Bonny Doon Classic Pro User manual

HYDRAULIC PRESSES AND TOOLING

Classic Pro Manual

20-Ton Press with Handpump

SAFETY WARNINGS & CAUTION

Shipping Crate: Please save the shipping box and plywood blocks with flange for future shipping

The warnings, precautions, and instructions discussed in this

manual cannot cover all possible conditions and situations that may

occur. The operator must understand that common sense and

caution are factors, which cannot be built into this product, but must

be supplied by the operator.

WARNING SYMBOLS AND DEFINITIONS

This is the safety alert symbol. It is used to alert you to

potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible serious or Life-Threatening injuries.

Owners Manual and Safety Instructions

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. KEEP CHILDREN AWAY. All children should be kept away from work area.

3. DO NOT ASSEMBLE OR OPERATE THE PRESS IF UNDER THE INFLUENCE OF ALCOHOL, OR

DRUGS. Read warning labels on prescriptions to determine if your judgment or reflexes are impaired while taking

drugs. If there is any doubt, do not attempt to assemble or operate.

4. AVOID MOVING PARTS DURING OPERATION. Keep fingers and hands away from all moving parts.

5. USE EYE and FACE PROTECTION. Wear ANSI approved impact safety face and eye protection.

6. DRESS SAFELY. Protective, gloves and non-skid footwear or safety shoes are recommended when working with

and operating the Press. Don't wear loose clothing or jewelry. They can get caught in moving parts. Also, wear a

protective hair covering to prevent long hair from getting caught in the Press.

14. DON'T OVERREACH. Keep proper footing and balance at all times.

.

11. STAY ALERT. Watch what you are doing. Use common sense. Do not operate any tool when you are tired.

12. 20 TON LIMIT. Do not operate the hydraulic jack beyond rated capacity.

13. BOLT PRESS SECURELY TO BENCH.

7. ALWAYS CENTER YOUR WORK, do not press anything off-center. Look at your setup from multiple angles to

insure that everything is centered within the press.

15. REPLACEMENT PARTS AND ACCESSORIES. When servicing, use only identical replacement parts. Only use

Approved accessories intended for use with this Press.

10. DO NOT COMPRESS SPRINGS, do not press cast iron, rocks, or any fragile or brittle objects.

Do not press items that could disengage and cause a potential hazard

Addresses practices not related to personal injury.

Indicates a hazardous situation which, if not avoided,

could result in serious or Life-Threatening injuries.

Indicates a hazardous situation which, if not avoided,

could result in serious or Life-Threatening injuries

12.2

Save this manual: Keep this manual for the safety warnings and precautions, assembly, operating, inspection, cleaning and

maintenance procedures. Keep this manual safe and dry for future reference.

READ ALL SAFETY, ASSSEMBLY AND OPERATING INSTRUCTIONS BEFORE ASSEMBLING OR OPERATING THE

PRESS. FAILURE TO DO SO CAN RESULT IN SERIOUS or LIFE-THREATENING INJURIES.

9. ALWAYS STAND BEHIND THE UPRIGHT COLUMNS OF THE PRESS WHENEVER USING THE

PRESS. INSURE THAT ALL PERSONS ARE LOCATED BEHIND THE COLUMNS WHEN PRESSING.

9. ALWAYS STAND BEHIND THE UPRIGHT COLUMNS OF THE PRESS WHENEVER USING THE

PRESS. INSURE THAT ALL PERSONS ARE LOCATED BEHIND THE COLUMNS WHEN PRESSING.

8. CONTAIN THE DIE AND OBJECTS WHENEVER POSSIBLE, Use form-boxes or silhouette die containers

to contain the urethane and dies.

8. CONTAIN THE DIE AND OBJECTS WHENEVER POSSIBLE, Use form-boxes or silhouette die containers

to contain the urethane and dies.

