BOSSCO AX1-2.5E Manual

Operation &

Maintenance Manual

BOSS Digital Pressurisation Equipment

AX Models (AX1-2.5E, AX2-2.5E, AX1-5E, AX2-5E)

PF Models (PF1-2.5E, PF2-2.5E, PF1-5E, PF2-5E)

Midi Models (MD1-2.5E, MD2-2.5E, MD1-5E, MD2-5E)

Digifiller (Digifiller 0.5, Digifiller 1.0, Digifiller 1.5, Digifiller 2.0)

Mini Models (MX1-3E, MX2-3E)

2

Contents

About this Manual 3

Conventions used in this Manual 3

Typography 3

Where to find more Information 3

Equipment Overview 4

Principal of Operation 4

Installation 5

Pipe Connections 5

Typical Installation Diagram 5

Flow Restrictors (Midi & Mini models only) 6

AX Skid Clearance and Connection Requirements 7

Pressfill (PF) Clearance and Connection Requirements 8

Midi (MD) Clearance and Connection Requirements 9

Mini (MX) Clearance and Connection Requirements 10

Electrical Power Supply 11

Fault Contacts 12

Power Filter 13

Commissioning 14

Pre-Commissioning Checklist 14

Controller Overview 15

Controller Programming 16

Hydraulic Commissioning 20

Commissioning Record 25

Operation 26

Fault Codes 26

Shutdown Procedure 27

Start-Up Procedure 27

Troubleshooting 28

Maintenance 31

Wiring Diagram 33

Service Log 34

Spares 36

Electrical Items (All Models) 36

AX Models (AX1-2.5E, AX2-2.5E, AX1-5E, AX2-5E) 37

PF Models (PF1-2.5E, PF2-2.5E, PF1-5E, PF2-5E) 38

Midi Models (MDE1-2.5, MDE2-2.5, MDE1-5, MDE2-5) 39

Digifiller Models (Digifiller 0.5, Digifiller 1.0, Digifiller 1.5, Digifiller 2.0) 39

Mini Models (MX1-3E, MX2-3E) 40

3

About this Manual

This Operation and Maintenance Manual contains all the necessary information to install,

commission, operate and maintain pressurisation equipment.

It is recommended to read all parts of this manual before undertaking any work on the equipment.

Conventions used in this Manual

This manual makes use of symbols to identify key pieces of information. Please take note of the

following symbols and their meaning:

DANGER –Important safety related information intended to prevent injury and/or

damage to the equipment, system or property.

CAUTION - Important information intended to prevent damage to the equipment,

system or property.

IMPORTANT - Important information intended to ensure that the equipment functions

correctly.

USEFUL –Useful information which may be helpful, but is not necessarily required for

the unit to function correctly.

Typography

This manual makes use of different typography to identify different types of information.

Italics Key words and phrases

(Round Brackets) Used to identify a button on the digital controller

[Square Brackets] A parameter on the digital controller

<Inequality Symbols> A message/fault code displayed on the digital controller

Where to find more Information

For further information please visit the BSS Website at: http://www.bssindustrial.co.uk/

BSS Technical (Leicester)

AMS Wigan

AMS Spares & Service (Nottingham)

Tel: 0116 262 3232

Tel: 0870 609 2101

Tel: 0870 850 3886

Email: enquires@bssgroup.com

Email: amspumps@bssgroup.com

Email: amsse@bssgroup.com

4

Equipment Overview

The function of this pressurisation unit is to provide a means of automated water top-up to sealed

heating and cooling systems. The equipment is designed to provide periodic water top-up to

compensate for minor losses in system pressure (e.g. slow leaks, air venting, etc.).

This equipment is not designed to cope with sudden losses of system pressure (e.g.

manual draining) or major water losses (e.g. large leaks). The equipment is also not

intended to be used for water boosting applications.

