damaged, or reshaped. Do not reuse deformed tips

BONART piezo tips are made of stainless steel. Avoid direct contact with teeth to prevent

damage to the enamel. We strongly advise practicing on models and aluminum plates prior to

operating on a live subject with the ART-SP2.

Avoid direct contact of piezo tips with the subject’s lips, cheeks, and tongue.

Wipe accretions from the tooth using the long axis of the scaler tip. DO NOT gouge the tooth

3-C:Precautions for hand-piece

Do Not Twist and Pull Cable

Do Not Bend

Do Not Twist

Do Not Bundle

Pull To Disconnect

- 9 -

Section IV: Infection Control

4-A General Infection Control

Always use standard personal protective equipment such as facemasks, eyewear, face shields,

gloves, and protective gowns.

4-B Water Supply Recommendations

In addition to using protective equipment, ensure that your water supply system conforms to

applicable Centers for Disease Control and Prevention (CDC) and American Dental Association

(ADA) standards, and that all required flushing, chemical flushing, and general infection control

procedures are followed.

To further protect against infection, using distilled or purified water is recommended.

4-C Cleaning and Sterilization:

All sterilization procedures must be followed in accordance to the EN ISO17664 standards.

In order to avoid bacterial or viral infections, always clean and sterilize the following components

after each treatment:

1. Hand piece

2. Tips

3. Metal Wrench

4. Micro-motor

5. Straight hand piece (Straight nose cone)(optional accessory)

6. Prophy angle (unless disposable)(optional accessory)

The hand piece, tips, wrench, straight handpiece and prophy angle can be autoclaved and can

withstand a maximum temperature of 135℃or (275℉) for a maximum of 3 minutes. After

completing the sterilization cycle, air-dry for about 20-30 minutes before reusing.

WARNING: Do not use any other method of sterilization (dry heat, radiation, ethylene oxide,

gas, low-temperature plasma, etc.)

NOTE:The SterilizationAssurance Level (SAL) of steam autoclave should be 10-6 (According

to ISO 13683:Sterilization of health Care products)

NOTE: Prior to cleaning and sterilizing your ART-SP2 unit, always remember to turn off the

device by using the power switch and to disconnect the power plug from the outlet.

Cleaning the ART-SP2 unit

Remove the hand piece from the cable, and the tip from the hand piece.

Clean and disinfect the surface of the outer casing, cords and connectors with a cloth and a

gentle disinfectant.

- 10 -

Cleaning and sterilizing the hand piece

Remove the hand piece from the hand piece cable and the tip from the hand piece.

Take special care not to break the threading pin of the hand piece. The threading pin is

where the tip attaches to the hand piece.

Disinfect the hand piece with a cloth and mild disinfectant containing a neutral pH.

Dry the electric contacts by blowing air onto them with the syringe.

Seal the hand piece in a sterilization pouch (without any tips). If you are short on

sterilization pouches, you may use the surgical tray in place of the sterilization pouch.

Autoclave the hand piece.

WARNING: Do not immerse the hand piece cable in sterilizing fluid. The ART-SP2 can be

severely damaged if sterilization fluid gets inside the unit.

Cleaning Piezo Tip or Wrench

Clean the tip or wrench preferably in an ultrasonic tank and rinse in distilled water.

Dry the tip or wrench.

Disinfect the tip with a cloth and mild disinfectant containing a neutral pH.

Seal the tip or wrench inside a sterilization pouch. If you are autoclaving more than 1 tip,

place each tip or wrench in an individual bag. You may also use the tip holder that comes

with the ART-SP2 in place of the sterilization pouch.

Autoclave the tip or wrench.

WARNING:Before starting the sterilization cycle, make sure that the inside of the tip is

completely dry by blowing air through the internal hole with the syringe. This will prevent

stains and patches from appearing on the surface of the tip.

Cleaning the micro-motor

Remove all attachments to the micro-motor prior to cleaning. The outer surface of the

micro-motor should be cleaned with an antiseptic solution. Never oil the micro-motor.

Ensure that no moisture gets inside the micro-motor.

