Bosche WTS User manual

User manual WTS Ver.1.16

Seite 1von 52

WTS

User manual

Status 1.16

Status: 31.08.2022

Version 1.16 .

User manual WTS Ver.1.16

Seite 2von 52

Foreword These operating instructions provide you with detailed

information about the WTB weight measurement system. It

introduces you to set-up, commissioning and operation.

These instructions contain safety instructions to guarantee

safe use of the weight measurement system.

The manufacturer strives to improve their products on an

ongoing basis. They reserve the right to carry out any and all

modifications and improvements that they consider to be

necessary. However, this means that there is no obligation to

carry out retrospective modifications in this connection.

Before using the weight measurement system, you must have

read and understood the operating instructions and the safety

regulations that they contain.

Caution! Risk of electric shock.

Caution

This operation must be performed by skilled personnel.

Attention

Pay particular attention to the following instructions.

A notice

Further information.

User manual WTS Ver.1.16

Seite 3von 52

Table of Contents

1USER WARNINGS ..................................................................................................................................... 4

2RECOMMENDATIONS FOR CORRECT INSTALLATION OF WEIGHING INSTRUMENTS ................................. 4

3RECOMMENDATIONS FOR CORRECT INSTALLATION OF THE LOAD CELLS ................................................ 5

3.1 LOAD CELL INPUT TEST (QUICK ACCESS) ................................................................................................ 7

3.2 LOAD CELL TESTING ............................................................................................................................... 7

3.3 MAIN SPECIFICATIONS OF THE INSTRUMENT ........................................................................................ 8

4TECHNICAL SPECIFICATIONS..................................................................................................................... 9

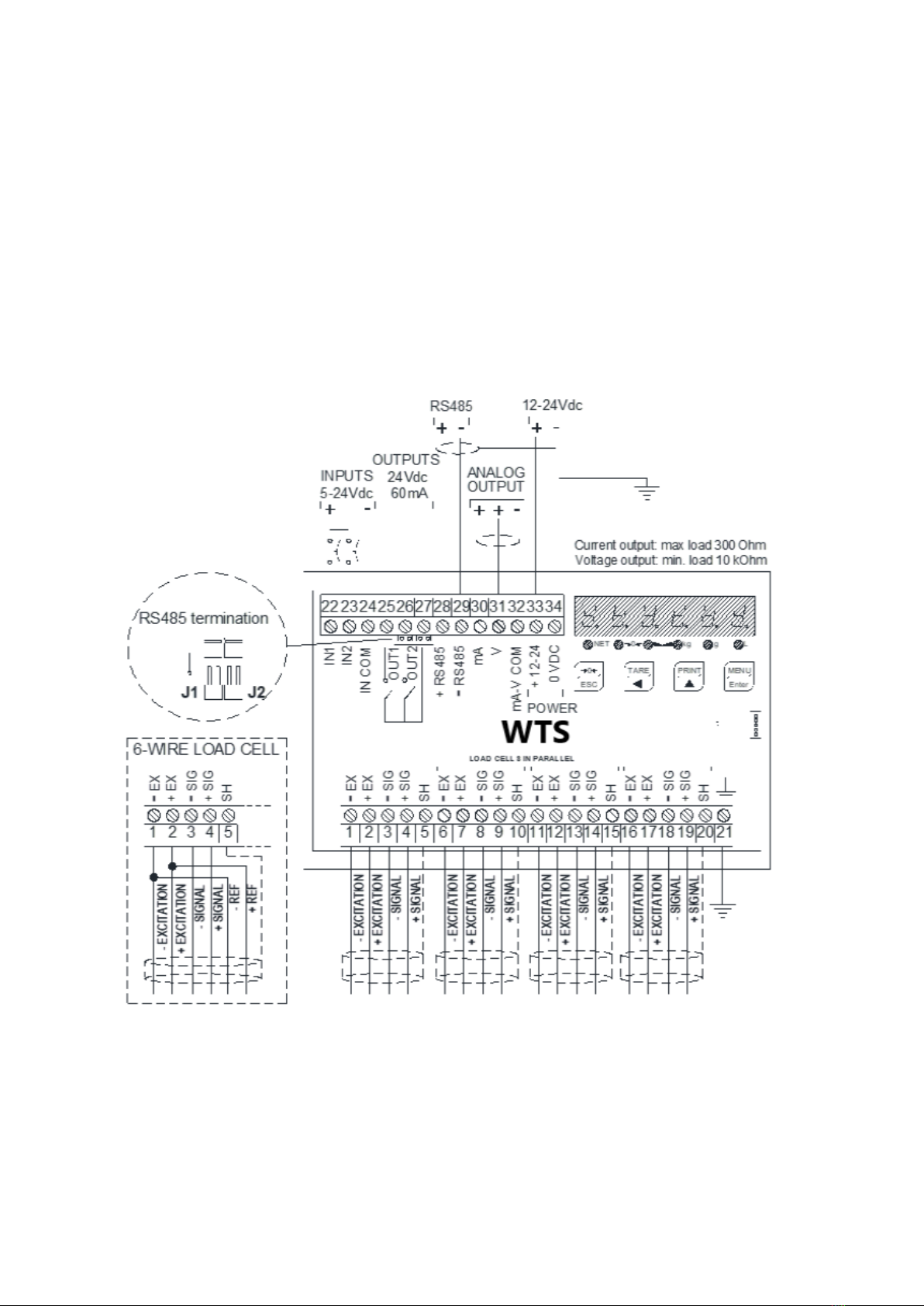

5ELECTRICAL CONNECTIONS .................................................................................................................... 11

5.1 BASIC INFORMATION........................................................................................................................... 11

5.2 WIRING DIAGRAM ............................................................................................................................... 11

6LED AND KEY FUNCTIONS ...................................................................................................................... 12

7MENU MAP............................................................................................................................................ 13

7.1 SETPOINTS ........................................................................................................................................... 13

7.2 SYSTEM PARAMETERS ......................................................................................................................... 13

8INSTRUMENT COMMISSIONING ............................................................................................................ 14

9PROGRAMMING OF SYSTEM PARAMETERS ........................................................................................... 15

9.1 THEORETICAL CALIBRATION ................................................................................................................ 15

9.1.1 MAXIMUM CAPACITY ...................................................................................................................... 16

9.1.2 TARE WEIGHT ZERO SETTING .......................................................................................................... 16