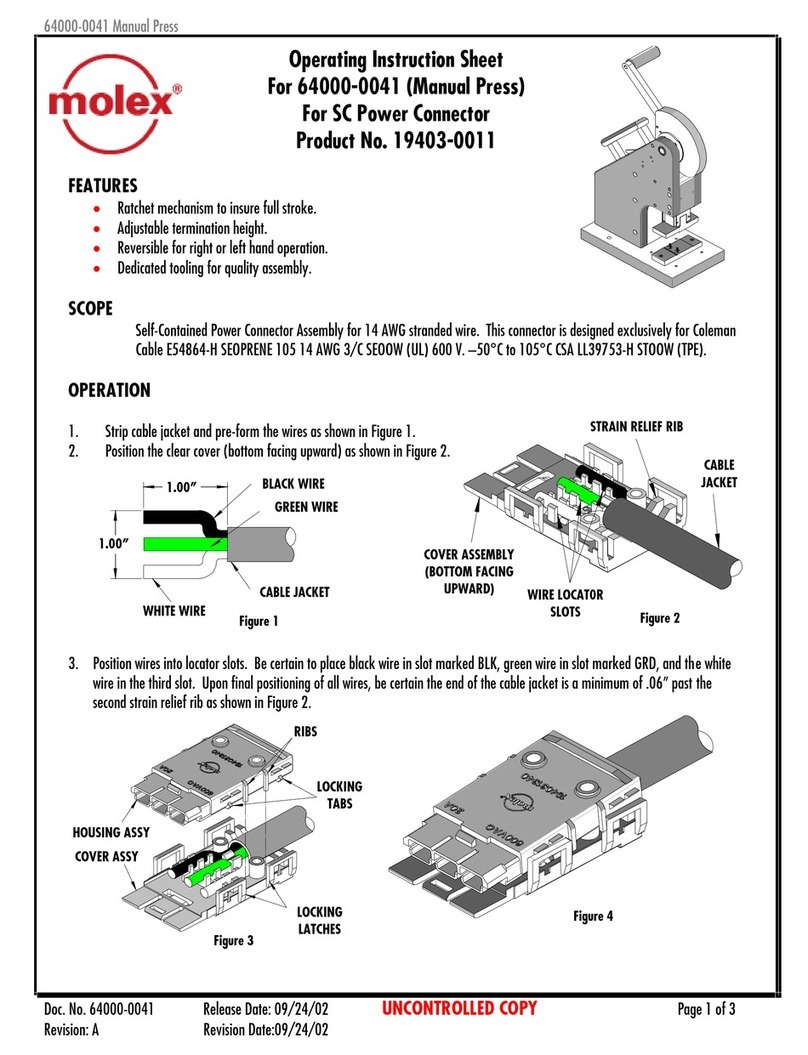

Identify all Parts

Riser block**

.

Cap head

screws with

hex key for

flange

1/4” T-handle Hex key

**MKIII only

Flange for mounting Cylinder in press frame.

(remove from plywood packaging)

Bolts(2), nuts(4), and

clamps for mounting

to edge of table or for

bolting through

desktop.

Tools Needed

Large Flathead Screwdriver

Adjustable wrench (two may be helpful)

