BOS Suspension VOID2 User manual

VOID²

User Manual

l

Terms and conditions

BOS Suspension offers warranty on its products on the following terms:

BOS guarantees to the original purchaser that the BOS product for which they

received this warranty is free from defects in material and workmanship for one

year from the date of original retail purchase. A proof of purchase will be asked for

any warranty claim. This warranty is not transferable to a subsequent purchaser.

Wear and tear parts such as dust seals, O-rings, bushings, rear shock mounting

hardware, stanchions, threaded parts and bolts are not covered under this

warranty.

Terms

This warranty is subject to legal jurisdictional or warranty rights of the country

where it has been originally purchased, which will prevail if different from the

terms herein listed.

Limits

BOS Suspension cannot be liable for any loss, inconvenience damages, whether

direct, incidental, consequential, resulting from the use of its products, local

legislation prevailing.

Warranty exclusions

This warranty does not cover the following cases:

• Damage to products resulting from improper assembly other than listed below

• Products that have been modified by the owner or a third party

• Improper use

• Damages resulting from an accident or a crash under any circumstances

• Invalid servicing procedures and servicing time frame not respected

• Replacement of the original parts by parts from others manufacturers

• Products whose serial numbers has been altered, defaced or removed.

Warranty procedure

The owner should always refer to an approved BOS service center for any

warranty claim. A proof a purchase is compulsory for any warranty claim.

Otherwise the warranty claim will not be considered. Always contact BOS

Suspension warranty department before returning any products that may fall

under this warranty. If “the faulty parts” do not fall under warranty, the customer

will be charged for any costs in respect with warranty such as transport and

package back and forth.

Warranty

The VOID shock that you’ve bought was designed and developed to fit most bikes on the market;

nevertheless you should refer to the tuning section of this manual to fit it perfectly to your bike, your

weight, and your riding style.

Your VOID shock is delivered with the correct mounting kits for the bike specified while ordering.

If you want to change or replace it please refer to the following plan:

Check the mounting direction

By referring to the compatibility table, available on the BOS MTB website download page.

Refer to the bike’s user manual

To follow your bike specific shock mounting procedure.

1. Introduction

Standard mounting kit:

MKP2-XX-YY

Example: MKP2-30-08

It’s necessary to measure precise

dimensions for each side of the

shock.

2. Assembly

Caution :

Never try to disassemble your shock. Limit yourself to the instructions given in this manual. This

shock is pressurized, for your own safety, do not try to open it. You also risk damaging the shock and

its internal mechanisms as well as voiding your warranty.

Contact an authorized service center for any maintenance operation.

XX

XX

YY

YY

3.1 AIR PRESSURE

In order to get the best performance from your BOS product, it’s essential to set up the shock to an

optimum air pressure based on your weight and your bike’s rear suspension geometry before using the

shock. Refer to the compatibility table in the download area of BOS website for the base recommended air

pressure.

Connect a shock pump to the Schrader valve located on the side of the upper part of the body, and inflate

to the recommended pressure.

3.2 EQUALIZING AIR CHAMBERS

In order for your shock to function correctly, you must equalize the air chambers after setting your

pressure.

To equalize the chambers, the shock must be

fitted on the bike.

Place the travel checker O-ring at 11 mm from

the shock seal, sit on your bike, and slowly

compress the suspension until the seal comes

to the O-ring. Let the suspension slowly extend

to its full travel. Slowly cycle the shock 15 times

over the first 11mm of its travel to complete

the equalization process.

valve

d'air

3. Settings

11mm

It’s recommended to us our BOS

shock pump with a digital gauge for

more accuracy, available on our

website:

http://boutique.bosmtb.com/

3.3 SETTING YOUR SAG

The sag is the amount of travel used by your suspension from your weight on the bike. It is set by adjusting

the air pressure.

BOS recommends a sag percentage of 30 to 35 %, depending on your use and your riding style.

