Bopp & Reuther DIMF 2.0 TVS User manual

Bopp & Reuther Messtechnik GmbH

Am Neuen Rheinhafen 4 - 67346 Speyer

Postfach 1709 - 67327 Speyer

Phone +49(0)6232/657-0

Fax +49(0)6232/657-505

http://www.burmt.de

Änderungen der Abmessungen, Gewichte

und anderer technischer Daten vorbehalten.

Printed in the Federal Republic of Germany

BA 06730-01-01 e

Rev. no. 01099-003

Page 1of 30

Density Transducer DIMF 2.0 TVS

for continuous measurement of density and concentration of liquids

with HARTCommunication

Operating Instructions

2

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

TABLE OF CONTENTS

Foreword 4

1 Technical data 5

1.1 Density transducer type DIMF 2.0 5

1.2 Evaluation electronics of transmitter type TR 6

1.3 Required differential pressure 7

2 Intended use 8

3 Measuring principle 8

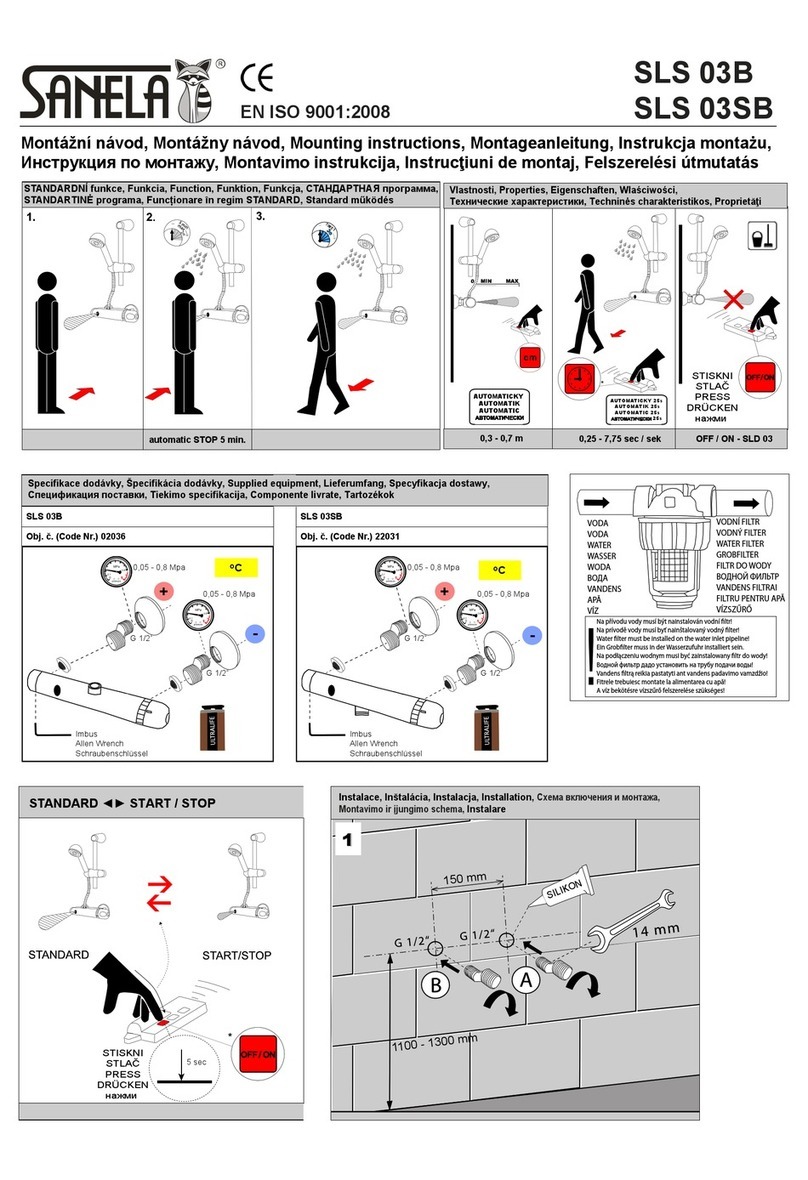

4 Installation examples 8

4.1 By-pass installation 8

4.1.1 Standard configuration 8

4.1.2 with sampling 9

4.1.3 with sampling and sight glass 9

4.1.4 with sampling and calibration or flushing connection 9

4.2 Installation into the product line 10

4.3 Examples for installation positions 10

5 Mounting 10

5.1 Density transducer 10

5.2 Piping 11

5.3 Process connections 11

5.4 Relationship between permissible ambient temperature and temperature of liquid 11

6 Electrical connection 12

6.1 Power supply voltage 12

6.2 Additional requirements in hazardous area for intrinsically safe operation 13

7 Commissioning 13

8 Factory setting 13

9 On-site adjustment 14

10 Configuration, operation 14

10.1 Operation via HARTcommunication 14

10.1.1 Process variable 15

10.1.2 Diagnosis 15

10.1.3 Basic settings 16

10.1.4 Operating modes 16

10.1.5 Special settings 17

10.2 Operation with the keys (configuration via the control unit) 17

10.2.1 Display 17

10.2.2 Keys 18

10.2.3 Operating mode 18

10.2.4 Programming mode 18

10.2.5 Operating mode 19

3

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

10.2.6 Short description of the control unit 19

10.3 Channel overview / channel assignment 20

11 Equations 21

12 Maintenance 22

13 Error detection/troubleshooting 22

13.1 Errors/defects caused by the liquid 23

13.2 Errors/defects caused by the transmitter 24

13.2.1 Error code table 25

13.3 Errors/defects caused by the density transducer 25

14 Self-monitoring functions 26

14.1 Monitoring supply voltage 26

14.2 Error message 26

15 Service 26

16 Appendix 27

16.1 Wiring diagram 27

16.2 Application examples for safe areas 28

16.3 Application examples for hazardous areas 29

16.4 Example of configuration log 30

16.5 EC prototype test certificate 30

4

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

Foreword

I. Transport, delievery, storage

