6 720 220 328 Subject to change without prior notice Revised 05-13

6HK Series

b. Strip the insulation off of the “W1” and “EM”

wires and insert into the thermostat control

wire block on the motor control board. Connect

the other end of the wires to the back of the

thermostat to the supplemental and emergency

heat terminals. Reference the user’s manual for

the thermostat for proper connection.

STEP 11: ROUTING NEW LINE VOLTAGE WIRES

FROM CIRCUIT BREAKER PANEL TO HEATER

ELECTRICAL BOX

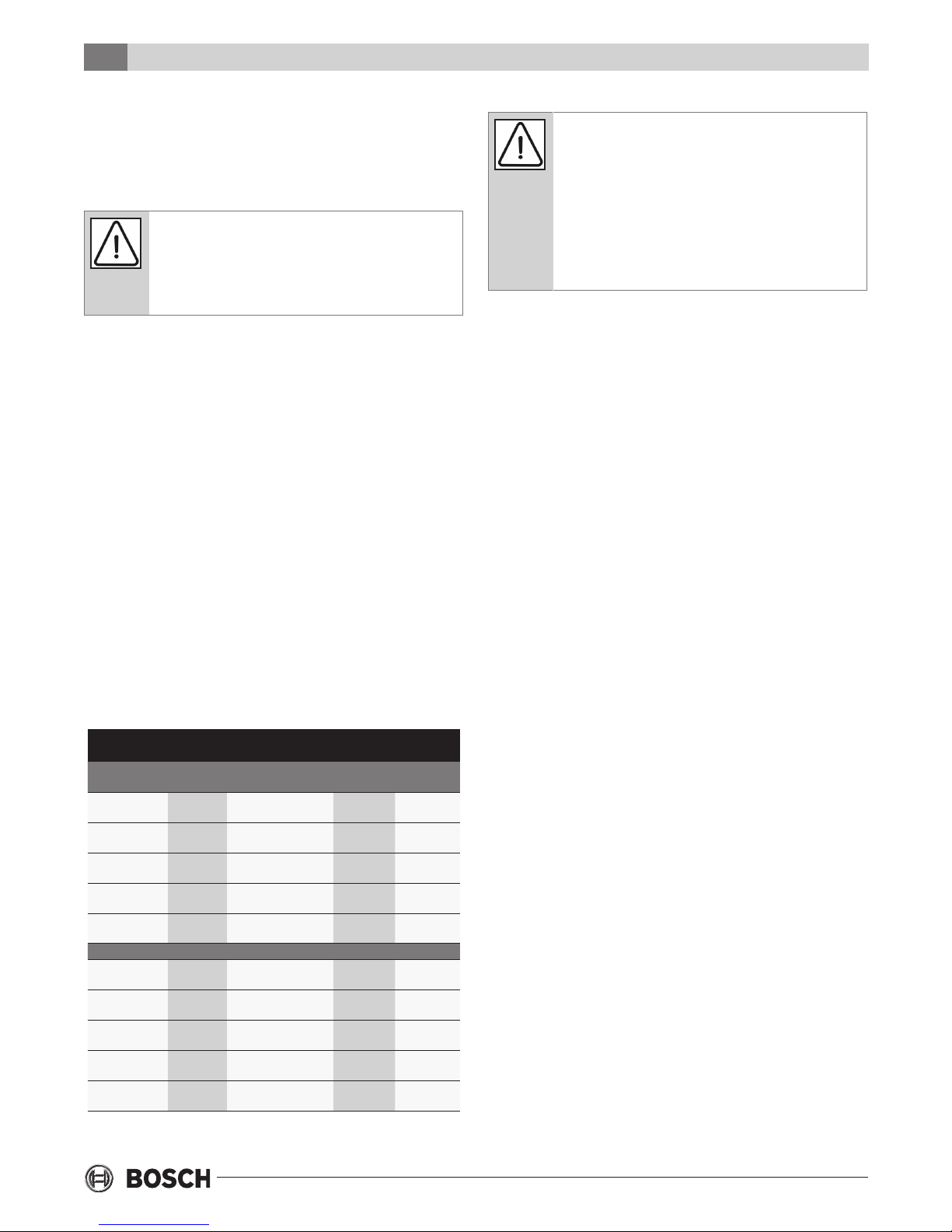

a. Select the proper wire size based upon the

heater electrical load that the blower motor and

electric heater element(s) will require. Refer to

the data tag label that is included in the heater

kit or the electrical data at the end of this

manual. Ensure that all national and local

electrical codes are followed for installation,

wire sizing, and breaker sizing.

b. Select the proper breaker size based upon the

heater electrical load that the heat pump will

require. Refer to the data tag label that is

included in the heater kit or the electrical data

at the end of this manual.

c. Route the new line voltage wiring and the

ground wire from the circuit breaker panel to

the heat pump.

d. Use the knockout provided in the heat pump

corner post as the entry for the electrical

service wiring. A plastic bushing should be used

to protect the wire insulation from the metal

edge of the knockout.

e. Connect one of the line voltage wires to “L1”

terminal connection and the other line voltage

wire to “L2” terminal connection. Torque to 22

in-lbs.

STEP 12:Use the ground lug provided in the heater

control box to connect the eld ground from the

power supply.

The heater electrical power provides service to

the unit’s Transformer, electrical heat element(s),

and blower motor only. The Compressor remains

on the original and now isolated circuit.