The bike manufacturer may also indicate a sag percentage. Please refer to your bike’s user manual for this

value. If the manufacturer recommendation differs from ours, you should test the bike on the trail at

different sag values to find the right amount for your riding style.

How to measure and set your sag

Slide the travel checker O-ring up to your shock’s dust seal.

Sit on your bike (if possible dressed with your riding outfit) feet on the pedals - horizontal position, and let

the suspension compress under your weight. Get off the bike without pushing on the suspension any more,

extend the rear suspension to its full travel by pulling up the saddle, and measure the distance between

the O-ring and the seal. This distance allows you to check the percentage of SAG obtained with the current

air pressure.

To convert the distance into percentage, refer to the table below.

length x stroke (mm)

222x67

240x76

267x87

SAG (%)

35

30

30

35

30

35

Shock travel (mm)

24

23

20

24

23

24

If the sag is not correct, adjust the air pressure in 15psi steps. Equalize the air chambers after each

adjustment.

Too much SAG: increase the air pressure.

Not enough SAG: reduce the air pressure.

SAG

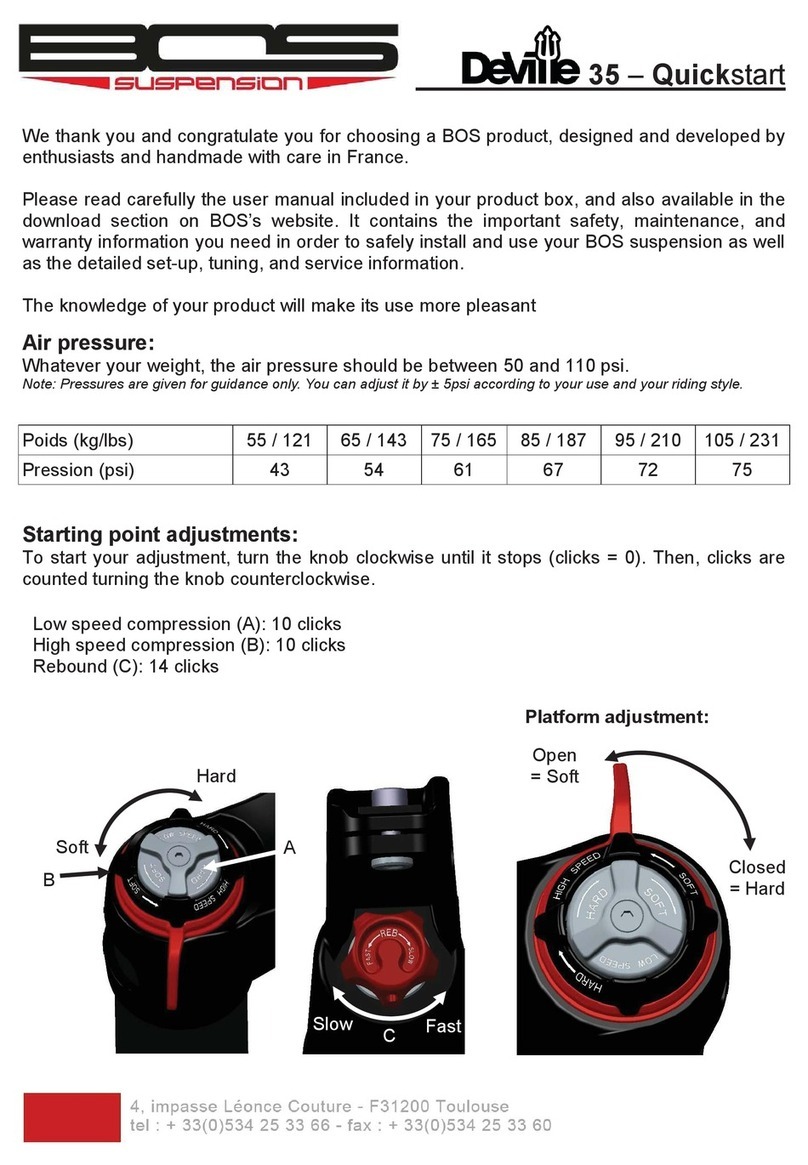

3.4 HYDRAULIC SETTINGS

The VOID shock is a three-ways adjustable shock, which means there are

three different damping adjustments: rebound, low-speed compression,

high-speed compression.