Storage and transport:

Protect the devices against humidity, soiling, impact, and damage.

Inspection of the delivery:

Upon receipt, check the delivery for completeness. Compare the data of the device with the data on the

delivery note and in the order records.

Report any transport damage immediately after delivery. Damage reported later cannot be recognized.

II. Warranty

For the scope and period of warranty, please refer to the contractual terms of delievery. Claims under

warranty shall be conditional to expert installation and startup in compliance with the operating

instructions for the device.

The electronics contains electrostatically sensitive parts. Therefore, electrostatic discharges must be

avoided when the electronics housing is open.

III. General safety information

Read and observe these Operating Instructions thoroughly and keep them

available for reference.

Installation must be carried out by qualified personnel.

For the installation and operation of the device, the regulations of ElexV, the

generally recognized rules of engineering practice and the Operating

Instructions must be observed.

We do not assume liability for the improper handling, use, installation,

operation, or maintenance of the device.

In the case of corrosive media, resistance of the oscillating tube must be

checked.

Damaged devices must be shut down.

!

5

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

1 Technical data

1.1 Density transducer type DIMF 2.0

Density range 0 to 5000 kg/m³

Calibration range 400 to 2000 kg/m³ (Standard)

see Configuration Data Sheet supplied

Accuracy better than ±0.02 % (±0.2 kg/m³) (Standard)

(under reference condition)

see Configuration Data Sheet supplied

Repeatability better than ±0.005 % (±0.05 kg/m³)

Temperature range of liquid - 40°C to + 150°C (Standard)

see Configuration Data Sheet supplied

Temperature influence without approx. 2,8 kg/m³/°C

compensation

Temperature compensation via integral Pt1000

in acc. with DIN Class A

directly in the transmitter

Pressure influence less than 0.02 kg/m³/bar

Operating pressure 100 bar (Standard)

see Configuration Data Sheet supplied

Liquid pumpable liquids

see Configuration Data Sheet supplied

Material: wetted parts 1.4571 (Standard)

see Configuration Data Sheet supplied

Material: transmitter housing made of 1.4571

Smallest inside diameter ∅10 mm

Specialties Gasket-free construction

on request. Material certificates

in acc. with DIN ISO10204-3.1B;

see Configuration Data Sheet supplied

Weight approx. 4.2 kg

Process connections Swagelok fittings for

outer pipe diameter 12 mm (Standard)

see Configuration Data Sheet supplied

All percentages are referenced to a density of 1000 kg/m³.

