Borg Warner Delco Remy 28MT Reference guide

Diagnostic

Procedures

Manual

For Starters

and Alternators

Table of Contents

I ) Introduction and Description

1–1. Introduction 1

1–7. Description 1

1–12. Electrical Fundamentals 2

II ) Diagnosis Charts

2–1. Overcharge Symptoms 8

2–2. Undercharge Symptoms 9

2–3. Milled Pinion Symptoms 10

III ) Testing

3–1. Testing Freedom Batteries 11

3–4. Testing Conventional Batteries 11

3–5. Test Procedure 12

3–7. Battery Cable Test with Single-Battery Location 12

3–10. Battery Cable Test with Dual-Battery Locations 14

3–13. Starter Solenoid Circuit Test 14

3–18. Magnetic Switch Circuit Test 16

3–21. Starter Replacement Determination 17

3–26. Alternator Wiring Test 18

3–29. Alternator Replacement Determination 19

3–33. Completion of All Tests 20

IV ) Summary

V ) Appendix

5–1. Smart IMS or SIMS Diagnostic Steps 22

5-2. Overcrank Protection (OCP) Circuit Check 23

5-3. Multi-Battery Charging with Series and Parallel Chargers 23

5-4. Group Charging on Current-Limiting or Series Chargers 24

5-5. Group Charging on Voltage-Limiting or Parallel Chargers 24

5-6. Heavy Duty Diagnostics Procedures Data 25

Section Page

delcoremy.com Page 1

1-1. INTRODUCTION

1-2. PURPOSE. This manual provides diagnostic procedures that

can be used for troubleshooting a heavy duty electrical system,

including the starting and charging systems. Some procedures

also may be used for preventative maintenance checks. These

procedures are applicable to systems using heavy duty starters

such as: Delco Remy 28MT™, 29MTTM, 31MT™, 35MTTM, 37MTTM,

38MTTM, 39MTTM, 41MTTM, 42MTTM, 50MTTM or a similar starter with

adequate battery power for the engine/starter application used.

1-3. DEFINITION OF DIAGNOSIS.

Diagnosis is

the three-part

process that begins when a problem is perceived and ends when

the equipment is confirmed as serviceable. Three questions must

be answered to assure completion:

1. What are the symptoms? This is what has been observed

(seen, heard, felt or smelled), indicating a problem.

2. What caused the symptoms? Diagnostic procedures are used

to identify the root cause of the problem.

3. How do we fix it? Usually this involves the adjustment, repair

or replacement of some part or parts.

1-4. This manual defines the procedures to determine the cause of

the symptoms. Actual adjustment, repair and replacement procedures

are provided in unit-specific service bulletins and manuals.

1-5. For educational purposes, study of this entire manual is

recommended. For diagnostic purposes, the flow charts in Section

II will reference appropriate procedures for specific symptoms.

1-6. EQUIPMENT REQUIRED. To perform the tests specified in

this manual, the following equipment is

required:

1. A variable carbon pile load tester with more than 500 amps

capacity with ammeter (and voltmeter).

2. A separate DC voltmeter, digital preferred, capable of reading

0.01 volt increments.

3. An inductive (clamp-on) ammeter for safe and accurate

current measurements.

4. A hand held or bench top type tester.

1-7. DESCRIPTION

1-8. SYSTEM. The heavy duty electrical system is comprised

of the starting and charging systems. These systems are, in

turn, comprised of batteries, the starter, the alternator, and the

interconnecting wiring and electrical and mechanical switches.

For maximum operating eciency,

all

parts of the system must be

functioning properly.

SECTION 1

Introduction and Description

FIGURE 1-1. Heavy Duty Electrical System

1. Battery

2. Starter

3. Alternator

4. Magnetic Switch

5. Push Button Switch

6. Key Switch

Page 2

1-9. BATTERIES. Batteries are perishable devices that wear out

at some point in time. With use, they deteriorate and eventually

become incapable of performing their important job. In addition,

new batteries may become discharged for various reasons.

Neither worn out nor discharged batteries can supply the power

necessary for cranking. Thus, the battery check becomes the

starting point for diagnosing electrical system problems.

1-10. SUBCIRCUITS. Because of vibration, corrosion, temperature

changes or damage, the performance of wiring, connections and

secondary components as well as the function of the starter and

alternator can deteriorate. This, in turn, can cause malfunctions

within the starting and charging systems. For the purpose of

testing, wiring and components are divided into four circuits that

must be tested. These are:

1. Cranking Circuit. This consists of the large cables that carry

the high starter current. Excessive loss here causes slow cranking

speeds, especially in cold weather. Inability to start from slow

cranking can lead to starter damage if the starter is cranked over

30 seconds. Deeply discharged or worn-out batteries also can

cause the same problem.

2. Solenoid Circuit. This consists of the wiring from the battery,

through a push button or magnetic switch, to the S terminal of

the starter solenoid, and back to the battery. Excessive loss here

can cause the solenoid to shift in and out (chatter), resulting in a

no-start condition. This can cause a damaged contact disc and

terminals of the starter solenoid. Deeply discharged batteries also

can cause this problem.

3. Magnetic Switch Circuit or IMS (when the magnetic switch is

used). This consists of the wiring from the battery, through a key

switch and/or start button, to the coil of the magnetic switch, and

back to the battery. Excessive loss here can cause a “no start”

complaint.

4. Charging Circuit. This consists of the wiring between the

alternator and the battery and back to the alternator. Excessive

loss here can cause the batteries to not charge properly. As noted

above, discharged batteries will cause other problems.

1-11. SEQUENCE OF PROCEDURES. It is important that these

procedures be followed in the exact sequence specified. Batteries,

wiring and connections should be checked and corrected to

the specifications given. If cranking problems still occur, then

connecting cables should be checked before replacing the starter

with a known good unit. Similarly, in the charging circuit, the

batteries, wiring and connections should be thoroughly checked

and corrected to the specifications given. Only then should the

alternator be checked and replaced if necessary.

