Contents

Safety.......................................................................3

Preparation.........................................................3

Operation............................................................3

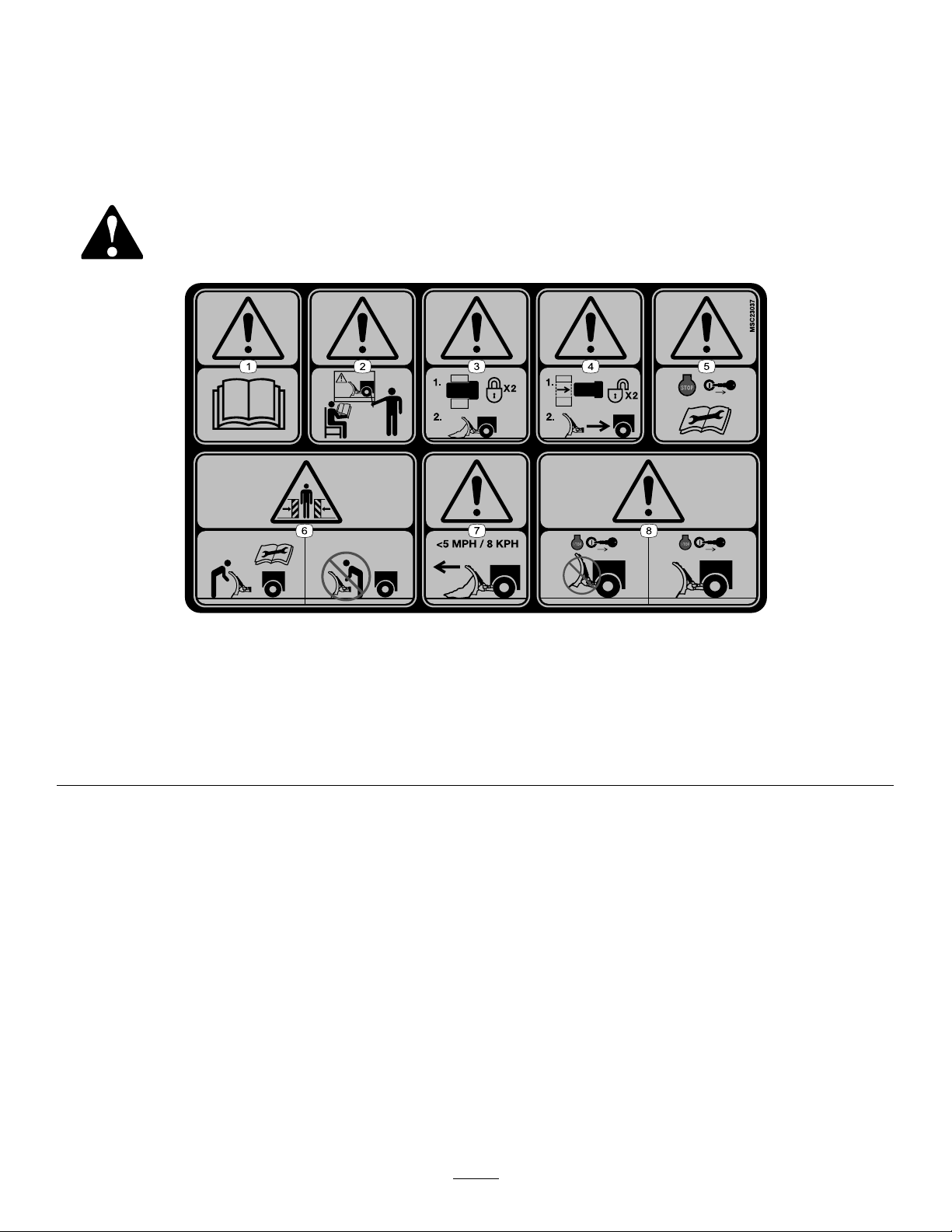

SafetyandInstructionalDecals..........................4

Setup........................................................................5

MountingthePlow..............................................5

ProductOverview.....................................................7

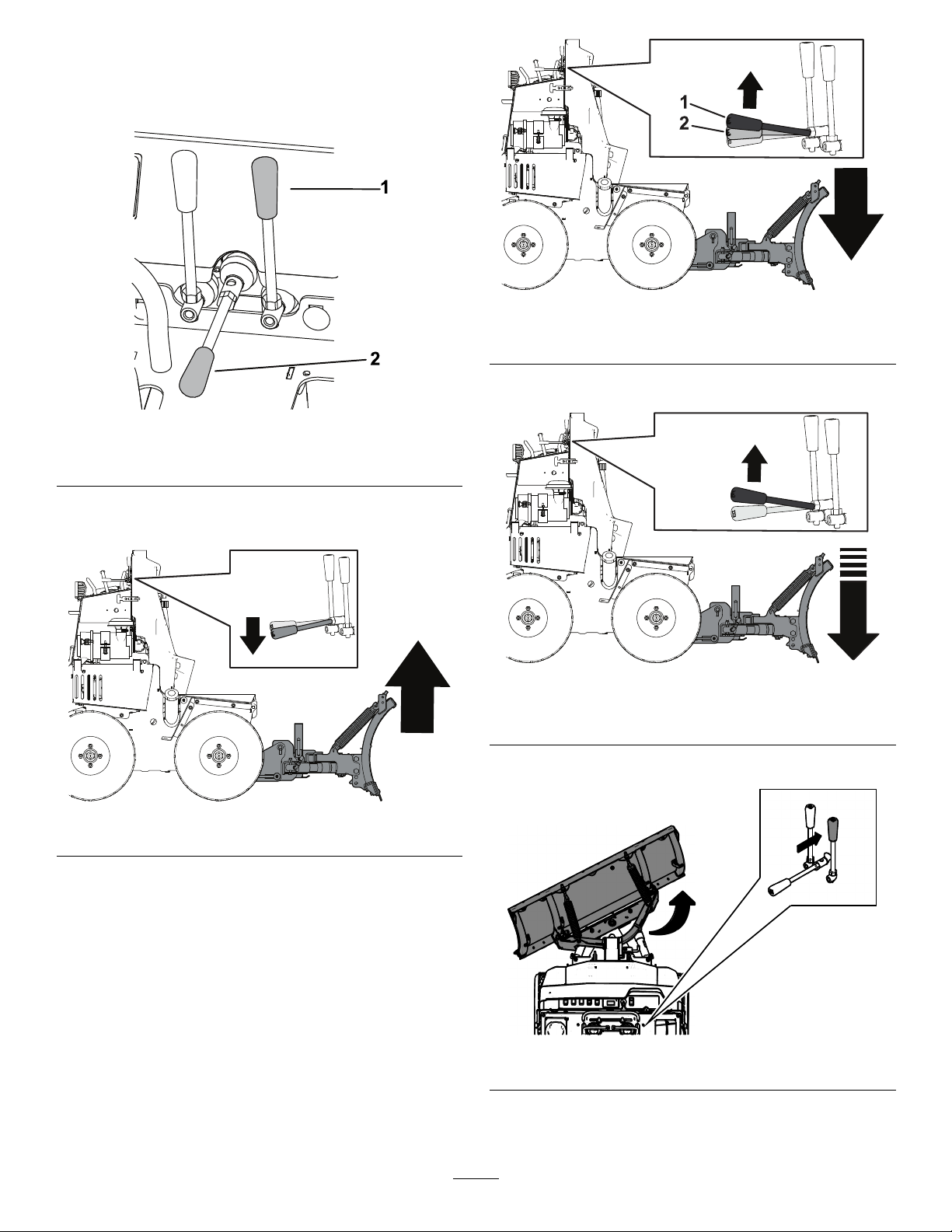

Controls.............................................................7

Operation..................................................................8

MountingthePlow..............................................8

RemovingthePlow.............................................8

OperatingTips...................................................8

Maintenance...........................................................10

RecommendedMaintenanceSchedule(s)...........10