For the exact specification of the device version, see the Configuration Data Sheet of the device

supplied.

6

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

1.2 Evaluation electronics of transmitter type TR

Functions Excites the oscillating element of the density transducer to

its natural frequency.

Equipped with a two-line display and four keys for displaying

data and configuring the on-site transmitter.

HARTcommunication

When the process data are changed, the user can perform a

simple modification of the set parameters.

Display parameters Density, concentration, operating temperature, etc.

Programmable parameters Lower range and upper range value of the output signal

(smallest measuring span approx. 5 kg/m³)

Calibration constants, constants of liquid, reference

temperature, etc.

HARTprotocol Operation using a PC or laptop equipped with the

SensorPort 2 configuration software together with the HART

interface or operation using a HARThand-held terminal

2.3 HC-275 of Rosemount

Output signal 4-20 mA, linearized and temperature-corrected,

can be assigned to any display parameter

(e.g. operating density, reference density, concentration, °Brix,

°Plato or other magnitudes derived from density)

Power supply 24 V DC (min. 14 V DC / max. 30 V DC)

Connection 2-wire technique via screw terminals;

cable enters via cable gland with M 20 x 1.5

or ½“ NPT thread for pipe installation (conduit system)

Cable specification 2 wires, twisted and shielded

Ambient temperature -10°C to +58°C

- 40°C to +70°C on request

Storage temperature -40°C to +70°C

Safety classes Exi (standard version):

EEx ia IIC T4 ZELM 99 ATEX 0008 X

Device group II

Category 1/2 G

Measuring tube designed for Zone 0

Exi (Tantalum version):

EEx ia IIC T4 ZELM 99 ATEX 0008 X

Device group II

Category 2 G

Exd:

see individual approval

94/9/EG, FM, CSA in preparation

Degree of protection (housing) IP 65

Dimensions (housing) ø100 (D) x 155 (L) x 120 (H) mm

Material (housing) Cast aluminum

Weight 1.2 kg

Calibration and configuration According to customer data at

Bopp & Reuther Messtechnik GmbH factory

7

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

1.3 Required differential pressure

Density transducers of the DIMF series measure independently of flow rate and also at flow rate zero.

Their application is therefore normally problem-free. Care must, however, be taken to ensure that the

operating flow rate in the transducer

- updates the sample fast enough

- equalizes the temperature in the tranducer

- avoids air or gas bubbles or

deposits in the oscillating tube

- does not cause cavitation in the oscillating tube

- does not cause wear through abrasives

Recommended operating flow rate through the density transducer:

DIMF 2.0: approx. 2.0 l/m.

Pressure loss diagram

DIMF2.0

10

1

0.1

0.01

0.001

0.1 1 10 100

Flow rate [l/min]

Pressure loss

∆P [bar]

(H2O; 20°C)

0 1.5 650 l/min

2 l/min

10.1 10 100

l/min

0.10.01 110

m³/h

Permissible flow rates

Recommended flow

DIMF2.0

8

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

2 Intended use

The density transducer type DIMF allows the continuous measurement of the density of liquids and liquid

mixtures. The proven oscillating element principle ensures great accuracy in combination with

outstanding long-term stability. The easy-to-get-on-with-construction assures reliable operation, even

under tough process conditions.

3 Measuring principle

The real sensor of the density transducer is an oscillating element in the form of a tube bent into a tuning

fork. The liquid to be measured passes continuously through this element. Excited electromagnetically by

an excitation coil, it will oscillate at its natural frequency. Changes in the density of the liquid lead to

changes in the natural frequency. This change in frequency, sensed by a pick-up coil, represents the

measurement effect. An additional built-in resistance thermometer measures the process temperature,

which can also be used to equalize the temperature influence in the transducer.

Each density transducer is calibrated with different liquids of different densities. The transducer constants

for the calculation of the density from the frequency, the calibration temperature and the correction

coefficients for temperature influence are given under section 16.4 Example of configuration log.

