Borg & Overstrom B6 User manual

Borg & OverströmGB01

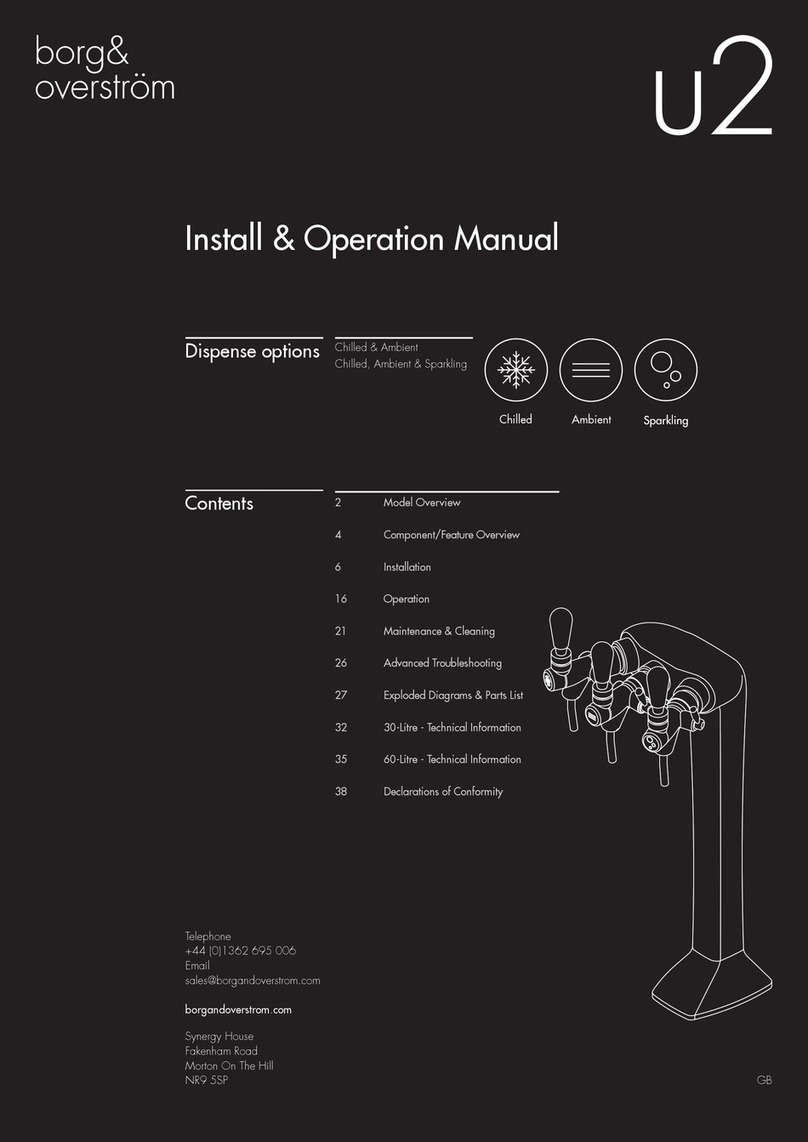

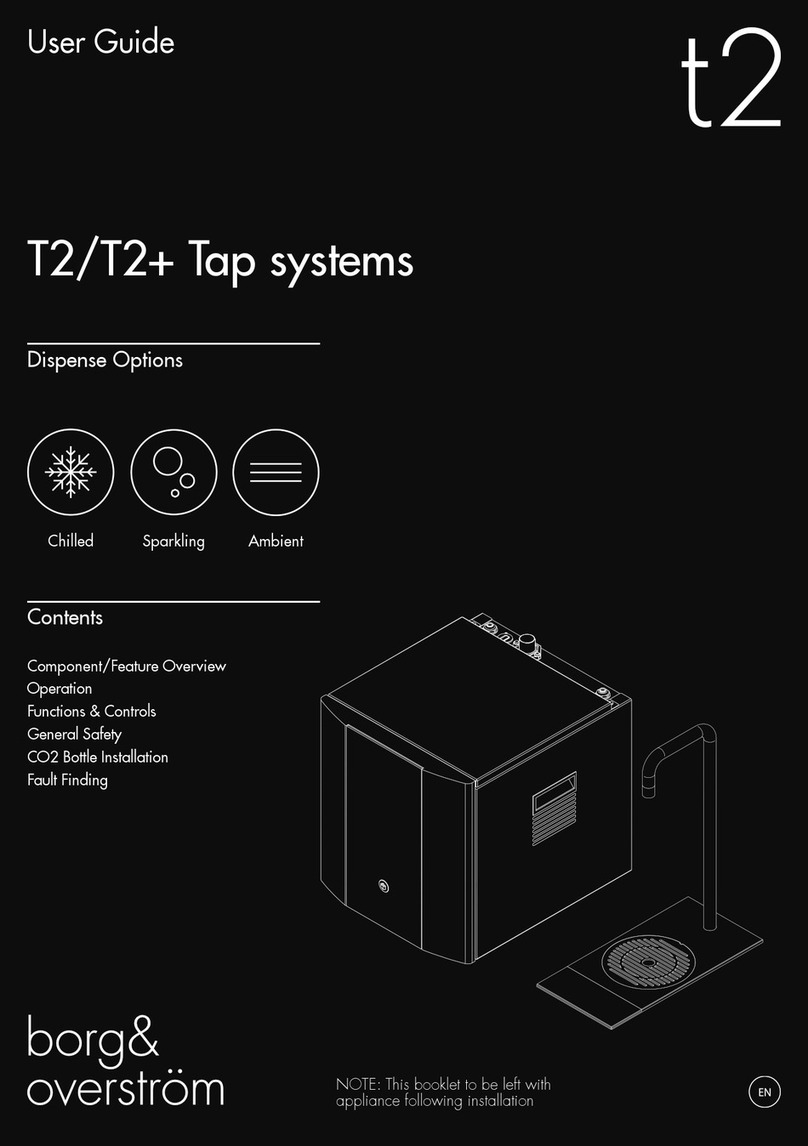

Dispense Options

Contents

NOTE: This booklet to be left with

appliance following installation

Component/Feature Overview

Operation

Functions & Controls

General Safety

CO2 Bottle Installation

Fault Finding

User Guide

B6

Chilled Sparkling Ambient Hot

e

c

o

bo

r

g

&

ov

e

rst

röm

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or instruction

concerning use of the appliance in a safe way and understand the hazards

involved. Children shall not play with the appliance. Cleaning and user

maintenance shall not be made by children without supervision.

The unit should be isolated from the electricity supply before removal of any covers. Great care must be employed

when working with high pressure carbon dioxide, and in no cases should the maximum operating pressure of

0.4MPa (4 bar) be exceeded.

- The appliance is not suitable for installation in an area where a water jet could be used.

- The appliance has to be placed in a horizontal position.

WARNING: Keep ventilation openings in the appliance enclosure or in the built-in structure clear of obstruction.

WARNING: When positioning the appliance, ensure the supply cord is not trapped or damaged.

WARNING: Do not locate multiple portable socket-outlets or portable power supplies at the rear of the appliance.

This appliance is intended to be used in household and similar applications such as:-

-Staffkitchenareasinshops,ofcesandotherworkingenvironments

- Farm houses and by clients in hotels, motels and other residential type environments

- Bed and breakfast type environments

- Catering and similar non-retail applications

A-weighted emission sound pressure level is below 70 dB(A)

Safety

R290 is a refrigerant-grade propane used on a wide range of commercial refrigeration

and air conditioning units. A highly pure propane, it has a low environmental impact

and nominal global warming potential (GWP), meaning it possesses no qualities that

can destroy the ozone layer. R290 also is the preferred hydrocarbon alternative of the

EnvironmentalProtectionAgency(EPA),substitutingmoreharmfuluorocarbonrefrigerants

like R22, R134a, R404a and R502.