9.1.3 ZERO VALUE MANUAL ENTRY ......................................................................................................... 16

9.2 REAL CALIBRATION (WITH SAMPLE WEIGHTS) .................................................................................... 17

9.3 FILTER ON THE WEIGHT ....................................................................................................................... 18

9.3.1 ANTI PEAK........................................................................................................................................ 18

9.4 ZERO PARAMETERS.............................................................................................................................. 19

9.4.1 RESETTABLE WEIGHT SETTING FOR SMALL WEIGHT CHANGES ...................................................... 19

9.4.2 AUTOMATIC ZERO SETTING AT POWER-ON .................................................................................... 19

9.4.3 ZERO TRACKING............................................................................................................................... 19

9.5 SETTING UNITS OF MEASURE............................................................................................................... 20

9.5.1 DISPLAY COEFFICIENT...................................................................................................................... 20

9.6 OUTPUTS AND INPUTS CONFIGURATION ............................................................................................ 22

9.7 SEMI-AUTOMATIC TARE (NET/GROSS) ................................................................................................ 24

9.8 PRESET TARE (SUBTRACTIVE TARE DEVICE) ......................................................................................... 25

9.9 SEMI-AUTOMATIC ZERO (WEIGHT ZERO-SETTING FOR SMALL VARIATIONS) ...................................... 26

9.10 PEAK..................................................................................................................................................... 26

9.11 ANALOG OUTPUT................................................................................................................................. 26

9.12 SERIAL COMMUNICATION SETTING..................................................................................................... 28

9.12.1 RS485 SERIAL CONNECTION........................................................................................................ 30

9.12.2 DIRECT CONNECTION BETWEEN RS485 AND RS232 WITHOUT CONVERTER.............................. 30

9.13 TEST ..................................................................................................................................................... 31

10 SETPOINTS PROGRAMMING .................................................................................................................. 32

11 ALARMS ................................................................................................................................................. 33

12 FAST CONTINUOUS TRANSMISSION PROTOCOL..................................................................................... 34

13 CONTINUOUS TRANSMISSION PROTOCOL TO REMOTE DISPLAYS.......................................................... 35

14 ASCII BIDIRECTIONAL PROTOCOL ........................................................................................................... 36

15 MODBUS-RTU PROTOCOL ...................................................................................................................... 41

User manual WTS Ver.1.16

Seite 4von 52

1 USER WARNINGS

RECOMMENDATIONS FOR THE PROPER USE OF WEIGHING INSTRUMENT

-Keep away from heat sources and direct sunlight

-Repair the instrument from rain (except special IP versions)

-Do not wash with water jets (except special IP versions)

-Do not dip in water

-Do not spill liquid on the instrument

-Do not use solvents to clean the instrument

-Do not install in areas subject to explosion hazard (except special Atex versions)

2 RECOMMENDATIONS FOR CORRECT INSTALLATION OF WEIGHING

INSTRUMENTS

The terminals indicated on the instrument’s wiring diagram to be connected to earth

must have the same potential as the weighed structure (same earthing pit or earthing

system). If you are unable to ensure this condition, connect with an earthing wire the

terminals of the instrument (including the terminal 0 VDC) to the weighed structure.

The cell cable must be individually led to its panel input and not share a conduit with

other cables; connect it directly to the instrument terminal strip without breaking its

route with support terminal strips.

Use “RC” filters on the instrument-driven solenoid valve and remote control switch coils.

Avoid inverters in the instrument panel; if inevitable, use special filters for the inverters and

separate them with sheet metal partitions.

The panel installer must provide electric protections for the instruments (fuses, door lock switch

etc.).

It is advisable to leave the equipment always switched on to prevent the formation of

condensation.

MAXIMUM CABLE LENGTHS

RS485: 1000 metres with AWG24, shielded and twisted cables

RS232: 15 metres for baud rates up to 19200

User manual WTS Ver.1.16

Seite 5von 52

3 RECOMMENDATIONS FOR CORRECT INSTALLATION OF THE LOAD CELLS

SIZING OF LOAD CELLS CAPACITY

For safety reasons, in case of static weighing, it is advisable to use the load cells at a

maximum of 70-80% of its nominal capacity (assuming that the load is uniformly distributed

over the entire weighed structure); depending on the handling mode of the load to weigh,

consider to further reduce the % of load with respect to the nominal capacity (ex.: forklifts

handling, bridge cranes, etc.).

In case of weighing with dynamic loads, the installer has to estimate the thrust speed, the

acceleration, the frequency, etc.

INSTALLING LOAD CELLS

The load cells must be placed on rigid, stable in-line structures; it is important to use the

mounting modules for load cells to compensate for misalignment of the support surfaces.

PROTECTION OF THE CELL CABLE

Use water-proof sheaths and joints in order to protect the cables of the cells.

MECHANICAL RESTRAINTS (pipes, etc.)

When pipes are present, we recommend the use of hoses and flexible couplings with open

mouthpieces with rubber protection; in case of hard pipes, place the pipe support or anchor

bracket as far as possible from the weighed structure (at a distance at least 40 times the

diameter of the pipe).

CONNECTING SEVERAL CELLS IN PARALLEL

Connect several cells in parallel by using - if necessary - a watertight junction box with

terminal box. The cell connection extension cables must be shielded, led individually into

their piping or conduit and laid as far as possible from the power cables (in case of 4-wire

connections, use cables with 4x1 mm2minimum cross-section).

WELDING

Avoid welding with the load cells already installed. If this cannot be avoided, place the welder

ground clamp close to the required welding point to prevent sending current through the load

cell body.

WINDY CONDITIONS - KNOCKS – VIBRATIONS

The use of weigh modules is strongly recommended for all load cells to compensate for

misalignment of the support surfaces. The system designer must ensure that the plant is

protected against lateral shifting and tipping relating to: shocks and vibration; windy

conditions; seismic conditions in the installation setting; stability of the support structure.

User manual WTS Ver.1.16

Seite 6von 52

EARTHING THE WEIGHED STRUCTURE

By means of a copper wire with suitable cross-section, connect the cell upper support plate

with the lower support plate, then connect all the lower plates to a single earthing system.