4 Installation examples

In principle, the density transducer can be installed directly into the product line (for permissible flow

rates, see section 1.3). For higher flow rates or measurements at containers, installation in a by-pass is

recommended.

4.1 By-pass installation

4.1.1 Standard configuration

Part Qty.

Shut-off valve ø12

Straight tube fitting

2

2

9

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

4.1.2 with sampling

4.1.3 with sampling and sight glass

4.1.4 with sampling and calibration or flushing connection

Part Qty.

Shut-off valve ø12

Straight tube fitting ø12

T-type connector ø12

Screw cap ø12

3

2

1

1

Part Qty.

Shut-off valve ø12

Straight tube fitting ø12

T-type connector ø12

Screw cap ø12

4

2

2

2

Part Qty.

Sight glass R3/8“

Shut-off valve ø12

Straight tube fitting ø12

Male connector R3/8“- ø12

T-type connector ø12

Screw cap ø12

1

3

2

2

1

1

10

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

4.2 Installation into the product line

Installation into the product line is possible up to a flow rate of 50 l/min (using H2O as an example). For

other viscosities, differing pressure losses must be considered.

Caution!

The pressure in the product line must never fall below the vapor pressure. Direct solar irradiation of the

density transducer must be avoided. If necessary, heat insulation must be provided.

4.3 Examples for installation positions

The device may be mounted in any position. However, depending on the properties of the liquid and the

flow velocity, the following positions are recommended:

Mounting position A: standard mounting position, e.g. for clean liquids at low

flow velocities

Mounting position B: self-draining position

Mounting positions C or D: for liquids with solids

5 Mounting

5.1 Density transducer

- Handle with care: do not knock the density transducer.

-Install density transducer into by-pass or directly into the product line.

- Deaerate the device before putting it into operation.

- Provide a constant flow through the density transducer.

- Any flow direction is possible.

- Normal flow rate to be approx. 1.5 to 6 l/min, max. 50 l/min

(provides current liquid sample, avoids deposits)

- Avoid generation of steam bubbles.

- The use of a clamp or a bracket is recommended

(e.g. mounting plate, pipe or wall clamp).

- If mounting position is "self-draining",

a clamp or a bracket must be used.

- The pipe bends of the density transducer must not

be bent during mounting.

Inclination 20°-

30°

A

B CD

11

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

5.2 Piping

- Inner diameter of connecting pipe: min. ø12

- Sampling connection to be fitted laterally when product line is in horizontal position.

- By-pass pipes should be as short as possible.

- If necessary, provide both heat insulation and flushing connections (the latter close to the

density transducer).

5.3 Process connections

Ensure that the density transducer connection is compatible with the by-pass connections.

For the connection type of your density transducer, see the Configuration Data Sheet supplied.

5.4 Relationship between permissible ambient temperature and temperature of liquid

DIMF ... (interconnected version)

Class Ambient

temperature

Temperature of

liquid

Type

T2

T3

T3

46

46

49

210

200

170

H High temperature

T3

T4

T4

T4

50

52

54

58

150

135

110

60

S+H Standard temperature

and high temperature

12

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

6 Electrical connection

6.1 Power supply voltage

- The transmitter type TR must be supplied with 24 V DC, 2-wire technique.

- Terminal voltage 14 to 30 V DC (terminals 1 and 2)

- Recommendation: 2-wire cables, twisted and shielded

(cable diameter 6-12 mm)

- Ground cable shield according to section 16.1 Wiring diagram.

- In order to ensure safe HARTcommunication, the limits for the

minimum load with RL≥250 Ωmust be observed.

- For the maximum amount of line and load resistance, see diagram below.

The maximum load depends on the supply voltage.

A

VU

RVUFor

A

VU

RVUFor

B

B

B

B

022.0

)5.8(

:2.15

004.0

)14(

:2.15

−

=≥

−

=<

Maximum load

0

200

400

600

800

1000

14 16 18 20 22 24 26 28 30

Supply voltage [V]

Load [ohm]

13

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

6.2 Additional requirements in hazardous area for intrinsically safe operation

- Observe installation requirement in accordance with DIN EN 60079-14 / VDE 0165, Part 1.

