Page 7

BONNET CIDELCEM GRANDE CUISINE

Siége social:

Rue des Frères Lumière - Z.I Mitry Compans

77292 MITRY MORY Cedex

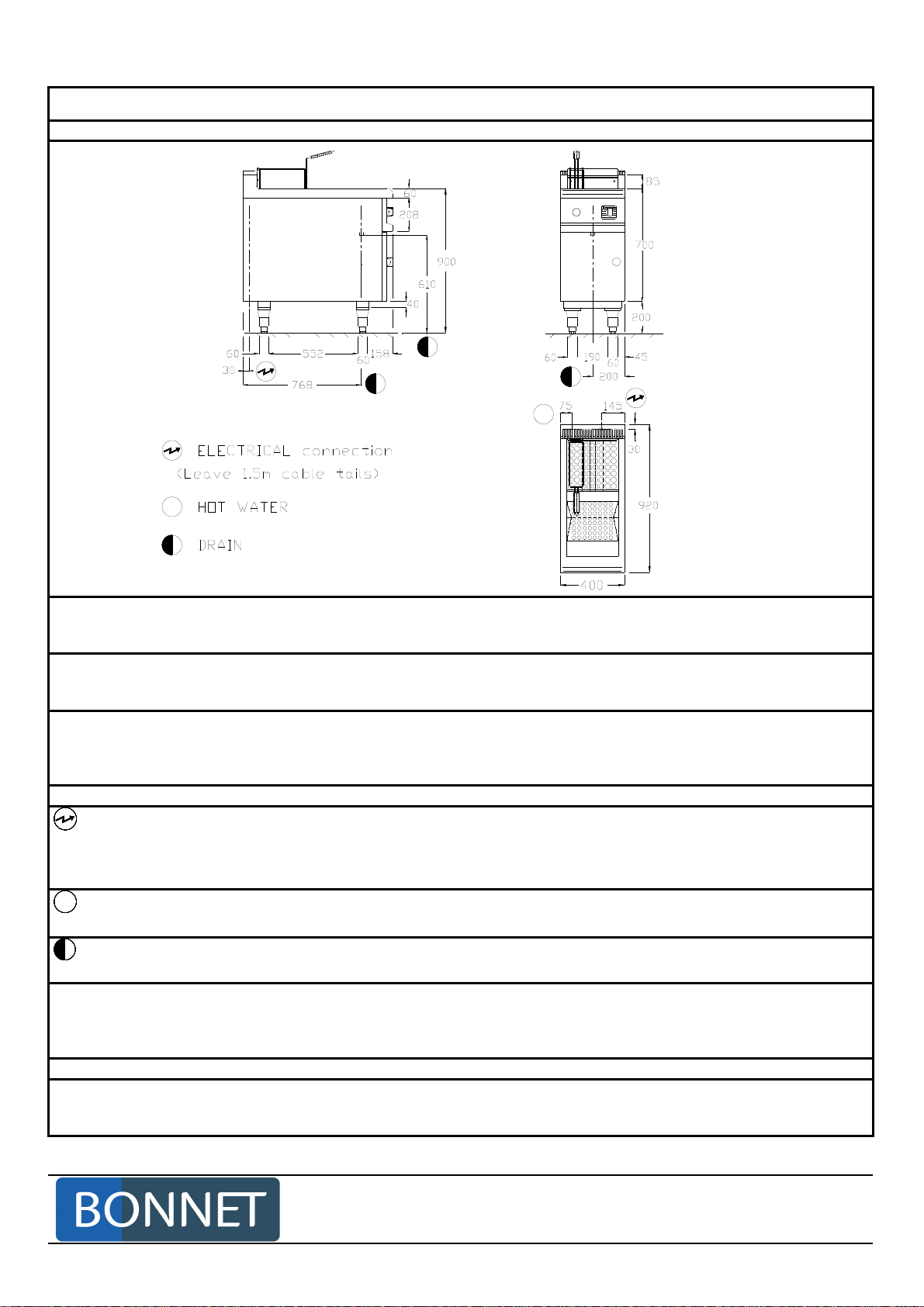

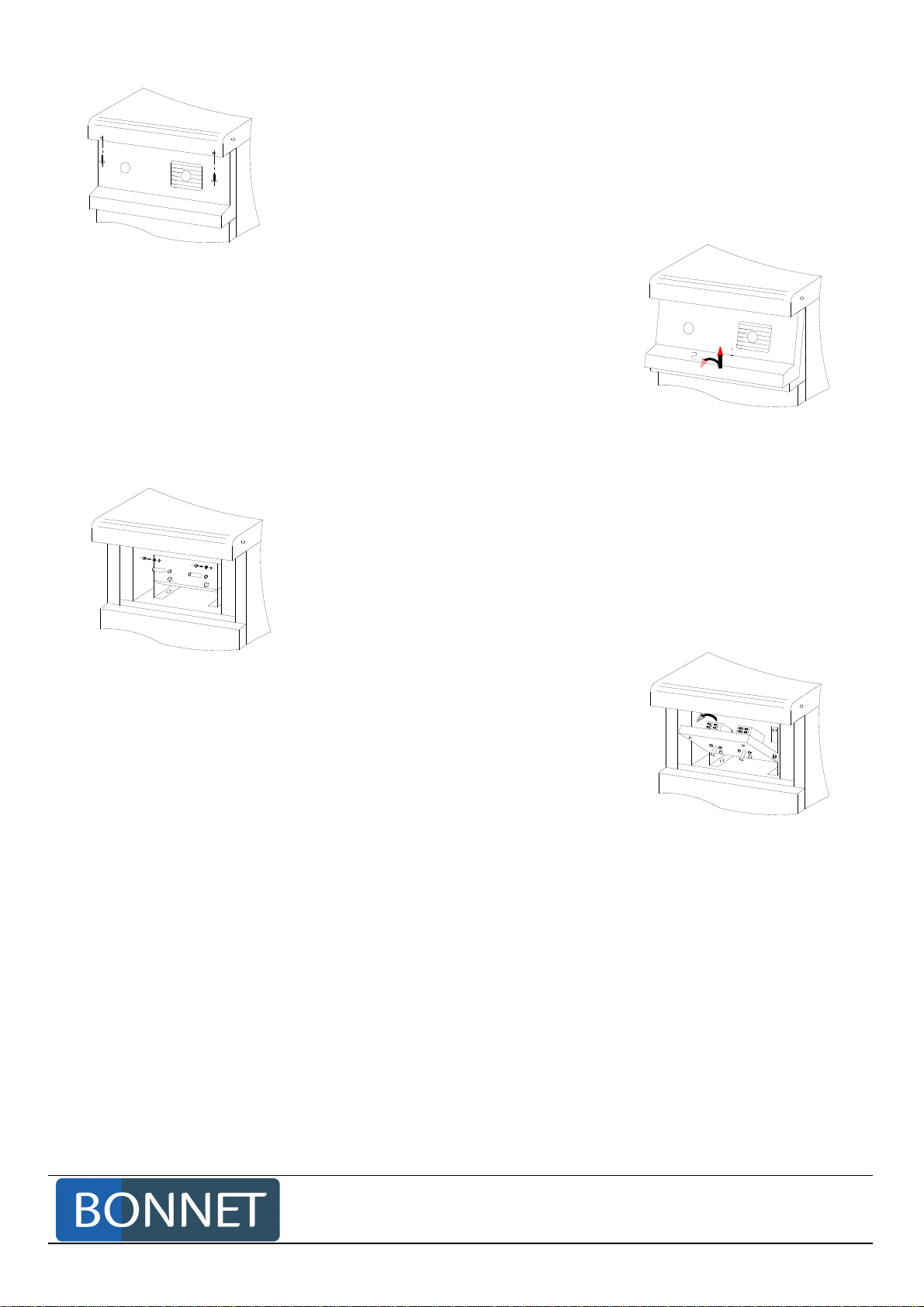

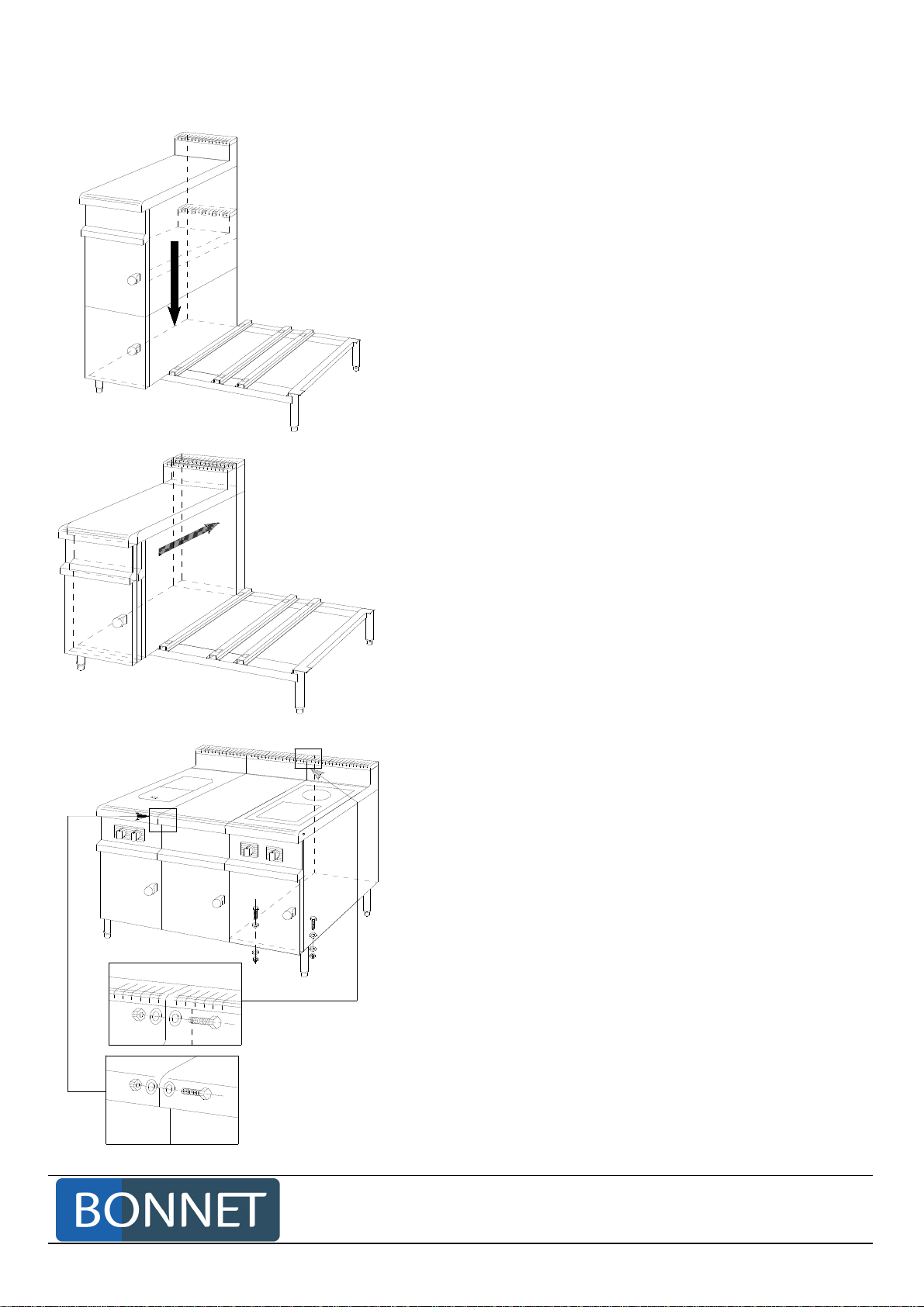

2.5 ASSEMBLY ONTO A SINGLE UNDERFRAME

Place appliance on the underframe, with rear of

appliance and the underframe approximately aligned. (The

underframe is symmetric front and rear are identical).

Push the unit backwards until the hooks in the base

locate into the 25mm square holes provided

Repeat these two operations for each appliance to be fitted

on the same underframe.

Fix the front to the underframe with HM 5 x 16mm nuts

and bolts + 2 washers either inside when the appliance

design makes this possible (cupboard) or from underneath.

Connect the units to each other:

1) at the rear inside the vent again with 5 x 16mm

fixings irrespective of the type of equipment.

2) at front inside the facia after removing the front of the

appliance (see section).

- Use HM5 x 16mm bolts + 5mm Ø washers for

boiling pan or deep fat fryer connected to

cooking unit (a captive nut is located in the side

rails behind the facia).

- Use HM5 x 16mm nuts and bolts + 5mm Ø

washer to connect cooking units together,

having removed the M5 captive nut from one of

the 2 appliances (from the screw side), using a

screwdriver.