MPE SC100 User manual

SC100

SC100SC100

SC100

INSTRUCTION MANUAL

INSTRUCTION MANUALINSTRUCTION MANUAL

INSTRUCTION MANUAL

2464 Vulcan Road

Apopka, Florida 32703

Revision Date: 6-23-14

M

MM

MOTOR

OTOROTOR

OTOR

P

PP

PROTECTION

ROTECTIONROTECTION

ROTECTION

E

EE

ELECTRONICS, INC.

LECTRONICS, INC.LECTRONICS, INC.

LECTRONICS, INC.

Phone:

Website: (407) 299-3825

www.mpelectronics.com

Order from: C A Briggs Company; 622 Mary Street; Suite 101 - Warminster, PA 18974

Phone: 267-673-8117 - 800-352-6265 - Fax: 267-673-8118; E-Mail: Sales@cabriggs.com - www.cabriggs.com

ORDERING INFORMATION:

SC100 - XX

Product Type

Scale Range

05 = 11.5 Ft/H2O

10 = 23.1 Ft/H2O

15 = 34.6 Ft/H2O

APPLICATIONS:

• Duplex Pumping Stations that Control Liquid Level

• Pump Down (Empty a Tank) or Pump Up (Fill a Tank) - See note by Ordering Information below

SPECIFICATIONS:

Input Power: 120VAC +/- 10%, 7.8 VA max

Power for Analog Input: 24VDC+/- 1V, Transient Protected

Agency Approval: UL 508, CAN/CSA UL FILE #: E101681

Operating Temperature: -20 °C to +65 °C

Storage Temperature: -45 °C to +85 °C

Indicators: LED

Relay Outputs: 10A Resistive @ 120VAC

3.6A Inductive @ 120VAC

Level Analog Input: 4-20 mA, 250 Ohms Load

Transient Protected

Color: White with Blue Lettering

Enclosure Material: Aluminum

5psi Transducer used with: SC100-05

10psi Transducer used with: SC100-10

15psi Transducer used with: SC100-15

For Pump Up Applications (Fill a Tank)

add UP to Part No. after Scale Range

STANDARD FEATURES:

• Bar Graph Level Display - 30 segment LED

• All Level Settings may be viewed or changed from the front of the unit

• Level Input Source – Analog Level Input [4-20mA from Pressure Transducer]

May be used with 5, 10, or 15 psi Pressure Transducer when correct Scale Range is selected

See Ordering Information below

• Level Input Zero and Span Calibration

• 24VDC Power Supply for analog Level Input

• Phoenix style connectors used

• 2 Pump Call Relay outputs

• High Level and Low Level Alarm Relay outputs

• Duplex Alternation

• 10 second Power Up Delay – After a power interruption, the first pump is delayed by 10 seconds

• 5 second Lag Pump Delay – After lead pump call, lag pump call is delayed by 5 seconds

• 90 second Low Level Alarm Delay – After a power interruption, low alarm is delayed by 90 seconds