Your shock’s base setting (internal) is set up for your bike’s geometry

when you purchase the shock. We use three basic settings which cover

the majority of bikes on the market.

The purpose of damping adjustments is to use all the shock’s travel

without bottoming-out (or only very occasionally), to give rear wheel grip,

but also to avoid the bike stalling out in holes, and finally to maintain a

good chassis position.

Below you will find the base settings for your shock, then it’s up to you to

analyze its performance on the trail and tune the settings to suit your

riding style. Do this carefully and methodically, step by step. Only change

one setting at a time and only by a few clicks. When it’s done, note the

setting and type of terrain.

If you get confused with the settings, return to the base settings and start

again.

Low-speed compression (A)

The low-speed compression (A) affects the shock’s performance in compression over small bumps or

through the beginning of the travel.

Harden the low-speed compression (by turning the knob clockwise) on rolling terrain with big

compressions and kickers.

It might be useful to soften the low-speed compression (by turning the knob counter-clockwise) on steep

gradients.

High-speed compression (B)

The high-speed compression acts mainly on harsh hits (jump landings, rough sections). It should be soft

enough to get all the travel without bottoming-out. If, on a given track, you bottom-out frequently, harden

the high-speed compression by turning the knob clockwise. However, don’t get hung up on bottoming-out

if it only happens once or twice during your run. You risk setting your shock for 3% of the course and losing

efficiency on the other 97%.

If your shock doesn’t get full travel, soften the high-speed compression by turning the knob to counter-

clockwise.

Rebound (C)

The main factor in adjusting the rebound is the position of the bike. A bike shouldn’t be “sunken down” all

the time, although the back does need to be fairly low. Adjusting the rebound will allow you to maintain

this balance.

If you feel like the back of the bike is pushing you forward on a slope or when braking, slow down the

rebound (turn the knob clockwise). It can be useful to go along with this adjustment (especially if the

problem persists) by slightly soften the low-speed compression.

However, if the bike seems too low at the back and/or the front end has a tendency to drift offline, speed

up the rebound

A

B

C

Base settings (regardless of internal shock setting):

Please refer to the shock chart list available to download at bosmtb.com for specific pressure and setting

suggestions for your bike and weight.

3.5 AJUSTING AIR VOLUME

The progressivity adjustment featured on the VOID, allows you to adjust the air spring rate on the last third

of stroke. Thus, if you have found satisfying settings (air pressure and hydraulic) on the first half of the

stroke, you can adjust the feel of the last millimeters of travel.

The most frequent and simplest cases are:

The shock has an overall setup to single out comfort and grip, and the bike sits low: by increasing the end-

stroke rate you will get a better control of the chassis through the shock and avoid bottoming out. The rate

curve should be more progressive (increasing at the end) by adding o-rings.

The overall setup of the shock is more responsive, with a high chassis balance. By decreasing the end

stroke rate by removing o-rings, you can make sure that you use all the travel.

This setting is adjusted by adding or removing O-rings placed inside the air can.

We suggest you to go about the set-up step by step. First add or remove two O-rings, then fine-tune the

setting with one O-ring at a time. Adding one O-ring in the chamber increases the end of stroke spring rate

by 2%.

Usually, the correct setting is between 0 and 4 O-rings. However, the range can go up to 10 O-rings

depending on the bike

Important :

To start your adjustment, turn the knob clockwise until it stops (clicks = 0). Then count the clicks

while turning the knob counterclockwise.