- Connected loads power supply voltage

Umax = 30 V Imax = 110 mA Pmax = 825 mW

Ci ≤34 nF Li ≤0.6 mH

- Power supply must be provided by a certified, intrinsically safe supply unit or by

safety barriers.

- In order to connect the bonding conductor safely, use the

internal and external bonding connector terminals, which have been designed

for a wire range of 1.5 mm² (inside) or 4 mm² (outside).

- If barriers are part of the supply circuit, they must also be connected to the common

bonding conductor.

7 Commissioning

- Flush product lines before connecting the density transducer

- Ensure that all connections are tight

- Deaerate density transducer

- Switch on power supply

8 Factory setting

The density transducer DIMF 2.0 TR has been parameterized according to customer specifications. After

switching on the power supply, the specified parameters (e.g. density, reference density or concentration)

and the operating temperature will be shown on the display.

If these parameters have changed since the order was placed, the setting can be modified (see

section 10 Configuration, operation).

14

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

9 On-site adjustment

An on-site adjustment is carried out if an error has been confirmed due to certain on-site conditions after

the reasons according to section 13.1 have been checked. By changing the transducer constant K0, a

simple adjustment can be performed.

Example: Measurement condition Temperature must be relatively stable

Rho (measured density) = 996.6 Kg/m³

Rho (setpoint value) = 996.0 Kg/m³ (e.g. value stated in table)

difference (misalignment)= +0.6 Kg/m³

current K0value = -7360.708 Kg/m³

setpoint K0value = K0(current) –

misalignment

correct K0value = - 7360.708 Kg/m³ - 0.6 Kg/m³

= -7361.308 Kg/m³

Now this value must be entered into the transmitter type TR.

If possible, the constants K1and K2should not be modified by the user.

Depending on the operating mode or application and the reason for the error, the adjustment can also be

carried out via the concentration coefficient KX0. Here the same procedure is applied.

10 Configuration, operation

The transmitter can be configured (operated) in two different ways:

1. HARTcommunication

2. On-site operation with keys and display

10.1 Operation via HARTcommunication

The device can be operated using a PC or laptop and the SensorPort 2 configuration software in

connection with a HARTinterface.

A HARTCommunicator is another operating element which can be used (e.g. model HC-275 of

Rosemount). The operating functions of the HC-275 are defined in the HART "Device Description

Language" (DDL). Using the HC-275 the DIMF can be operated or configured on site. For the electrical

connection, see section 16.1.

15

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

10.1.1 Process variable

Measured value: The current measured value is displayed. The measured value can be selected

from a list with density or concentration operating modes.

The units are defined in this list. The measured value is firmly assigned to the

HARTprimary variable and thus also to the current output.

Operating density,

reference density,

frequency, temperature: The uncorrected or the temperature-corrected operating density, the reference

density, the oscillation frequency and the medium temperature can also be

displayed in the concentration operating mode and transmitted via HART

variables 2 to 4. The assignment is free.

Measured value The measured value is displayed as a percentage of the measuring range

current %: span.

Display current: The setpoint value of the present current output is displayed in mA.

10.1.2 Diagnosis

Communication status

Device address: The device address for polling operation can be assigned a value between 1

and 15. Address = 0 means analog operation, address > 0 means polling

operation. If the DIMF is to be installed in a multidrop system,

the address must be between 1 and 15. For this, the DIMF must first

be configured with the desired address in a point-to-point connection.

Number of preambles: The read value indicates how many preambles the master has to send to the

slave in its inquiry. The written value indicates how many preambles

the DIMF has to send to the master.

Device status

Configuration changed: If the configuration is changed during operation, the "configuration

changed" flag will be set and displayed.

Reset "configuration

changed" flag: The "configuration changed" flag can be removed.

Error codes: The error codes of the DIMF are displayed. The most recent error

is displayed. All previous error messages are no longer

available.

Limiting values

Temperatures: The DIMF measures the product temperature and the temperature in the

electronics housing. The min. and max. limiting values are stored and

displayed.

16

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

10.1.3 Basic settings

Device information

Model code: The model code of the device is displayed.

Device identification: The serial number of the electronics is displayed.

Device type: The device type is displayed.

