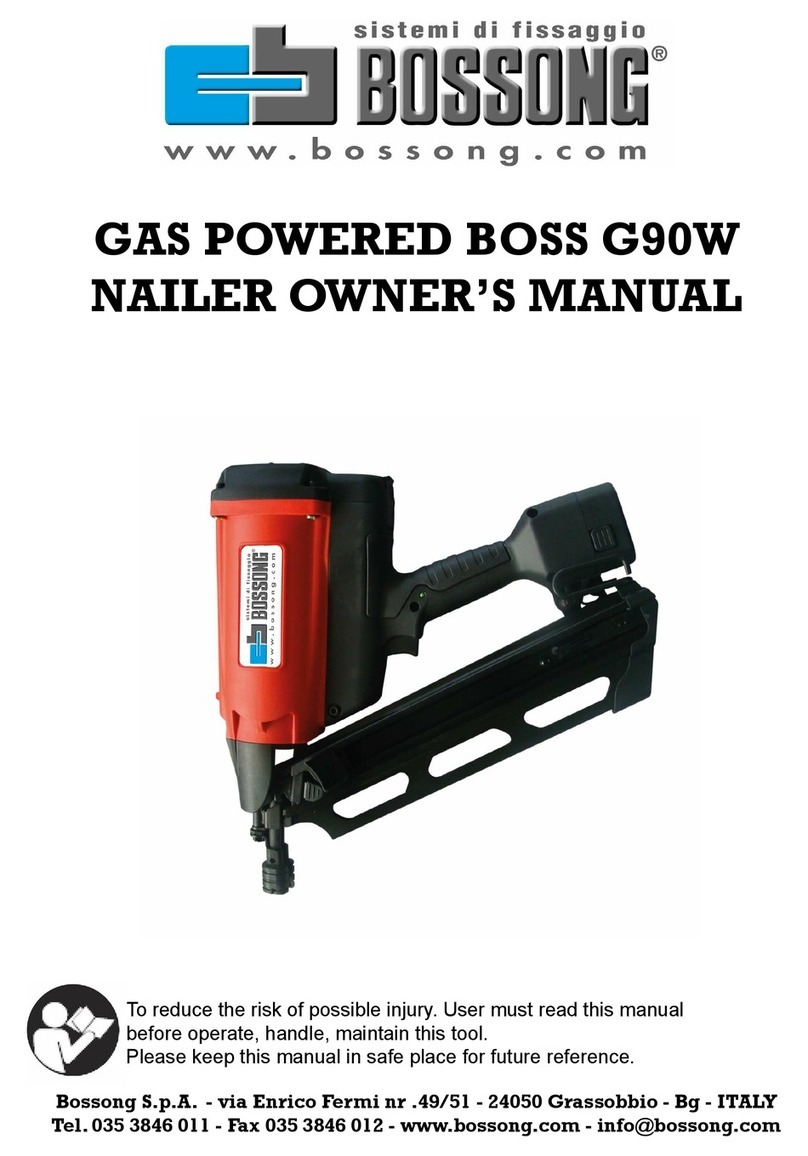

Bossong boss g40 User manual

GAS POWERED

NAILER OWNER’S MANUAL

To reduce the risk of possible injury. User must read this manual

before operate, handle, maintain this tool.

Please keep this manual in safe place for future reference.

Bossong S.p.A. - via Enrico Fermi nr .49/51 - 24050 Grassobbio - Bg - ITALY

Tel. 035 3846 011 - Fax 035 3846 012 - www.bossong.com - info@bossong.com

1. General warning

General safety warning

Tool safety warning

Fuel safety warning

Battery safety warning

Charger safety warning

2. Operation instruction

Load and unload the fuel cell

Load and unload the fastener

Depth of drive adjustment

Actuatemethodandthestepstorethetool

Jam clearing for tool

Charge the battery and LED on tool and charger

3. Maintenance instruction

General maintenance

Lubrication and cleaning

Cold weather

4. Trouble shooting

5. Declaration of conformity

Table of content

3

3

3-4

5

5

5-6

6

6

6-7

7

7

8

9

9

9

9

9

10-11

12

2

1. General warning

UsermustweareyeprotectionwhichconformstoANSIspecicationwith

frontandsideprotectionagainstyingobject;whenhandling,

operating, and servicing the tool. It is employer’s responsibility

to enforce user and all other nearby personnel at worksite to

wear eye protection when operating the tool.

It is recommended to wear ear protection near or at the job site

to prevent hearing damage.

Beware of the danger of entangled clothe and hair. Do not

dress loose clothing and jewelry at work. Keep you hair,

clothing, and gloves away from moving part of the tool.

KeepyourngerAWAYfromthetriggerwhenthetoolisnotinuse.This

willpreventaccidentalreofthetool.