• Level Simulation – Automatically ends after 1 minute

1

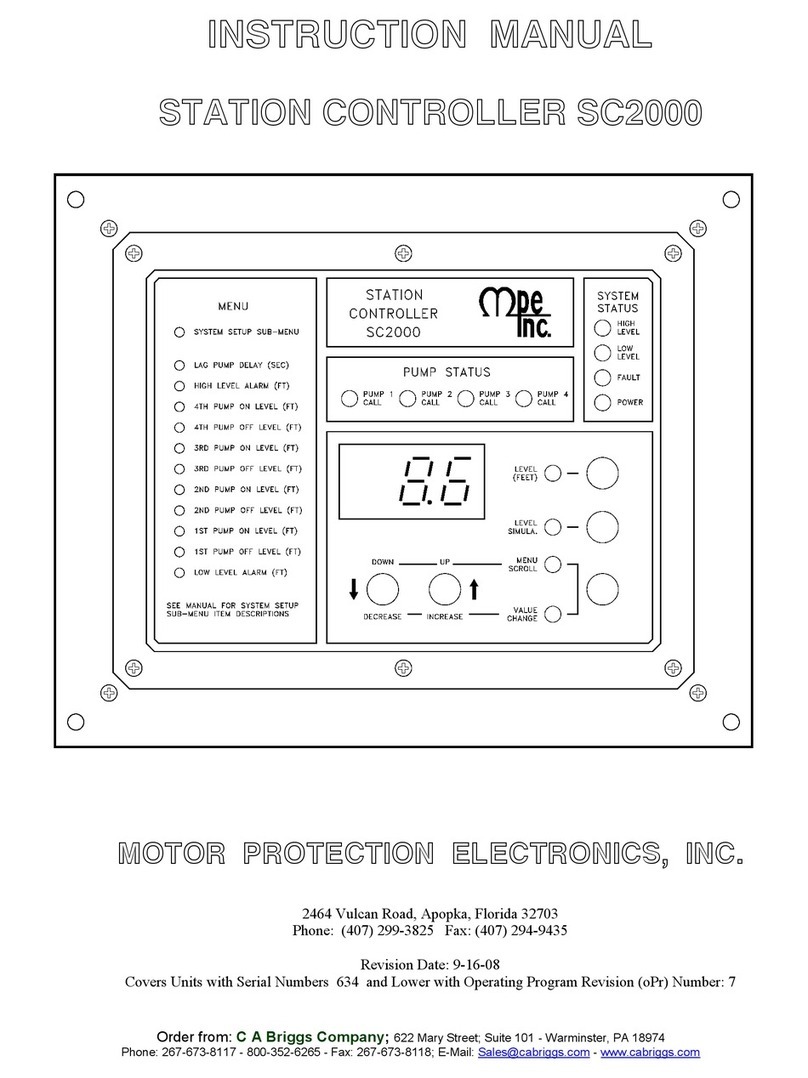

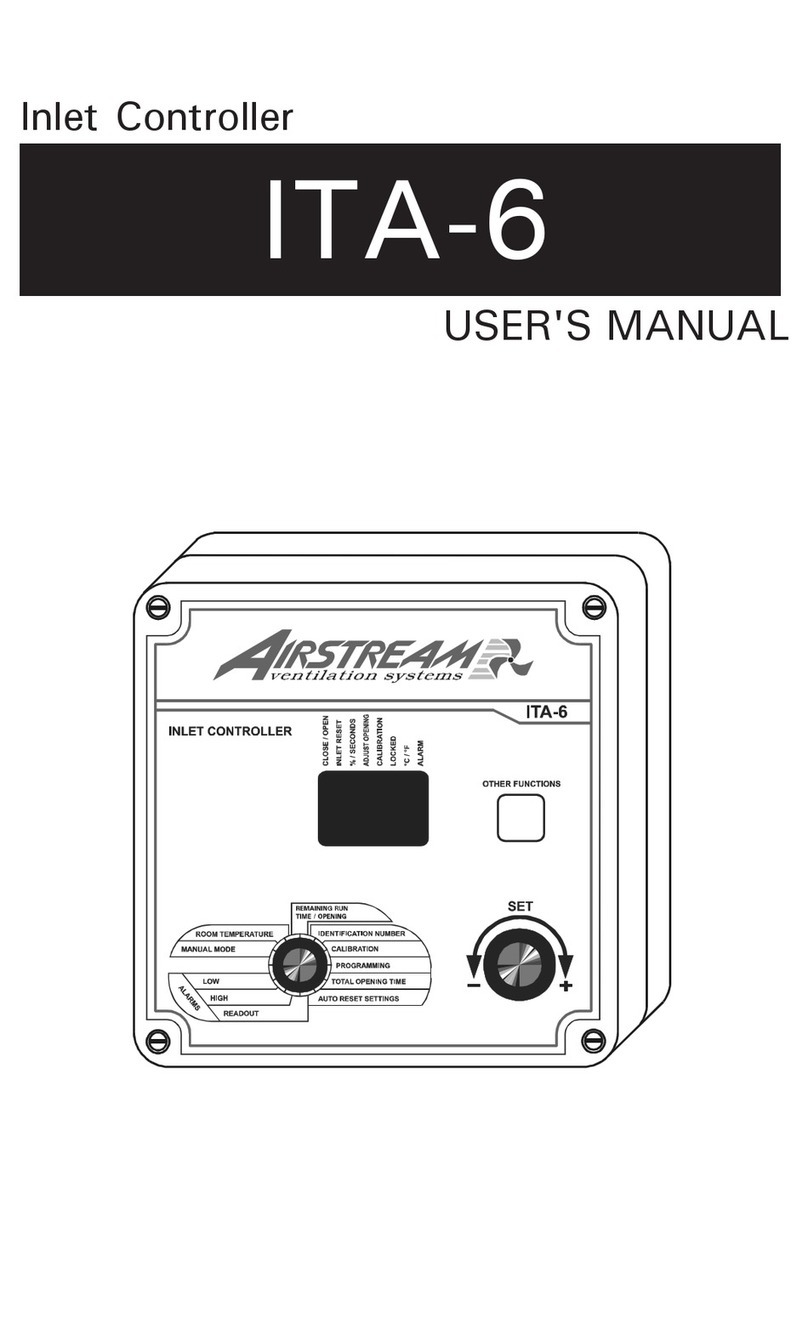

STATION CONTROLLER SC100

VIEW OR CHANGE LEVEL SETTINGS

Menu:

To enter the menu press the Setting Select pushbutton once. To move in the menu from left to

right, press the Setting Select pushbutton again. To exit the menu, press the Setting Select

pushbutton once while at the right most end of the menu.

Viewing Settings:

When the menu indicator over one of the Level Setting potentiometers is on, the current setting will

be shown on the bar graph display.

Changing Settings:

When the menu indicator over one of the Level Setting potentiometers is on, the potentiometer may

be turned to adjust the setting.

Note: The Off setting should be adjusted first, and then adjust the Lead and Lag settings. The

Lead and Lag settings are prevented from being too close to the Off setting. If the Off setting is

moved too close to the Lead and Lag settings, the Lead and Lag settings will be shoved away from

the Off setting and away from what is set on their respective potentiometers.

LEVEL SIMULATION

Entering Level Simulation Mode:

To enter the Level Simulation mode press the Setting Select pushbutton until the “Level Simula.“

menu indicator is turned on. Note that the Level Display bar graph will initially show what the actual

level was prior to entering the Level Simulation Mode.

Changing the Simulated Level:

To change the simulated level, press the Increase or Decrease pushbuttons as desired. The pump

1 and 2 call relays, and the high and low level alarm relays will operate just as though the water

level were actually changing.

Exiting the Level Simulation Mode:

To exit the Level Simulation mode, press the Setting Select pushbutton once. Unless you wish to

view the Level Settings continue to press the Setting Select pushbutton until all of the menu indica-

tors are off. If the controller is left in the Level Simulation mode, a one minute timer will time out

and return the controller to normal operation. The one minute timer is reset whenever the Increase

or the Decrease pushbutton is pressed.

2

LEVEL DISPLAY

Scale Range:

The Level Display Scale shows level in feet of water. In order for the level to be accurate, the cor-

rect pressure transducer must be used with the controller. The following shows which pressure

transducer goes with the different controllers:

Level Input Calibration:

The analog Level Input on the controller is calibrated at the factory and will not normally need to be

adjusted. If minor adjustments are required, they can be made using the Span and Zero calibration

potentiometers accessible from the front of the unit. When either the Span or Zero calibration is

changed, the other will be affected and should be re-checked and calibrated if necessary, until both

are correct.

Zero Calibration:

First – Use an analog calibration device to apply a 4.0mA signal to the Level Input.