Philips Screwdriver

1.25” tooling bolt

5/16” hex key

for Hand

Pump

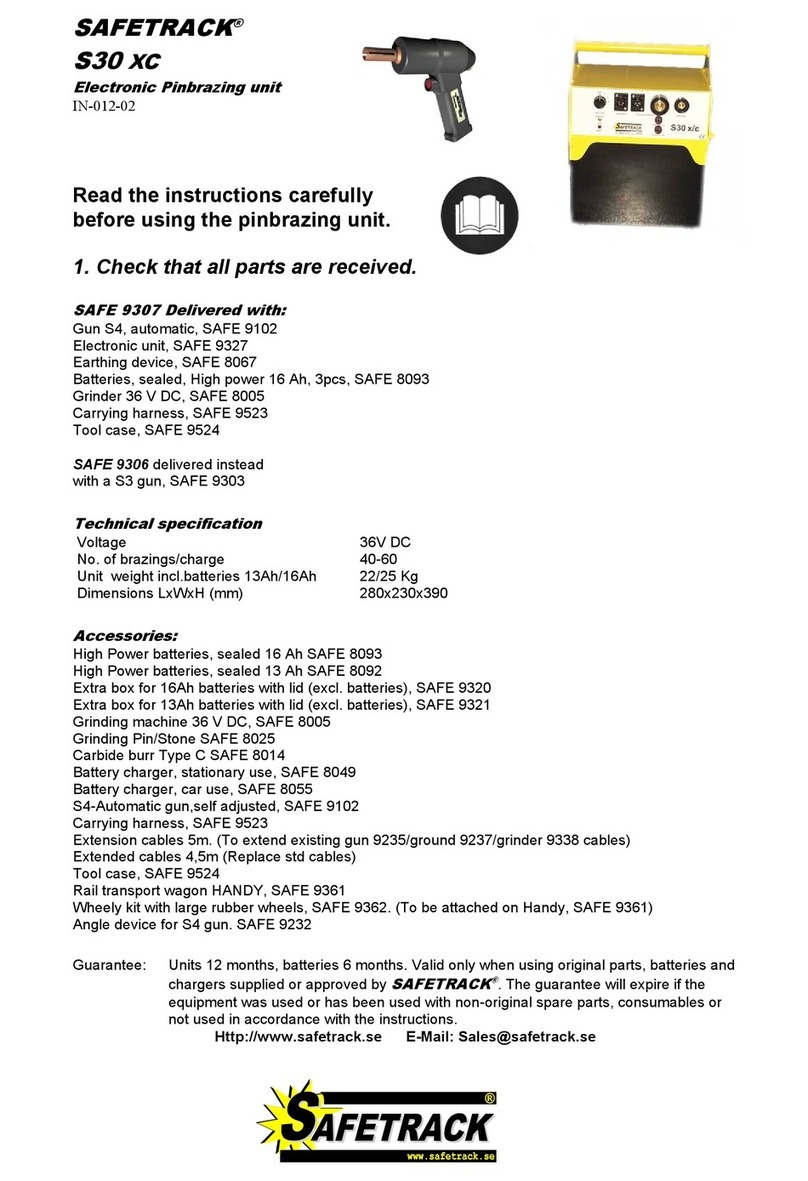

Pro Manual Hand-pump

12.2

6ft hose with quick connect included

gauge

pump handle

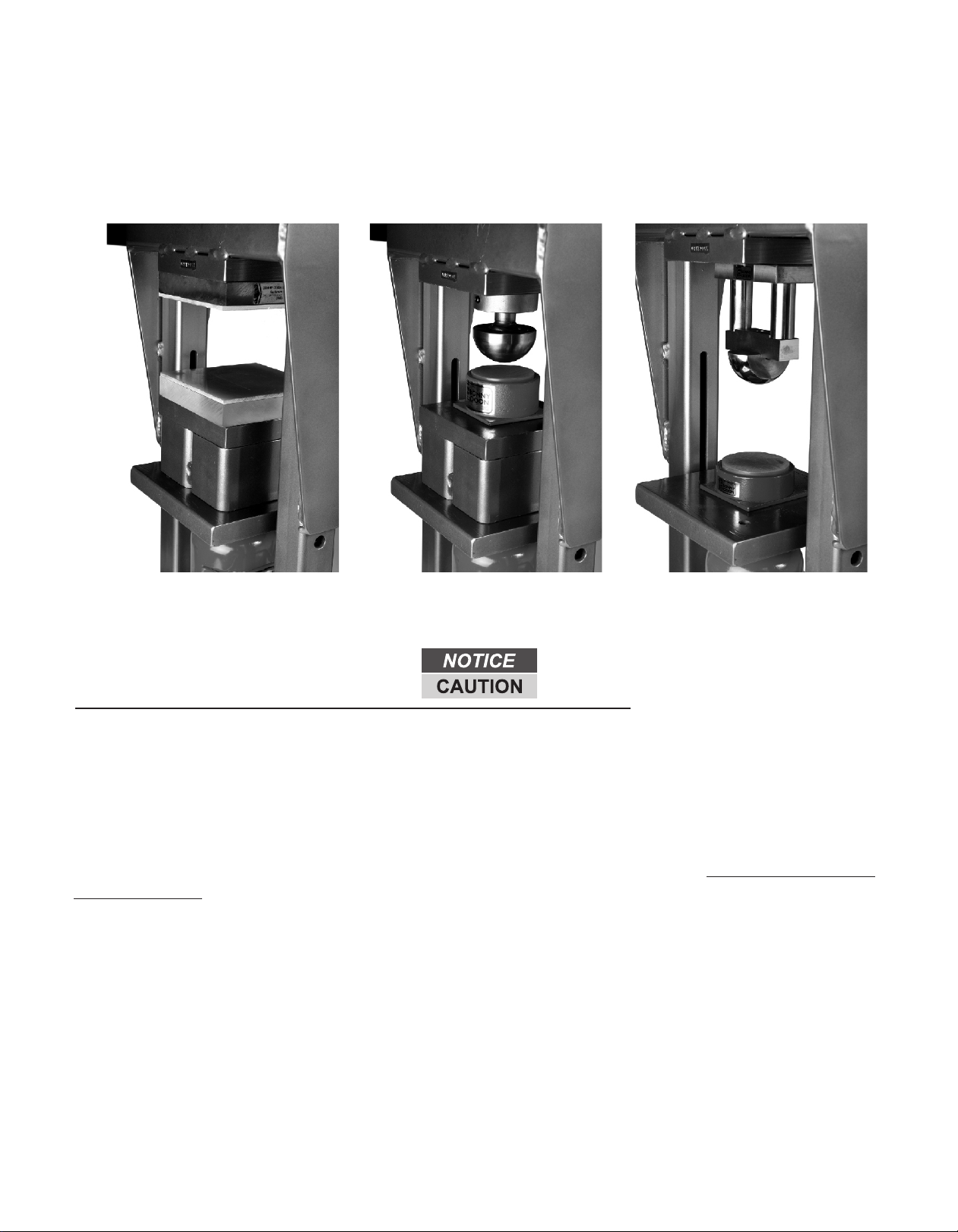

Connecting the Hose

You may want to use some rags

to put under the handpump so it

wont tip over.

Start by turning the handpump

on its side so the hex plug is

facing up as shown.

Have some paper towels ready

in case any oil leaks. Use the

included 5/16 hex key to un-

thread the plug.

Continued on next page--->

threaded end

w/ teflon

pressure release

knob

reservoir fill plug

Place the flange on top of

your cylinder. The flange

will be attached to the

press platen, keeping your

cylinder centered and

secure in the press.

-------->

Continued on next page.

Place screwdriver under the head of

the bolt and pry bolt upwards to

make room for the ram. Gently lower

the platen onto the ram head.

Close up of platen bolt, DO NOT

UNSCREW BOLT.

Remove the plug so that

you can now connect the

hose.

Carefully thread the end of

the hose w/ teflon into the

fitting. You will need to turn

the entire hose to do so.

Make sure it goes in straight

and square and you get at

least two threads engaged.

Once the hose has been

threaded in a few turns

you can use your

adjustable wrench to

tighten the fitting with

firm pressure. Use a

second wrench on the T-

fitting to assist in

tightening this

connection.