WARNING: Do not dip the micro-motor and cord directly into sterilization fluids. The

chemicals will interfere with normal operations if it reaches the inside of the system.

WARNING: Do not leave disinfectants on parts longer than recommended by the

manufacturer of the disinfectant to avoid damaging materials.

NOTE: The micro-motor should be cleaned after each use between patients.

- 11 -

Cleaning the straight hand piece (straight nose cone) attachment (optional accessory)

Clean the straight hand piece preferably in an ultrasonic tank and rinse in distilled water.

Dry the straight hand piece.

Disinfect the straight hand piece with a cloth and mild disinfectant containing a neutral pH.

Seal the straight hand piece inside a sterilization pouch. If you are autoclaving more than 1

tip, place each straight hand piece in an individual bag. You may also use the tip holder that

comes with the ART-SP2 in place of the sterilization pouch.

Autoclave the straight hand piece .

Cleaning the ProphyAngle(optional accessory)

The prophy angle should be cleaned to remove hair and debris approximately after every 10 dental

polishing.

1. Remove prophy angle from handpiece and rubber cup.

2. Remove head gears by turning knurled knob clockwise ( threads are reversed) turn to your right.

3. Clean with fine brush and lubricate head gears with mineral oil, Vaseline or any non-toxic

lubricant.

4. Place head gears back and tighten by turning Left or counterclockwise.

5. Normal polishing speeds are around 3,000 to 3,000 RPM, exceeding this may damage your

prophy angle.

Section V: Installation

5-A General Information

If the installation of your ART-SP2 system is performed by non-Bonart dealer personnel, check to

see that the requirements below are followed.

5-B Water Line Requirements

Incoming water supply line pressure to the Scaler must be 25 psi (172 kPa minimum) to 60

psi (414Kpa maximum). If your dental water supply line pressure is above 60 psi, install a

water regulator on the water supply line to your ART-SP2 unit.

After installing the water supply system, flush the water thoroughly prior to connecting to

the scaler.

Manually shut off the water valve of your dental water supply system prior to leaving the

office unoccupied and unattended.

5-C Electrical Requirements

Refer to Section X: Specifications

- 12 -

Unpacking the Unit

Carefully unpack your ART-SP2 unit and verify that all components and accessories are included:

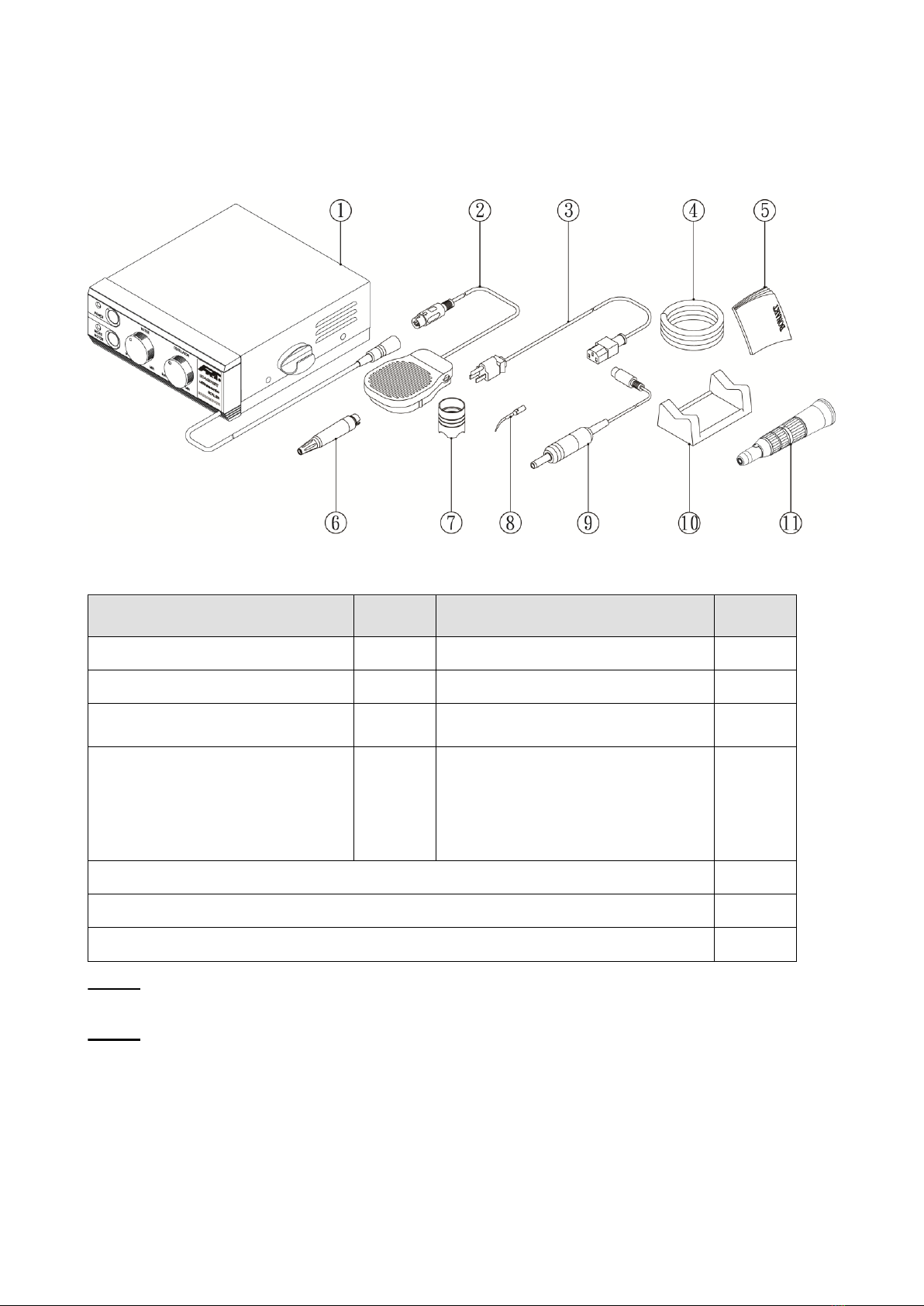

(Figure 1)All components and accessories

Item

Quantity

Item

Quantity

(1) Main Unit

1

(2) Foot Control / Foot Switch

1

(3) AC Power Cord Set.

1

(4) PU Water Tubing

1

(5) User Manual & Literature

Packet

1

(6) Piezo Hand piece.

1

(7) Metal Torque-Limited

Wrench

1

(8)

ART-BS1 Universal Pointed Tip

ART-BS2 Chisel Head Flat Tip

ART-BS3 Round Flat Tip

1

1

1

(9) Micro-motor

1

(10) Micro-motor seat

Optional

(11) Straight Hand Piece

Optional

NOTE: Other piezo tips are available and can be purchased separately through dealers.

Included items are subject to change depending on location.

NOTE:While unpacking, check your ART-SP2 unit for any damages. If any damages

are found, please contact your dealer immediately. Enter the unit serial number on your

warranty card and mail it within 14 days from the date of purchase.

- 13 -

5-E Power Cord / Power Connection

Always make sure that the power switch is set to the OFF position before performing the

following tasks:

oPlugging and unplugging theAC cord into the back of the unit.

oPlugging and unplugging the 3-prong plug into a grounded electrical outlet.

Safety Instructions

A. Grounding:

Verify that the main unit is connected to a grounded outlet prior to connecting other parts to

the main unit.

B. Main voltage range and fuse:

Check the voltage of the ART-SP2 for compatibility with your local voltage before plugging

the power cord into the outlet.

5-F Foot Control Cable Assembly Connection

Align the pins of the foot control plug with the receptacle on the back of the device and push firmly

until seated.

5-G Water Supply Line Connection

Push the blue water tube (hose) over the stainless steel receptacle on the back of the unit. Then

tighten the screw over it.

Connect the quick connector to the water supply line. The ART-SP2 standard package comes with a

male quick connector. If a female quick connector is necessary, please contact a Bonart authorized

dealer to purchase it.

Inspect all connections for leaks.

