en-us

5

1.4 Appliance handling safety

WARNING

Unit is heavy and requires at least two people or

proper equipment to move.

▶Do not lift appliance by door handle.

▶Remove the door for easier handling and installation.

See instructions in this manual.

WARNING

Hidden surfaces may have sharp edges.

▶Use caution when reaching behind or under appliance.

▶Wear gloves to avoid cutting fingers on sharp edges

during installation.

WARNING

Do not use the oven for storage.

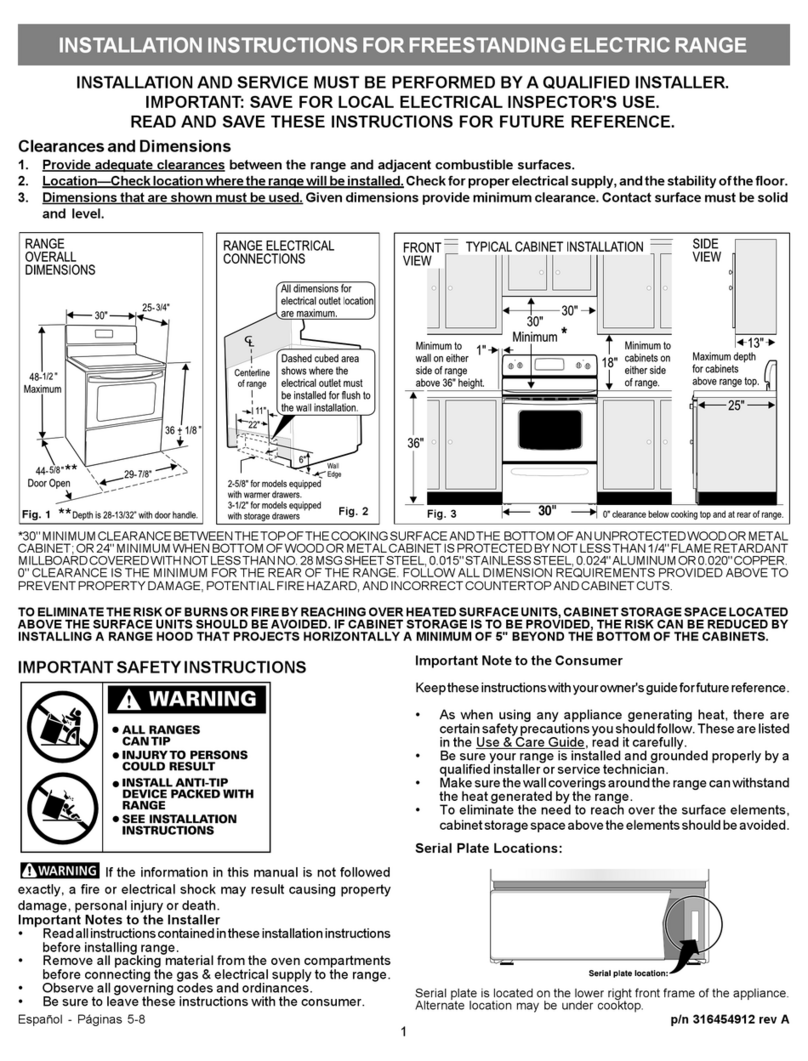

1.5 Installation location

To eliminate the risk of burns or fire by reaching over

heated surface units, cabinet storage space located above

the surface units should be avoided. If cabinet storage is

to be provided, the risk can be reduced by installing a

hood that projects horizontally a minimum of 5" (12.7cm)

beyond the bottom of the cabinet.

Verify that cabinets above the range are a maximum of

13" (330 mm) deep.

1.6 Safety codes and standards

This appliance complies with the latest version of one or

more of the following standards:

¡CAN/CSA C22.2 No. 61 - Household Cooking Ranges

¡UL 858 - Household Electric Ranges

¡ANSI Z21.1b-2012 Household Cooking Gas Appliances

¡Installation must conform with local codes or, in the ab-

sence of local codes, with the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or, in Canada, the Natural Gas

and Propane Installation Code, CSA B149.1.

It is the responsibility of the owner and the installer to de-

termine if additional requirements and/or standards apply

to specific installations.

1.7 Electrical safety

¡Installer - show the owner the location of the circuit

breaker or fuse. Mark it for easy reference.

¡If required by the National Electrical Code (or Canadian

Electrical Code), this appliance must be installed on a

separate branch circuit.

¡Local codes vary. The installer is responsible for ensur-

ing that the installation, connections, and grounding

comply with all applicable codes. The manufacturer is

not responsible for any issues associated with the im-

proper installation of this product.

¡Be sure your appliance is properly installed and

grounded by a qualified technician.

¡The circuit breaker should have a contact separation of

at least 3mm on all poles.

¡Do not use an adapter.

¡Refer to the rating plate for more information.

→

"Rating plate location", Page27

WARNING

Before installing, turn power OFF at the service panel.

▶Lock service panel to prevent power from being turned

ON accidentally.

ELECTRIC SHOCK HAZARD

▶Disconnect power before installing or servicing. Before

turning power ON, be sure that all controls are in the

OFF position.

▶DO NOT remove connections.

▶DO NOT use an extension cord.

▶Improper grounding can result in a risk of electric

shock.

▶Failure to follow these instructions can result in death,

fire, or electrical shock.

GROUNDING INSTRUCTIONS

▶This appliance must be grounded.

▶Grounding reduces the risk of electric shock by provid-

ing a safe pathway for electric current in the event of a

short circuit.

▶Be sure your appliance is properly installed and

grounded by a qualified technician.

▶Installation, electrical connections and grounding must

comply with all applicable codes.

Before you turn on power supply, make sure all controls

are in the OFF position.

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS