Page 5 3BE390723NI – 11/09

BONNET GRANDE CUISINE

Registered Office:

Rue des Frères Lumière - Z.I Mitry Compans

77292 MITRY MORY Cedex

2. INSTALLATION: GENERALITIES

NATURE AND POSITION OF THE CONNECTIONS

See the "Technical characterisitcs" at the beginning of these instructions.

2.1 GENERAL REQUIREMENTS

Aqualified engineer mustcarry out the installation,modificationorrepairof the appliance inaworkmanlike

manner.

These appliances must be installed with sufficient ventilation to prevent the formation of excessive

concentrations of substances noxious for the health in the room in which they are installed.

The equipment is not designed to work in an explosive atmosphere. Due to this, it must not be

installed in a zone subject to ATEX directive.

The appliances must be installed according to the standard EN 1717 and the national regulation in

force relating to water.

These units must only be placed against a wall or a partition. The latter must be of non-combustible

materials or, if not, must be covered with an appropriate, good insulating and non-combustible

material.

The manufacturer certifies that the packaging meets the provision 94/62/CE (provision relating to

packagings and packaging waste of 12.20.94) and requests that final installer (and user) observes

the rules relating to the removal of the packaging (recycling or reconditioning).

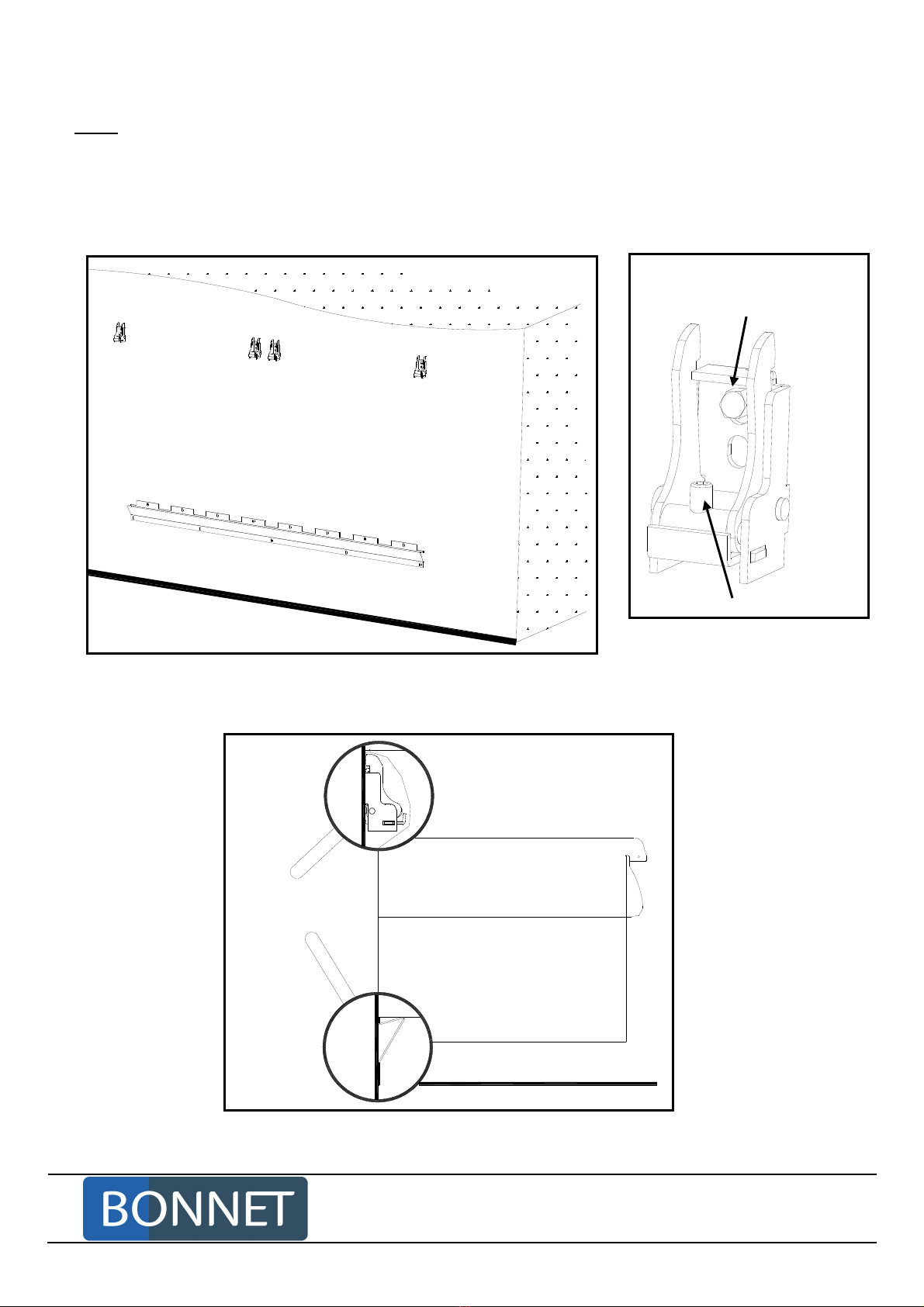

2.2 HANDLING

The appliance should only be handled with adapted lifting equipment.

