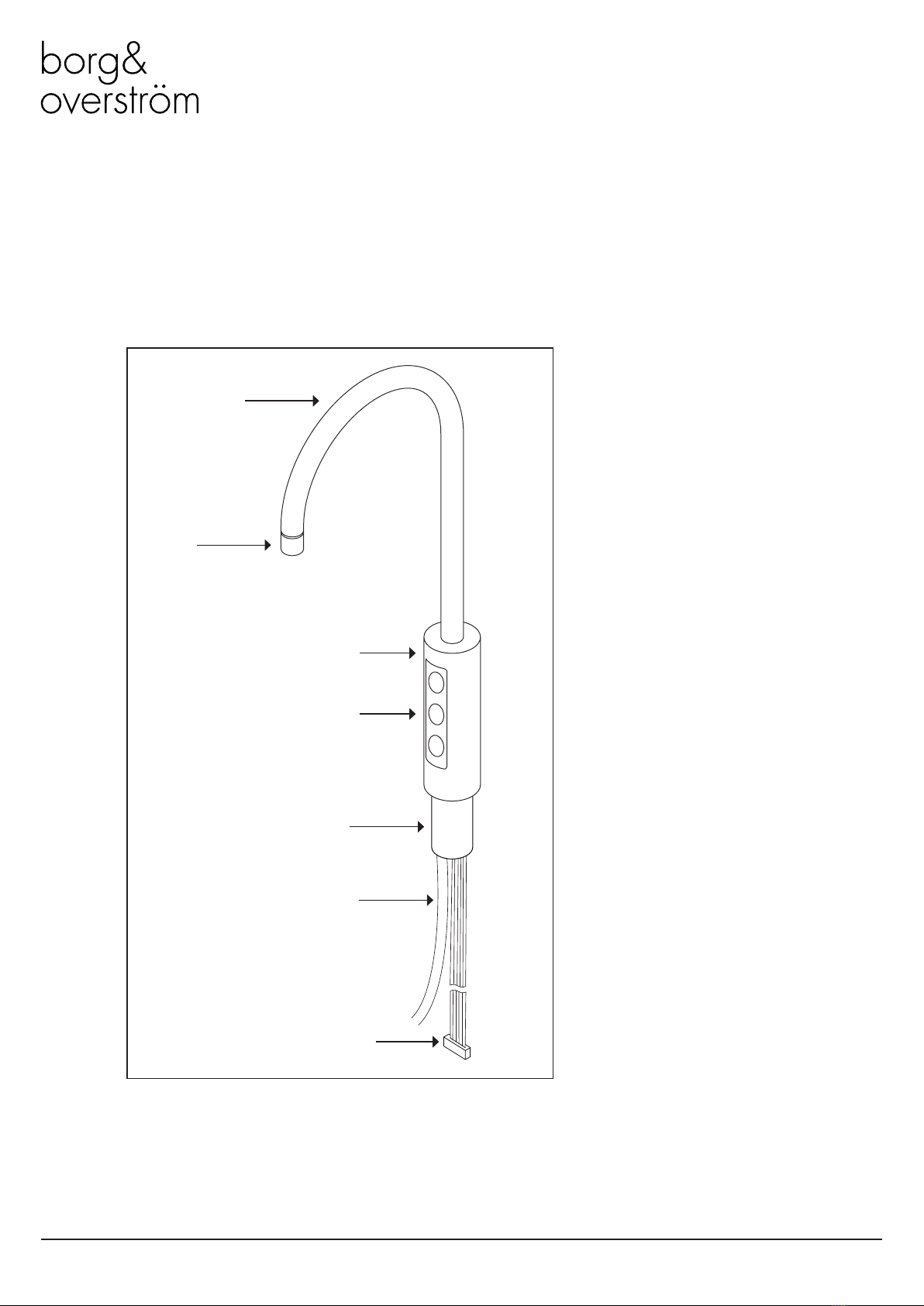

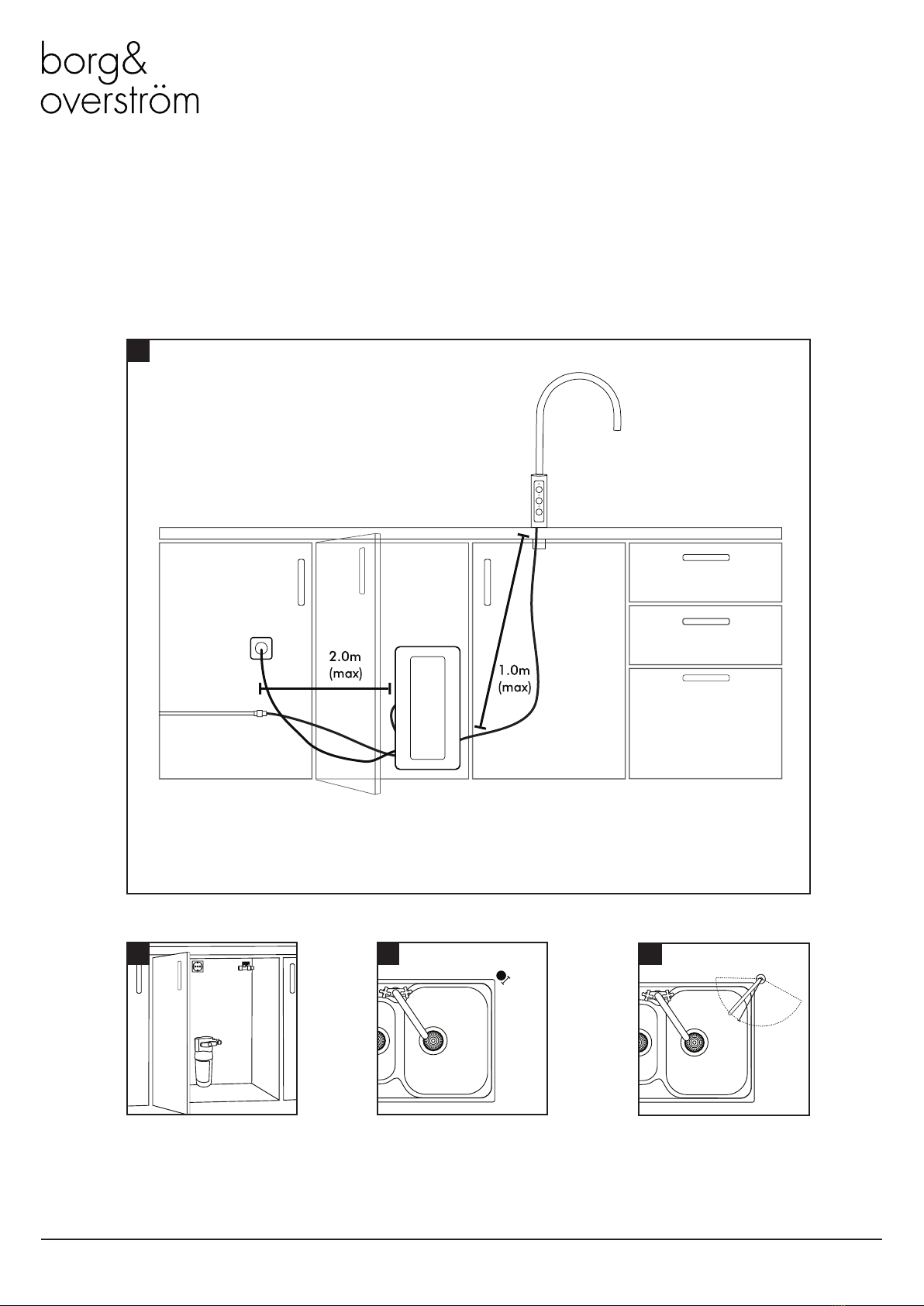

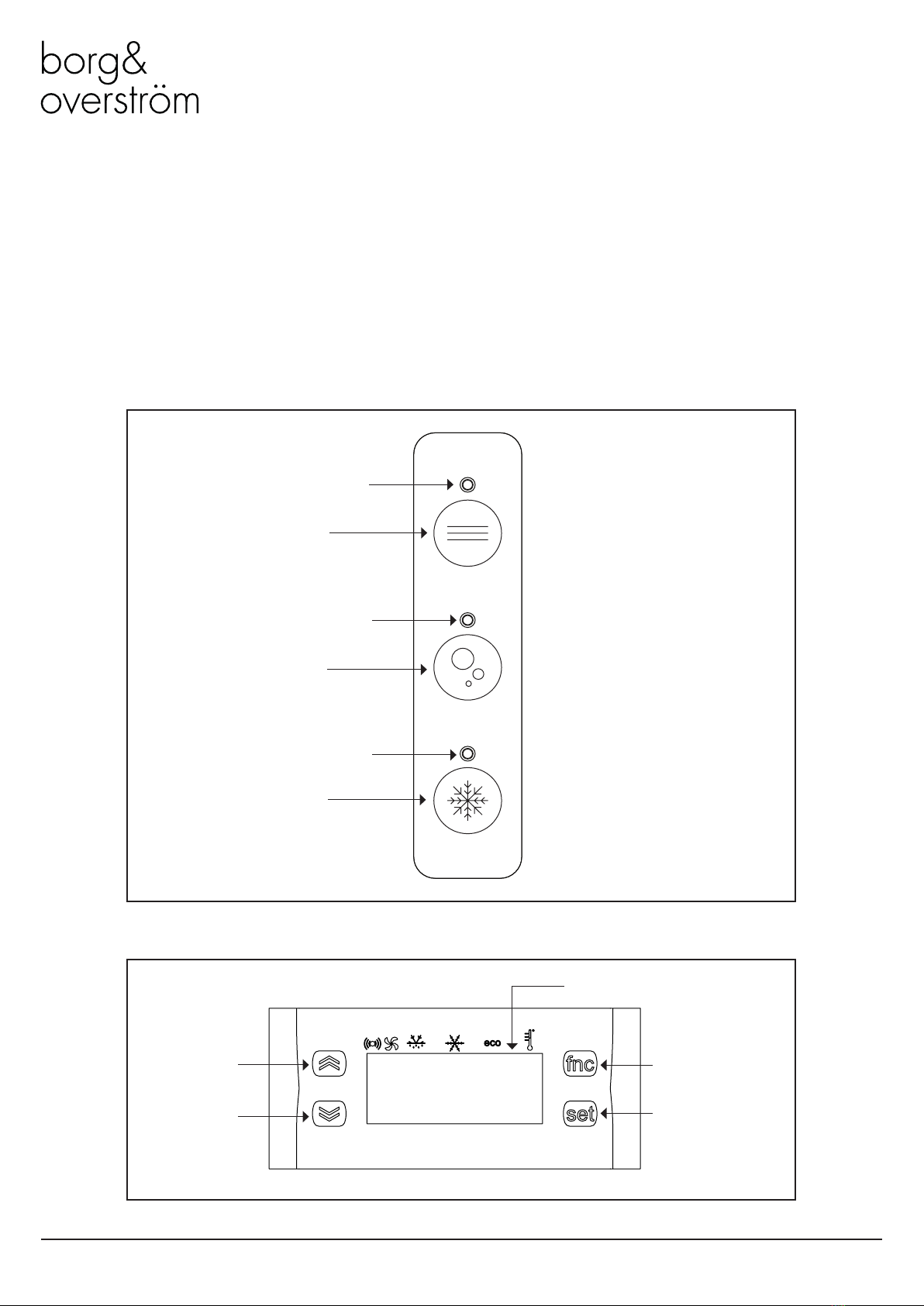

Borg & Overstrom u1 User manual

Other manuals for u1

5

This manual suits for next models

1

Table of contents

Other Borg & Overstrom Dispenser manuals

Borg & Overstrom

