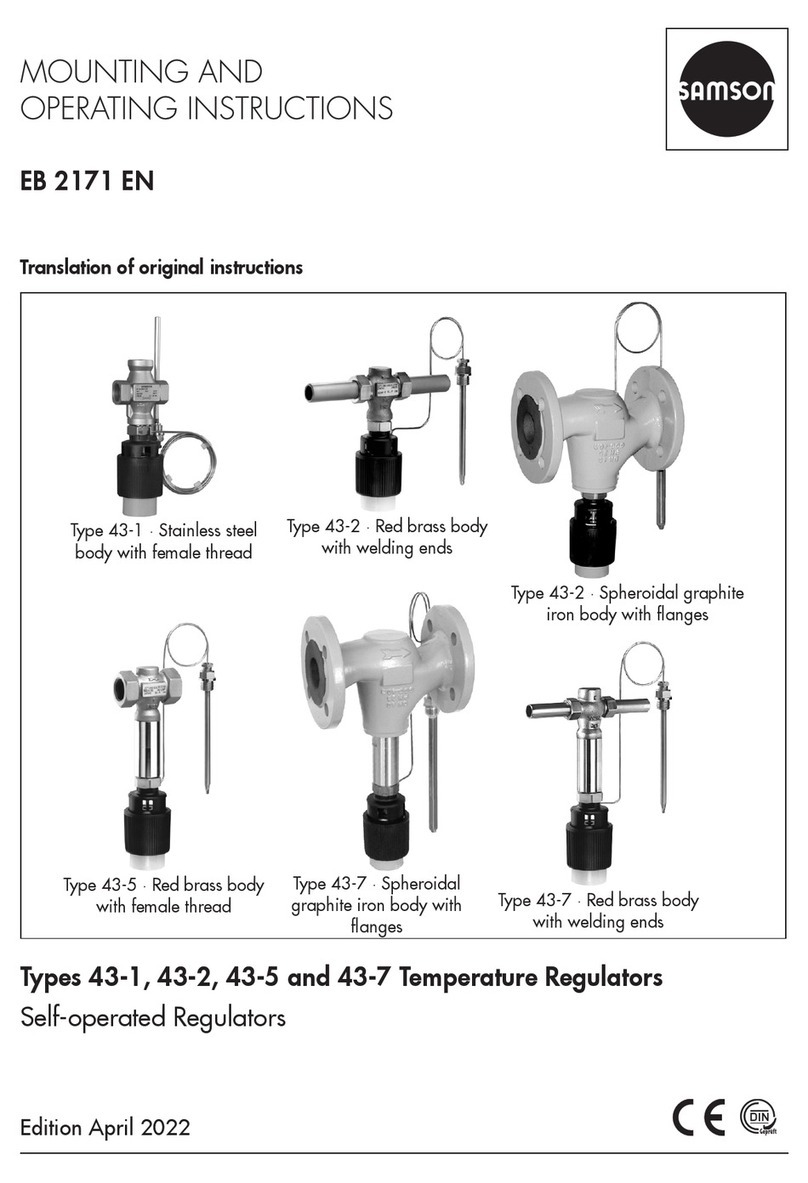

1 Design and principle of oper-

ation

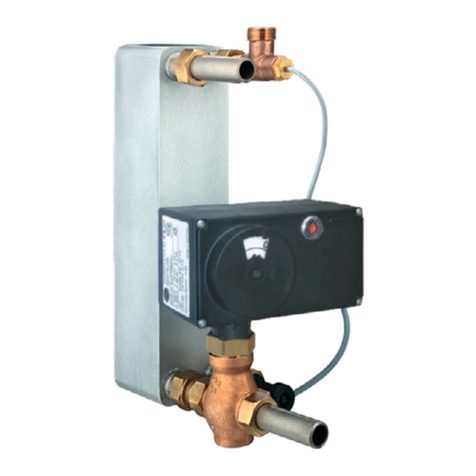

Also see Fig. 1 on page 5.

Depending on the direction of flow, the regula-

tor functions as a pressure build-up regulator

with safety function (direction of flow A →B)

or as a pressure relief valve (direction of flow

B→C). The position of the pressure build-up

plug (2) determines the flow rate across the

area released between the plug and seat.

The pressure regulator is designed to keep the

pressure constant at an adjusted set point, es-

pecially in cryogenic plants.

The regulator consists of a valve with three

ports A, B and C, a spring-loaded operating

diaphragm (3) with set point adjuster (6) and

a pressure build-up plug (2).

Pressure build-up regulator

The process medium flows from port A to

port B. The valve is open when no pressure is

applied. The pressure downstream of the

valve is transmitted to the operating dia-

phragm (3). The resulting positioning force

moves the pressure build-up plug (2) depend-

ing on the spring force adjustable on the set

point adjuster (6). The valve is closed when

the pressure downstream of the valve has

reached the adjusted set point.

Pressure build-up regulator with safety func-

tion

The regulator additionally functions as a

safety valve for the pressure chamber up-

stream of port A. When the pressure exceeds

the set point by approx. 5 bar, the positioning

force overcomes the force of the closing

spring (4), causing the pressure build-up

plug (2) to open and the pressure to be re-

lieved to ports B and C.

Pressure relieve valve

The process medium flows from port B to

port C. As long as there is no pressure drop

across ports B and C, the plug seals off to-

wards the operating diaphragm (3).

The pressure at port B acts on the operating

diaphragm (3). The resulting positioning

force opposes the force of the set point

spring(s) (5) and opens the tubular plug (2.1)

when the adjusted set point is exceeded by

approx. 5 bar to equalize the pressures. The

medium escapes through the inside of the

plug through port C.

Optionally, the regulator can be equipped

with a non-return unit (10). The unit prevents

the medium from flowing back to port C and

allows maintenance work to be performed on

the pressure build-up regulator without hav-

ing to drain the tank.

To connect the regulator to the pipelines con-

taining the process medium, soldering nip-

ples with ball-type bushings (11) are avail-

able as accessories. Filters (12) for installa-

tion in ports A and B to prevent the valve from

clogging are also available as accessories.

1.1 Process medium, application

range

The pressure regulator is designed for cryo-

genic gases and liquids at temperatures from

–196 to +200 °C and pressures up to 40 bar.

Set points range from 1to 40 bar.

4EB 2558 EN

Design and principle of operation