Electrostatic charges accumulated because of the product rubbing against the pipes and the

weighed container walls are discharged to the ground without going through or damaging the

load cells. Failure to implement a proper earthing system might not affect the operation of the

weighing system; this, however, does not rule out the possibility that the cells and connected

instrument may become damaged in the future. It is forbidden to ensure earthing system

continuity by using metal parts contained in the weighed structure.

FAILURE TO FOLLOW THE INSTALLATION RECOMMENDATIONS WILL BE

CONSIDERED A MISUSE OF THE EQUIPMENT

User manual WTS Ver.1.16

Seite 7von 52

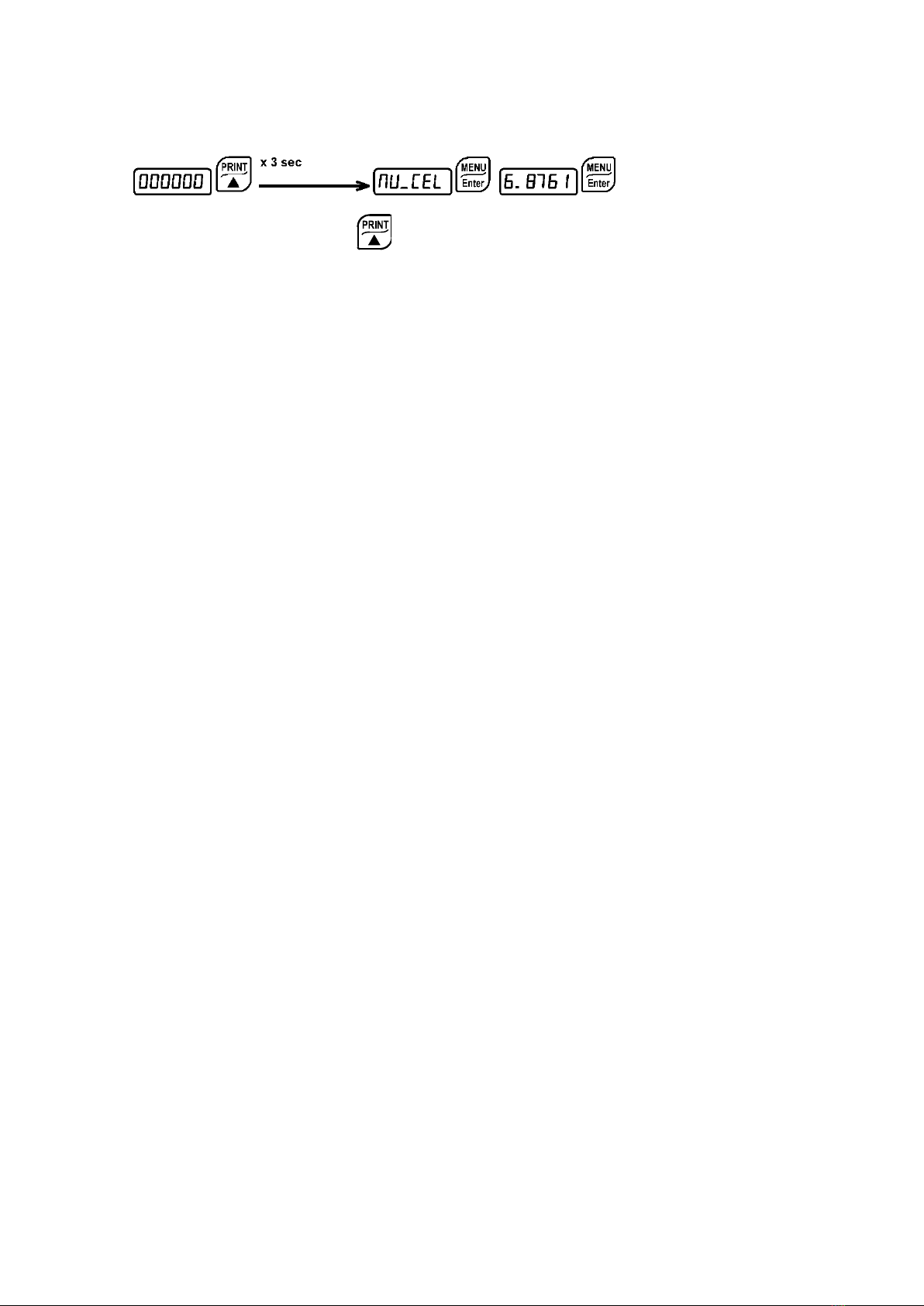

3.1 LOAD CELL INPUT TEST (QUICK ACCESS)

From the weight display, press for 3 seconds; the response signal of the load cells is

displayed, expressed in mV with four decimals.

3.2 LOAD CELL TESTING

Load cell resistance measurement (use a digital multimeter):

Disconnect the load cells from the instrument and check that there is no moisture in the cell

junction box caused by condensation or water infiltration. If so, drain the system or replace it

if necessary.

The value between the positive signal wire and the negative signal wire must be equal or

similar to the one indicated in the load cell data sheet (output resistance).

The value between the positive excitation wire and the negative excitation wire must be

equal or similar to the one indicated in the load cell data sheet (input resistance).

The insulation value between the shield and any other cell wire and between any other cell

wire and the body of the load cell must be higher than 20 Mohm (mega ohms).

Load cell voltage measurement (use a digital multimeter):

Take out the load cell to be tested from underneath the container, or alternatively, lift the

container support.

Make sure that the excitation of two wires of the load cell connected to the instrument (or

amplifier) is 5 Vdc ±3%.

Measure the response signal between the positive and the negative signal wires by directly

connecting them to the tester, and make sure that it is comprised between 0 and ±0.5 mV

(thousandths of a Volt).

Apply load to the cell and make sure that there is a signal increment.

IF ONE OF THE ABOVE CONDITIONS IS NOT MET, PLEASE CONTACT THE

TECHNICAL ASSISTANCE SERVICE.

User manual WTS Ver.1.16

Seite 8von 52

3.3 MAIN SPECIFICATIONS OF THE INSTRUMENT

-Weight indicator and transmitter for Omega/DIN rail mounting suitable for back panel or

junction box. Six-digit semi-alphanumeric display (8mm h), 7 segment. Four-key keyboard.

Dimensions: 25x115x120 mm.

-IP67 box version (170x140x95mm). Four fixing holes diameter 4 mm (centre distance 122x152

mm).

-Displays the gross weight; from external contact allows to zero set or display the net weight

(both values will be lost when the instrument is turned off).