Borg & Overstrom U2 User manual

Borg & Overstrom

Borg & Overstrom u2 40L User manual

Borg & Overstrom

Borg & Overstrom b5 User manual

Borg & Overstrom

Borg & Overstrom B6 User manual

Borg & Overstrom

Borg & Overstrom T1 User manual

Borg & Overstrom

Borg & Overstrom C2 User manual

Borg & Overstrom

Borg & Overstrom T1 Tap systems User manual

Borg & Overstrom

Borg & Overstrom T2 User manual

Borg & Overstrom

Borg & Overstrom T2 User manual

Popular Dispenser manuals by other brands

SAIER

SAIER Concept PDG 2906 operating instructions

Royal Catering

Royal Catering RCCS-3.5L user manual

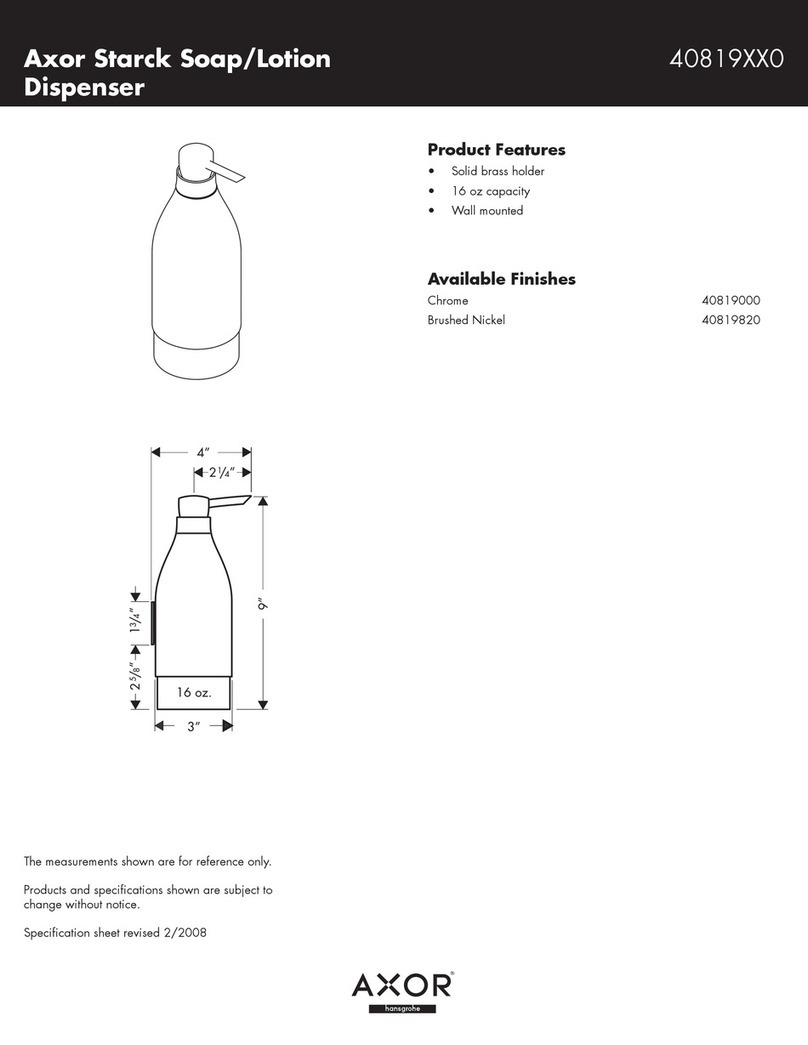

Axor

Axor Starck Soap/Lotion Dispenser 40819XX0 Specification sheet

LINDR

LINDR Green Line new CWP 100 instruction manual

Bradley

Bradley Elvari 5B1-11 Installation and maintenance guide

Orbegozo

Orbegozo DA 2000 instruction manual