1-12. ELECTRICAL FUNDAMENTALS

1-13. TERMS AND DEFINITIONS. The following are electrical terms

and definitions used in this manual:

1. Voltage. Voltage is the electrical pressure or force that causes

current or electrons to flow through a conductor. The voltage

also can be described as the dierence in electrical pressure

between two points in a circuit. This electrical force or pressure is

measured in volts.

2. Current. Electrical current is the flow or movement of electrons

in a conductor. This movement can be compared to the flow of

water through a pipe. Without pressure (voltage), the current

will not flow. Electrical flow is measured in amperes, most often

abbreviated as amps.

3. Resistance. Resistance is the opposition to current flow. For

a given electrical pressure (voltage), resistance decreases current

flow. This can be detected by voltage loss or drops in the electrical

circuit. Electrical resistance is measured in ohms.

4. Magnetic Field. When electrical current flows through a

conductor, a magnetic field is produced around the conductor.

By measuring the strength of this magnetic field, it is possible

to determine the amount of the current flow or amperage. This

principle is the basis for the function of the clamp-on or induction

type ammeter.

1-14. MEASURING VOLTAGE WITH THE VOLTMETER. The

voltmeter is used to measure electrical pressure or voltage. The

unit of measure is the volt. Voltmeters are always connected

across (in parallel with) a part of the electrical circuit (See Figures

1-6 and 1-7). The voltmeter measures the dierence in electrical

potential or pressure between the points where the voltmeter is

attached.

1-15. VOLTMETER SELECTION. Voltmeters for the purposes

described in this manual are DC instruments with a range as

follows:

1. Low scale: 0-3 volts

2. 12-volt vehicles: 0-16volts

3. 24-volt vehicles: 0-32volts

MAGNETIC FIELD

CURRENT DP-1005

delcoremy.com Page 3

NOTE

The use of digital voltmeters is highly recommended for the

following reasons:

• Digital voltmeters are generally more accurate than analog

(needle movement) instruments.

• Digital readings need no interpretation; everyone sees the

same number.

• Digital instruments are generally auto ranging; they

automatically select the proper range for the value of the

reading.

• Reversing polarity with a digital instrument will simply result

in a negative reading (minus sign) whereas with an analog

voltmeter, reversing polarity could damage the meter.

• If analog meters are not read directly facing the meter,

inaccuracies may result.

1-16. VOLTMETER USE. Figures 1-6 through 1-8 illustrate the

proper use of the voltmeter and the types of readings that can be

expected.

1. Figure 1-1 shows the voltmeter being used with no current flow

or with the starter not operating.

FIGURE 1-1. Voltmeter Readings with

No Current Flow

FIGURE 1-2. Voltmeter Readings with

Current Flow

NOTE

When the voltmeter is connected parallel to a cable (meter

leads and cable ends start and end at the same point), the meter

will measure the voltage potential at both ends of the cable.

Without current flowing, the values always will be the same and

the voltmeter will read zero.

2. Figure 1-2 shows the voltmeter being used with current flow

(starter pulling 500 amps).

NOTE

The V1 reading (See Figure 1-2) means that with 500 amps

flowing through the positive cable, there is a 1.0 volt drop in

that cable. There must be current flow in order to produce a

voltage drop. The V2 reading (See Figure 1-2) of 0.3 volt means

that with 500 amps flowing through the negative cable, there is

a 0.3 volt drop in the negative cable.

3. Figure 1-3 illustrates the digital voltmeter reading in a DC

system with both correct and incorrect polarity. Whenever the

minus sign is displayed, the meter leads must be reversed to

obtain the correct polarity.

0 V DP-1006

0 V

O V

V4

12.5V

0 V

V3

0 V

12.5 V

12.5V

V2

12.5 V

V1

0 V

0 V

12.5 V

12.5 V

DP-1007

0.3 V

0.3 V

V2

8.5 V

V1

1.0 V

7.5 V

8.5 V

V2

7.2 V

0.3 V

V1

0 V

8.5 V

7.5 V

Page 4

DIGITAL VOLTMETER

CONNECTED CORRECTLY

IN RELATIONSHIP TO

POLARITY

DIGITAL VOLTMETER

CONNECTED INCORRECTLY

IN RELATIONSHIP TO

POLARITY (VALUE CORRECT

BUT MINUS SIGN WILL SHOW

TO ALERT OPERATOR THAT

LEADS ARE REVERSED)

DP-1008

12.5

V1

-12.5

V1

FIGURE 1-3. Correct and Incorrect

Polarity Readings

1-17. MEASURING CURRENT FLOW WITH THE AMMETER. The

ammeter is used to measure current flow. The unit of measure

is the ampere or amp. Unless the induction pickup (clamp-on)

ammeter is used, the circuit must be opened and the ammeter

connected in series in order to take measurements.

1-18. AMMETER SELECTION. With but a few exceptions (See

Figure 1-10), it is desirable to make ammeter readings without

opening up the circuit and thus disturbing a circuit defect and

preventing it from being discovered. Therefore, the use of a

clamp-on induction-type ammeter is recommended for most of

the measurements described in this manual. This type is easy to

use, cannot be damaged by misconnection, and will not damage

the vehicle wiring. A clamp-on ammeter operates by measuring

the magnetic flux produced by current flow through a conductor

and translating that into amperes, which are displayed on the

meter readout.

1-19. AMMETER USE. Figures 1-4 through 1-6 illustrate the use of

various types of ammeters.