This tool is not designed to be used in explosive atmosphere. The design of

this tool will generate spark and the exhaust will also cause possible

dangertoignitehighlyammablefuelorgas.Donotusethistoolinthis

kind of environment. Please also not smoke while using or handling the

tool and fuel cell.

Thefuelcellishighpressureliqueedgasbottle.Keepitawayfromspark,

reorhightempandexplosiveenvironment.Donotpuncturethebottleor

attempttoopenthefuelcell.Whenthefuelusedup,donotincineratethe

bottle. Follow the recycle instruction on the bottle.

Do not store the tool in temperature above 120°F(50°C). High temperature

willresultinexplosionorreandthereleaseofammablegas.Whennot

in use, keep the tool from high temperature source or direct sun light.

The tool needs to be used in well ventilated area. Do not inhale the exhaust

or fume or the gas because they are potentially dangerous to human body.

Keep body balance when operating the tool, do not over reach.

Keep the tool, fuel, charger and battery out of the reach of children. The

tool is dangerous in the hand of untrained person.

Tool safety warning

Do not modify or repair the tool in any method other than the original

design.Thetoolmayfunctionunexpectedlyafterthemodicationand

cause dangerous.

Never point the nozzle of the tool to anyone includes yourself. This tool is

self-contained with power source and will be dangerous if not use with

care. Always assume the tool is loaded with nail and fuel.

General safety warning

3

Do not drive this tool over materials that is too hard or too soft. Hard

material can ricochet nail and hurt people, soft material may be penetrate

easilyandcausethenailtofreey.

Pleaseuseonlylubricationliquidspeciedinthismanualtoperformthe

lubrication. Use other lubrication may cause damage to the tool and the

risk of malfunction that will injure the operator.

Please keep the tool in clean condition, wipe off grease or oil after work. Do

not use any solvent based cleaner to clean the tool. It is possible the

solvent will deteriorate the rubber or plastic components on the tool.

Greasy handle and body will cause accidental drop of the tool and injury to

nearby person.

Pleaseusefastenerspeciedinthismanualandonthetool.Usefastener

that is not compatible to the tool will cause jamming of the tool and injury

to operator or nearby person.

Do not use the tool to perform other job than designate function. Especially

not use the tool as a hammer, impact on the tool will increase the risk of

cracked body and accidental discharge of fastener.

Remove the fuel cell and battery before performing maintenance, repair,

cleaning and jam clearing.

Load the fastener at last to prevent unexpected danger of loading fuel cell

and battery.

Never use the tool if the trigger and safety or springs are damaged in any

way.

Whenfasteningelectricalcables,makesurethecablesarenotenergized.

Hold the tool only by insulated gripping surfaces. Use only fasteners

designed for electrical cable installations. Inspect that the fastener has not

damaged the insulation of the electrical cables. A fastener that damages

theinsulationofelectriccablescanleadtoelectricshockandrehazards.

Fuel safety warning

Use only the fuel cell recommended by the manufacturer. Read the Safety

Data Sheet to understand more of your fuel cell contents.

Recycle the empty fuel cell according to the local law. Do not attempt to

recharge the fuel cell or incinerate the empty fuel cell.

Do not expose the fuel cell or tools loaded with fuel cell under direct sun

light exposure. Prevent to put above items at temperature higher than

120°F(50°C).Overheatingthefuelcellcanresultinexplosionorre.

Do not puncture or attempt to open the fuel cell. The fuel cell contains

ammablegasevenifitappearsempty.

Thecontentofthefuelcellisextremelyammable,keepitawayfromall

source of ignition.

4

Battery safety warning

Use only batteries that are supplied by the manufacturer.

Recycle the battery according to local law. Do not incinerate the battery of

attempt to puncture and crush the battery.

Donotimmersethebatteryintowaterorotheruid.Donotexposethe

battery to rain or snow.

Do not expose the battery or tools loaded with battery under direct sun

light exposure. Prevent to put above items at temperature higher than

120°F(50°C).Overheatingthebatterycanresultinexplosionorre.

Do not allow direct contact of the battery nodes with metal or conductive

material.

Charge the batteries every 3 months even the tool is not used to prevent

battery over-discharged over time.

Charger safety warning

Do not use the charger in explosive atmosphere. The electrical device is not

designed to use in such environment.

Do not charge battery outdoors or in temperatures below 40°F (5°C).

Do not puncture or attempt to open battery case or cells.

Donotimmersethechargerintowaterorotheruid.Donotexposethe

charger under rain or snow.

Do not use the charger if the cord is damaged or the charger is defect.

Unplug the charger by pulling the adaptor unit, not by pulling the cord.

Do not cover the charger with anything.

Do not use a step up transformer or engine generator as the power source

of the charger.

Pleasechargethebatteryforatleast6Hoursbeforethersttimeuseof

the new battery.