To remove the water line from the ART-SP2 scaler, turn off the water supply or disconnect the water

supply line from the water tube. Then loosen the screw on the water tube from the receptacle of

the unit and gently pull the water tube off.

5-H Hand piece Cable Assembly Connection

The hand piece is the housing for the piezo tips. It is the part that you hold during operation. The

hand piece must be attached to the hand piece cable prior to using. To attach, connect the free end

of the cable to the matching receptacle on the back end of the hand piece. Do not twist or turn.

- 14 -

5-I: Polishing Hand piece Assembly and Start Up. (Optional accessories)

To detach, pull the cable from the hand piece in a straight motion. Do not twist, turn, or yank the

hand piece from the cable.

Polishing Hand Piece Assembly and Start Up. (Optional accessories)

(Figure 2)

To assemble the polishing hand piece, connect the Prophy Angle, Straight Hand Piece, and

Micro-motor by following the steps below:

1. Connect the straight hand piece and the micro-motor by pushing the straight hand piece over the

rod of the micro-motor. It should snap into place.

(Figure 3)

2. Attach the prophy angle to the straight hand piece by following the steps below:

A) Unlock the prophy angle from the straight hand piece by turning the locking ring clockwise.

This should open the lock. Note: When you first unpack the straight hand piece, there may

be a metal rod at the top that serves as a placeholder. Remove the rod after you open the

lock.

(Figure 4)

- 15 -

B) Match the groove at the base of the prophy angle with the top of the straight hand piece and

connect them together.

(Figure 5)

C) Close the lock by turning the locking ring counter-clockwise. The prophy angle should now

be locked onto the straight hand piece and should not fall off during operation.

(Figure 6)

D) If you wish to remove the prophy angle, follow step Ato release the lock on the prophy angle.

WARNING:The prophy angle should be cleaning and lubricated on a regular basis.

To polish, follow the steps below:

1. Place a rubber cup on the prophy angle and put paste in the cup to begin polishing.

2. Press the Micro-motor (mode) button to switch from scaling to polishing mode.

3. Adjust the Oscillating dial to a low speed, 2,000 rpm.

4. Press on the foot switch to engage the polishing hand piece and begin polishing.

5. Add paste as needed.

Assembling the Scaler Unit

1 Ensure that the power switch is set to off. If plugged in, the power indicator light should not be

lit.

2. Plug the power cord of the main unit into a grounded AC power outlet.

3. Insert the tip into the hand piece and lock it into place by using the enclosed wrench. Be

careful not to overturn the tip as it may cause the tip and hand piece to break.

4. Ensure that the water tube connection to the water supply source and main unit is secure.

- 16 -

Section VI: General Description and Information of Parts

1. Main unit

5. Water control knob

9. Water hose input

2. Hand piece

6. Power control knob

10. Power cord socket

3. Power button

7. Micro-motor socket

11. Forward/Reverse switch

4. Micro-motor (Mode) button

8. Foot switch socket

Figure 7.ART-SP2 diagram

1. Main Unit

The main unit generates power and produces a signal that is passed to the hand piece. The

hand piece is then powered up and vibrates the installed tip.

2. Hand piece

The hand piece is the housing for the piezo tip. It consists of four piezoelectric plates that

vibrate. The plates are driven by the electrical signal from the Main unit. The ART-SP2 unit

is compatible with Bonart BS-type piezo tips and other brands of piezo tips with a comparable

thread. Do not use Bonart BS-type piezo tips with the ART-SP2.

3. Power button (ON/OFF)

The power button is used to turn the ART-SP2 main unit on and off. When the power is on,

the LED indicator should be lit. When turned off, the LED power indicator should not be lit.

Do not press the foot switch while turning on the ART-SP2.

4. Micro-motor (Mode) button

The micro-motor (Mode) button is used to switch between polishing and scaling mode.

When pushed, the LED indicator should be lit, indicating that the system is operating in

polishing mode. Under polishing mode, the micro-motor is engaged. To return to scaling

mode, push the button again.