1. Figure 1-4 illustrates the use of an in-line digital ammeter.

Note that the circuit must be disconnected in order to use this

type of meter. The type of unit shown is an internal shunt and

generally used for loads of 10 amps or less. Care must be taken

to not measure current greater than the meter rating. This type

of ammeter is not recommended for most of the measurements

described in this manual. However, if this is the only type

available, be sure to follow the meter manufacturer’s instructions

for connection and use.

FIGURE 1-4. In-Line Digital Ammeter

2. Figure 1-5 shows an in-line digital ammeter used to measure an

unknown current draw. An example of this might be the result of a

parasitic load. On the 10 amp scale, the current would be too low

to be measurable. However, with the meter on the 300 mA scale,

the current draw in milliamps can be read.

FIGURE 1-5. In-Line Ammeter

3. Figure 1-6 shows a clamp-on ammeter, the most common type

of current measurement described in this manual. Zero out the

meter before using and make sure the jaws are completely closed

during use. Place the meter jaws around the cable, with the arrow

points in the direction of current flow, to measure all the current.

10A

10 AMPS OR LESS LOAD DP-1009

UNKNOWN

CURRENT

DRAW

DP-1010

delcoremy.com Page 5

CLAMP-ON

TYPE AMMETER

DP-1011

FIGURE 1-6. Clamp-On Type Ammeter

1-20. MEASURING RESISTANCE WITH THE OHMMETER. The

ohmmeter is used to measure electrical resistance. The unit of

measure is the ohm. The ohmmeter is connected across the unit

or portion of the circuit for which the resistance is to be measured.

The ohmmeter has its own power source, usually a small battery,

which causes current to flow through the circuit to be measured.

Since the meter power source (battery) voltage is known, the

current is inversely proportional to the resistance of the circuit.

The meter automatically computes and reads out the resistance:

E (voltage) divided by I (current) equals R (resistance).

1-21. OHMMETER SELECTION. As with voltmeters and ammeters,

both analog (needle) and digital ohmmeters are available. Digital

ohmmeters are preferred for the same reasons as the others.

Additionally, most digital ohmmeters have a diode scale which can

be used to test diodes and transistors.

1-22. OHMMETER USE. Figures 1-7 through 1-9 illustrate some

typical uses of the ohmmeter.

CAUTION

Typical heavy duty electrical system voltage (12 or 24-volts)

could produce a current flow through the ohmmeter that could

damage the meter. Never connect an ohmmeter to a circuit that

is under voltage. Always disconnect the battery ground cable

before using the ohmmeter.

1-23. As shown in Figures 1-7 and 1-8, the ohmmeter also is

useful as a continuity meter. An infinite ohmmeter reading (See

Figure 1-7) indicates an open circuit (no continuity). A very low

(approaching zero) reading (See Figure 1-8) indicates continuity.

Figure 1-9 illustrates some digital ohmmeter applications.

FIGURE 1-7. Analog Ohmmeter Showing

Open Circuit

NOTE

Most digital meters have a diode scale ( ) which must be

used to check diodes or transistors rather than the ohm scale.

1-24. APPLYING AN ELECTRICAL LOAD WITH A CARBON PILE.

(See Figure 1-10) The carbon pile is a variable resistor designed

to carry high current. A carbon pile, along with a voltmeter and

ammeter, is normally an integral part of a modern battery tester.

In addition to load testing batteries, carbon piles are used to test

starter and alternator circuits.

FIGURE 1-8. Analog Ohmmeter Showing

Continuity

TOUCHING

GROUND

OHMMETER

OPEN

OHMETER

DP-1012

TRUCK

FRAME

DP-1013

Page 6

EXAMPLES

DP-1014

.4502.3

0.00

COIL DIODE

DIGITALDIGITAL

OL

FIGURE 1-9. Digital Ohmmeter

CAUTION

On 24-volt systems, use only a carbon pile specifically designed

for 24-volt use. A 12-volt carbon pile could be damaged if used

in a 24-volt circuit.

1-25. THE BASIC HEAVY-DUTY ELECTRICAL SYSTEM. Today’s

basic heavy duty electrical system (See Figure 1-1) consists

of batteries (usually three or four, but up to eight connected),

a starter, an alternator, a magnetic switch, an ignition switch,

a push-button switch, and the required wiring. The batteries

provide the high current required by the starter. The magnetic

switch controls the battery current to the starter solenoid. The

ignition and push-button switches activate the magnetic switch,

which in turn energizes the starter. If all functions work properly,

the engine will crank.

1-26. The mechanical energy of the running engine provides the

power for the alternator. The alternator creates the electrical

energy needed to recharge the batteries and power the vehicle’s

electrical accessories and loads.

DP-1015

FIGURE 1-10. Carbon Pile

1-27. How well the electrical system components are matched

will determine in a large part how eectively and eciently the

system will operate. Another important factor in system design is

that system wiring must be adequate to carry the current required

by each circuit.

1-28. HEAVY DUTY SYSTEM BATTERIES. The battery, or batteries,

in the heavy duty electrical system are devices for storing energy.

They convert chemical energy into the electrical energy needed

to operate the starter. With the engine running, the alternator

supplies electrical energy to the batteries, which they convert into

chemical energy and store for later use.

delcoremy.com Page 7

There are three types of lead acid batteries used in commercial

vehicle applications today: the maintenance-free flooded

electrolyte battery, the AGM battery, and the Thin Plate Pure Lead

(TPPL) AGM battery. Unlike maintenance-free, flooded, lead acid

batteries that have liquid electrolyte, an AGM battery contains

a glass mat separator made of fiberglass that is placed between

each plate to absorb the electrolyte.

Fleets should prevent batteries from becoming deeply

discharged—dropping to less than 10 volts due to extended

storage with vehicle support loads. Also, trying to start trucks

with a low state of charge or weak capacity batteries can cause

high amperages and low voltages. This can overheat the starter

motor and damage battery cables.