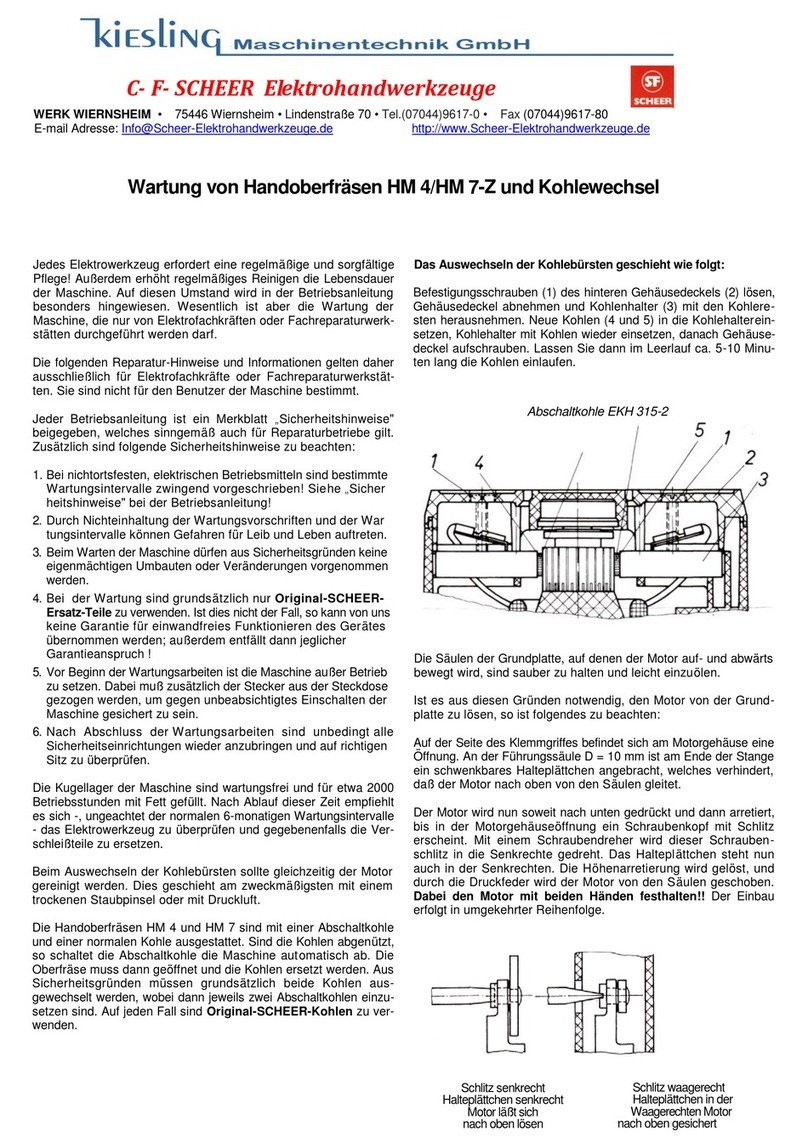

Installing the Cylinder

Using a Philips

Screwdriver, remove the

screws holding the flange

to the plywood

packaging. Replace

screws in plywood and

keep packaging.

Our new Pro cylinder is a robust

hydraulic cylinder with easy to

use quick connect plumbing. The

stroke is 5.91” and cannot be

overextended. This cylinder can

be easily connected to a manual

hand-pump or electric pump.

Close up of platen bolt,

pry this up to assist in

placing the ram into

the center of the

frame.

Use your flathead screwdriver to pry up the press

platen so you can place the hydraulic cylinder. Make

sure to place the tip of the screwdriver under the

bolt. Do not ever remove or loosen this bolt. Notice

on the underside of the platen will be two threaded

holes. Make sure to orient these holes facing down.

Center the cylinder in the press

and line up the two threaded

holes with the flange. Use the

included 1/4-20 x 1/2” long

screws to attach the flange to

the platen.

platen

Use the included 3/16” hex key to

tighten both bolts to the platen.

Continued on next page ------>

Now you are ready to connect

the pump to the cylinder. Start

by unscrewing the black plastic

caps from both ends.

Push the two ends of the quick

connect together.

While pushing them together

thread the sleeve on the

cylinder end over the threads

on the hose end. You only want

to tighten this fitting by hand.

Make sure that the fitting is

tight and that there is no gap

in between them. Do not use

any tools to tighten this fitting.

With this easy to use quick connect fitting you can switch between an electric pump and a manual

pump within about 15 seconds. This setup would give you the best combo of speed (electric

pump) and precision control when you need finesse (manual handpump)

Securing the Press

You will want to securely attach your press to your workbench top. The press frame has pre-drilled

holes to be used with lag bolts or through bolts depending upon your workbench material. The

Pro Manual Hand pump comes with clamps to secure it to the edge of a workbench top, or you

can use the bolts to bolt it directly onto your bench top.

Start by putting the bolt

through the holes in the

hand pump and secure with

a nut so it is tight on the

handpump base.

Add the aluminum clamp

block on the bottom and

secure with the second nut.

Tighten this down with your adjustable

wrench.

The ram should be lowered all the way down at the end of each day’s use. This keeps the ram clean and free of

dust and debris which wears on the seals.

Manual Handpump: Check the level through the reservoir fill plug hole with the ram all the way down. The

level should be 1/2” below the bottom of the reservoir fill plug hole. You can use a paperclip or toothpick to

check the level. Only use “Hydraulic Oil, AW-46”.

Clean: Clean the press and ram by using a clean cloth with a detergent or mild cleaner. Store and use the press

in a well protected area free of corrosive vapors, abrasive dust, and harmful elements. Keep all warning labels

clean and legible.

Oil Level: The oil level is topped off when shipped. It may leak during transport. All hydraulics leak over time

and use, if your press is leaking more than a tablespoon per week then it is in need of repair. If it is leaking less

than a tablespoon per week it is within the normal limits of use. Do Not overfill the Pro Manual Hand pump,

it needs some air in the reservoir to function properly.