Sensor type: Defaults to 0.

Manufacturer code: The manufacturer's name is displayed.

Distributor code: The distributor's name is displayed.

TAG: The TAG address (measuring point number) is displayed.

Date: The date of the most recent configuration change will be displayed.

(must be overwritten manually).

Descriptor: A short text of 16 characters can be entered by the user or be

read.

Message: A short text of 32 characters can be entered by the user or be

read.

Write protection: The DIMF does not support write protection.

Manufacturing no. sensor: The manufacturing number of the sensor can be read.

Manufacturing no. device: The manufacturing number of the device can be read. It is identical with

the sensor manufacturing number.

Revision levels, universal,

standard, software,

hardware: The revision numbers are read.

Tranducer data

Transducer factors: The factors K0, K1, K2, KT0, KT1, KT2 and Tkal can be read and changed.

Medium data

Medium factors: The factors α, KC0, KC1, KX0, KX1, KX2 and Tref can be read and changed.

Process data

Damping: Damping affects the display and the output current.

A value between 0 to 5 can be set. The increment is

approx. 0.25 s.

Upper/lower

range value: The meter range is factory-set for each

application.

Minimum measuring

range span: The measuring range span can be freely defined within the meter range.

However, the set values must not be below the minimum measuring span

range, as this may lead to step changes of the output current.

Upper range

value Characteristic value for the 20-mA point.

Lower range

value: Characteristic value for the 4-mA point.

17

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

10.1.4 Operating modes

Simulation

Current simulation: In order to test the devices connected in series, a fixed output

current of 3.9 to 22 mA can be set. After the test, the current value

0 mA must be entered to end simulation.

Alarm 21.8 mA: An alarm signal can be transmitted via the current loop.

The current then rises to 21.8 mA. This alarm is generated due to a

maloperation of the DIMF. The alarm function can be switched off.

Selection of

measured variable: The measured variable has been assigned to the HARTprimary variable and

thus to the current output. When displaying density, the user can change

between operating or reference density. When calculating the concentration,

the user can select between the two different methods.

10.1.5 Special settings

Electronic adjustment

Calibrate current output: The characteristic of the analog current output can be calibrated in its zero

point at 4 mA and in its slope at 20 mA. It must be observed that the zero point

will be calibrated before the upper range value.

Reset device: With this command, the device can be restored to a defined operating state

present after the supply voltage was applied.

10.2 Operation with the keys (configuration via the control unit)

To access the keys, the screw cover of the longer end of the housing must be opened. When the housing

cover has been opened, the degree of protection of the housing is not ensured.

After the configuration has been completed, the housing cover must be remounted and the screws must

be fastened fingertight (be careful not to damage the sealing ring).

For the Exd version the housing may only be removed after it has been ensured that

there is no explosive atmosphere.

The covers of the Exd version are secured against opening. In order to open the cover, the locking bar

must be swiveled sideways and clamped in this position. After closing the covers, they must be

resecured.

10.2.1 Display

The transmitter type TR has a two-line display with 8 digits for each line. Each line is subdivided into two

fields:

- in the 1st field the channel no. is displayed (1 digit)

- in the 2nd field the corresponding measured values

or the constants are displayed (7 digits).

The values displayed in the upper line cannot be changed. The values displayed in the lower line

(programming line) can be changed.

The activated line is marked with a triangle behind the channel number. By pressing the ENTER key, you

can toggle between the lines.

!

18

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

10.2.2 Keys

The transmitter type TR has four operating keys:

and - increases or decreases the channel no. in operating mode

- increases or decreases the digits in the programming mode

↵- moves to the next input position (the corresponding digit blinks)

- accepts the current channel contents when

shifting to the very right and leaving the display

- toggles between the lower and the upper line (only in operating mode)

P - changes from the operating to the programming mode

- in programming mode: places the comma next to the entry position (blinking digit)

- deletes error message on channel "]"

- pressing this key for a couple of seconds resets the entry position (blinking digit)

10.2.3 Operating mode

In the operating mode, the measured values and constants displayed cannot be changed. When the

transmitter type TR is switched on,

- a display test is carried out

- the operating mode is activated automatically

- the current measured variable, density (kg/m³) or concentration (%),

depending on the operating mode, is displayed in the upper line

- the current temperature (°C) is displayed in the lower line

- the upper line is activated

If a different value is to be displayed in the lower line, the lower line must be activated by pressing "↵".

Then you select the corresponding channel no. (see table in section 10.3) by pressing " " or " " . Once

the last channel number has been reached the display moves back to the first channel. Once the first

channel number has been reached, the display moves to the highest channel no.

10.2.4 Programming mode

Depending on the operating mode, in programming mode, the device parameters and the medium

constants can be programmed or modified on site. The constants can only be programmed in the lower

line. For this, the "P" key must be actuated until the first digit blinks in the display field. This digit can then

be changed with the keys " " or " ". Pressing the ↵key moves you to the next entry position

(corresponding digit blinks). To place a comma, you press the P key for a short moment. After leaving the

last position, the channel is accepted with the current contents. By pressing the P key for approx. 3

seconds the current input position can be reset to the previous position.

- while programming the K0and KX0 values all measured and

calculated values are frozen;

the upper display line will not be activated.

- if the "programming" function has been initiated but not terminated,

it will be terminated automatically after approx. 2 minutes;

the old value will be restored.

- channel no. "]“ is used for displaying error codes;

these can be deleted by pressing the "P" key

(see error code table in section 13.2.1).

19

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

10.2.5 Operating mode

By selecting the operating mode (channel E) you define the calculation method according to which the

measured variable is to be acquired and the output signal is to be represented.

By selecting the operating mode you define

- the assignment of the primary HARTvariables (current output signal)

- the measured value in "channel 4".

The following operating modes are available:

- density in kg/m³ (for equation 1, 2 and 3, see section 11)

(there is a choice between operating density or reference density, depending on the

αvalue)

- concentration in % (for equation 1, 2, 4 and 5, see section

The analog output signal (4 to 20 mA) can be freely assigned to the desired measuring range (lower

range value: channel 5, upper range value: channel 6) within the meter range.

The minimum measuring range span should not be below a density range of 5 kg/m³.

10.2.6 Short description of the control unit

Key

P ↵

Channel selection

Operating mode Activate

programming mode Increase channel no. Decrease channel no.

Toggle between lines

Prolonged pressing:

Display test

Set parameters

Programming mode

Set decimal point

Prolonged pressing

resets entry position

Increase digit Decrease digit

Move to next digit

or

accept value

Exit programming

mode

Select channel Toggles between the lines ↵

Programming

(activate programming

level

P Accept value ↵

P

Place comma

Select position

↵

Set digit

Programming line

Digit blinks in P mode

Digit

2-line displa

y

?

7 6543 210

Channel Display

20

We reserve all rights of ownership and exploitation in respect of these

documents, including industrial property rights. These documents may only

be used with our express consent in writing, and only to the extent permitted

in any such consent. The documents may not be duplicated or made

available to third parties. In case of violation of the aforementioned

provisions, we reserve all rights.

10.3 Channel overview / channel assignment

Chann

el

Operating mode Unit Limiting values

no. Density (ρ) Concentration (%) min. max.

E 0 1 - 0 1 (2)

Operating density

(α=0)

0 Reference density

(α≠0)

Reference density kg/m³ 0 10000

1

Current output

Proportional to

density

Current output

Proportional to

concentration

mA 4 20

2 Oscillating frequency Oscillating frequency Hz 0.5 10000

3 Temperature Temperature °C -50 +210

Display parameters

4

Density a percentag

of measuring range

span

Concentration (C) %, # 0 10000

5 ρmin Cmin kg/m³ or # 0.0 10000

Measur

ing

range

6 ρmax Cmax kg/m³ or # 0.1 10000

7 K0kg/m³ -100000 100000

8 K1kg/m³ • s -100000 100000

9 K2kg/m³ • s2-100000 100000

A KT0 kg/m³ • k -10 10

b KT1 10-6 • k-1 -100 0

C dedicated - - -

Transducer constants

F tKal °C -50 +210

H 20mA corr. mA 18 22

I Pt corr. (offset) - 0.5 1.5

J Pt corr. (slope) - 0.5 1.5

System

constants

L 4mA-Korr mA 3.8 4.2

n - KC0 kg/m³ • k 999999.9 999999.9

o - KC1 k

-1 999999.9 999999.9

P - KX0 # 999999.9 999999.9

r - KX1 # / kg/m³ 999999.9 999999.9

U - KX2 10-5 • # / ( )2999999.9 999999.9

d tRef °C -50 +210

Medium constants

Y α- kg/m³ • k -10 10

] Errors (see section 13.2.1)