Should the appliance need to be transported, this must be on its original pallet and it must not be

stacked on other appliances under any circumstances.

If the appliance is to be moved without its pallet, it should be carried and not pulled.

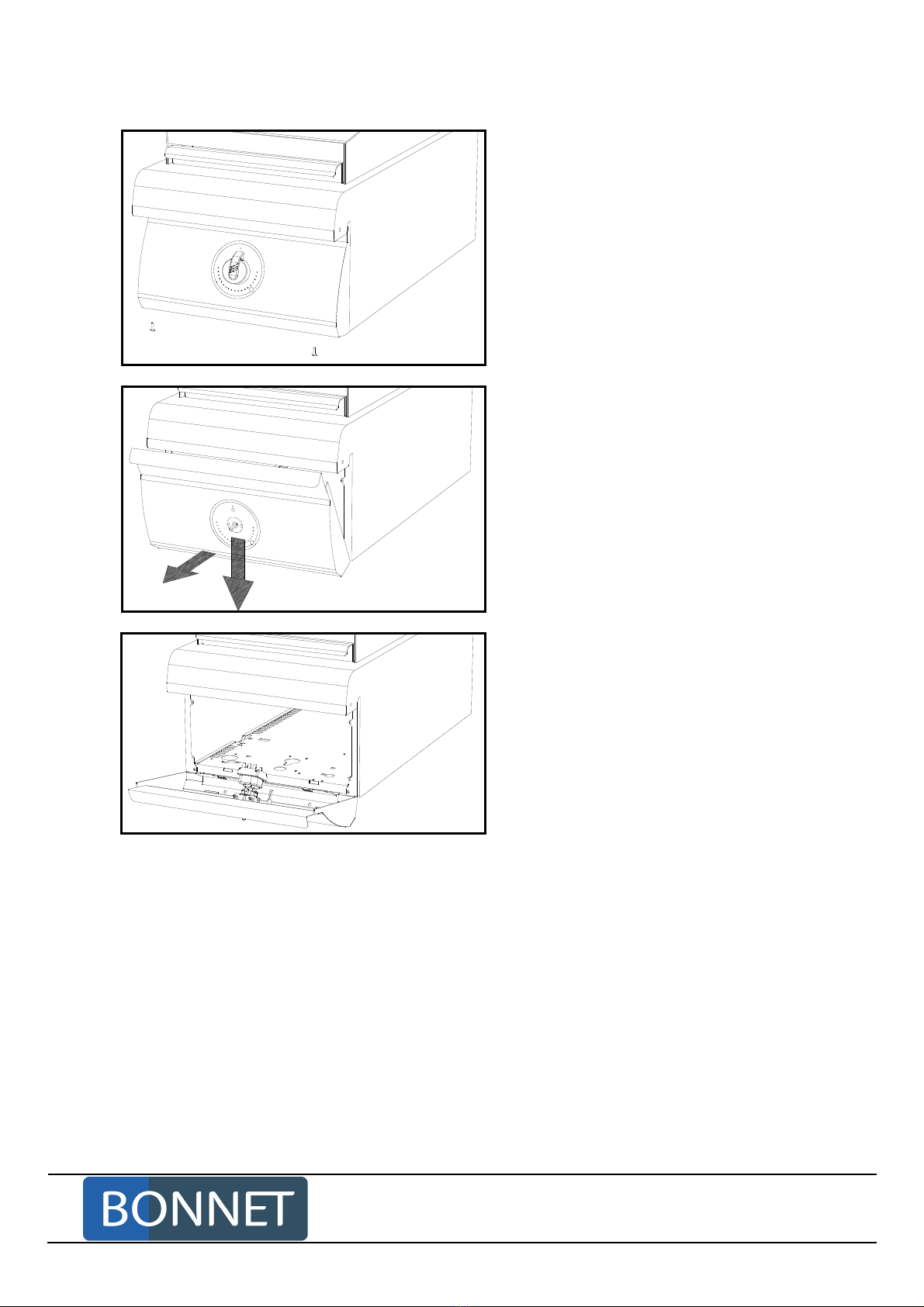

2.3 UNPACKING

Before installation, remove the strapping from the appliance. The individual parts are not bolted down.

Remove the protective plastic film from the stainless steel parts before heating.