Change the oil at least once a year. The first oil change should be performed no more than 12 months after

purchase, change every 6-12 months thereafter, more frequently with heavy use.

Save all warnings and instructions for future reference.

Cleaning, Maintenance, and Lubrication

Before each use, inspect the general condition of the Press and Ram. Check for broken, cracked, or bent parts,

loose or missing parts, and any condition that may affect the proper operation of the product. If a problem

occurs, it may have an effect on the proper operation of the product. If a problem occurs, have the problem

corrected before further use.

The Classic press allows for up to 7” of space between the two platens, the MKIII allows for 10” between the

two platens. This accommodates many of the large Bonny Doon tools such as the bracelet formers and the

deep-draw kits. On the MkIII you will want to use the riser block for most operations.

Always use a minimum of 2” of tooling in the press. The ram is designed to move no more than 5.91” For

thin operations such as blanking dies or embossing with pattern plates you will need aluminum spacers to

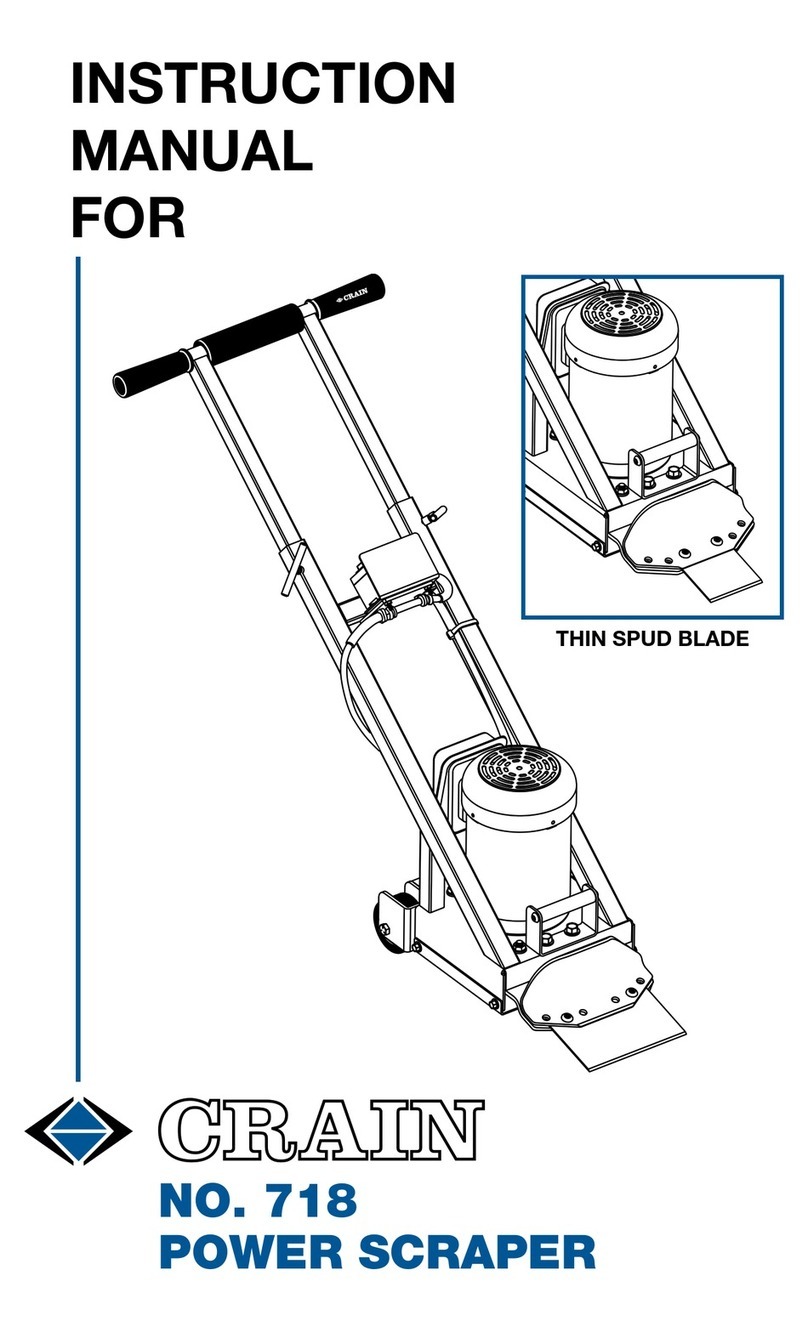

take up the extra space. All three of the images below have at least 2” of tooling.

Shown with 2” of

spacer blocks

Shown with Master tool

holder, Mushroom

Shown with Bracelet

forming kit.

Always use a minimum of 2” of tooling in the press.