Table of contents

Popular Plumbing Product manuals by other brands

ZURN

ZURN Aquaflush Z6000 Installation, operation, maintenance and parts manual

Axor

Axor 34133XX1 34213XX1 installation instructions

Elkay

Elkay Crosstown Farmhouse Series installation instructions

Moen

Moen 3865 Series installation guide

LIVARNO home

LIVARNO home 402407-2204 Installation & operating instructions

enware

enware LEVA Series Installation and maintenance instructions

Hans Grohe

Hans Grohe Sanibel 5001 A18 14736000 Instructions for use/assembly instructions

Chicago Faucets

Chicago Faucets HYTRONIC user guide

Clou

Clou Xo CL/06.04003.29 installation instructions

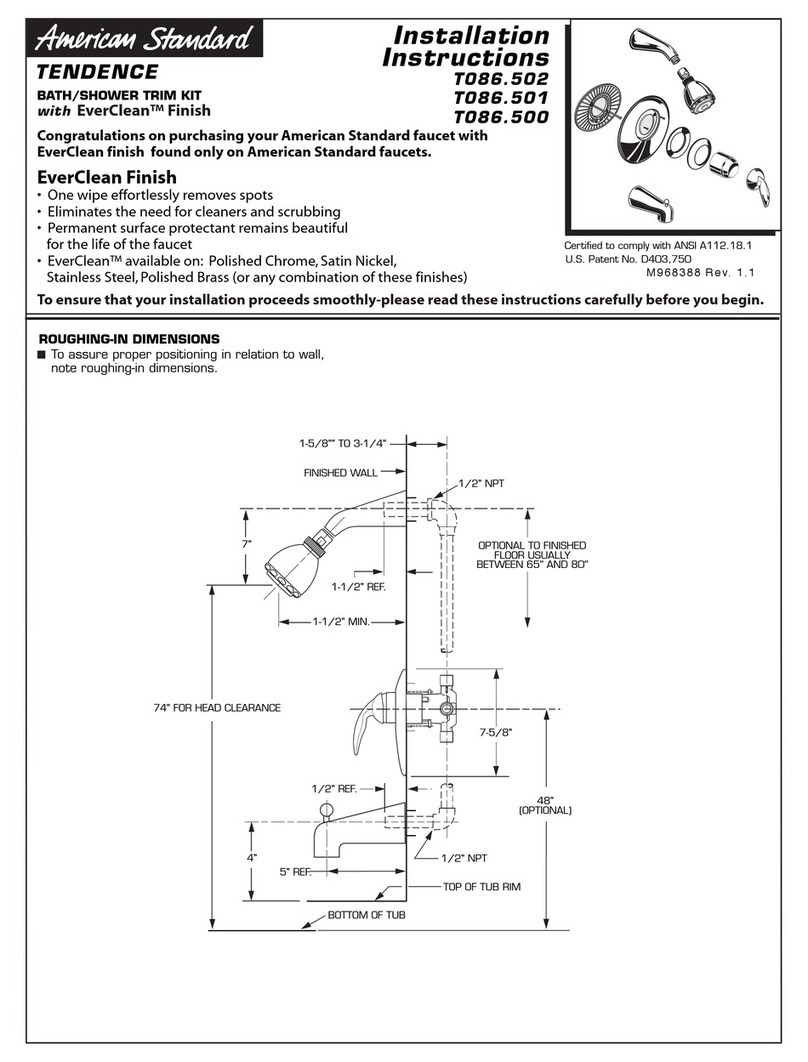

American Standard

American Standard Tendence T086.500 installation instructions

Omni cubed

Omni cubed SINK HOLE SAVER manual

Kohler

Kohler K-352 installation guide