-Peak weight function.

-Transmits the gross or net weight via optoisolated analog output 16 bit, current 0-20mA, 4-

20mA or voltage 0-10V, 0-5V ( ±10V / ±5V by closing a soldering jumper).

-Transmits the gross or net weight via RS485 serial port, by means of protocols:

▫Modbus RTU

▫ASCII bidirectional protocol

▫Continuous transmission

User manual WTS Ver.1.16

Seite 9von 52

4 TECHNICAL SPECIFICATIONS

POWER SUPPLY and CONSUMPTION

(VDC)

12 - 24 VDC +/- 10% ; 5 W

NO. OF LOAD CELLS IN PARALLEL and

SUPPLY

max 8 ( 350 ohm ) ; 5VDC/120mA

LINEARITY / ANALOG OUTPUT LINEARITY

< 0.01% F.S. ; < 0.01% F.S.

THERMAL DRIFT / ANALOG OUTPUT

THERMAL DRIFT

< 0.0005 % F.S. /°C ; < 0.003 % F.S./°C

A/D CONVERTER

24 bit (16.000.000 points)

MAX DIVISIONS (with measurement range:

+/-10mV = sens. 2mV/V)

+/- 999999

MEASUREMENT RANGE

+/- 19.5 mV

MAX SENSITIVITY OF USABLE LOAD

CELLS

+/-3 mV/V

MAX CONVERSIONS PER SECOND

80 conversions/second

DISPLAY RANGE

- 999999 ; + 999999

NO. OF DECIMALS / DISPLAY

INCREMENTS

0 - 4 / x 1 x 2 x 5 x 10 x 20 x 50 x 100

DIGITAL FILTER / READINGS PER

SECOND

10 levels / 5 – 80 Hz

OPTO LOGIC OUTPUTS

N.2 - max 24 VDC ; 60mA

DIGITAL INPUTS

N.2 - optoisolated 5 - 24 VDC PNP

SERIAL PORTS

RS485

BAUD RATE

2400, 4800, 9600, 19200, 38400, 115200

HUMIDITY (non condensing)

85 %

STORAGE TEMPERATURE

- 30°C + 80°C

WORKING TEMPERATURE

- 20°C + 60°C

OPTOISOLATED ANALOG OUTPUT

16 Bit - 65535 divisions

0-20 mA; 4-20 mA (max 300 ohm);

0-10 VDC; 0-5 VDC;

+/- 10 VDC; +/- 5 VDC (min 10 kohm).

OPTO RELAY OUTPUTS

N.2 - max 24 VDC ; 60mA

WORKING TEMPERATURE

-20 °C +60 °C

Equipment to be powered by 12-24 Vdc LPS or Class 2 power source.

User manual WTS Ver.1.16

Seite 10 von 52

IP67 BOX VERSIONS

IP67 box with transparent cover and

six M16x1.5 cable glands

IP67 box with external keypad and

six M16x1.5 cable glands

IP67 box with external keypad and

six M16x1.5 cable glands

And integrated power supply

User manual WTS Ver.1.16

Seite 11 von 52

5 ELECTRICAL CONNECTIONS

5.1 BASIC INFORMATION

-It is recommended that the power supply negative pole be grounded.

-It is possible to supply up to eight 350 ohm load cells or sixteen 700 ohm load cells.

-Connect terminal “0 VDC” to the RS485 common of the connected instruments in the event

that these receive alternating current input or that they have an optoisolated RS485.

-In case of an RS485 network with several devices it is recommended to activate the 120

ohm termination resistance on the two devices located at the ends of the network, as

described in the paragraph RS485 SERIAL CONNECTION.

5.2 WIRING DIAGRAM

2 outputs: settable setpoints or remote output management via protocol.

2 inputs (Default: SEMI-AUTOMATIC ZERO input 1; NET/GROSS input 2): settable to

have the following functions: SEMI-AUTOMATIC ZERO, NET/GROSS, PEAK or REMOTE

CONTROL (see paragraph OUTPUTS AND INPUTS CONFIGURATION).