5

Load and unload the fuel cell

Open the fuel cell door by pulling the

door and rotate.

Insert the fuel cell into the chamber.

Align the fuel cell nozzle to the fuel stem

on the tool.

Close the fuel cell door.

Load and unload the fastener

Connect to battery and fuel cell before

you load the fasteners. The tool had the

chance to cycle once when connected to

the battery. If you load the fastener

before the battery connected, the

fastener may be shoot out accidentally.

Point the nozzle away from any

personnelandkeepyourngeroutof

trigger when loading the fastener.

To load the nail, slide in the nail strip

into the magazine until the nail strip passed the nail stopper.

Pull the pusher until it is beyond the stopper.

Release the pusher to engage the nail strip and feed it into the nozzle.

To unload the fastener from the magazine, press the release lever on the

pusher and tilt the tool to slide the nail strip to the rear end of the

magazine.

Unload the nail strip by press the nail stopper and slide out the nail strip.

For 3 steps magazine design, follow the same safety precaution

and continue with following steps

To load nail, pull the pusher to the rear until it is locked to the magazine at

rear position.

Slide nail strip into the magazine.

Release the pusher to push the nail into the nozzle.

To unload the fastener from the tool, pull the

pusher to the rear locking position. Slide the

nail out of the magazine.

2. Operation instruction

6

Depth of drive adjustment

This tool is equipped with tool free depth of

drive adjustment. Test the depth of drive on

scrap piece before you start your work.

Turn the knob to adjust the depth of drive.

Repeataboveprocedureuntilyoundyour

desired depth of drive setting.

Actuate method and the steps to re the tool

This tool is equipped with single sequential trigger system only.

To actuate the tool, depress the safety against the work piece, and then pull

the trigger.

To actuate the tool again, you will need to release the safety fully and

release the trigger before you repeat above procedure.

Make sure you are driving against work piece before you pull the trigger.

Jam clearing for tool

In the case of nail jam, disconnect the power source (fuel cell and battery)

before you perform any action.

If you tool is equipped with jam clear door, open the quick jam clear door

on the side to expose the jammed nail.

If your tool is equipped with removable nozzle, press the release button and

pull off the nozzle.

Remove the jammed nail with needle nose pliers or similar type of tool. Do

not use your hand to remove the nail.

Close the jam clear door or assemble back the nozzle after you clear the

jam.

7

Charge the battery and LED on tool and charger

There is battery comes along with the tool. It will

take 2 hours before the new battery can be fully

charged.

There will be no LED light when the charger is

connected to electric and no battery is on the

charger.

The LED on the charger will turn red when it is

charging a battery.

The other LED will turn green when the battery is

fully charged.

In the case of battery failure, the red and green LED will blink in sequence.

Whenthetoolisconnectedtoachargedbattery,theLEDindicatoronthe

tool will turn green.

Ifthetoolisrunningoutofbattery,theindicatorLEDwillturnred.When

the LED indicator turns red, stop using the tool and replace the battery.

8

General maintenance

Keepthetoolincleanconditionatalltimes.Wipeoffgreaseoroilwithdry

clean cloth to prevent accidental tool drop. Avoid to use solvent base cleaner

to clean the tool, certain solvent will damage or weaken the composite parts

of the tool.

Cleantheintakelterregularlytokeepthetoolinfullefciency.

Lubrication and cleaning

This tool should not need extra lubrication since the fuel already contains

some lubrication oil.

The combustion chamber and cylinder can be cleaned by applying

automobilecarburetorcleaner.Youwillneedtoremovethe2screwonthe

handle and 4 screws on the top cap to expose the internal component of

cylinder.

Cold weather

This tool is not suggested to be used in cold winter. The cold weather will

decreasethecombustionefciencyandalsothebatteryperformance.Usethe

tool only at temperature above : -7°C(19°F).

Warning: disconnect the power source (fuel cell and battery) before

performing any maintenance

3. Maintenance instruction

9

4.Trouble shooting

symptom Counter measures

Red LED indicator light is on and

the tool did not operate.

•Batterychargemightbetoolow.

•Replacebatterywithafullychargedone.

Tool operates normally but did

notdrivethenailstoush.

•Adjustthedepthofdrivesettingtodee

pest.

•Cleanthecylinderwithpropercleaner.

•Checkfuelcellandreplaceasrequired.

•Depressthesafetyandholdfor1minute

before activate the trigger. If the tool did

notre,theremightbesealleakingover

the combustion chamber. Send to service

center near you.

Fan does not run and the indicator

light is red.

•Thebatteryisout.Replacethebattery

with a

fully charged one.

•Thebatterynodeisdirtyoroily.Clean

the battery node with clean cloth.

•Ifallabovedidnotwork,sendtoservice

center near you.

Battery does not accept charge

or the charger get hot when

charging.