(Alternate Method – Raise the pressure transducer (or bubbler tube) out of the water.)

Next – Adjust the Zero Potentiometer until the lowest bar graph segment is on steady.

Note: The lowest segment will blink when the Zero calibration is too low. It will also blink

if the 4-20mA signal is absent or connected backwards.

Span Calibration:

First – Use an analog calibration device to apply a 20.0mA signal to the Level Input.

(Alternate Method – Place the pressure transducer (or bubbler tube) under a know depth

of water.)

Next – Adjust the Span Potentiometer until the highest bar graph segment is on steady.

(Alternate Method – Adjust the Span Potentiometer until the display reads the known

depth of water covering the pressure transducer (or bubbler tube).)

Note: The highest segment will blink when the Span calibration is too high.

3

Scale Range

11.5 Ft/H2O

23.1 Ft/H2O

34.6 Ft/H2O

Part Number

SC100-05

SC100-10

SC100-15

Transducer Calibration

20mA at 5 psi

20mA at 10 psi

20mA at 15 psi

4

ELECTRICAL CONNECTION DIAGRAM

SUBMERSIBLE PRESSURE TRANSDUCER CONNECTION

BUBBLER SYSTEM BS2000 CONNECTION

LEVEL INPUT CONNECTION DIAGRAMS

5

CONTROL SCHEMATIC EXAMPLE – DUPLEX With 24V Float Backup

ENCLOSURE MECHANICAL LAYOUT

6

7

PANEL CUTOUT

Not Printed to Scale. Do Not Use as a Template.

