SAFETRACK

®

S30 XC

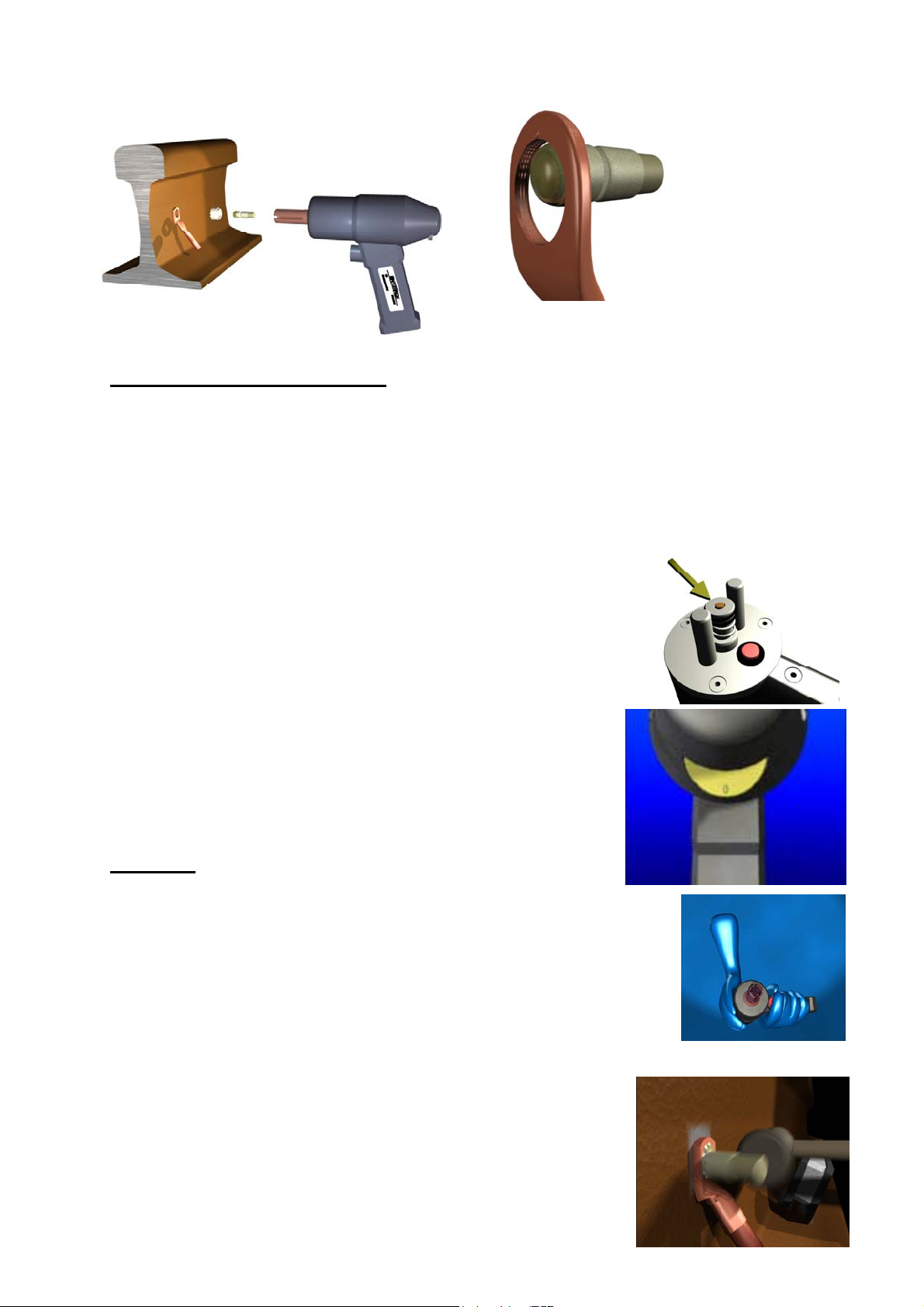

Electronic Pinbrazing unit

IN-012-02

Read the instructions carefully

before using the pinbrazing unit.

1. Check that all parts are received.

SAFE 9307 Delivered with:

Gun S4, automatic, SAFE 9102

Electronic unit, SAFE 9327

Earthing device, SAFE 8067

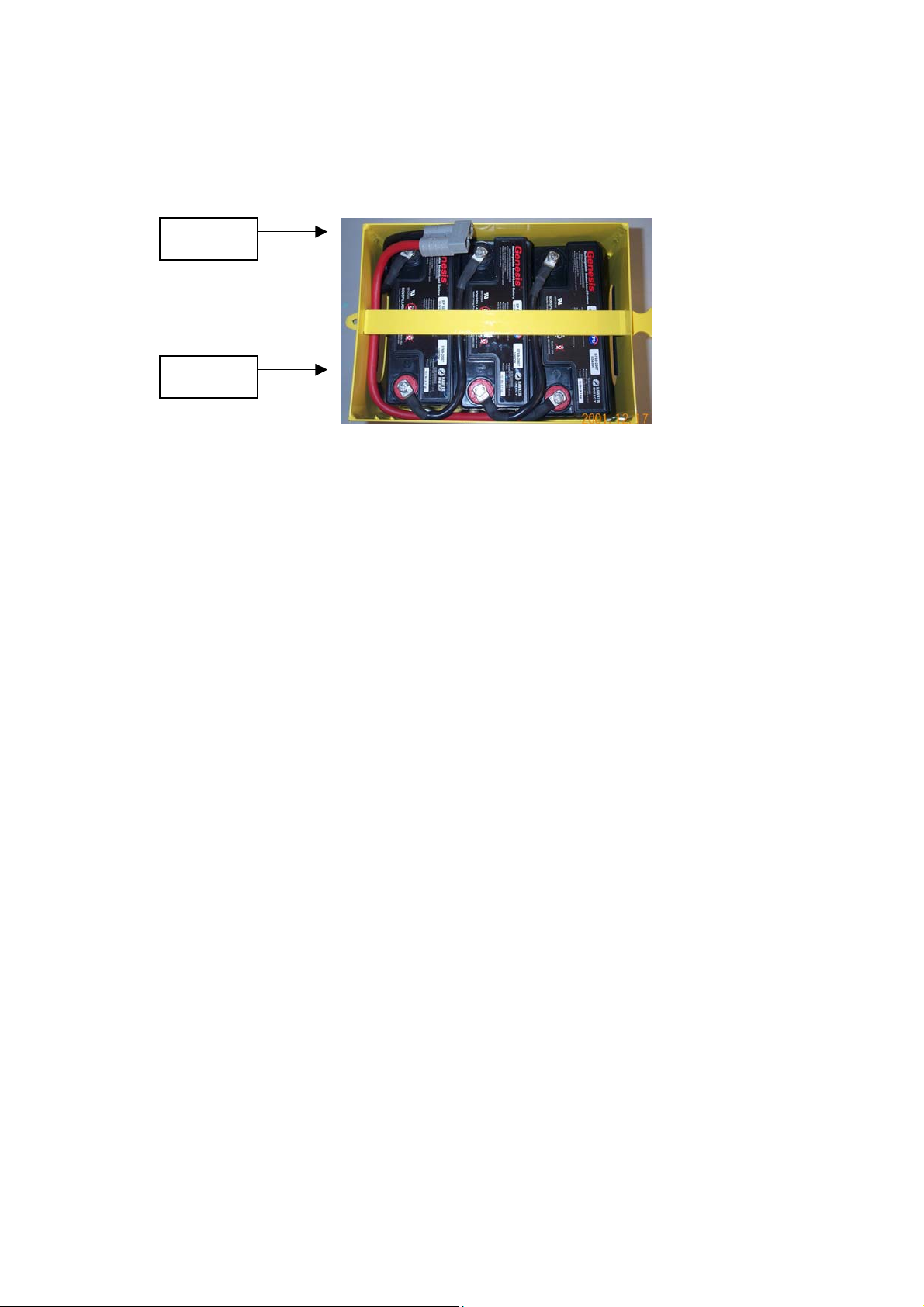

Batteries, sealed, High power 16 Ah, 3pcs, SAFE 8093

Grinder 36 V DC, SAFE 8005

Carrying harness, SAFE 9523

Tool case, SAFE 9524

SAFE 9306 delivered instead

with a S3 gun, SAFE 9303

Technical specification

Voltage 36V DC

No. of brazings/charge 40-60

Unit weight incl.batteries 13Ah/16Ah 22/25 Kg

Dimensions LxWxH (mm) 280x230x390

Accessories:

High Power batteries, sealed 16 Ah SAFE 8093

High Power batteries, sealed 13 Ah SAFE 8092

Extra box for 16Ah batteries with lid (excl. batteries), SAFE 9320

Extra box for 13Ah batteries with lid (excl. batteries), SAFE 9321

Grinding machine 36 V DC, SAFE 8005

Grinding Pin/Stone SAFE 8025

Carbide burr Type C SAFE 8014

Battery charger, stationary use, SAFE 8049

Battery charger, car use, SAFE 8055

S4-Automatic gun,self adjusted, SAFE 9102

Carrying harness, SAFE 9523

Extension cables 5m. (To extend existing gun 9235/ground 9237/grinder 9338 cables)

Extended cables 4,5m (Replace std cables)

Tool case, SAFE 9524

Rail transport wagon HANDY, SAFE 9361

Wheely kit with large rubber wheels, SAFE 9362. (To be attached on Handy, SAFE 9361)

Angle device for S4 gun. SAFE 9232

Guarantee: Units 12 months, batteries 6 months. Valid only when using original parts, batteries and

chargers supplied or approved by

SAFETRACK

®

. The guarantee will expire if the

equipment was used or has been used with non-original spare parts, consumables or

not used in accordance with the instructions.