Bosch TRONIC 5000C Pro Reference manual

Other Bosch Water Heater manuals

Bosch

Bosch TR8500 21/24 DESOAB User manual

Bosch

Bosch RDE182141M User manual

Bosch

Bosch Highflow 17e User manual

Bosch

Bosch Highflow 17e User manual

Bosch

Bosch Tronic 3000 C Pro US12 User manual

Bosch

Bosch Tronic 1000 T User manual

Bosch

Bosch Tronic 3000 C Pro US12 User manual

Bosch

Bosch GWH C 920 ES Reference manual

Bosch

Bosch TR5000 Series User manual

Bosch

Bosch GWH 1600 P NG User manual

Bosch

Bosch THERM 1000 O Guide

Bosch

Bosch Pro Tankless GWH-635-ES-N User manual

Bosch

Bosch WR 11 B Technical Document

Bosch

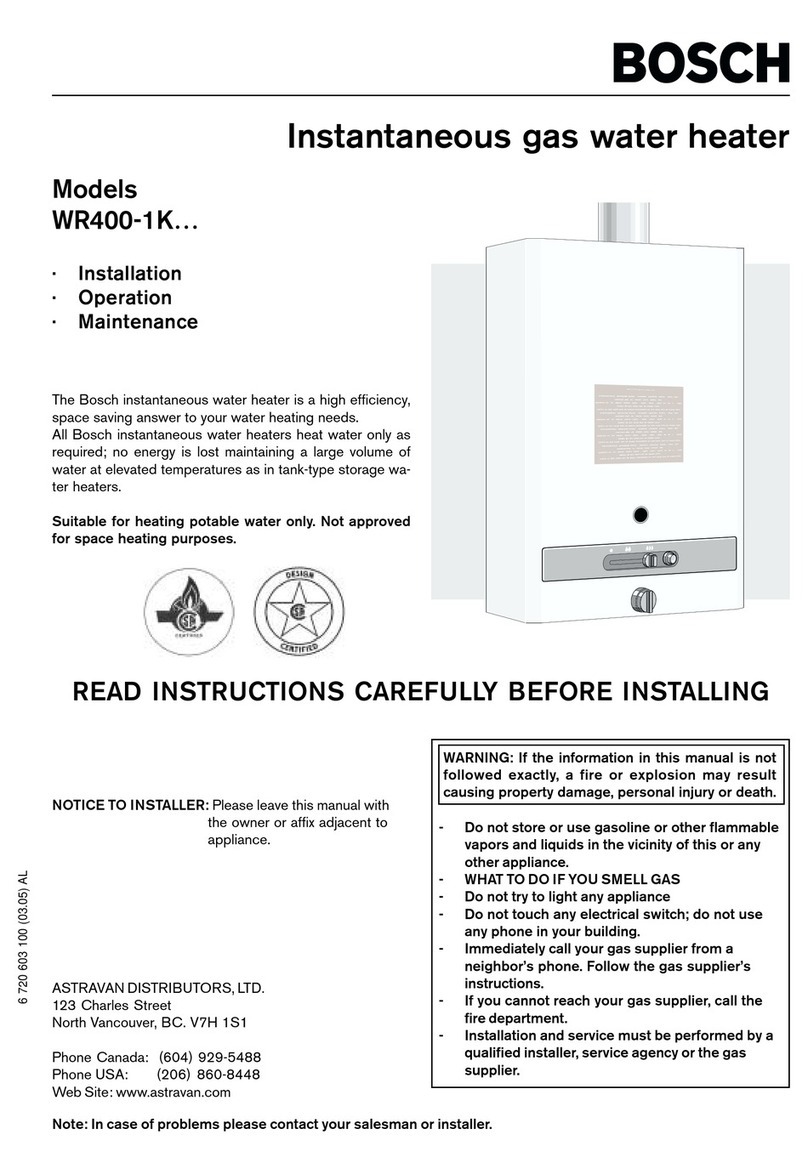

Bosch WR400 K T2 Series Owner's manual

Bosch

Bosch Therm 4300 Series Guide

Bosch

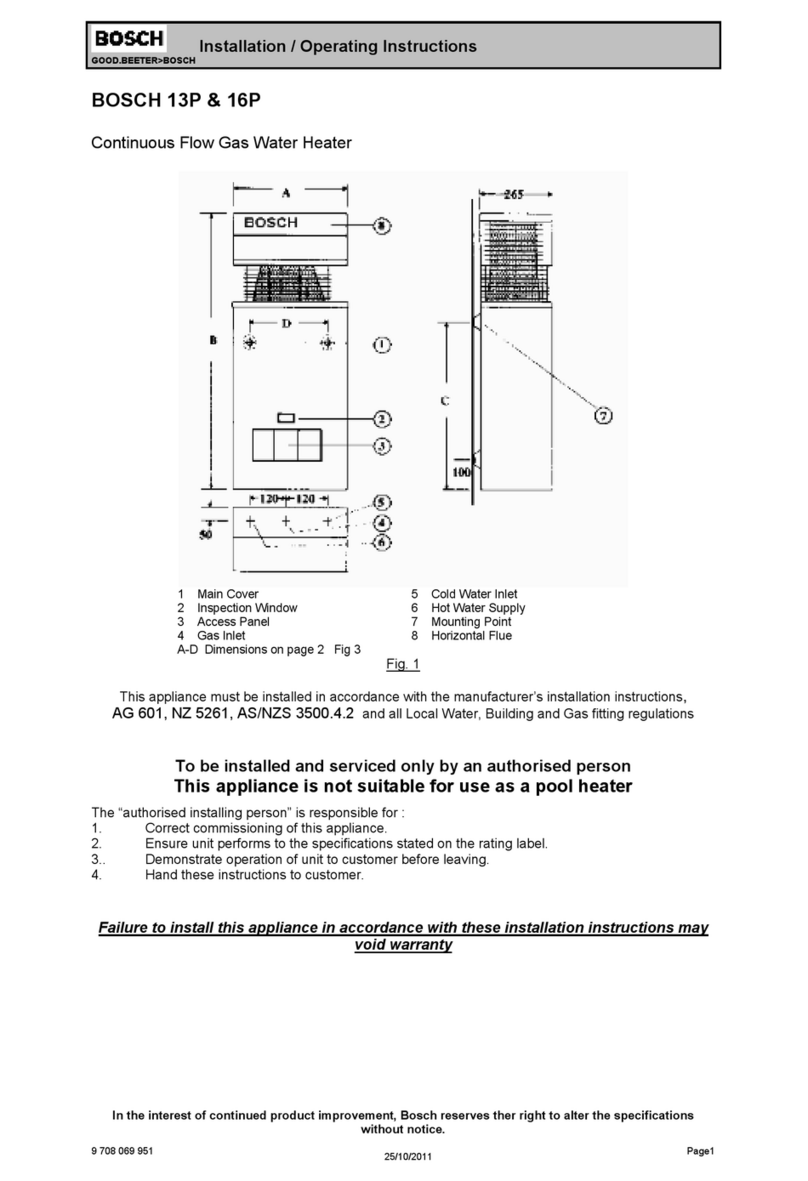

Bosch 13P Manual

Bosch

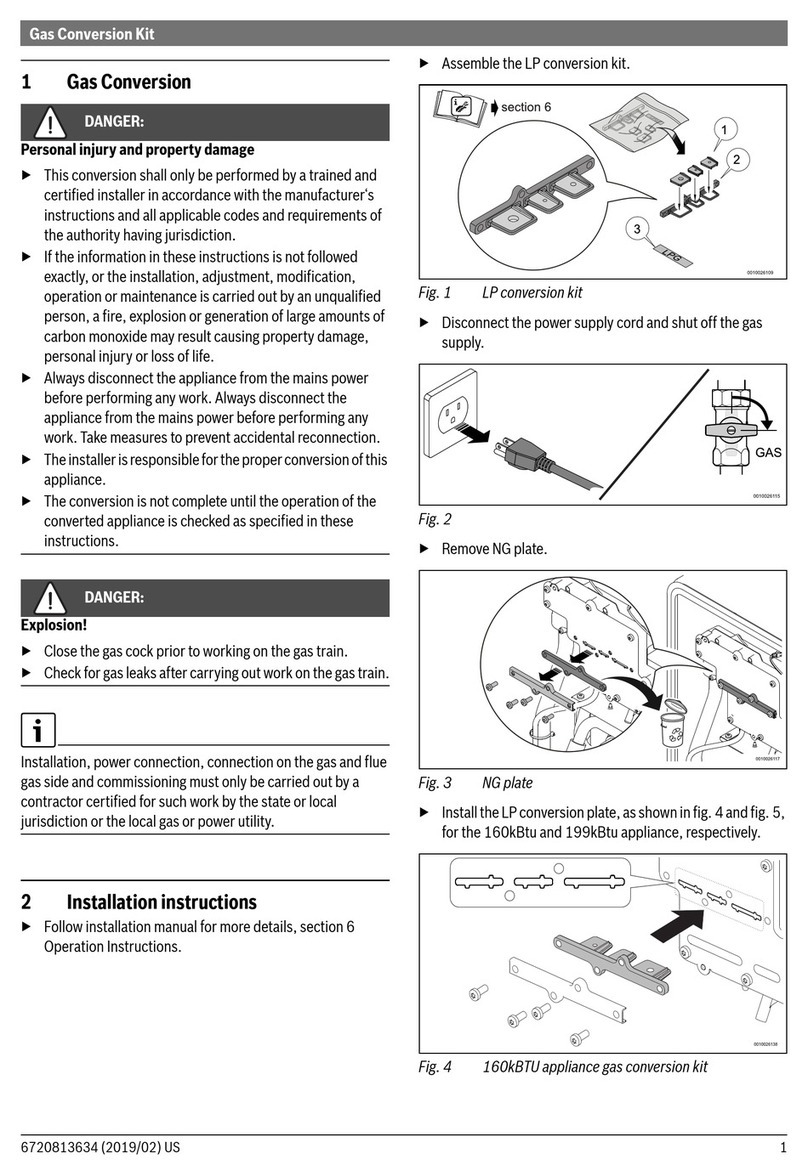

Bosch Greentherm 9000 User manual

Bosch

Bosch GWH 260 PN Reference manual

Bosch

Bosch AQUASTAR 125B LPL operati User manual

Bosch

Bosch C 1210 ESC Reference manual

Popular Water Heater manuals by other brands

Kenmore

Kenmore 153.582400 Use & care guide

STIEBEL ELTRON

STIEBEL ELTRON Eltronom SHU 5 S Operating and installation instructions

clage

clage E-Mini Series Operating and installation instructions

Toyotomi

Toyotomi Oil Miser OM-180 installation manual

Bradford White

Bradford White EF Series Service manual

Eccotemp

Eccotemp 40-H Use & care manual

Dimplex

Dimplex ECSd125-580 Installation and user instructions

Dux

Dux 32FCR6N installation manual

Noritz

Noritz N-132M Owner's guide and installation manual

TESY

TESY GCV7/4S 10047 Instructions for use and maintenance

A.O. Smith

A.O. Smith Gphe 50 instruction manual

Toyotomi

Toyotomi Oil Miser OM-148 (Type D) Operation and maintenance instructions