Principal of Operation

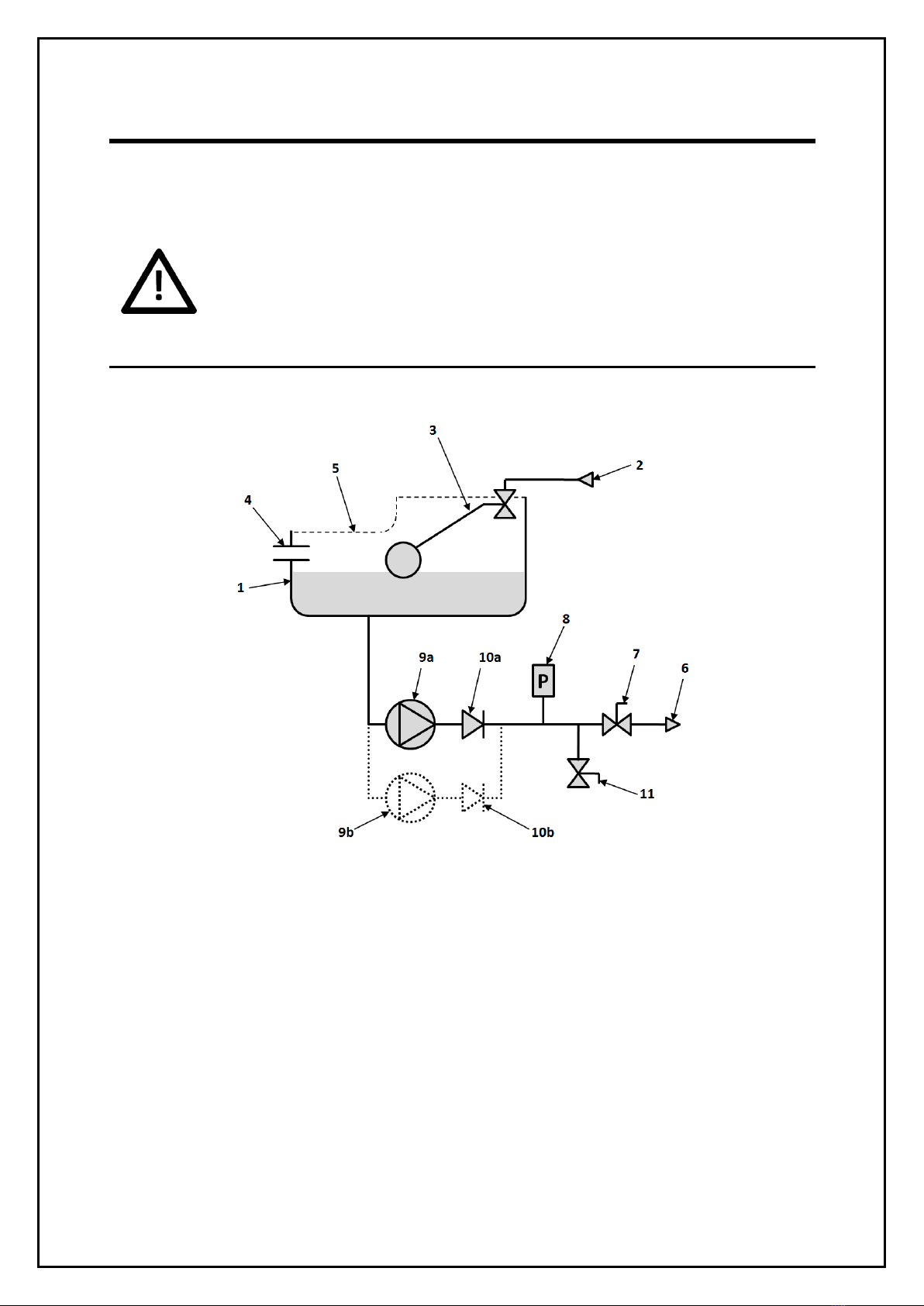

The following schematic shows the internal arrangement of a pressurisation unit:

The pressurisation unit is fitted with a break tank (1) which is filled from the mains water supply (2)

via a float operated valve (3). The break tank is fitted with an overflow (4) in case the break tank

overfills, and a weir overflow (5) in case the primary overflow fails.

The pressurisation unit is connected into the heating system (6) via an isolation valve (7).

The pressure sensor (8) monitors the system pressure.

If the pressure sensor detects a drop in pressure, the pump (9a) will pump water from the break tank

into the system. Once the required pressure has been reached, the pump will stop.

On twin pump models, a second pump (9b) is provided. The two pumps will run in a duty/standby

configuration (i.e. the active pump will alternate with each pump start).

The pump(s) are fitted with non-return valves (10a, 10b) to prevent backflow.

A drain valve (11) is provided for draining down the unit and for commissioning purposes.

5

Installation

This pressurisation unit is not designed to be installed in an outdoor environment. The

unit must be installed in a frost free environment, away from precipitation and water

sprays/jets. If there is a risk of flooding, the unit must be installed on a raised plinth.

Please refer to the appropriate datasheet for the maximum working pressure and

temperature of the pressurisation unit. The conditions at the point of connection to

the system must not exceed these values.

Pipe Connections

To avoid damaging the float valve, the mains water supply pipe must be flushed before

connection to the pressurisation unit.

All pipe connections must be made with appropriate jointing compound/PTFE tape.

If PTFE tape is used, care must be taken to ensure that the tape does not obstruct the

orifice of the fitting.

Non-return valves, pressure reducing valves and RPZ valves must not be installed

between the pressurisation unit and the heating/cooling system. These devices will

prevent the pressure sensor from reading the system pressure.

The pressurisation unit and expansion vessel should be connected to the system at the

same point, to provide a neutral pressure reading. This point of connection should be

in the system return, on the suction side of the circulation pump.

Typical Installation Diagram

This manual suits for next models

17

Table of contents

Other BOSSCO Industrial Equipment manuals