Bosch TRANSFLOW j-45096 User manual

Other Bosch Measuring Instrument manuals

Bosch

Bosch PLR50 C User manual

Bosch

Bosch GLL 2-20 Professional User manual

Bosch

Bosch GTL 3 Professional User manual

Bosch

Bosch GLM 50 C Professional User manual

Bosch

Bosch PTD 1 User manual

Bosch

Bosch Atino User manual

Bosch

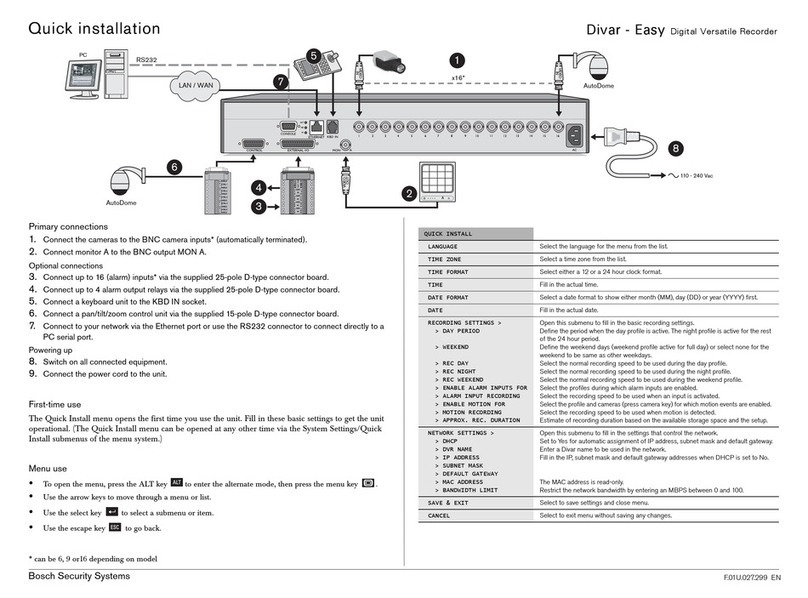

Bosch Divar Original operating instructions

Bosch

Bosch PLR 50 User manual

Bosch

Bosch GTL 3 Professional User manual

Bosch

Bosch BEA 750 User manual

Bosch

Bosch GIC 120 C Professional User manual

Bosch

Bosch GRL 250 HV User manual

Bosch

Bosch GAM Professional 220 User manual

Bosch

Bosch D-tect 120 Professional User manual

Bosch

Bosch Tronic 3000T Technical Document

Bosch

Bosch GMS 100 M User manual

Bosch

Bosch PLR 50 User manual

Bosch

Bosch LR 24 Professional User manual

Bosch

Bosch GCL 25 Professional User manual

Bosch

Bosch PLR15 User manual