Table of contents

Other MPE Controllers manuals

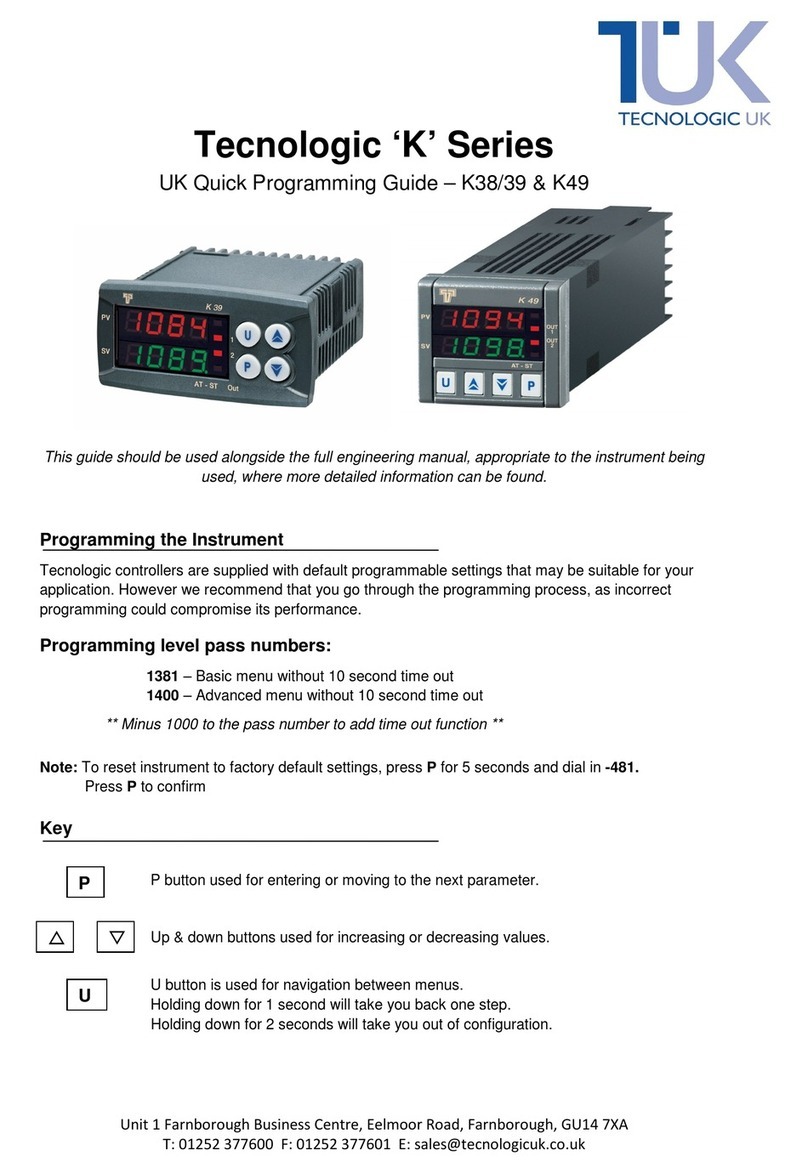

Popular Controllers manuals by other brands

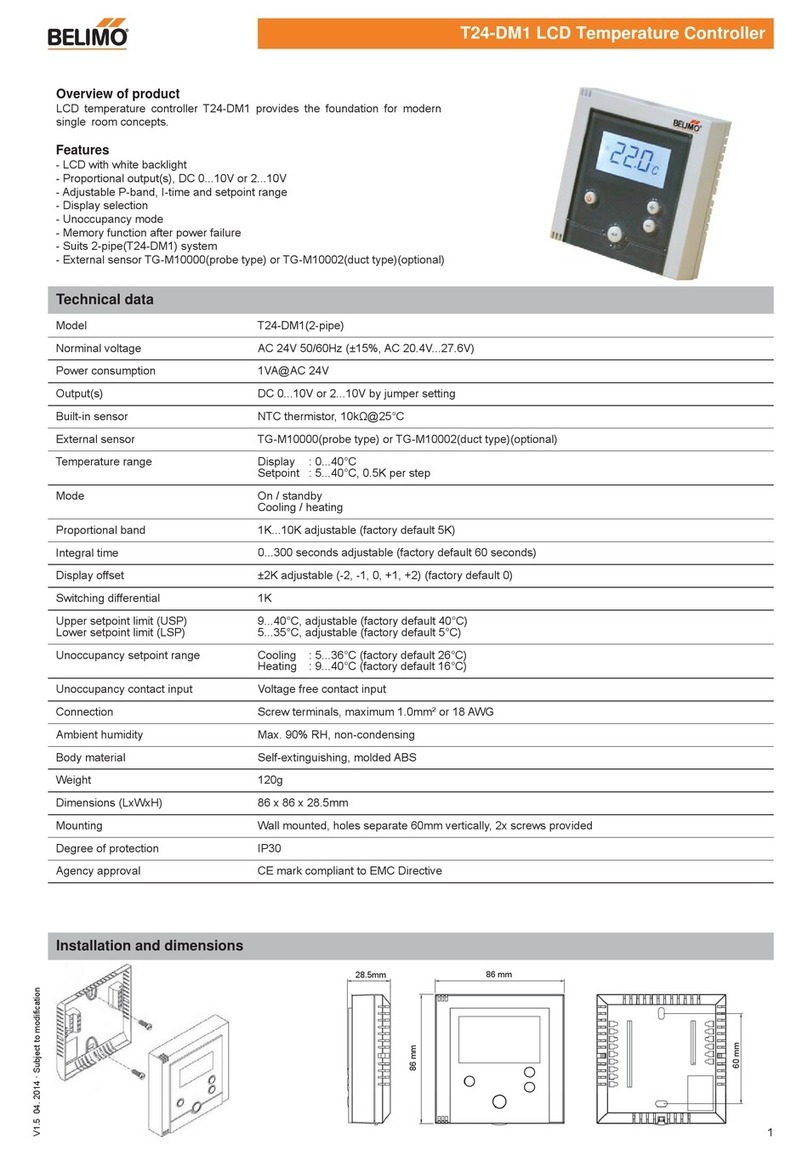

Belimo

Belimo T24-DM1 manual

Full Gauge Controls

Full Gauge Controls Microsol II power manual

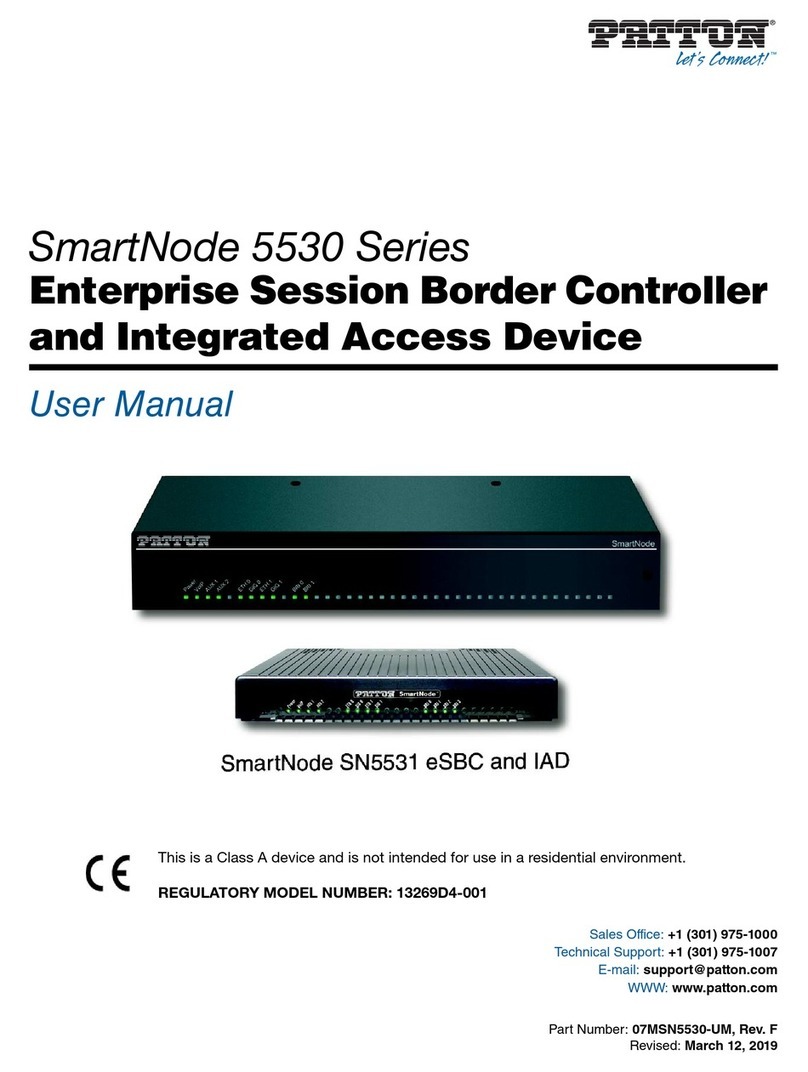

Patton

Patton SmartNode 5530 Series user manual

Rockwell Automation

Rockwell Automation ARMORSTART 280D Getting started

Aqua Lung

Aqua Lung Legend LX Second Stage Technical maintenance manual

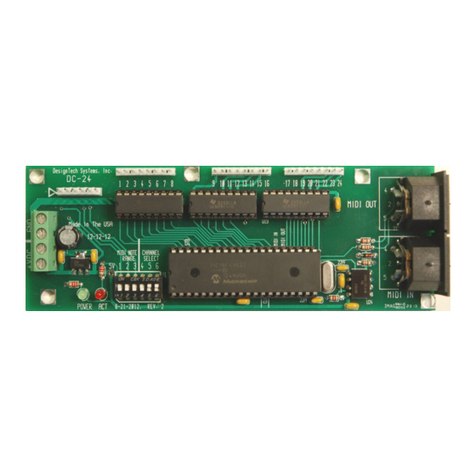

DesignTech

DesignTech DC-24 Instructions for Installation and Configuration