Low-speed compression: 12 clicks from fully closed position

High-speed compression: 17 clicks from fully closed position

Rebound: 12 clicks from the fully closed position

Important :

With a significant hydraulic compression support, the VOID shock allows the bike to maintain a high

dynamic balance, as well as giving good response, and improved handling. BOS recommends setting up

the bike with a fast rebound to keep the chassis balanced, and avoid the bike sitting low in its travel.

The feeling of «fast» or «slow» rebound will differ from one rider to another. Thus it’s difficult to

define it precisely. We advise you to define your own range of correct rebound - the range of settings

between «too fast» and «too slow». Then, always choose a setting in the faster part of that range, for

example the three last clicks (counterclockwise) on a range of nine.

Caution :

Before tightening the vice, make sure the

jaws grip a flat surface and are not

touching the rebound knob.

Caution :

The shock body must not be unscrewed.

The air can is unscrewed by hand without

additional tools.

Procedure

Place the head of the shock in a soft-jawed

vice (figure 1).

Lightly tighten the vice jaws to prevent

damaging the shock.

Note your shock pressure, taking into

account the loss of pressure when

connecting your pump. Slowly deflate the

shock. The shock body will retract slightly.

Unscrew the air can (a) while keeping the

body (b) in its initial position (figure 2).

Remove the air can (figure 3)

Insert or remove O-ring(s) from the body

side of the shock and put them in position

(figure 4).

Make sure that O-ring(s) do not block the hole in the shock.

Make sure you have aligned the air can (a) sticker with the rebound knob (figure 5).

Replace the air can by screwing back by hand until the stickers align to ensure the proper torque (figure 6).

If the stickers do not align when the air can is hand tight, re-inflate and equalize the shock air chambers

(chapter 3.2) then finish tightening the air can.

Mount the shock on your bike re-inflate it shock and equalize the shock air chambers (chapter 3.2).

4

1

2

3

!

4

5

B

!

A

6

Caution :

Only use O-rings provided by BOS. The dimensions and the material are specifically chosen for this

purpose.

Caution :

The shock body must not be unscrewed.

The air can is unscrewed by hand

without additional tools.

Caution :

Before tightening the vice, make sure the

jaws grip a flat surface and are not touching

the rebound knob.

3.6 AIR VALVE ADJUSTMENT

It is possible to place your VOID air valve around the air can, and also position it toward or away from the

piggyback. This allows the shock to be fitted on a maximum of frames.

To modify the direction of your valve, or rotate it around the air can follow the instructions below:

Place the head of the shock in a soft-jawed

vice (figure 1).

Lightly tighten the vice jaws to prevent

damaging the shock.

Note your shock pressure, taking into

account the loss of pressure when

connecting your pump. Slowly deflate the

shock. The shock body will retract slightly.

Unscrew the air can while keeping the body

in its initial position (figure 2).

1

2

3

4

4

Caution :

Never place the valve in front of the piggyback, in the no-valve area, even if it is facing away from the

piggyback. The piggyback may hit the valve and seriously damage your shock.

Remove the air can (figure 3)

Change the position of the valve sleeve if

needed and rotate it according on your

needs (figure 4).

Make sure you have aligned the air can (a)

sticker with the rebound knob (figure 5).

Replace the air can by screwing back by hand until the stickers align to ensure the proper torque (figure 6).

If the stickers do not align when the air can is hand tight, re-inflate and equalize the shock air chambers

(chapter 3.2) then finish tightening the air can.

Mount the shock on your bike; re-inflate it and equalize the shock air chambers (chapter 3.2).

Service

It is essential to clean your shock after each day of riding without waiting! Nothing is worse for the life of

your seals than dirt and dust.

The cleaning process is also extremely simple: wipe off the body and the seal with a clean, soft rag. You can

occasionally lubricate the exterior of the seal with fork oil.

Do not under any circumstances use degreaser, solvent, or any abrasive material.