Units with R290 can only be maintained and repaired by authorized technicians who are

properlytrainedandcertied.

Component/Feature Overview

Contents:

1 no B6 Unit

1 no Power Cord Set

1 no Warranty Card

1 no Co2 Regulator with Gauge & Connection tube*

Please Note:

Mains Installation Kits & Filters are

supplied as extra items according to

individual ordering requirement.

B6

Major Components

Power Connection

*Sparkling versions only

ec

o

bo

r

g&ov

e

r

st

röm

Unit Lid

Control Panel

Drip Tray

Dispense Outlet

Side Panel

Handles

Water Inlet

On/Off Switch

CO2 Inlet*

Installation Requirements

• Identify a suitable location for the B6 unit. It should be positioned within 2.0m of suitable services connections.

Allow 15cm of free space at the rear for ventilation.

• The B6 unit must be installed in accordance with the relevant requirements of:

• The appropriate building regulations by application of either The Building Regulations (England

and Wales), The Building Regulations (Scotland) or The Building Regulations (Northern Ireland). In

territories other than those listed the local regulations in force must be complied with.

• The Water Supply (Water Fittings) Regulations (England, Wales and Northern Ireland) or The Water

Bye-laws in Scotland.

• The unit must not be installed where it is liable to freeze. If the unit is thought to be frozen it must not be

switched on. It should be allowed to thaw and must then be thoroughly inspected to ensure it is undamaged.

• Water: Mains potable water – internally regulated to 0.2MPa (2 bar)

• Minimum to maximum ambient room operating temperature: 5°C - 35°C

• CO2: Food Grade CO2 to be supplied

• Min mains pressure 0.05MPa (0.5 bar) dynamic

• Electricity: 10A supply – Earth Leakage Protected

CO2 Bottle Installation - Sparkling Versions Only

2

13

OFF 58 PSI

4

Unpack CO2 Regulator and t

elbow tting to spigot outlet. Attach the regulator to the

CO2 bottle, ensuring the small

pressure relief vent in the stem

is facing away from you or

anyone else. Ensure the regulator

is closed. Hand tighten securely.

Connect the assembled CO2

bottle and regulator to the CO2

inlet using a ¼” pipe.

Stand the cylinder in a suitable

place. We recommend between

3.5 - 4 bar (58 PSI) (max). Do

not exceed 4 bar pressure.

The hot versions will be in

commissioning mode which

stops the unit from running only

allowing dispensing. Dispense

from unit to ensure tank is full.

e

c

o

bo

r

g

&

ove

r

st

röm

Hot tank commissioning mode - Hot Versions Only

Press the lock symbol for 10

seconds to take the unit out

of commissioning mode and

the LED’s and display will

change.

e

c

o

bo

r

g&ov

e

r

s

t

röm

secs

10

7

Connect the unit to the

electricity supply and

ensure unit is switched on.

Allow the machine to stand

for 15 minutes for the initial

chilling and heating process to

complete.

8

eco

borg&overström

mins

10

1234

Operation & Connections

eco !

‘eco’ Mode Chilled Dispense Warning Symbol

Ambient Dispense

Sparkling Dispense

Hot Unlock Button Hot Dispense

Dispensing from unit:

Press and hold dispense icon and release to nish dispense.

For hot press unlock then hold hot button.

Chilled icon pulsing – Unit is chilling down

Hot tank icon pulsing – Hot tank heating up

‘eco’ Mode:

‘eco’ mode symbol illuminates when unit is in ‘eco’ mode, to awaken unit press and hold any dispense icon.

The B6 will activate ‘eco’ mode in the below instances

Dispense inactivity

Low room light level

To turn on/off eco mode tap the chilled icon 7 times and hold on the 7th. 2 beeps will indicate Eco is on and

1 beep will mean Eco is off.

Warning Symbol

‘Warning triangle’ symbol will illuminate and ash upon a fault. The number of ashes can relate to a particular

fault.

Advanced functions

For technician or operating service provider use only.

