EN

2

www.bora.com

4.10 Connecting external switch contacts ...............................19

– Preparing PKAS3/PKAS3AB ............................................. 20

– Preparing the control unit on PKA3/PKA3AB ................... 20

– Preparing connection cables for external switching

equipment......................................................................... 20

– Installing the external switch device.................................. 21

4.11 Establishing communication and power connection......22

4.11.1 Connecting the control knobs.............................................22

– Connecting the control knobs to the cooktop extractor ... 22

4.11.2 Ports on cooktop extractor system PKAS3/PKAS3AB.......23

– Connecting an additional fan ............................................ 23

4.11.3 Connecting cooktop extractor PKA3/PKA3AB...................23

– Connecting the control unit and fan to the

cooktop extractor.............................................................. 23

– Removing the power supply cable..................................... 23

– Connecting an additional fan ............................................ 24

4.11.4 Establishing contact between the cooktop extractor

and cooktops .......................................................................24

4.11.5 Connecting the power supply..............................................24

– Connecting the cooktop extractor to the power supply .... 25

4.12 Basic configuration ............................................................25

4.13 Initial operation ...................................................................25

4.14 Function test........................................................................25

4.15 Sealing the appliances .......................................................25

4.16 Handover to user ................................................................25

5 Decommissioning, disassembly and

disposal 26

5.1 Decommissioning ...............................................................26

5.2 Disassembly ........................................................................26