- 17 -

5. Water control knob

The water control knob allows you to control the amount of water that flows through the hand

piece. If turned clockwise, the amount of water will decrease. If turned counter-clockwise,

the amount of water will increase. Please note that water is necessary to cool the tip and

prevent overheating so it is necessary to ensure that an adequate amount of water flows

through the hand piece while operating the device. The larger the water stream, the lower the

temperature, and vice versa.

WARNING:Do not turn the water knob counter-clockwise more than three full turns.

Doing so will damage the internal water line needle.

WARNING:If needed, gently adjust the water control knob to prevent any serious

damages to the water valve.

6. Power control knob

The Power Control Knob allows you to control the power intensity. When turned clockwise,

the power intensity increases. When turned counter-clockwise, the power intensity decreases.

7. Micro-Motor Socket

The micro-motor socket is where you connect the micro-motor to the main unit. It is located

on the back of the main unit at the bottom left.

8. Footswitch Socket

The foot switch socket is where you connect the foot switch to the main unit. It is located

next to the water hose input on the back of the main unit.

9. Water hose input connector

The water hose input connector is the contact point for the water tube and the main water

supply line. Use either a male or female quick connect to connect the water tube to the water

supply. The ART-SP2 comes with a male quick connect attached to the water tube.

10. Power cord socket

The power cord socket is where you connect the power cord to the main unit.

11. Forward / Reverse switch

The Forward/Reverse switch allows you to control the direction of the micro-motor. It is

located on the back of the main unit.

- 18 -

Section VII: Techniques

7-A Performing Ultrasonic Scaling Procedures

1. Use purified or distilled water to prevent infection when patients experience tissue laceration

during treatment

2. Keep the power cord tidy to avoid tripping and other accidents.

3. Position the footswitch in an easily accessible spot for the user. Keep the footswitch cord

tidy to avoid tripping and other accidents.

4. Lock the tip in the hand piece securely using the enclosed wrench.

CAUTION: DO NOT FORCE OR OVERTURN THE TIPINTO PLACE! Doing so will

damage the tip, hand piece, and wrench.

NOTE: The scaler will not operate if the tip is either removed from the hand piece or

improperly installed.

5. Hold the hand piece over a sink or drain with a tip installed. Verify that water is reaching the

tip.

6. Check your Bonart piezo tip for wear and replace as needed.

7. Use the foot control to regulate water flow to the hand piece. Hold down the foot control to

allow water to flow through. Release the foot control to stop.

8. Adjust the water flow to the desired level using the water-adjustment knob. Increase the

water flow by turning the water control knob clockwise. Decrease the water flow by turning

the water control knob counter-clockwise.

NOTE: Increased water flow results in a cooler hand piece temperature and vice versa.

CAUTION: During operation, a continuous flow of water is required to keep the hand

piece cool.