STEP 13: Remove the wiring diagram that is

adhered to the back side of the front panel. Replace

with the wiring diagram that was included with the

heater kit. Using spray adhesive glue is

recommended.

STEP 14: Place the adhesive back heater data label

next to the knockout in the post where the new

electrical service for the fan motor and heater

elements is entering the cabinet.

STEP 15: RESTORING POWER / TURNING ON THE

UNIT

a. Turn the disconnect switch or breaker switch to

the “ON” position for the compressor and for

the new separate circuit servicing the blower

motor and the heating elements.

b. Test the unit in “COOLING” and “HEATING” to

ensure that full functionality of the unit has

been restored.

c. Run the unit in heating mode with the heating

elements engaged for at least 10 minutes to

ensure the unit does not shut down due to any

temperature limiting device.

STEP 16: Install the cover on the heater electrical

box and reinstall the heat pump access panel(s)

with the screws that were set aside in Step 1.

Always contact your local distributor if there is

ever any doubt

SPLIT UNITS (CE/TAXXX-XAV,

CE/TAXXX-XAH, TAXXX-XAC)

This section is for CE vertical & horizontal split

units and TA horizontal (excluding the TA025) split

units only. See the section below for other split

systems or the section above relating to packaged

units.

CE-VT / HZ & TA-HZ (TA025-HZ

excluded) Units Covered in this Section

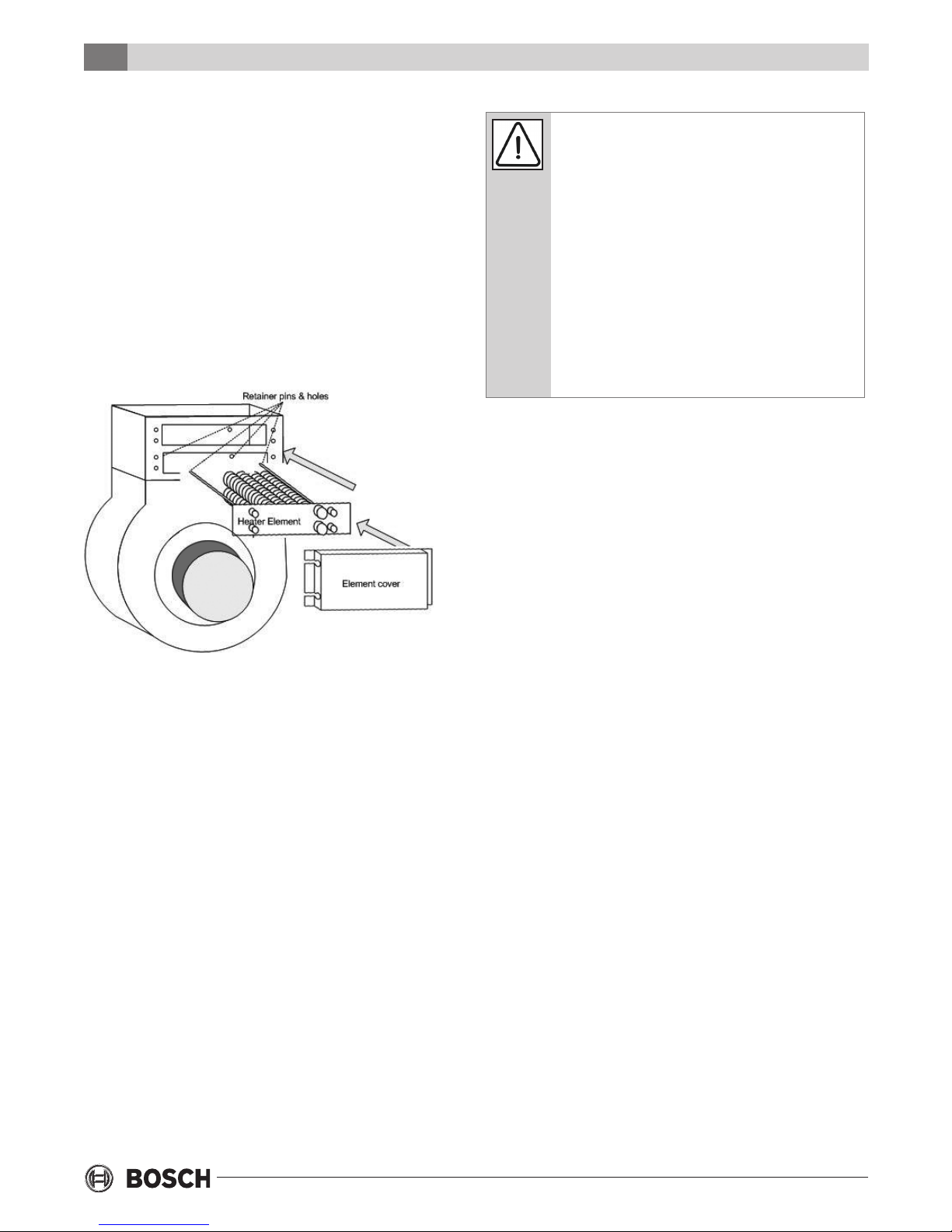

Within this range of the units, the electric heater kit

and the air handler will share a common electrical

box, therefore a single complete new electrical box

will be provided with the electrical heater kit.

Installation