A voltmeter on the battery terminals will indicate the battery’s

State of Charge (SOC).

State of Charge Flooded

Battery

AGM

Battery

TPPL AGM

Battery

100% 12.70+ 12.80+ 12.84+

75% 12.40 12.60 12.50

50% 12.20 12.30 12.20

25% 12.00 12.00 11.90

0% 11.80 11.80 11.50

Page 8

PRELIMINARY DIAGNOSIS FLOW CHART

2-1. OVERCHARGE SYMPTOMS

• High voltmeter readings

• Battery smells bad

• Battery spews acid or smells

• Bright or burned out lights

INTERNAL VOLTMETER

REPLACE ALTERNATOR

RUN ENGINE APPROX 2000RPM

CHECK VOLTS AT ALTERNATOR

EXTERNAL REGULATOR

USE REG. SVC. BULLETIN

TO ISOLATE DEFECT

VERIFY COMPLAINT

REPAIR VOLTMETER

RETEST WITH COOL,

CHARGED BATTERIES

REPLACE DEFECTIVE

BATTERY

COMPLETE

CHECK DASH

VOLTMETER

CHECK BATTERY

TEMPERATURE

TEST BATTERIES

(PAGE 3-1)

COMPLETE

119˚F OR

LESS

120˚F OR MORE

DEFECTIVE

LESS

THAN 15.5 V

DEFECTIVE

OK

OK

MORE

THAN 15.5 V

SECTION II

Diagnosis Flow Charts

delcoremy.com Page 9

PRELIMINARY DIAGNOSIS FLOW CHART

2-2. UNDERCHARGE SYMPTOMS

• Slow or no cranking

• Low voltmeter reading

• Dim lights/slow turn signal flashers

START VEHICLE

CHECK ALTERNATOR

VOLTAGE & OUTPUT

(PAGE 19)

TIGHTEN BELT TO

MANUFACTURER

TENSION SPECS

CHECK STARTER

SOLENOID CIRCUIT

(PAGE 14)

REPAIR WIRING

CIRCUIT - VERIFY

REPAIR

CHECK DRIVE BELT

VERIFY COMPLAINT

TEST BATTERIES

(PAGE 11)

CHECK CRANKING

CIRCUIT

(PAGE 12)

REPAIR AND VERIFY

REPAIR

SEE STARTER

REPLACEMENT

DETERMINATION

(PAGE 17)

CHECK PULLEYS FOR

LOCKED BEARINGS

REPAIR DEFECTIVE

COMPONENT

REPLACE BELT

CHARGE BATTERIES

CRANK ENGINE

CHECK ALTERNATOR

VOLTAGE & OUTPUT

(PAGE 19)

SLOW

OK

OK

OK

LOCKED

DEFECTIVE

OK

OK

OK

DEFECTIVE

OK

OK BUT

DISCHARGED

MISSING

LOOSE

Page 10

PRELIMINARY DIAGNOSIS FLOW CHART

2-3. MILLED PINION SYMPTOMS

• Starter spins / no-crank

• Click / no-crank (may be intermittent)

VERIFY COMPLAINT

VISUALLY CHECK

RING GEAR

CHECK STARTER PER

APPROPRIATE

SERVICE BULLETIN

REINSTALL STARTER AND

PERFORM CIRCUIT CHECKS

(SEE PAGE 3-4)

REMOVE STARTER –

VISUALLY CHECK PINION CHECK AND REPAIR

SOLENOID CIRCUIT

REPAIR VERIFIED

REPAIR OR REPLACE

STARTER

(DO NOT INSTALL)

REPLACE RING GEAR

AND CHECK FLANGE

TO FLYWHEEL DIM

REPLACE STARTER

AND VERIFY REPAIR

CONNECT VOLTMETER

FROM SOLENOID “S”

TERMINAL TO GROUND –

ENGAGE START SWITCH

DEFECTIVE

OK

MILLED TEETH

OK

OK

OK

SYMPTOMS CONTINUE

MILLED PINION

MORE THAN 6.0 V NO VOLTS

delcoremy.com Page 11

3-1. TESTING FLOODED LEAD ACID

MAINTENANCE FREE BATTERIES WITH

A HYDROMETER EYE

CAUTION

When handling batteries, wear face or eye protection and

provide good ventilation. Have a water supply available, and

keep away from fire, flame or sparks.

3-2. TEST PROCEDURE.

Disconnect

NOTE

If battery has threaded terminals, use terminal adapters or verify

you are testing on the lead pads not the threaded terminals.

Testing using the studs can create a false bad battery reading.

NOTE

If you are using an hand held electronic tester, then follow the

instructions provide with the tester.

Inspect

1. Each battery visually for damage.

2. Battery hydrometer eye.

• If battery has no hydrometer eye, proceed to step 3.

• Eye shows green, proceed to step 3.

• Eye shows dark, recharge battery, then proceed to step 3.

• Eye shows yellow, replace battery.

3. Apply 300 amp load to battery for 15 seconds and turn o

load. Wait one minute.

4. If battery has no hydrometer eye, measure terminal voltage:

Test

a. If 12.4 volts or more, continue test.

b. If less than 12.4 volts, recharge battery, and repeat steps

3 and 4.

Test

5. All batteries passing previous inspection or test as follows:

a. Apply test load of 1\2 CCA rating at 0˚F in amps.

b. After 15 seconds with load on, measure and record battery

terminal voltage.

c. Turn load o.

d. Estimate battery temperature and check recorded voltage

against following table.

Temp. F 70 50 30 15 0

Min. Volts 9.6 9.4 9.1 8.8 8.5

e. If recorded voltage does not meet or exceed that in table,

replace battery. Otherwise, battery is okay.

3-3. TEST COMPLETION.