User manual WTS Ver.1.16

Seite 12 von 52

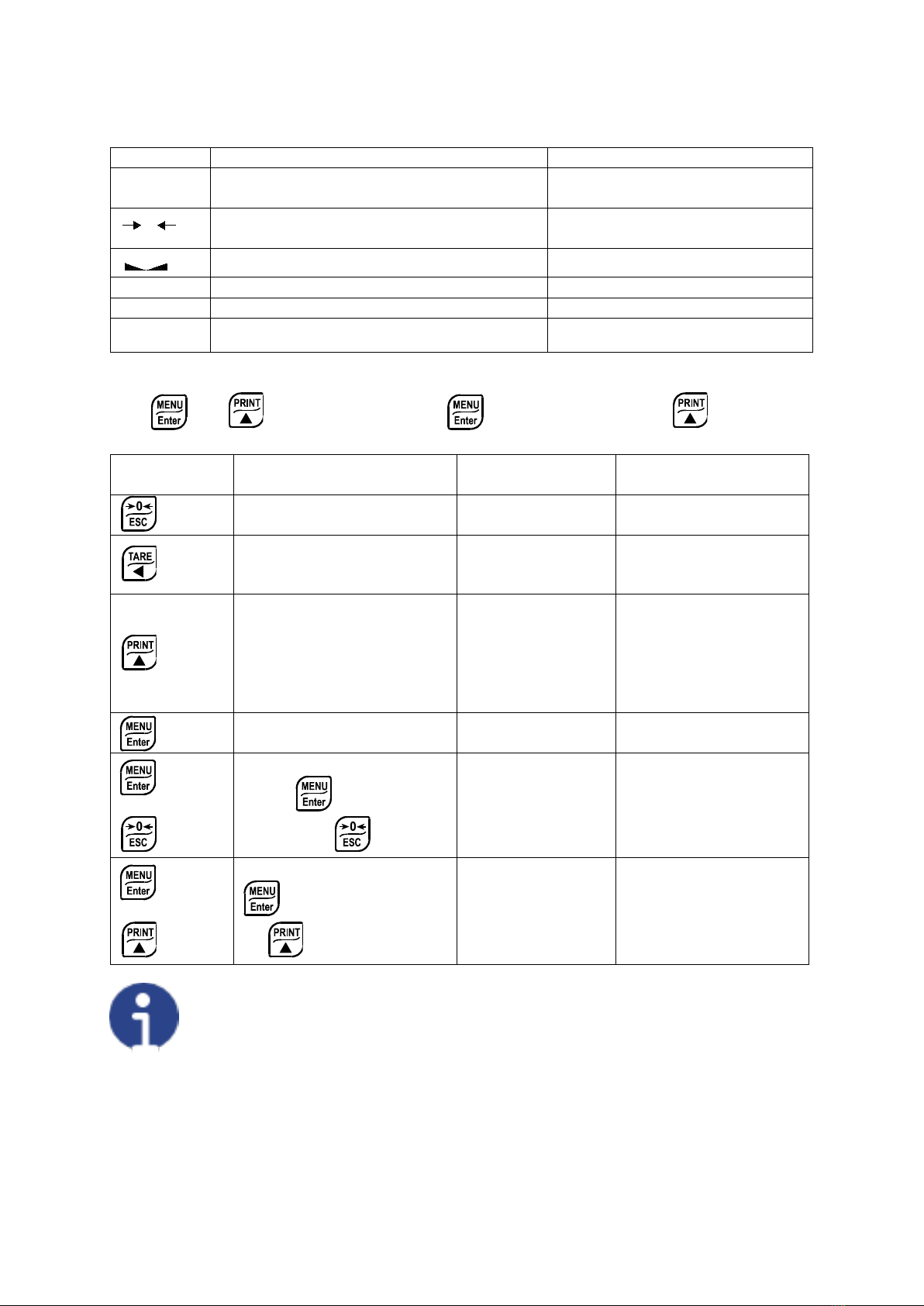

6 LED AND KEY FUNCTIONS

LED

Main function

Secondary function *

NET

net weight LED: net weight display (semi-

automatic tare or preset tare)

LED lit: input 1 closed

zero LED (deviation from zero not more

than +/- 0.25 divisions)

LED lit: input 2 closed

stability LED LED lit: output 1 closed

kg

unit of measure: kg

LED lit: output 2 closed

g

unit of measure: g

no meaning

L other unit of measure no meaning

*) To activate the secondary LED function, during weight display press and hold down the

keys and at the same time (press immediately followed by ).

KEY Short press

Long press

(3 sec)

Into menus

Tare resetting

Cancel or return to

previous menu

Gross Net Net Gross

Select figure to be

modified or return to

previous menu item

Gross weight:

mV load cell test

Net weight:

temporarily display

the gross weight

Modify selected figure

or go to next menu

item

Setting setpoints and

hysteresis

Confirm or enter in

submenu

+

Setting general parameters

(press immediately

followed by )

+

Setting preset tare (press

immediately followed

by )

The LEDs light up in sequence to indicate that a setting and not a weight is being

viewed.

0

User manual WTS Ver.1.16

Seite 13 von 52

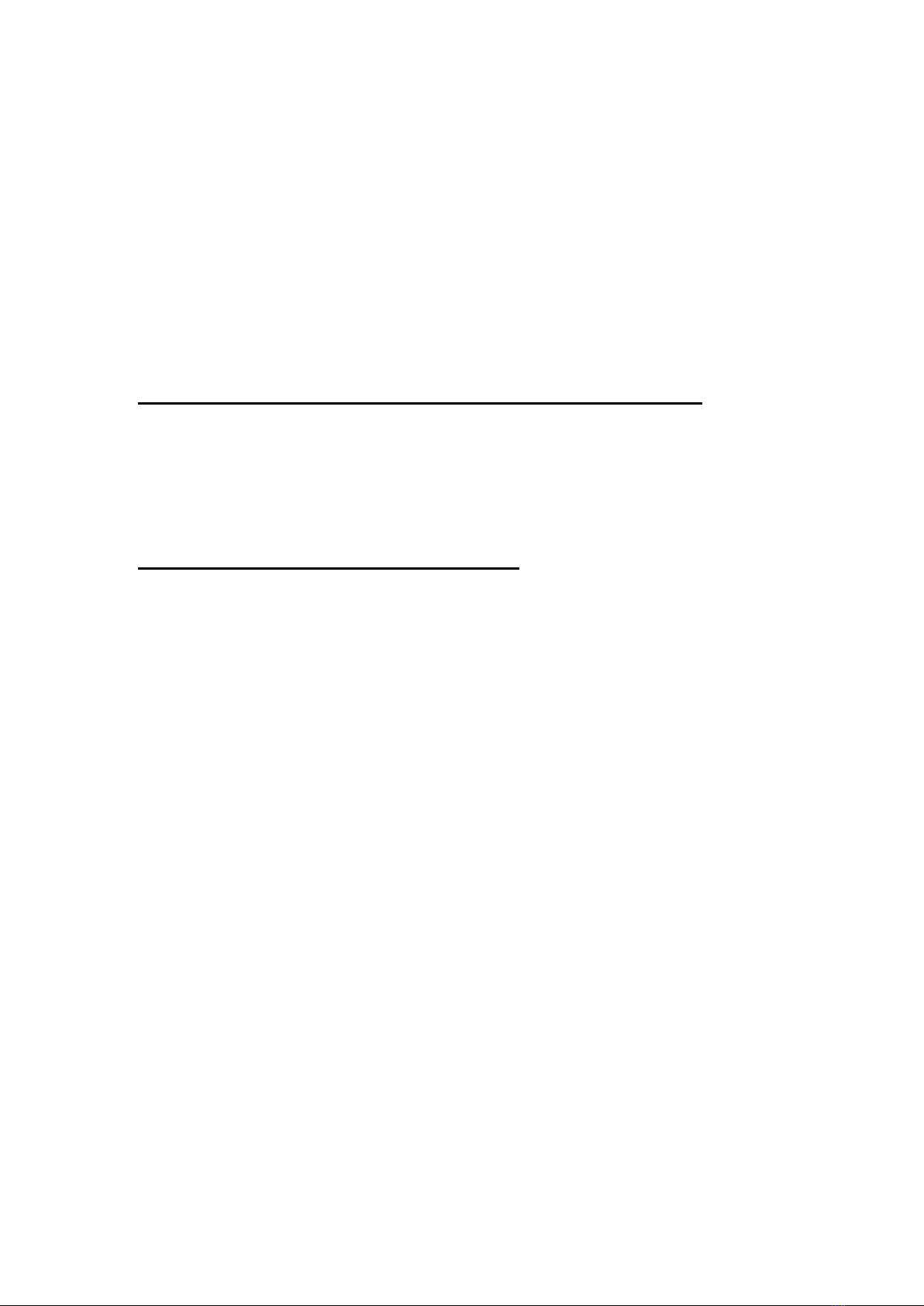

7 MENU MAP

Within the menu, the changes are applied immediately after pressing the button (no

further confirmation).

