Ferm ATM1042 User manual

WWW.FERM.COM

HU

CS

SL

PL

LT

LV

BS

RU

EL

MK

EN

DE

NL

FR

ES

PT

IT

SV

FI

NO

DA

Original instructions 04

Übersetzung der Originalbetriebsanleitung 09

Vertaling van de oorspronkelijke gebruiksaanwijzing 14

Traduction de la notice originale 19

Traducción del manual original 24

Tradução do manual original 29

Traduzione delle istruzioni originali 34

Översättning av bruksanvisning i original 39

Alkuperäisten ohjeiden käännös 43

Oversatt fra orginal veiledning 48

Oversættelse af den originale brugsanvisning 52

Eredeti használati utasítás fordítása 57

Překlad püvodního návodu k používání 62

Prevod izvirnih navodil 67

Tłumaczenie instrukcji oryginalnej 72

Originalios instrukcijos vertimas 77

Instrukciju tulkojums no oriģinālvalodas 82

Prevod originalnog uputstva 87

Prevod originalnog uputstva 87

Перевод исхоvдных инструкций 91

Μετάφραση του πρωτοτύπου των οδηγιών χρήσης 97

Превод на оригиналните упатства 102

SR

ATM1042

2

Fig. 1

Fig. 2

Fig. 3

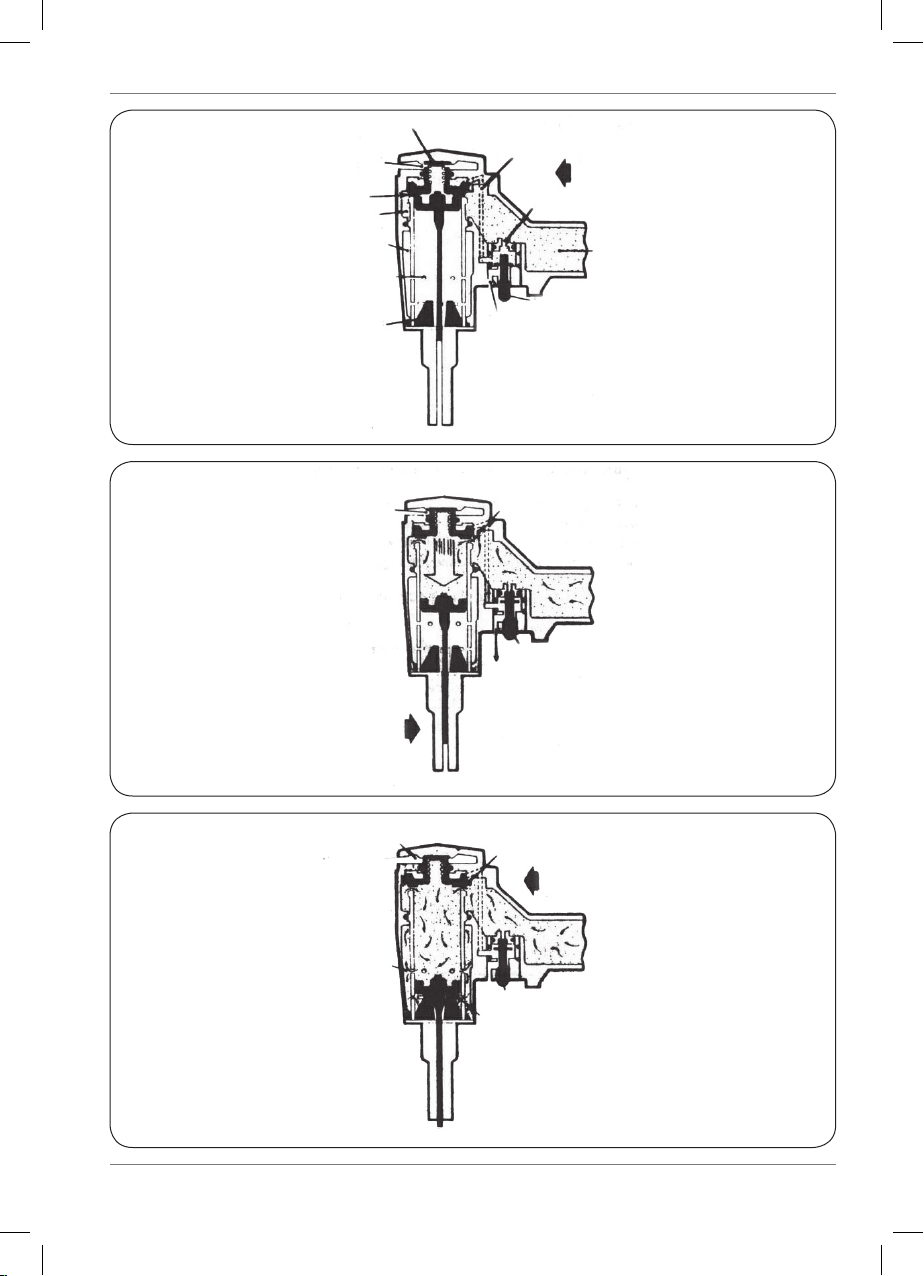

Head valve bumper Port between head valve and trigger valve

Resevoir of high pressure air

Trigger valve released

Passage for air release from head valve

Bumper

Hole in cilinder wall

Return chamber

Resevoir of high pressure air

Head valve closed

Exhaust is open

Exhaust sealed by head valve bumper

Trigger valve actuated

Air released from above head valve

Driving stroke

Piston is sealed against bumper

Trigger valve still actuated

Air flows into return chamber

Exhaust still closed Head valve open

Head valve open

End of stroke trigger still pulled

3

Fig. 4

Fig. 5

Fig. 6

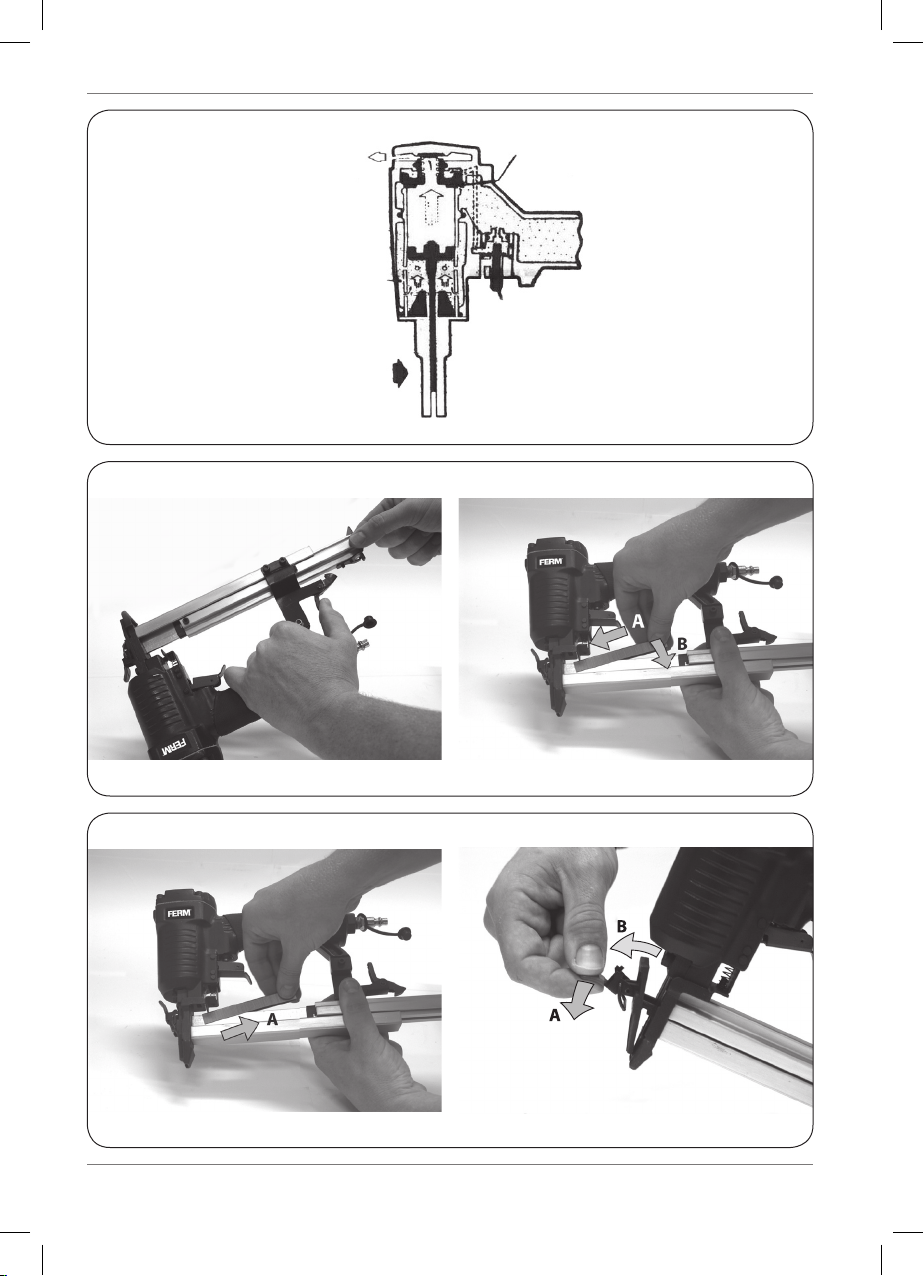