Clean

1. Cable ends and battery terminals with wire brush.

Tighten

1. Battery hold-downs to specifications.

NOTE

Leave battery cables disconnected and proceed with wiring

tests.

ST1201 ADAPTER

PRIMARY BATTERY

CONNECTION AREA

STUD TERMINAL

DP-1019

FIGURE 3-1. Testing Batteries

3-4. TESTING BATTERIES

CAUTION

When handling batteries, wear face or eye protection and

provide good ventilation. Have a water supply available, and

keep away from fire, flame or sparks.

SECTION III

Diagnostic Testing

Page 12

3-5. TEST PROCEDURE

Disconnect

NOTE

If battery has threaded terminals, use terminal adapters or verify

you are testing on the lead pads not the threaded terminals.

Testing using the studs can create a false bad battery reading.

NOTE

If you are using an hand held electronic tester, then follow the

instructions provide with the tester.

Inspect

1. Each battery visually for damage.

2. Electrolyte level.

• If fluid is above top of plates in all cells, proceed to step 3.

• If fluid is not above top of all plates, add water as required

and charge battery for 15 minutes at 15-25 amps to mix

electrolyte. Then proceed to step 3.

3. Electrolyte specific gravity with hydrometer at 80˚ F. Readings

for all cells should not be less than 1.230. The dierence between

high and low reading should not exceed 0.050.

• If battery meets above requirements, proceed to next test.

• If readings show a dierence of more than 0.050, replace

the battery.

• If readings show less than 0.050 dierence but one or

more cells read less than 1.230, recharge the battery.

Remove

1. All battery caps.

Test

2. Apply 300 amp load to battery for 15 seconds and turn o

load.

3. If blue haze is seen in any cell, replace battery. Otherwise,

proceed with next test.

Test

1. All batteries passing previous inspections or tests as follows:

a. Measure and record electrolyte temperature and replace

vent caps.

b. Apply test load of 1\2 CCA rating at 0˚F in amps.

c. After 15 seconds with load on, measure and record battery

terminal voltage.

d. Turn load o.

e. Check recorded voltage against following table for

electrolyte temperature.

Temp. F 70 60 50 40 30 20 10 0

Min. Volts 9.6 9.5 9.4 9.3 9.1 8.9 8.7 8.5

f. If recorded voltage does not meet or exceed that in table,

replace battery. Otherwise, battery is okay.

3-6. TEST COMPLETION.

Clean

1. Cable ends and battery terminals with wire brush.

Tighten

1. Battery hold-downs to specifications.

NOTE

Leave battery cables disconnected and proceed with wiring

tests.

FIGURE 3-2. Testing Batteries

3-7. BATTERY CABLE TEST WITH

SINGLE BATTERY LOCATION

(SEE FIGURE 3-3)

CAUTION

If the vehicle has a combination 12/24-volt system using a series-

parallel switch or a T/R alternator, do not use this procedure.

Contact BorgWarner Technical Support at 800-372-0222 or email

drts@borgwarner.com for information on such systems.

delcoremy.com Page 13

Slow or sluggish cranking may be caused by high resistance in the

battery cables or connections, especially in cold weather. After all

batteries test well and the terminals are clean, check the battery

cables. This involves placing an adjustable carbon pile load on the

batteries at the starter and then measuring the voltage drop in

each cable. The voltage drop in the positive cable plus the voltage

drop in the negative cable equals the total drop or the dierence

between the battery voltage and the starter voltage.

3-8. TEST PROCEDURE.

NOTE

For a 24-volt system, use a 24-volt carbon pile. As an

alternative, connect only one 12-volt battery to the system

(disconnect all other batteries). Test at 12-volts but use the

amperage specified for a 24-volt system. Immediately upon

completion of tests, reconnect batteries in the approved manner

for a 24-volt system.

Connect

CAUTION

Starter solenoid BAT terminal is at battery voltage when

batteries are connected.

1. Positive carbon pile lead to starter solenoid BAT terminal.

2. Negative carbon pile lead to starter ground terminal.

3. Battery cables (see NOTICE above) if not already connected.

NOTE

At starter, make voltmeter connection to terminal—not to

carbon pile clamp.

4. Low scale digital voltmeter from starter solenoid BAT terminal

to battery positive.

Test

1. Turn on carbon pile and adjust load to 500 amps (250 amps

for 24-volt system).

2. Read and record positive cable voltage drop (V4), then turn o

carbon pile.

Connect

NOTE

At starter, make voltmeter connection to terminal—not to

carbon pile clamp.

1. Low scale digital voltmeter from starter ground terminal to

battery negative.

Test

1. Turn on carbon pile and adjust load to 500 amps (250 amps

for 24-volt system).

2. Read and record negative cable voltage drop, (V5) then turn

o carbon pile.

3. Add positive cable loss (V4) and negative cable loss (V5) to

get total cable loss (V3). This loss (V3) shall not exceed:

• 12-volt system with 37MT, 40MT, 41MT or 42MT starter — 0.500

volt maximum voltage loss

• 12-volt system with 50MT starter — 0.400 volt maximum loss

• 24-volt system with 37MT, 40MT, 41MT, 42 MT, or 50 MT starter

— 1.000 volt

4. Replace cables or repair circuits with excessive voltage drop.

3-9. TEST COMPLETION. If temporary 12-volt test connections

were made for 24-volt systems, reconnect batteries to vehicle

specifications for 24-volt operation before starting vehicle.

However, if the tests following are to be performed, keep the

temporary 12-volt hook-up.

FIGURE 3-3. Battery Cable Test –

Typical 12-Volt System

Page 14

3-10. BATTERY CABLE TEST WITH

DUAL-BATTERY LOCATIONS

(SEE FIGURE 3-4)

This test applies if the vehicle has more than one battery location

and the batteries are connected to the starter by separate cables.