7.1 SETPOINTS

7.2 SYSTEM PARAMETERS

+

3 s

+

3 s

User manual WTS Ver.1.16

Seite 14 von 52

8 INSTRUMENT COMMISSIONING

Upon switch-on, the display shows in sequence:

-instrument model (e.g.: “

”);

-“

” followed by the software code (e.g.:

);

-program type:

(base);

-“

” followed by the software version (e.g.:

);

-“

” followed by the hardware code (e.g.:

);

-the serial number (e.g.:

);

Check that the display shows the weight and that when loading the load cells there is an

increase in weight. If there is not check and verify the connections and correct positioning of

the load cells.

-If the instrument has already been theoretical CALIBRATED (plant system

identification tag present on the instrument and on the cover: load cell’s rated data already

entered):

oReset to zero (follow the procedure in paragraph TARE WEIGHT ZERO SETTING)

oCheck the calibration with sample weights and correct the indicated weight if necessary

(follow the procedure in paragraph REAL CALIBRATION (WITH SAMPLE

WEIGHTS)).

-If the instrument HAS NOT BEEN CALIBRATED (missing plant system identification tag)

proceed with calibration:

oIf load cells data are unknown, follow the procedure in paragraph REAL

CALIBRATION (WITH SAMPLE WEIGHTS)

oEnter the rated data of load cells following the procedure given in paragraph

THEORETICAL CALIBRATION

oReset to zero (follow the procedure in paragraph TARE WEIGHT ZERO SETTING)

oCheck the calibration with sample weights and correct the indicated weight if necessary

(follow the procedure in paragraph REAL CALIBRATION (WITH SAMPLE

WEIGHTS)).

-If you use the analog output, set the desired analog output type and the full scale value

(see paragraph ANALOG OUTPUT).

-If you use serial communication, set the related parameters (see paragraph SERIAL

COMMUNICATION SETTING).

-If setpoints are used, set the required weight values and the relevant parameters (see

paragraphs SETPOINTS PROGRAMMING and OUTPUTS AND INPUTS

CONFIGURATION).