5.3 Environmentally-friendly disposal .....................................26

6 Notes 27

1 General information 3

1.1 Liability................................................................................... 3

1.2 Validity of the operating and installation instructions...... 3

1.3 Product conformity............................................................... 3

1.4 Data protection ..................................................................... 3

1.5 Presentation of information................................................. 3

2 Safety 4

2.1 Use as intended ....................................................................4

2.2 General safety instructions.................................................. 4

2.3 Safety instructions for installation...................................... 5

2.4 Safety instructions –

repairs, servicing and spare parts

... 6

2.5 Safety instructions – disassembly and disposal............... 6

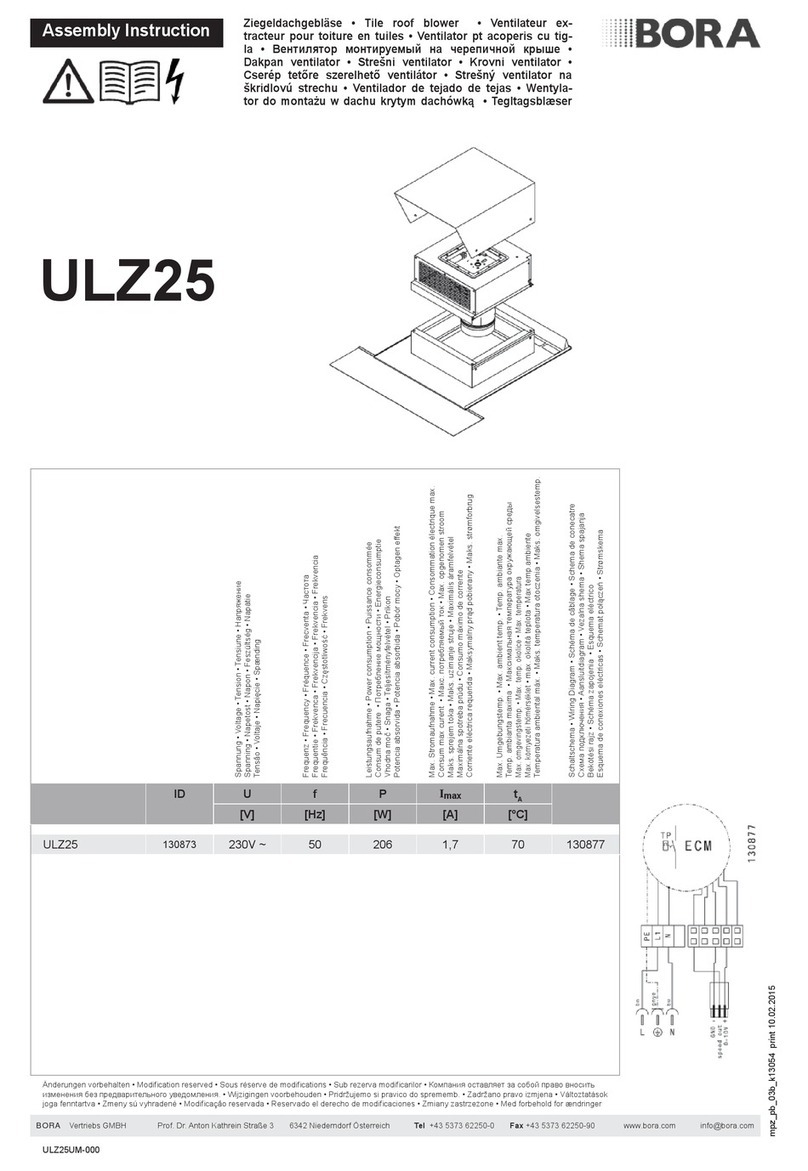

3 Technical data 7

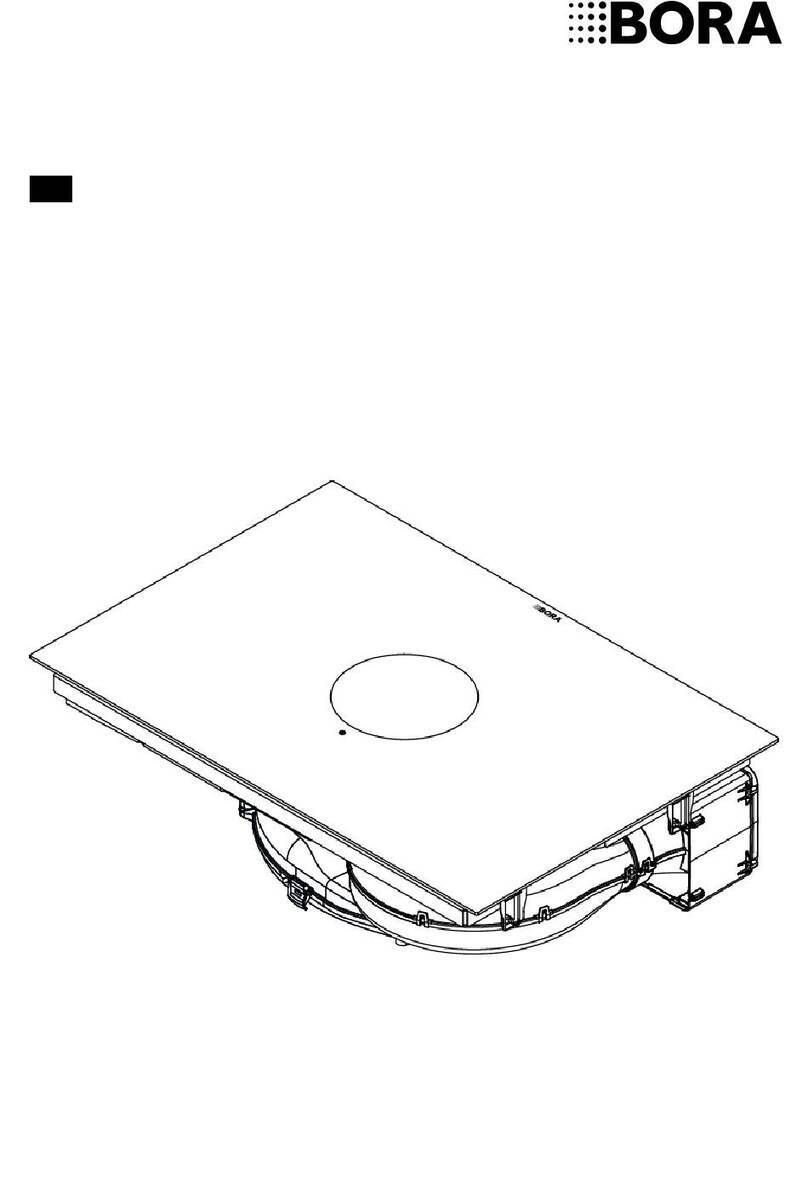

3.1 BORA Pro cooktop extractor PKA3/PKA3AB .................... 7

3.2 BORA Pro cooktop extractor system with integrated fan

PKAS3/PKAS3AB..................................................................8

3.3 BORA Professional 3.0 control knob dimensions.............. 8

4 Installation 9

4.1 General installation instructions ........................................ 9

4.1.1 Operating the cooktop extractor with a fireplace that

depends on the air in the room............................................. 9

4.2 Checking the scope of delivery ........................................... 9

– Scope of delivery of PKA3/PKA3AB ................................. 10

– Scope of delivery of PKAS3/PKAS3AB............................. 10

4.3 Tools and aids......................................................................10

4.4 Assembly instructions........................................................10

4.4.1 Safety clearances.................................................................10