.........................................................................10

MaintenanceSafety.............................................10

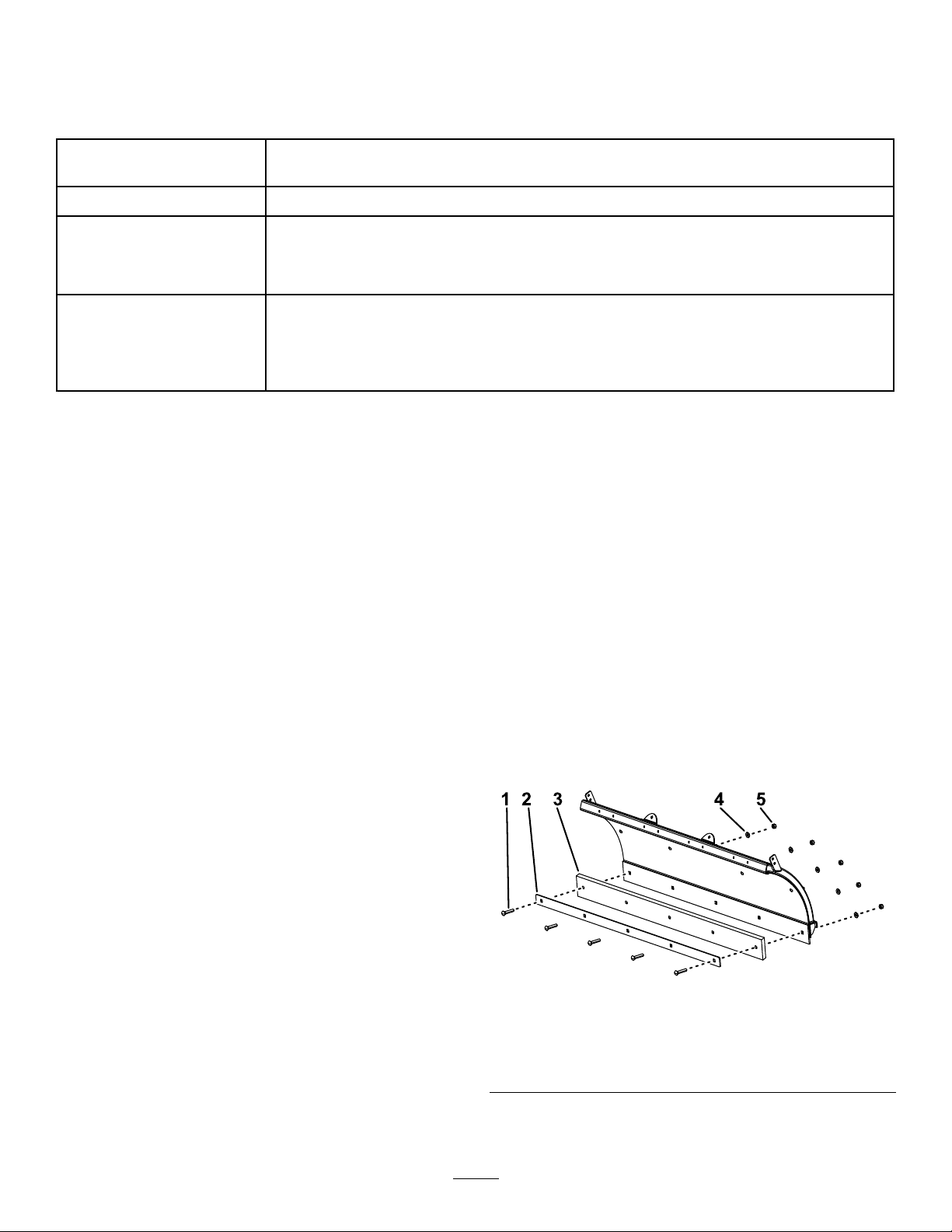

ReplacingtheCuttingEdge..................................10

.........................................................................10

Storage....................................................................11

StoringthePlow................................................11

RemovingthePlowfromStorage.......................11

Troubleshooting......................................................12

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.Toreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafety-alert

symbol,whichmeans:Caution,Warning,or

Danger—personalsafetyinstruction.Failureto

complywiththeinstructionmayresultinpersonal

injuryordeath.

Preparation

•ReadtheOwner’sManualbeforeoperatingor

servicingtheplow.

•Ensurethatonlytrainedpersonnelinstallsand

performsmaintenanceontheequipmentand

hydrauliccomponents.

•Alwayswearappropriatepersonalprotective

equipmentwhenloading,unloading,andservicing

theplow.

Operation

•Usea500kg(1/2ton)minimumliftingdeviceto

moveheavyplowcomponents.

•Donotexceed8km/h(5mph)whileoperating.

•Neverputanypartofyourbodybetweentheplow

andthevehicle.

•Wearappropriateclothing,includinghearingand

eyeprotection,protectivegloves,andsubstantial,

slip-resistantfootwear.Tiebacklonghair,secure

looseclothing,anddonotwearloosejewelry.

•Whentransportingtheplow,ensurethatitis

properlysecured.Instructionsareavailableat

www.bossplow.com.

•Whentransportingthevehicle,positiontheplow

soasnottoblockyourvisionorheadlights.

•Donotchangethebladepositionwhentraveling.

•Alwayslowerthebladewhenthevehicleisnotin

use.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•RefertotheOwner’sManualforproperparking

procedures.

•Turnthevehicleandplowoffbeforelling,

servicing,orcleaningit.

•Donotclimbintoorrideontheplow.

•Keepyourhands,feet,andclothingawayfrom

movingpartsandmountingpoints.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

3