User manual WTS Ver.1.16

Seite 15 von 52

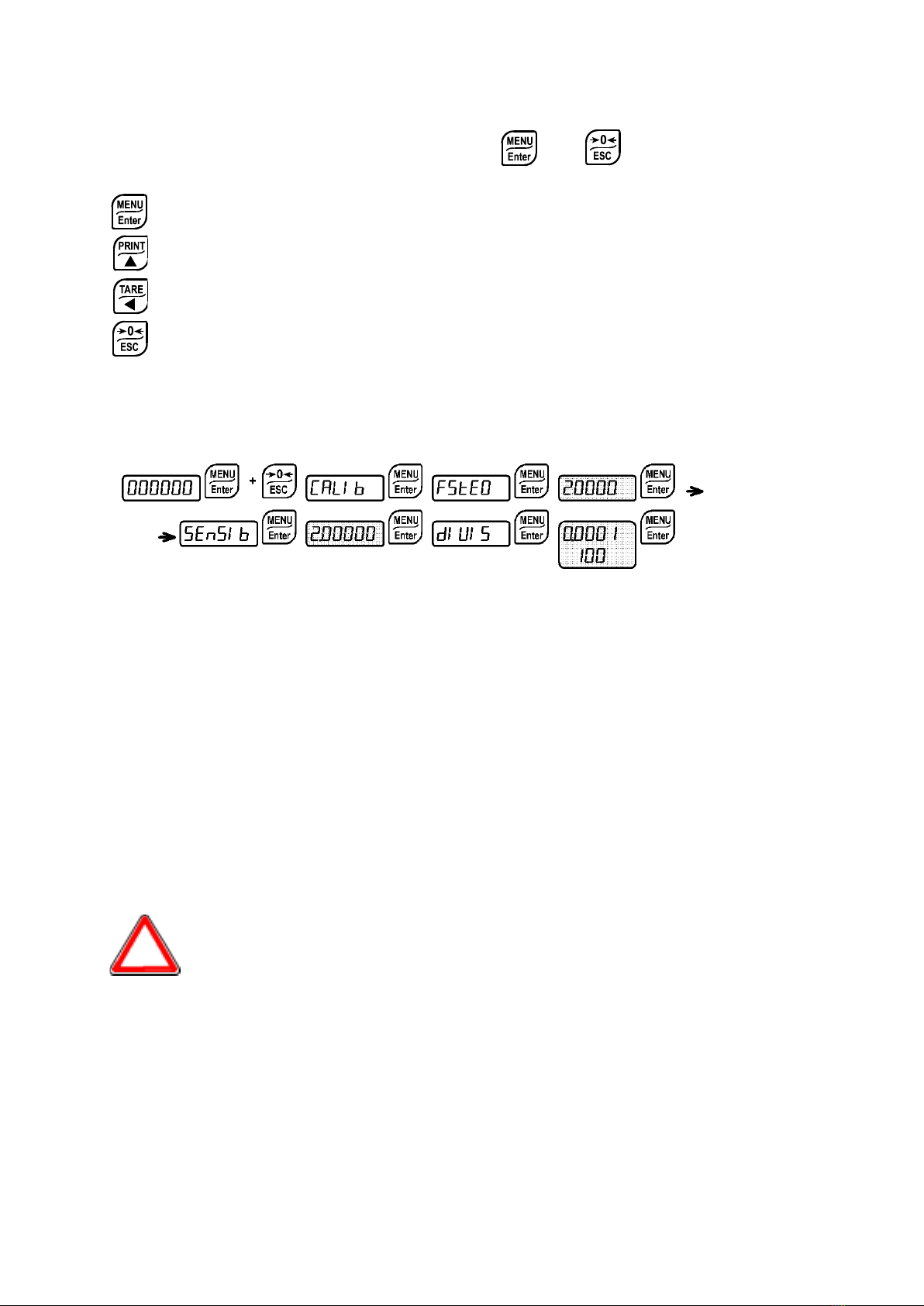

9 PROGRAMMING OF SYSTEM PARAMETERS

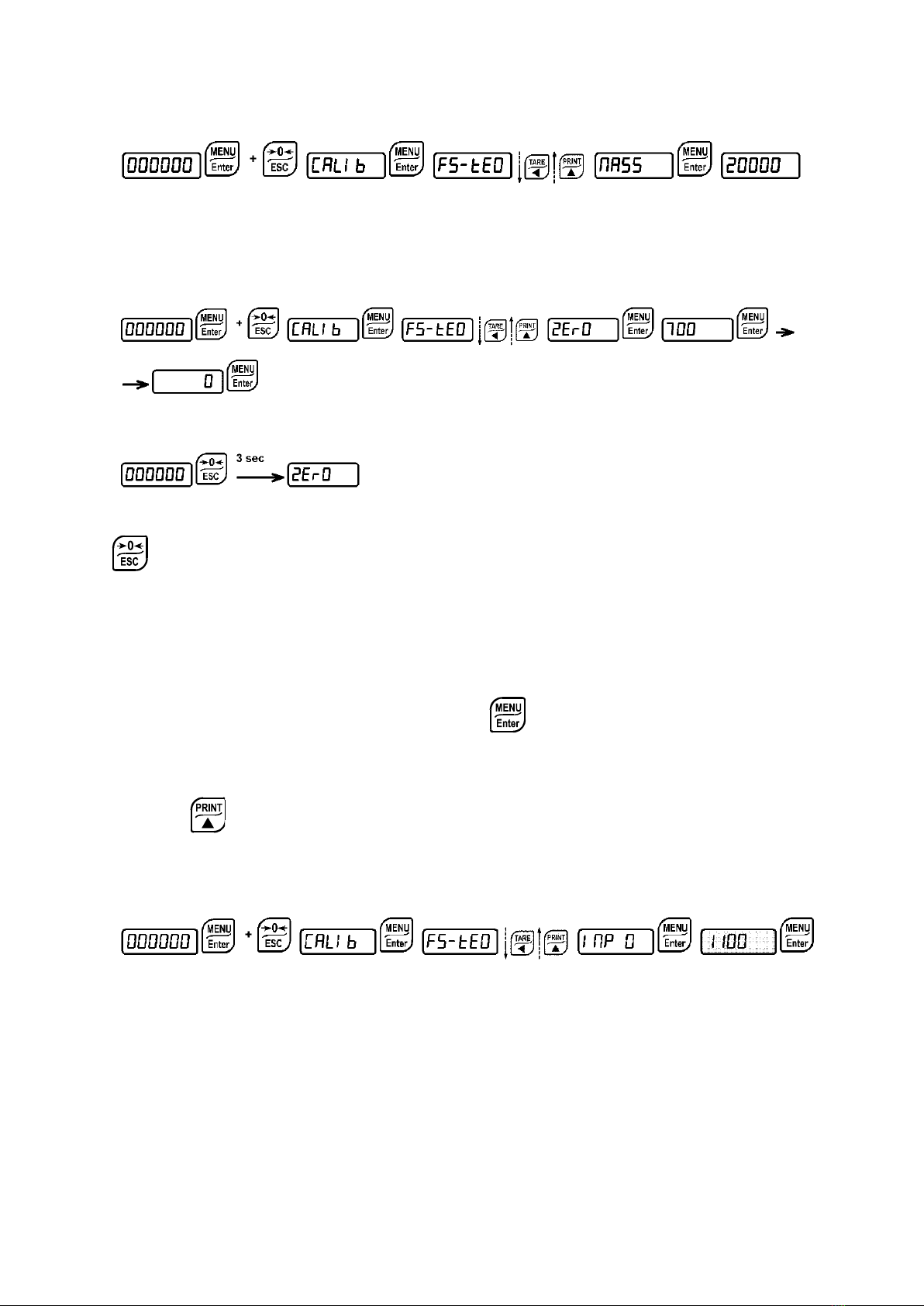

From the weight display, press simultaneously keys and to access the parameter

setting.

: to enter a menu/confirm the data entry.

: to modify the displayed value or menu item.

: to select a new value or modify the displayed menu item.

: to cancel and return to the previous menu.

9.1 THEORETICAL CALIBRATION

This function allows the load cell rated values to be set.

To perform the theoretical calibration set the following parameters in sequence:

-

(default:

): the system full scale is given by one cell capacity multiplied by

the number of cells used. Example of system full scale value calculation: 4 cells of 1000kg

FULL SCALE = 1000 X 4 = 4000. The instrument is supplied with a theoretical full scale

value

corresponding to 10000. To restore factory values, set 0 as full scale.

-

(default: 2.00000 mV/V): sensitivity is a load cell rated parameter expressed in mV/V.

Set the average sensitivity value indicated on the load cells. It’s possible to set a value between

0.50000 and 7.00000 mV/V. Example of 4-cell system with sensitivity: 2.00100, 2.00150,

2.00200, 2.00250; enter 2.00175, calculated as (2.00100 + 2.00150 + 2.00200 + 2.00250) / 4.

-

:the division (resolution) is the minimum weight increment value which can be

displayed. It is automatically calculated by the system according to the performed

calibration, so that it is equal to 1/10000 of full scale. It can be changed and be variable

between 0.0001 and 100 with x1 x2 x5 x10 increments.

-By modifying the theoretical full scale or the sensitivity, the real calibration is

cancelled and the theoretical calibration only is considered valid.

-If the theoretical full scale and the recalculated full scale in real calibration (see

section REAL CALIBRATION (WITH SAMPLE WEIGHTS)) are equal, this

means that the calibration currently in use is theoretical; if they are different, the

calibration in use is the real calibration based on sample weights.

-By modifying the theoretical full scale or the sensitivity, the system’s parameters

containing a weight value will be set to default values (setpoint, hysteresis, etc.).

User manual WTS Ver.1.16

Seite 16 von 52

9.1.1 MAXIMUM CAPACITY

: Maximum displayable weight (from 0 to full scale; default: 0). When the weight exceeds

this value by 9 divisions the following is displayed ‘

’. To disable this function, set 0.

9.1.2 TARE WEIGHT ZERO SETTING

This menu may also be accessed directly from the weight display, holding down the

key for 3 seconds.