Essentially, this is the same as the previous test with a single

battery location (paragraphs 3-7 through 3-9) except as follows:

3-11. TEST PROCEDURE (See Figure 3-4).

NOTE

If the system usually operates on 24-volts, connect one battery

at each location to the starting motor, making a temporary 12-

volt system.

1. Disconnect batteries from first set.

2. Test second set cables as described in paragraph 3-8 except

apply 250 amp load at starter (125 amp for 24-volt system).

3. Use same voltage drop or loss limits as specified in paragraph

3-8.

4. Reconnect first set of batteries and disconnect second set.

5. Repeat steps 2 and 3 for first set of cables.

6. Replace cables or repair circuits with excessive voltage drop.

3-12. TEST COMPLETION. If temporary 12-volt test connections

were made for 24-volt system, reconnect batteries to vehicle

specifications for 24-volt operation before starting vehicle.

However, if the tests following are to be performed, keep the

temporary 12-volt hook-up. CARBON PILE

POSITIVE

VOLTAGE

LOSS

NEGATIVE

VOLTAGE

LOSS

FIRST SET

SECOND SET

FIGURE 3-4. Battery Cable Test -

Typical Dual Box 12-Volt System

3-13. STARTER SOLENOID CIRCUIT

TEST

The starter shifting in and out, or not pulling in, is often caused by

high resistance in the starter solenoid circuit. When the solenoid

circuit has excessive voltage loss, the starter pinion may not

engage the flywheel. If it does engage, it may drop out too soon

when battery voltage lowers. The solenoid circuit usually consists

of a magnetic switch with leads to and from the starter solenoid.

Some vehicles use only a push-button switch to control the starter

solenoid and this same test applies.

delcoremy.com Page 15

NOTE

For starters with an integral magnetic switch, use the test

procedures specific to those starters.

NOTE

When testing 24-volt systems, use the same temporary 12-volt

connection as for the Battery Cable Test, paragraph 3-7.

3-14. SOLENOID CIRCUIT VOLTAGE LOSS TEST (See Figure 3-5).

Disconnect

1. Lead to S terminal on starter solenoid.

Connect

1. Carbon pile to switch wire lead and to starter ground terminal

(a small clamp or jumper wire may be helpful).

2. Positive lead of digital voltmeter set on low scale to solenoid

BAT terminal.

3. Negative lead of voltmeter to switch wire lead to which

carbon pile is connected. Meter will show battery voltage.

NOTE

In the following step, if the magnetic switch does not close on a

12-volt vehicle, perform Magnetic Switch Circuit Test, paragraph

3-18, then return to this point in the Starter Solenoid Circuit

Test.

NOTE

In the following step on a 24-volt vehicle, if the temporary

12-volt system will not close the magnetic switch, bypass it

with a heavy jumper connected between the two large studs

on the magnetic switch. Electrically this does the same thing

as pushing the button and closing the switch. With no button

to release, the jumper must be disconnected after each voltage

reading.

Test

1. Have assistant push starter button with key on. Listen for

sound of magnetic switch closing. Voltmeter reading should be

zero.

2. Turn on and adjust carbon pile to 100 amp load (60 amp if 24-

volt system).

3. Read and record voltage (V6) onvoltmeter.

4. Voltage loss shall not exceed:

12-volt system - 1.0 volt

24-volt system - 2.0 volt

5. If circuit voltage loss is less than maximum, solenoid circuit

is okay, turn o and disconnect carbon pile and proceed to

Magnetic Switch Circuit Test, paragraph 3-18. If voltage loss

exceeds maximum, loss is excessive. This may be caused by

loose terminals, corrosion, too small a wire, switch located too far

from starter, or worn out magnetic switch. Perform Wiring Test,

paragraph 3-15, and Magnetic Switch Contactor Test, paragraph

3-16, to isolate the problem.

VOLTAGE (6)

CARBON PILE

FIGURE 3-5. Starter Solenoid

Circuit Test

3-15. WIRING TEST (See Figure 3-6). With carbon pile connected

as instructed in previous Starter Solenoid Circuit Test, proceed as

follows:

Connect

1. Plus lead of digital voltmeter set on low scale to solenoid BAT

terminal.

2. Minus lead of voltmeter to a large terminal on magnetic

switch. If voltage shows, reconnect lead to other large terminal on

magnetic switch.

NOTE

In the following step, on a 24-volt vehicle, if the temporary

12-volt system will not close the magnetic switch, bypass it

with a heavy jumper connected between the two large studs

on the magnetic switch. Electrically this does the same thing

as pushing the button and closing the switch. With no button

to release, the jumper must be disconnected after each voltage

reading.

Page 16

Test

1. Push starter button with key on.

2. Turn on and adjust carbon pile to 100 amp load (60 amp if

24-volt system).

3. Read and record voltage (V9) onvoltmeter.

Connect

1. Positive lead of digital voltmeter set on low scale to switch

wire lead to which carbon pile is connected.

2. Negative lead of voltmeter to other large terminal on

magnetic switch.

Test

1. Push starter button with key on.

2. Turn on and adjust carbon pile to 100 amp load (60 amp if

24-volt system).

3. Read and record voltage (V10) on voltmeter.

4. Add voltage loss (V10) to voltage loss (V9), previously

recorded, to get total wire voltage loss.

5. Total wire voltage loss shall not exceed:

12-volt system - 0.8 volt

24-volt system - 1.8 volt

6. Replace and repair wiring and connections if voltage loss is

excessive.

NOTE

Perform the following test only if the magnetic switch closed in

preceding tests.

3-16. MAGNETIC SWITCH CONTACTOR TEST (See Figure 3-6).

