RE 51433-B/04.10 | 30, 50, 80 NFF2 Bosch Rexroth AG 3/30

Inhalt

Inhalt

1 About this document......................................................................................5

1.1 Related documents..................................................................................5

1.2 Abbreviations used ..................................................................................5

2 General safety instructions............................................................................5

2.1 Intended use ............................................................................................6

2.2 Improper use............................................................................................6

2.3 Qualification of personnel ........................................................................6

2.4 Safety instructions in this document ........................................................7

2.5 Adhere to the following instructions .........................................................8

2.6 Obligations of the operator ......................................................................9

2.7 Safety equipment.....................................................................................9

3 Scope of delivery ..........................................................................................10

4 Product description......................................................................................11

4.1 Performance description........................................................................11

4.2 Device description .................................................................................11

4.3 Component overview .............................................................................12

4.4 Product identification .............................................................................14

5 Transport and storage..................................................................................15

5.1 Transporting the off-line filter system.....................................................15

5.2 Storing the off-line filter system .............................................................15

6 Assembly.......................................................................................................16

6.1 Assembling the off-line filter system ......................................................16

7 Commissioning.............................................................................................17

7.1 First commissioning ...............................................................................17

8 Operation.......................................................................................................18

9 Maintenance and repair................................................................................19

9.1 Cleaning and care..................................................................................19

9.2 Maintenance ..........................................................................................19

9.3 Replacing wear parts .............................................................................19

9.4 Exchanging the suction filter (protective pump filter) .............................20

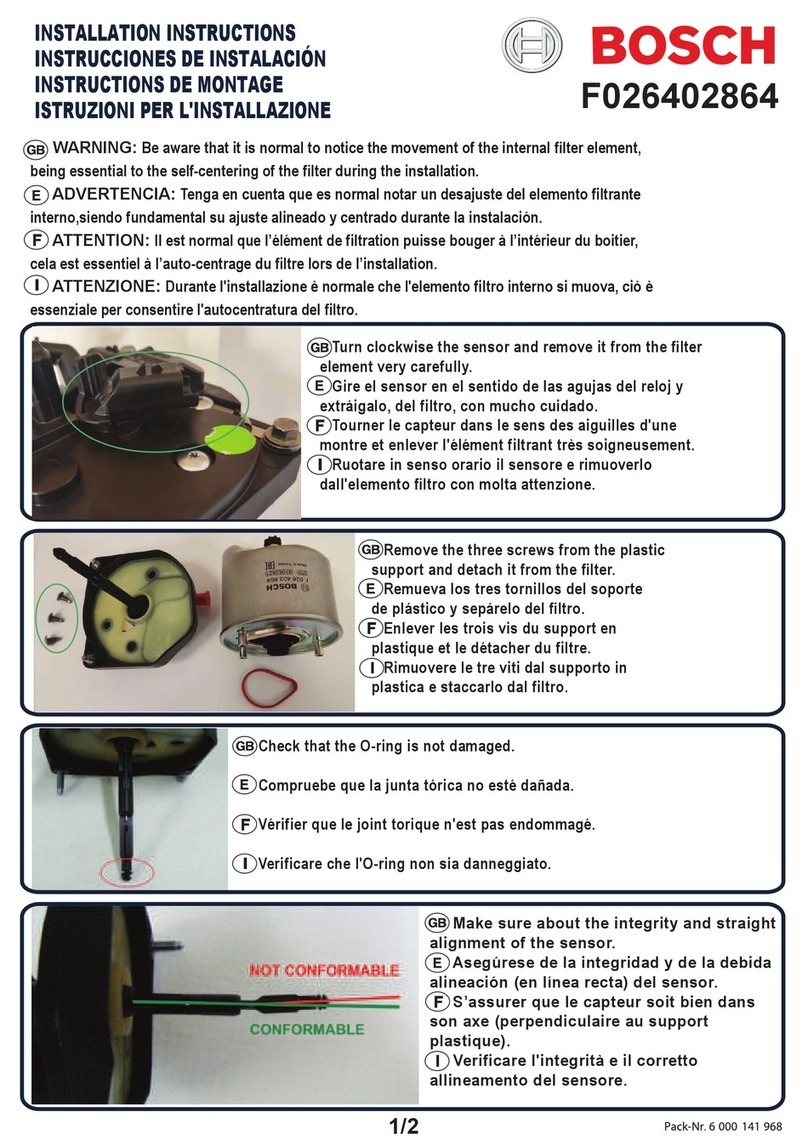

9.5 Exchanging the filter element ................................................................20

9.6 Repair ....................................................................................................22

9.7 Spare parts ............................................................................................22

10 Disposal.........................................................................................................23

10.1 Environmental protection ....................................................................... 23

11 Extension and conversion ...........................................................................24

12 Troubleshooting............................................................................................25

12.1 How to proceed for troubleshooting.......................................................25

13 Technical data...............................................................................................26

14 Appendix........................................................................................................27

14.1 Address directory...................................................................................27

14.2 Declaration of conformity ....................................................................... 27