Perform this procedure after having set the THEORETICAL CALIBRATION data.

Use this function to set to zero the weight of the empty system after commissioning and then

later on to compensate zero variations due to the presence of product residues.

Procedure:

-Confirm the message

(Zero) by pressing .

-The weight value to be set to zero is displayed. In this phase all of the LEDs are flashing.

-Confirming once again, the weight is set to zero (the value is stored to the permanent

memory).

-Press to display the value of the total weight reset by the instrument, given by the

sum of all of the previous zero settings.

9.1.3 ZERO VALUE MANUAL ENTRY

WARNING: Perform this procedure only if it’s not possible to reset the weighed structure

tare, for example because it contains product that can not be unloaded.

Set in this parameter the estimated zero value (from 0 to 999999; default: 0).

User manual WTS Ver.1.16

Seite 17 von 52

9.2 REAL CALIBRATION (WITH SAMPLE WEIGHTS)

After having performed the THEORETICAL CALIBRATION and TARE WEIGHT ZERO

SETTING, this function allows correct calibration to be done using sample weights of

known value, if necessary, any deviations of the indicated value from the correct value

to be corrected.

Load onto the weighing system a sample weight, which must be at least 50% of the maximum

quantity to be weighed.

By confirming the message

the flashing value of the weight currently on the system is

displayed. In this phase all of the LEDs are off. Adjust the value on display by using the arrow

keys if necessary. After confirming, the new set weight will appear with all the LEDs flashing.

After an additional confirmation, the message

will be restored and by repeatedly

pressing the key the weight will once again be displayed.

Example: for a system of maximum capacity 1000 kg and 1 kg division, two sample

weights are available, one of 500 kg and the other one of 300 kg. Load both weights onto

the system and correct the indicated weight to 800. Now remove the 300 kg weight, the

system must show 500; remove the 500 kg weight, too; the system must read zero. If this

does not happen, it means that there is a mechanical problem affecting the system

linearity.

CAUTION: identify and correct any mechanical problems before repeating the

procedure.

-If theoretical full scale and recalculated full scale in real calibration are equal, it

means that the theoretical calibration is currently in use; otherwise, the real

calibration based on sample weights is in use.

-If the correction made changes the previous full scale for more than 20%, all the

parameters with settable weight values are reset to default values.

LINEARISATION OPTION ON MAX 8 POINTS:

It is possible to perform a linearisation of the weight repeating the above-described

procedure up to a maximum of eight points, using eight different sample weights. The

procedure ends by pressing the button or after entering the eighth value; at this

point it will no longer be possible to change the calibration value, but only to perform a new

real calibration. To perform a new calibration, should return to the weight display and then re-

entering into the calibration menu.

By pressing after having confirmed the sample weight that has been set, the full scale

appears, recalculated according to the value of the maximum sample weight entered and

making reference to the cell sensitivity set in the theoretical calibration (

).

User manual WTS Ver.1.16

Seite 18 von 52

9.3 FILTER ON THE WEIGHT

Setting this parameter allows a stable weight display to be obtained.

To increase the effect (weight more stable) increase the value (from 0 to 9, default

4).

As seen in the diagram:

-By confirming the

message, the currently programmed filter value is displayed.

-By changing and confirming the value, the weight is displayed and it will be possible to

experimentally verify its stability.

-If stability is not satisfactory, confirming brings back the message

and the filter may

be modified again until an optimum result is achieved.

The filter enables to stabilise a weight as long as its variations are smaller than the

corresponding “Response Time”. It is necessary to set this filter according to the type of

application and to the full scale value set.

FILTER

VALUE

Response times [ms]

Display and serial port refresh

frequency [Hz]

0

80

80

1

190

80

2

260

40

3

450

26

4 (default)

900

13

5

1700

13

6

2500

13

7

4200

10

8

6000

10

9

7500

5

9.3.1 ANTI PEAK

When the weight is stable, the anti peak filter removes any sudden disturbances with a

maximum duration of 1 second. Confirm the filter on the weight with ENTER and select one

of the following options:

: anti peak filter enabled (default);

: anti peak filter disabled.

User manual WTS Ver.1.16

Seite 19 von 52

9.4 ZERO PARAMETERS

9.4.1 RESETTABLE WEIGHT SETTING FOR SMALL WEIGHT CHANGES

(from 0 to full scale; default: 300; considered decimals: 300 – 30.0 – 3.00 – 0.300): this

parameter indicates the maximum weight value resettable by external contact, keypad or serial

protocol.

9.4.2 AUTOMATIC ZERO SETTING AT POWER-ON

(from 0 to 10% of full scale; default: 0): If at switch-on the weight value is lower than

the value set in this parameter, the weight is reset.To disable this function, set 0.

9.4.3 ZERO TRACKING

(from 1 to 5, default:

): When the zero weight value is stable and, after a

second, it deviates from zero by a figure in divisions smaller or equal to the figure in divisions

set in this parameter, the weight is set to zero. To disable this function, set

.

Example: if the parameter

is set to 5 and

is set to 2, the weight will be

automatically set to zero for variations smaller than or equal to 10 (

x

).

User manual WTS Ver.1.16

Seite 20 von 52

9.5 SETTING UNITS OF MEASURE

Available unit of measure are:

: kilograms

: grams

: tons

: pounds*

: newton*

: litres*

: bar*

: atmospheres*

: pieces*

: newton metres*

: kikogram metres*

: other generic units of measure not included in the list*

If the print function is enabled, the symbol corresponding to the selected unit of measure will

be printed after the measured value.

For the units marked with * it’s possible to set also the display coefficient

(parameter

, see the related paragraph). To use

is necessary to

enable it, closing the

input (see paragraph OUTPUTS AND INPUTS

CONFIGURATION).

9.5.1 DISPLAY COEFFICIENT

By setting the coefficient

the display is changed accordingly.

If one of the inputs is set to

mode (see paragraph OUTPUTS AND INPUTS

CONFIGURATION) when the input is closed the value will be displayed modified according to

the

coefficient; when the input is opened the standard weight display will be restored.

: (max settable value: 99.9999; default: 1.0000) will have different meanings according to the

value set in

, i.e. the selected unit of measure. (see paragraph SETTING UNITS OF

MEASURE).

Table of contents

Other Bosche Measuring Instrument manuals