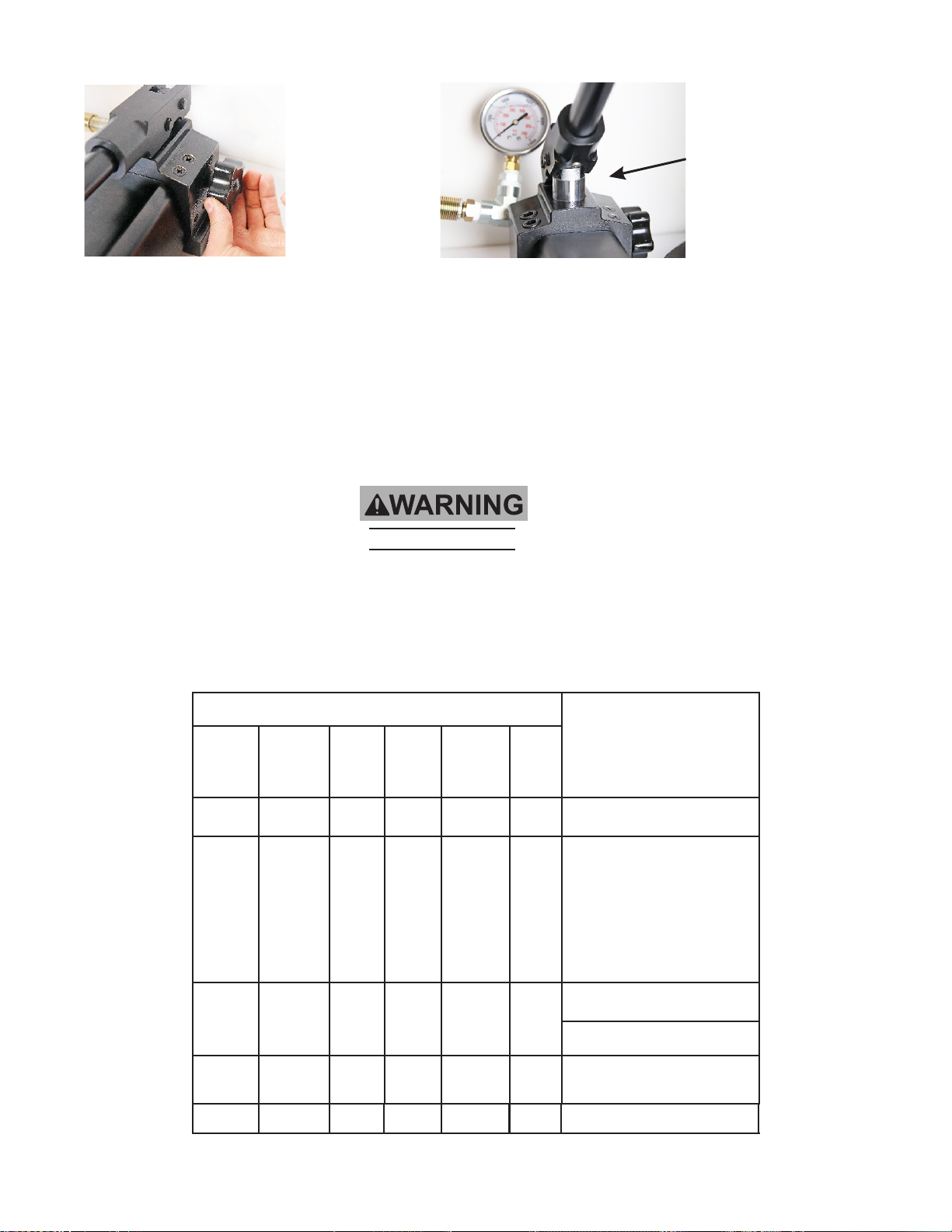

Troubleshooting

POSSIBLE SYMPTOMS PROBABLE SOLUTION

(Make certain that the ram is

not supporting a load while

not push to

its force

capacity

Cylinder

lowers

under load

Pump

stroke

feels

spongy

Cylinder

will not

lift all

the way

Oil

leaking

from

filler

plug

Xcheck that Release Valve Knob

Xis closed fully.

XX

Valves may be blocked and may not

X

close fully. To flush the valves:

1. Lower the Platen and securely

close the Release Valve.

2. Manually lift the platen

several inches.

3. Open the release valve

and let the platen down

as quickly as possible.

XX

ram may be low on oil. Check

Xthe oil level and refill if needed.

Ram may require bleeding - see

instructions above .

Unit may have too much

Xhydraulic oil inside, check fluid

level and adjust if needed.

IMPORTANT!

3. Pump the pump handle and raise the platen most of the way up.

6. Re-tighten the Oil Filler Plug.

2. Tighten the Pressure Release Knob.

1. Slightly loosen the Oil Filler Plug.

To remove excess air from hydraulic system:

Before first use, check for proper hydraulic oil level in the pump. It should be filled no more than 1/2” below the level of the Oil

Filler hole. There must be some air in the pump reservoir for it to work properly. Then thoroughly test the press for proper

operation prior to its actual use. If the cylinder and pump appears not to be working properly it may be necessary to bleed its

hydraulic system of excess air.

5. Test several times by tightening the Pressure Release Valve and raising the lower platen 2-4 inches and releasing.

4. Undo the Pressure Release Knob 1/2 turn or so, lowering the platen all the way down.

If after purging the press still does not operate properly do not use press until it has been repaired or replaced by a qualified service

technician.

X X

It is normal to have

small amounts of oil

around the cylinder

here. You may even get

some small droplets of

oil on your workbench.

X

attempting a solution)

Cylinder will Oil leaking

from

connections

XTighten connections

Pressure Release

Knob - open and

close only 1/2

turn

If the solutions presented in the Troubleshooting guide do not solve the problem, have a

qualified technician inspect and repair the Press before use. After the ram is repaired:

Test it carefully without a load by raising it and lowering it fully, checking for proper

operation, BEFORE RETURNING THE PRESS TO OPERATION.