On the same note, do not ever power wash the seals.

Cleaning

Oil service

Full service

Recreational use

After each ride

Once a year

Every two years

Racing use

After each ride

Once a year

Once a year

3. Maintenance11

Caution :

Oil changes and service should be performed at an official BOS service center. These are the only

locations able to identify and resolve damaged or worn parts on your product, especially in the case

of extreme shocks or premature wear on structural elements such as body, mounting kits, and shaft.

B

!

A

6

5

What is the basic set up?

Your VOID shock was delivered with intermediate external hydraulic settings and inflated to a 80 to 100psi

pressure; nevertheless you should refer to the tuning section of this manual to fit it perfectly to your bike,

your weight, and your riding style.

You can find all the information about standard settings for your bike in the chartlist on the BOS website

download section.

There is air leaking when I connect the high pressure pump, what can I do?

Check that your pump is correctly connected to the valve shell. Make sure that the Shrader valve core is

correctly tightened.

My shock is too stiff on the first inches of travel and / or the rebound is very fast. What can I do?

The two air chambers are not correctly equalized. Check out chapter 3.2 to see how to equalize your air

chambers.

Once reassembled, the shock stickers are not aligned. What can I do?

To be sure that the stickers will be correctly aligned, check out chapter 3.5.

My shock has a slight negative travel. Is that normal?

The BOS air spring is designed to lower the engagement threshold as much as possible. Therefore, it is

possible on some bikes that there will be a small negative travel.

Where can I purchase replacement stickers and valve cap?

You can purchase these items through your approved BOS center, or on the BOS store on bosmtb.com.

I noticed some play between my shock and the frame, what can I do?

Check that your mounting hardware is torqued to your manufacturer’s specifications. If it is, the rear shock

mounting hardware must be replaced. Contact an approved BOS service center, or connect on BOS

website.

My shock is compressing when I deflate it, is that normal?

When you deflate your shock from the air valve, you are only deflating the positive air chamber. The

negative air chamber is still pressurized and pulls on the shock’s shaft. If you want to avoid this, deflate

step by step (30 to 40psi), and balance the air chambers between each step (5 to 6 slow compressions and

extensions over the first 11mm of the shock’s travel).

My shock makes a whistling or clicking sound when I compress it.

These sounds are normal to the functioning of the hydraulics when the rebound or low-speed compression

circuit is closed or almost closed. Check your settings and bring them closer to the base settings in your

product’s user manual to reduce this noise.

4. FAQ11

I’ve not had success in setting up my shock. What can I do?

The internal tuning (settings/air damper) it’s a preset tuning to correspond to a maximum of peoples,

however it’s possible to adapt all of this parameters to match with your weight, your use and your style,

even so to optimize your set up please contact your BOS service center.

For any other questions, please visit our FAQ page on the BOS website or send us a message to

Date

Location

Air pressure

(Psi)

HS

Compression

LS

Compression

Rebound

Remarks

5 .Notes

4, impasse Léonce Couture - F31200 Toulouse

tel : + 33(0)534 25 33 66 - fax : + 33(0)534 25 33 60

Table of contents

Other BOS Suspension Bicycle Accessories manuals

BOS Suspension

BOS Suspension Deville 35 User manual

BOS Suspension

BOS Suspension iDYLLE 39 FCV User manual

BOS Suspension

BOS Suspension KIRK User manual

BOS Suspension

BOS Suspension IDYLLE User manual

BOS Suspension

BOS Suspension IDYLLE 2014 User manual

BOS Suspension

BOS Suspension RARE FCV Series User manual

BOS Suspension

BOS Suspension DEVILLE 35 FCV User manual

BOS Suspension

BOS Suspension Deville 35 User manual

BOS Suspension

BOS Suspension iDYLLE 39 SC User manual

BOS Suspension

BOS Suspension iDYLLE 39 SE User manual