7-B Applications of the TIP

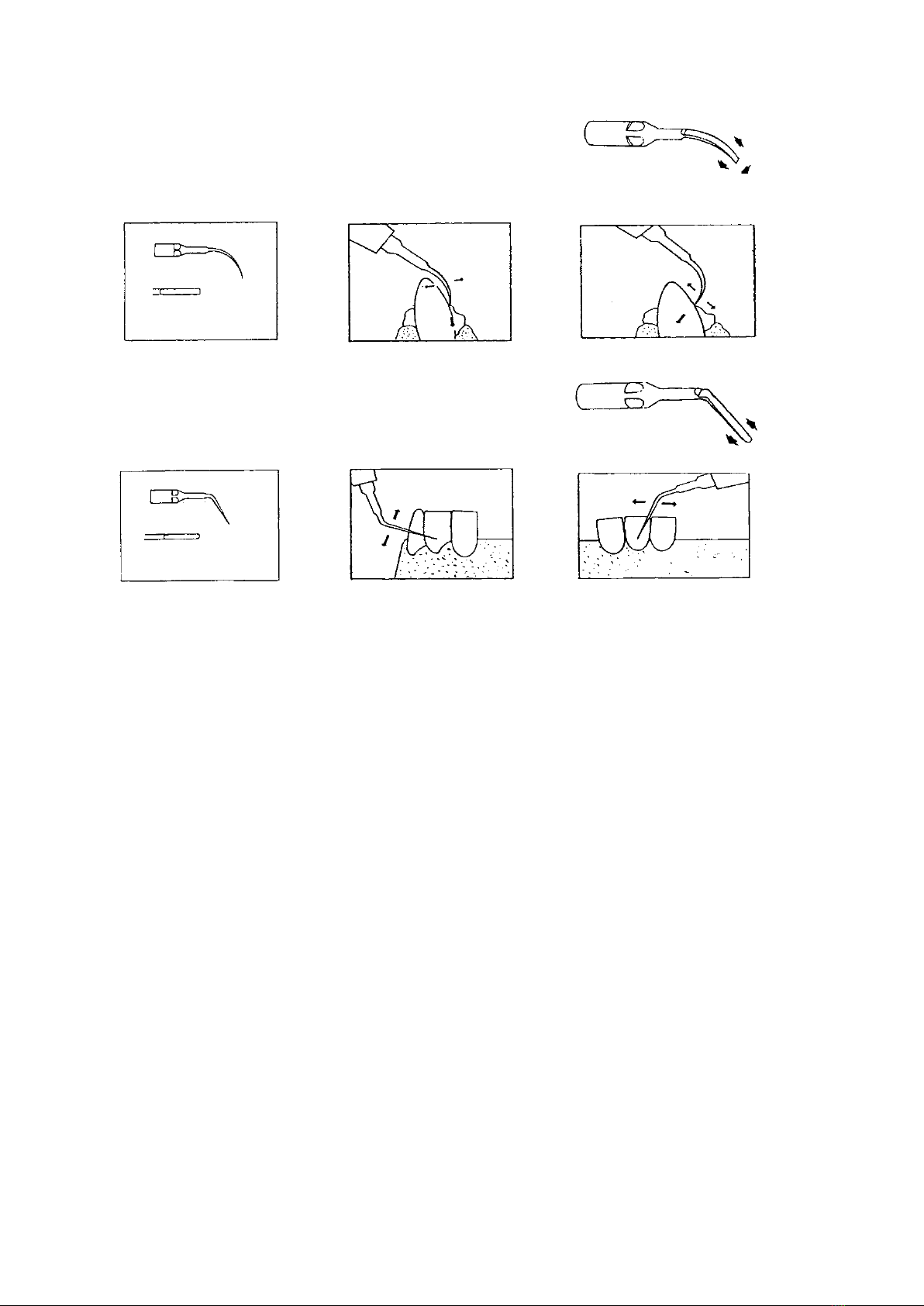

A. Tangential application (BS1 TIP)

Do not apply the BS1 tip directly to the tooth. Doing so

may damage the enamel. Control the hand piece with a

slow and steady motion.

- 19 -

B. Frontal application (BS2 TIP)

Apply the BS2 tip directly against the tartar, but not

directly against the tooth. Use a slight amount of

pressure.

C. Tangential application (BS3 TIP)

Do not apply pressure when applying the BS3 tip to the

enamel.

Section VIII: System Maintenance

8-A Hand piece maintenance

1. After each use the hand piece and tip should be rinsed with clean water for about 20 to 30

seconds.

2. Inspect the hand piece cable daily to ensure it is in good condition.

3. For sterilization of the hand piece please refer to Section IV.

8-B TIP maintenance

Worn out tips can adversely affect performance, resulting in insufficient power and vibration.

Check tips regularly for wear and tear and replace as necessary.

8-C Main Unit Maintenance

The housing of the ART-SP2 as well as the hand piece cord, should be cleaned and disinfected

(using alcohol or soap and warm water) on a daily basis.

Table of contents

Other Bonart Media Converter manuals

Popular Media Converter manuals by other brands

EECI

EECI CO-485USB Technical reference

Buffalo

Buffalo Buffalo AirStation WLI-T1-S11G user manual

RKC INSTRUMENT

RKC INSTRUMENT COM-ME-6 instruction manual

TRENDnet

TRENDnet TFC-1000 Quick installation guide

Moxa Technologies

Moxa Technologies A50 user manual

Editware

Editware VPE-300 Series Installation information