•Replacethebattery.Ifthisactioncorrects

the problem, the battery is damaged or

exhausted.

•Replacethechargerifthebatteryworks

neontoolbutcannotbechargedon

charger..

Charger get hot, make noise or

start to smoke

•Thechargerisdamagedandshouldnot

be used any more. Unplug the charger

immediately and replace it with a new

charger.

Workcontactelementisnot

fully depressed and the tool can

not be used.

•Theworkcontactelementisbendorthe

track of the safety mechanism is sticky to

the dirt

build up. Clean the safety track. Repair or

replace the work contact element.

•Lockoutmechanismisactive.Load

more nails.

10

symptom Counter measures

Tool will not cycle, the indicator

LED is green and the fan runs.

•Runoutoffuel,replaceanewfuelcell.

•Sparkwireisloose,checkthesparkwire

by removing the cap.

•Sparkplugisdirty.Cleanthesparkplug.

•Ifallabovedidnotwork,sendtoservice

center near you.

Tool operate normally, but no

nail is driven

•Wrongtypeofnailswasused.Please

change to correct nail spec.

•Thecylinderneedscleaning.

•Nailisjammed,cleanthejammednail

before use.

•Thenailpusherdidnotengageproperly

with the nail strip. Adjust to fully engage-

ment.

Combustion chamber is not

returning to start position.

•Theworkcontactelementisbendingor

dirty.

Check the work contact element and repair

orreplace it. Clean the safety track.

Driver did not return to initial position, miss

refrequencygethigherthanusual.

•Checkandreplacefuelcell.

•Cleanthetoolwithpropercleaninguid.

•Checkforpistonringwearstatus.

•Thetoolmaybeoverheated.Cleanor

replacetheintakeairlter.

Tool appears to be loosing

power.

•Checkfuelcell.

•Cleanorreplaceairintakelter.

•Checksparkplugwire.

•Cleanthetoolwithpropercleaninguid.

For failure other than above situation, please stop using the tool and contact your local

dealer for service.

11

12

5. Declaration of conformity

Gas Concrete Nailer

1. Fastener type and size

• Nailshank :2.6~3.0mm(0.102”~0.118”)

• Naillength :15~40mm(9/16”~1-1/2”)

• Collationtype :plasticcollation

• Nailstripangle :0°

• Magazinecapacity :4nailstrips,or40nails

2. Tool spec

• Modelnumber :BOSSG40

• Typeoftool :ConcretePinNailer

• Dimension(LxWxH) :460x116x375mm

• Weightoftool :3..8Kg(8.4lb)

• Shotlimit :1000shots/hour

• Driverate :2-3shots/sec

• Chargetimeofbattery :120mins

• Batteryvoltage :6Volt

• ShotsperCharge :4500shots

• Shotsperfuel :1200shots

• Usabletemperature :-7°C(19°F)~50°C(120°F)

• Applications&suitability :Drywalltrack,steeltoconcretejob

• Actuatingsystem(safetyyokeinstalled) :fullsequentialonly

• Triggerdevice :Fingeractivatedtrigger.

3. Noise and vibration data

• NoisecharacteristicvaluesinaccordancewithEN12549+A1

• A-weightedsoundpressurelevelatworkstation :97.4dB

• A-weightedsoundpowerlevel :100.8dB

• PeakC-weightedinstantaneoussoundpressurelevelatworkstation:<130dB

• VibrationvalueaccordingtoISO8662-11+A1 :3.67m/s2

• Measurementuncertainty(Standard) :1.83m/s2

Declaration of conformity

We BOSSONGS.p.A.

ViaEnricoFermi,51(Z.I.2)

24050 GRASSOBBIO (Bergamo) Italy

Tel.+390353846011

declare under our sole Chiodatrice a gas per calcestruzzo BOSS G40

responsibilitythatthe 2006/42/EC(MSD);2006/95/EC(LVD);2004/108/EC(EMC)

conformswiththedirective 2011/65/EU(RoHS)

andthestandards ENISO12100;EN792-13+A1;EN12549+A1;ISO8662-11+A1

EN60745-1;EN60745-2-16;EN55014-1;EN55014-2+A2

EN61000-3-2;EN61000-3-3;EN50581

EN60335-1;EN60335-2-29;EN62233

EN61558-1;EN61558-2-16

Serial number signed:

Andrea Taddei – Direttore Generale

Table of contents

Other Bossong Nail Gun manuals

Popular Nail Gun manuals by other brands

Paslode

Paslode IM200 F18 operating manual

Craftsman

Craftsman 351.181790 Operator's manual

Parkside

Parkside PAT 12 B2 Operation and safety notes translation of the original instructions

TJEP

TJEP KYOCERA Safety and operation instructions

Parkside

Parkside PET 25 B1 Operation and safety notes

Ferm

Ferm ATM1051 Original instructions