Hold ‘Hot Unlock Icon’ for 10 seconds for decommissioning and commissioning

Tap Control Panel

Sanitisation Guide

Please note that this sanitisation uid contains an active caustic/alkaline agent.

Always use responsibly and with care remembering that due to it’s alkaline nature

unnecessary concentrated/prolonged contact with materials,

including metals, can cause damage.

Always rinse all contact surfaces after with clean water.

Avoid skin contact and wear protective gloves when handling sanitisation uids.

In the event of any skin contact, ush immediately with clean, cold water.

5 sec

2Ltr

5 sec

1

11

21

31

4

1

51

61

71

8

1

91

10 1

11 1

12

1

13 1

14 1

15 1

16

1

17 1

18 1

19 1

20

Sanitisation Guide

To be completed by a technician or service provider

Waste Electrical Products:

- The WEEE symbol indicates that this item contains electronic components which must be

collected and disposed of separately.

- Never dispose of electrical waste in general municipal waste. Collect and dispose of

such waste separately.

- Make use of the return and collection systems available to you, or your local recycling

programme. Contact your local authority or place of purchase to nd out what schemes

are available.

- Electrical and electronic equipment contains hazardous substances which, when disposed

of incorrectly, may leak into the ground. This can contribute to soil and water pollution

which is hazardous to human health; and endangers wildlife.

- It is essential that consumers look to re-use or recycle electrical or electronic waste to avoid

it going to landll sites or incineration without treatment.

Basic Troubleshooting

Problem/Report Possible Cause Suggested Action

No water dispensing Water supply turned off Check that power supply, and all taps/ valves/ lters

on the incoming water supply are tted and are turned

on

Leak detection in unit triggered Disconnect the power and water supply, check for

leaks.

Faulty water pressure regulator, or other failure Contact your distributor

Hot tank dry start Check on heater connections and water supply

Waste kit full Empty level sensor tank

No/low sparkling water No/incorrect CO2 pressure Check CO2 bottle, regulator and non-return valve.

Replace as necessary

Carbonator tank not lling Contact your distributor

Warm drinks Insufcient cooling air ow through the fridge Contact your distributor

Faulty compressor, or other failure

Water lying on top edge of

lower door panel and/or bottom of

cabinet.

Overowing drip tray waste container Empty waste container and check drainpipe is not

blocked

Water lying in bottom of machine Leak in pipe work and/ or lter Contact your distributor

Bleeping noise Level sensor tted and tank full Empty level sensor tank

Not all symbols showing Unit is in heater commissioning mode Check water is dispensing then hold lock symbol

10secs

Refer to instruction manual for full fault codes and diagnostics.

© Copyright Borg & Overström. This guide is printed by Borg & Overström

and shall not be reproduced or copied in anyway.

Customer services:

aftersales@borgandoverstrom.com

call +44 1362 695 006

For full distributor

service manual visit:

www.borgandoverstrom.com/manual/b6

General Safety

- Always place the dispenser in its vertical position,

on a surface which can capably support its weight.

- During use this machine must remain in

its upright position.

- Adequate ventilation must be allowed.15cm clearance

behind the unit minimum.

- Keep the machine away from sunlight, heat and moisture.

- The environment where this machine is installed must be

free of dust and corrosive/explosive gases.

15cm

Ref: 702116

Version: 02

Table of contents

Other Borg & Overstrom Dispenser manuals

Borg & Overstrom

Borg & Overstrom U2 User manual

Borg & Overstrom

Borg & Overstrom u2 40L User manual

Borg & Overstrom

Borg & Overstrom T2 User manual

Borg & Overstrom

Borg & Overstrom T2 User manual

Borg & Overstrom

Borg & Overstrom b5 User manual

Borg & Overstrom

Borg & Overstrom C2 User manual

Borg & Overstrom

Borg & Overstrom u1 User manual

Borg & Overstrom

Borg & Overstrom T1 Tap systems User manual

Borg & Overstrom

Borg & Overstrom T1 User manual