TO PREVENT SERIOUS INJURY: Use caution when troubleshooting a malfunctioning

Press. Completely resolve all problems before use.

Do not use a damaged or malfunctioning press.

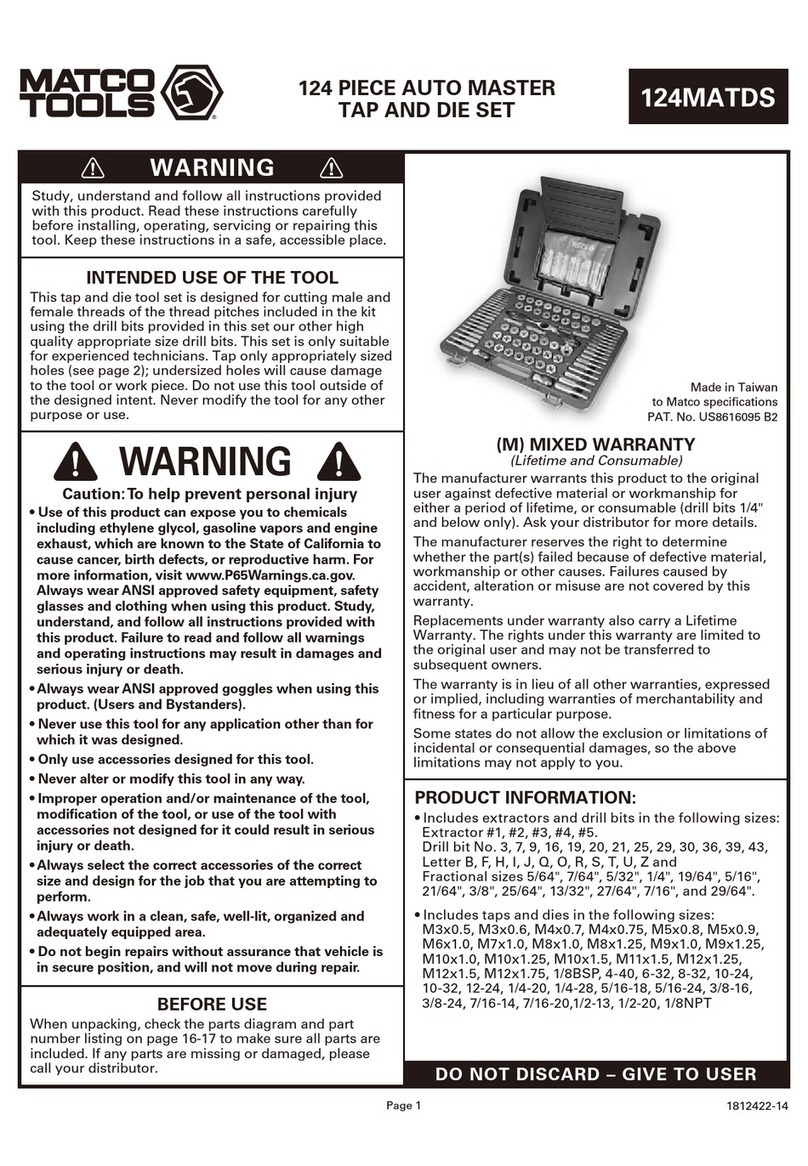

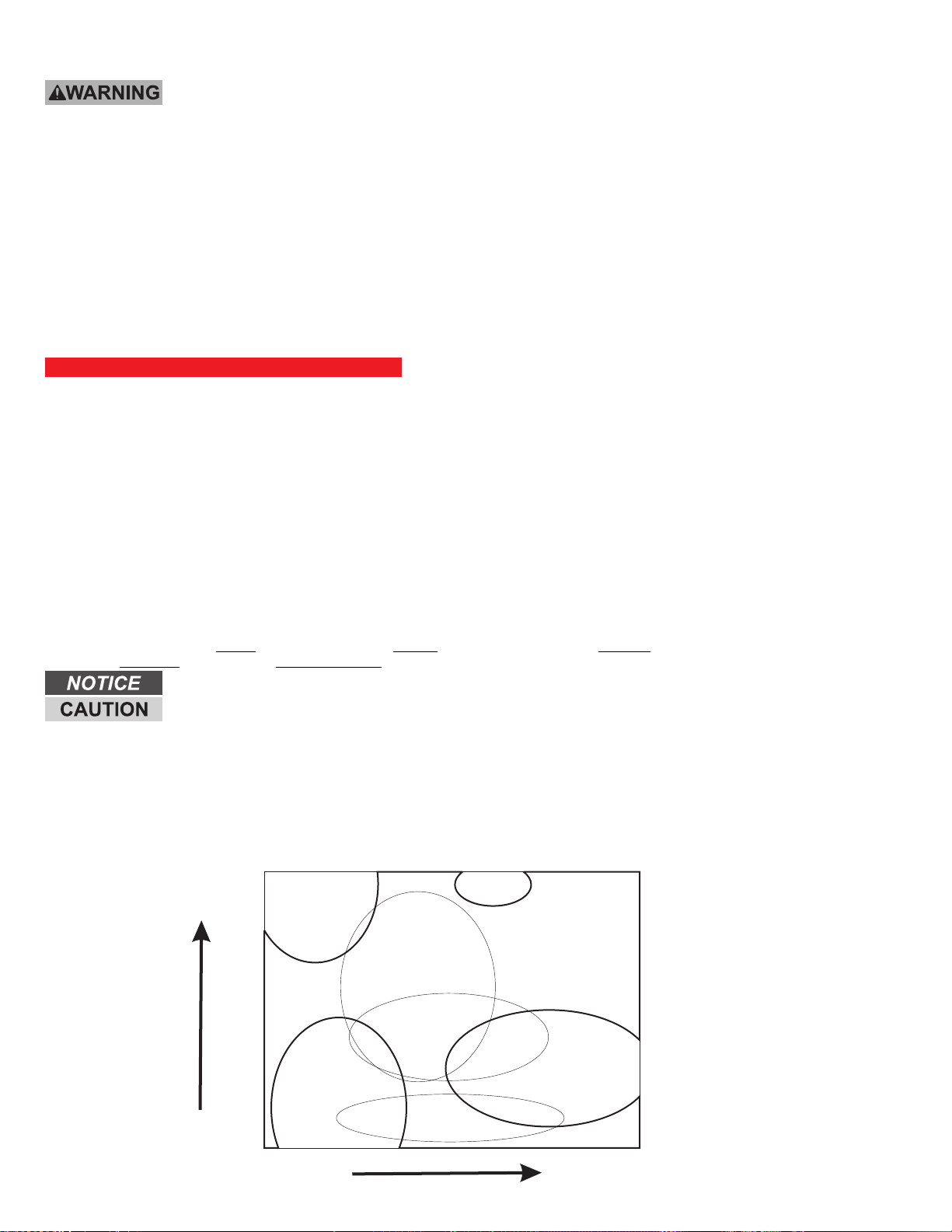

Simple Complex

Silhouette dies Conforming dies

Non-conforming dies

Coining

High Pressure

Low pressure

Blanking dies

Complexity of die

Pressure Requirement

Embossing

Deep-drawing

Always use the least amount of pressure or force to obtain the desired results

ALWAYS CENTER THE WORK. Use of the tooling holes will automatically do this for you. If using matrix dies, or blanking dies, place

them in the center of the platen because you will get a more even impression, and the platen will not tilt under pressure.

1. Never get in a hurry!

4. Remember the 5 “C’s”, Cover your face and eyes, Center your work in the press, Contain the work whenever possible, stand

behind the Columns, and exercise Common Sense.

UNDERSTAND FORCE and SURFACE AREA: the smaller the surface area of a punch the more force is

applied at the point of contact. The 20 ton rating on this press is in reference to 1 square inch. In other words, if

you place 20 tons of force on 1 square inch of work you will get 20 tons per square inch (40,000 pounds per sq

inch). If 20 tons of force is applied to a workpiece or a punch with an area of only ½ square inch then the force

applied to that workpiece or punch will be equal to 80 tons. This is far beyond the material limits of many metals

including steel and may represent a dangerous condition. Understand the material properties of each item you

are placing in the press. Consequently if you exert 20 tons of force on a workpiece of 10 square inches then you

are exerting only 2 tons of force per square inch of workpiece.

DO NOT EXCEED THE PROPER PRESSURE FOR THE JOB. See chart below for ranges of pressures for various processes. Avoid

using small surface-area punches such as small daps and punches.

3. Exercise thought before pumping the press!