With carbon pile connected as instructed in previous Starter

Solenoid Circuit Test, proceed as follows:

Connect

1. Digital voltmeter set on low scale across large terminals of

magnetic switch. Battery voltage will show immediately.

Test

1. Push starter button with key on. Voltage will read zero.

2. Turn on and adjust carbon pile to 100 amp load (60 amp if

24-volt system).

3. Read and record voltage (V11) across magnetic switch on

voltmeter, then release starter button.

4. Magnetic switch contactor voltage loss (V11) shall not exceed

0.2 volts for 12- or 24-volt system.

5. Replace magnetic switch if contactor voltage loss is excessive.

DP-1024

CARBON PILE

SECOND WIRE LOSS (10)

CONTACTOR

LOSS (11)

FIRST

WIRE

LOSS (9)

FIGURE 3-6. Solenoid Circuit Wiring

and Contactor Test

3-17. TEST COMPLETION. Turn carbon pile o. Remove

carbon pile and voltmeter from circuit. Leave solenoid S wire

disconnected and temporarily taped for insulation at the terminal.

3-18. MAGNETIC SWITCH CIRCUIT TEST

This test must be performed using full voltage of the system. If

a 24-volt system was temporarily connected to a 12-volt system

for a previous test, proceed to the Alternator Wiring Test,

paragraph 3-26. Then, return to this test after the batteries have

been reconnected to the 24-volt system. Note that the lead to

the S terminal on the starter solenoid remains disconnected from

previous tests (See Figure 3-7).

delcoremy.com Page 17

3-19. TEST PROCEDURE.

NOTE

Magnetic switch that does not close or drops out too soon

can be caused by high resistance or open circuit in the control

circuit.

NOTE

Leave the S lead disconnected to prevent engine from cranking

during these tests.

Connect

1. Digital voltmeter set on battery voltage scale to two small

terminals on magnetic switch. If magnetic switch has only one

small terminal, use switch bracket for other connection.

Test

1. With key on, push start button. Listen for click that signifies

magnetic switch closing. Note and record voltmeter reading V(13).

2. If magnetic switch closed (click detected or voltage at both

large switch terminals) and voltage V(13) is within 1.0 volt (2.0

volts for 24-volt system) of battery voltage V(12), this circuit is

okay.

3. If magnetic switch does not close and voltage V(13) is within

1.0 volt (2.0 volt for 24-volt system) of battery voltage V(12),

replace magnetic switch and retest.

4. If voltage V(13) is more than 1.0 volt (2.0 volt for 24-volt

system) below battery voltage, move the voltmeter lead on the

magnetic switch ground to frame or motor ground terminal. With

key on, push start button and read voltage V(14). If voltage V(14)

is within 1.0 volt (2.0 volts for 24-volt system) of battery voltage,

repair magnetic switch ground lead or connections. If not, replace

voltmeter ground lead at magnetic switch ground terminal.

5. Repeat step 4, moving voltmeter plus lead to the following

locations and measuring the specified voltages with the key on

and the push-button depressed.

If any voltage is not within 1.0 volt (2.0 volts for 24-volt system) of

battery voltage, repair or replace the wire or component specified

and retest:

V(15)-wire between push-button and magnetic switch

V(16) push-button

V(17) wire between push-button and key switch

V(18) key switch

V(19) wire between key switch and solenoid BAT terminal

3-20. TEST COMPLETION. Remove voltmeter from vehicle. If

all tests have been completed satisfactorily, reconnect lead to S

terminal on starter solenoid so that engine can be started.

PUSH

BUTTON

MAGNETIC

SWITCH

VOLTAGE (13)

V(15)

V(16)

IGNITION

BATTERY

CABLE

VOLTAGE (12)

V(19)

V(14)

V(17) V(18)

DP-1025

FIGURE 3-7. Magnetic Switch

Circuit Test

3-21. STARTER REPLACEMENT

DETERMINATION

Up to this point, the batteries and starter wiring have been

checked. The following additional checks should be made before

considering starter replacement, and finally, the criteria for starter

replacement, if necessary.

3-22. COLD WEATHER CRANKING. Starter circuits with a

magnetic switch also can fail to hold during cold weather starting

and low voltage, even though the switches and circuits tested

okay at higher temperatures. This condition will sound as though

the starter is failing to stay engaged with the engine. It is caused

by the cold weather low voltage of the system releasing the

electrical connection of the magnetic switch. To test for this

condition, proceed as follows:

Test

CAUTION

Large terminal studs on magnetic switch are at battery voltage.

Engine should crank when jumper is connected.

1. With key switch on, press start button and have assistant

clamp heavy battery jumper cable between two large studs on

magnetic switch. Engine should crank.

2. Immediately remove jumper to stop engine cranking.

3. If engine starts with jumper in place, replace magnetic switch.

Page 18

4. If vehicle now starts properly, make sure starter mounting bolts

are tight and proceed to Alternator Wiring Test.

3-23. AVAILABLE CRANKING VOLTAGE. If batteries, switches and

wiring have been checked and starter still cranks slowly, check for

available voltage at the starter while cranking. Proceed as follows:

Test

1. Have assistant press push-button with key switch on while

measuring voltage across solenoid BAT terminal and starter

ground terminal.

2. If voltage is 9.0 volts (18 volts for 24-volt system) or less while

cranking, check battery interconnecting cables as specified in

next step.

3. Measure voltage across each battery while cranking. Touch

voltmeter leads to terminals of every battery. If dierence

between any two battery readings in same box is more than 0.5

volt, or if any cable or connection feels warm to the touch, check

or replace interconnecting cable(s) as required.

3-24. RING GEAR AND PINION CHECK. One final check before

replacing the starter is to inspect the pinion and ring gear.

Inspect

1. Pinion and ring gear visually while assistant bars engine over.

Be sure to check entire ring gear.