Trigger valve released.

Air pressure returns to top of head valve

Exhaust open Head valve closed

Returning

Air in return chamber pushes

piston forward

4

EN

PNEUMATIC TACKER, STAPLES

12-25MM

Thank you for buying this Ferm product.

By doing so you now have an excellent product,

delivered by one of Europeís leading suppliers.

All products delivered to you by Ferm are

manufactured according to the highest standards

of performance and safety. As part of our

philosophy we also provide an excellent customer

service, backed by our comprehensive Warranty.

We hope you will enjoy using this product for

many years to come.

The numbers in the text refer to the diagrams

on pages 2-3.

Read the operating instructions carefully

before using this device. Familiarize

yourself with its functions and basic

operation. Service the device as per the

instructions to ensure that it always

functions properly. The operating

instructions and the accompanying

documentation must be kept in the

vicinity of the device.

Contents

1. Technical specifications

2. Safety instructions

3. Air supply and connections

4. Loading the air stapler

5. Operating the air stapler

6. Maintaining the air stapler

1. TECHNICAL SPECIFICATIONS

Technical data

Air pressure 4 -7 bar (60-100 psi)

Max. staple size 1.05x5.1x0.58 mm

Package contents

1 Air stapler

1 Bottle machine oil

1 Strip fasteners 22 mm

1 DIN coupling

1 Instructions for Use

1 Warranty card

1 Safety instructions

2. SAFETY INSTRUCTIONS

Explanation of symbols

Indicates potential for bodily harm,

fatality or risk of damaging the machine,

in the event that the instructions in this

operator’s guide are ignored.

Wear ear and eye protection