NEVER TRY TO EMBOSS OR USE BLANKING DIES WITHOUT THE TOP SPACER/S.The top spacer is to make the tooling holes "go

away". These holes can damage your die. You will want to use aluminum spacers for thin work such as blanking dies and embossing with

pattern plates. The cylinder has a stroke of 5.91” so it will not go all the way to the top.

ALWAYS BOLT TOOLING IN PLACE. NEVER use a cast spoon stake in the press. The cast stakes are not designed for use in any

press. They are cast iron and will shatter and/or eject out of the press. Tooling attachment holes are in the top platen of the press for this

reason. Only use tooling designed for use in a hydraulic press.

ASSEMBLE YOUR WORK ON A PALLET AND SLIDE THE PALLET INTO THE PRESS. This allows you to locate everything without

disturbing your assembly. The way I describe this in the workshops is that "it is easier to assemble the pizza on a pan and slide the whole

works into the oven, rather than trying to assemble the whole thing in the oven.

(The “pallet” is usually a platen protector or aluminum spacer)

ALWAYS LOWER THE RAM WHEN FINISHED FOR THE DAY. The ram is slightly oily and an excellent dust and grit magnet. Abrasive

grit, corrosive vapors, dust and other harmful substances are to be avoided. When not in use, lower the ram back into its protective

sheath.

Tips for Using your Hydraulic Press

2. Use the proper tool for the job!

ALWAYS WEAR SAFETY GLASSES OR A FACE SHIELD. Things can always break under the pressures that you are working with.

Cast Acrylic will withstand incredible pressure if it is fully supported on the back side, but if it is hanging over the edge, and the urethane

pad starts to bend the area that is hanging over it is sure to break. Do not use small daps or punches with urethane pads. This will ruin

the pad by cutting it, and the punch can also eject out of the press if pressure was excessive, the punches are for use with the contained

block of urethane or forming box. See “Understanding PSI and Surface Area” below.

12.2

Table of contents