4.4.2 Minimum installation dimensions (standard set-up)...........10

4.4.3 Worktop and kitchen units ..................................................11

4.4.4 Recirculation when using the cooktop extractor

as a recirculation system.....................................................11

4.5 Cut-out dimensions.............................................................11

4.5.1 Flush installation..................................................................12

4.5.2 Surface mounting ................................................................12

4.6

Installing the control knob in the floor unit front panel

....13

4.6.1 Cooktop extractor bore holes..............................................13

4.6.2 Example bore holes .............................................................13

4.6.3 Fitting the control knob .......................................................13

4.7 Planning variations for PKA3/PKA3AB.............................14

4.7.1 Airflow straight to the side ..................................................14

4.7.2 Airflow to the left (installation rotated by 180°).................15

– Airflow to the left with the curved duct piece ................... 15

4.7.3 Rotating the cover frame by 180° ......................................15

4.8 Installing the cooktop extractor........................................16

4.8.1 Fitting the cooktop extractor...............................................16

4.8.2 Securing the cooktop extractor...........................................16

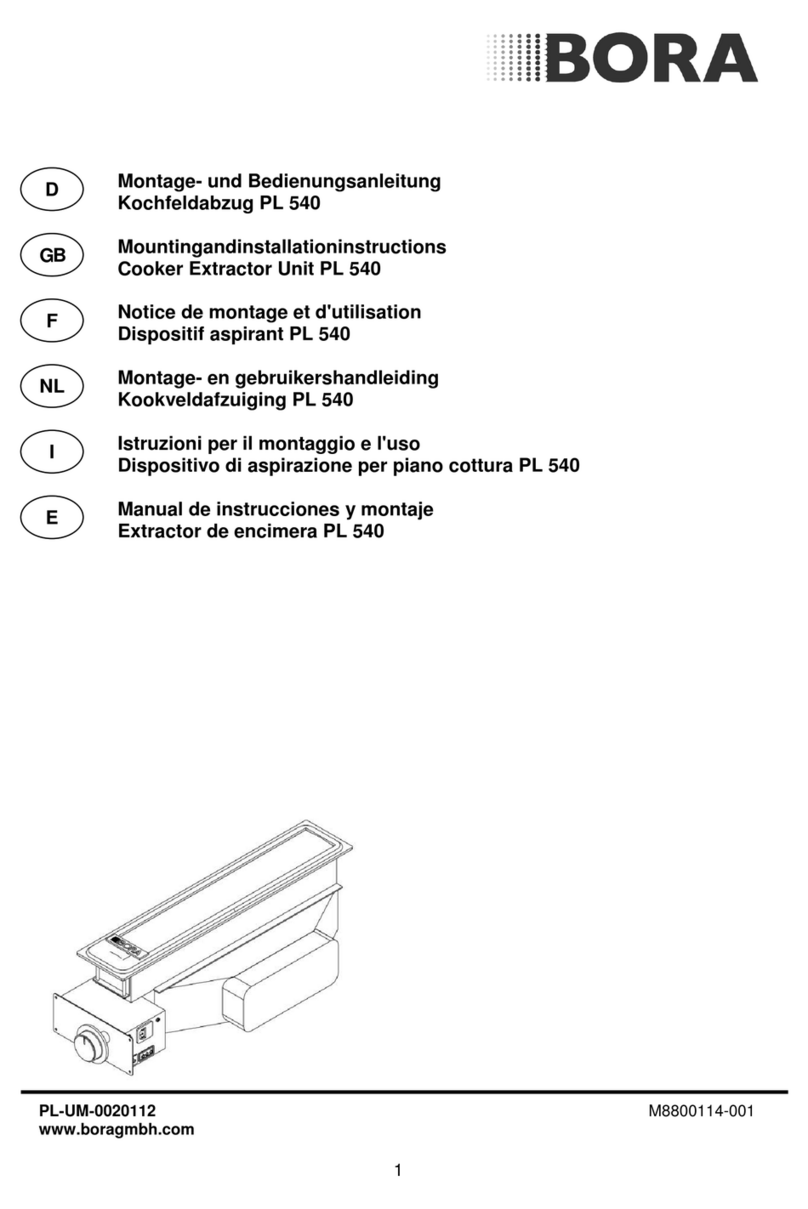

4.9 Installing the duct system..................................................17

4.9.1 Duct connection dimensions...............................................17

4.9.2 Preparing for installation .....................................................18

4.9.3 Connecting the duct system to the appliance....................18

4.9.4 Standard set-up for PKA3/PKA3AB....................................19

4.9.5 Installing the additional fan .................................................19

Table of Contents