2. If pinion is damaged, replace starter. If ring gear is damaged,

replace ring gear and note that there is a likelihood the pinion also

may be damaged.

3-25. STARTER REPLACEMENT. After making all tests specified,

if the vehicle does not crank properly, the problem is with the

starter or engine. Replace the starter and re-check to see if engine

cranks properly. If not, then look for a mechanical problem with

the engine.

3-26. ALTERNATOR WIRING TEST

This procedure is the first step in checking out the charging

system: output of the alternator, batteries and accessory loads

with a minimum of voltage loss. Any loss slows the rate of charge

to the batteries and could cause the batteries to be partially

discharged. Discharged batteries can result in starter damage.

Low output voltage can cause improper performance of other

vehicle electrical components.

3-27. TEST PROCEDURE (See Figure 3-8). Instead of using the

alternator output, this test uses the same current but draws it

from the batteries. Using a carbon pile load, current flows in

reverse through the circuit with the engine o. Proceed as follows:

NOTE

24-volt systems must be connected to a temporary 12-volt

configuration as described for Battery Cable Test, paragraph

3-8.

NOTE

Before proceeding with this test, make sure that the batteries

have been tested and that the terminal has been cleaned and

tightened.

CAUTION

Alternator output terminal is at battery voltage. Engine must be

o for this test.

Connect

1. Carbon pile to alternator output terminal and to ground.

NOTE

Jumper wires may be used to extend voltmeter leads if

necessary.

2. Digital voltmeter set on low scale from alternator output

terminal to positive battery terminal.

Test

1. Turn on and adjust carbon pile to alternator-rated amperage

output.

2. Read voltmeter and record voltage (V24), which is positive

circuit voltage loss. Immediately turn o carbon pile.

Connect

1. Digital voltmeter set on low scale from alternator ground to

negative battery terminal.

Test

1. Turn on and adjust carbon pile to alternator rated amperage

output.

2. Read voltmeter and record voltage (V25), which is negative

circuit voltage loss. Immediately turn o carbon pile.

3. Add positive circuit loss (V24) and negative circuit loss (V25)

to get total system loss (V23). This loss (V23) shall not exceed:

• 12-volt system - 0.500 volt maximum voltage loss

• 24-volt system - 1.000 volt maximum voltage loss

4. Replace cables or repair circuits with excessive voltage loss.

This manual suits for next models

9

Table of contents

Popular Controllers manuals by other brands

Samson

Samson 2357-31 Mounting and operating instructions

Elimko

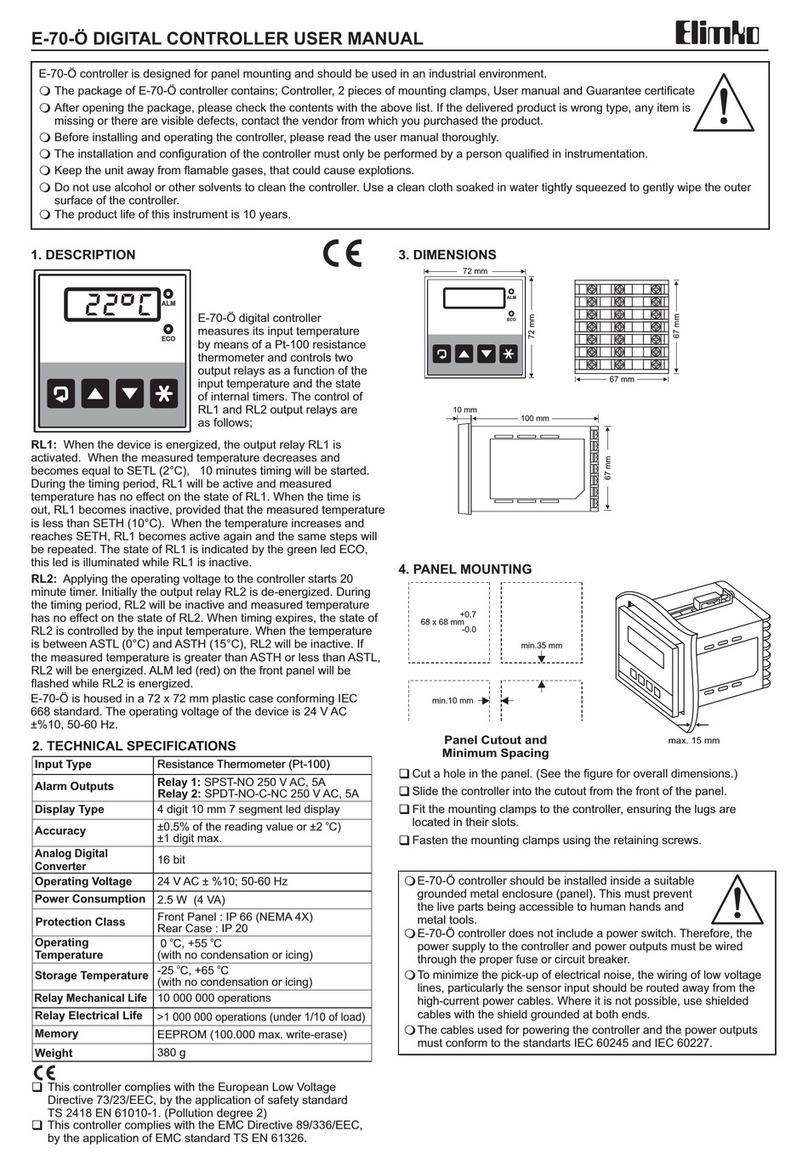

Elimko E-70-O user manual

Honeywell Home

Honeywell Home TheraPro HR90 owner's guide

Isimet

Isimet LA Series Installation, Operations, Start-up and Maintenance Instructions

Cansec

Cansec Canlan M200 quick start guide

MPE

MPE SC100 instruction manual