Lubricate the appliance.

Note carefully the following supplementary

points for safe operation of the air stapler, as

well as the other cautions in these instructions

for use.

• Use the air stapler solely for the purpose for

which it was intended.

• Never use the air stapler in a way that could

lead to a fastener being fired at the user or

bystanders.

• Do not use the air stapler as a hammer.

• The air stapler should only be carried by the

handgrip. Never carry the air stapler by the air

hose.

• Never make any unauthorised changes or

modifications to the design or the function of

the air stapler.

• At all times, be aware that incorrect use can

lead to serious injury to yourself and others.

• Never leave the air stapler unattended with a

connected air hose.

• Never use the air stapler whenever there is no

legible warning label affixed to the appliance.

Special safety instructions for air tools and

compressors

• For proper operation of the machine with

a full continuous load under maximum

operating pressure, please make sure that the

temperature of the working environment in an

enclosed area is not more than +25°C.

• It is recommended to use the compressor

with a maximum operation of 70% in one hour

under full load, to allow for proper operation of

the product over time.

5

EN

• Check that the tank is fully decompressed before

connections with the tank are unscrewed.

• It is prohibited to make holes in, or welds to, or

purposely to distort the compressed air tank.

• Do not perform any actions on the compressor

without first having taken the plug out of the

plug socket.

• Do not aim water jets or jets of flammable

liquids at the compressor.

• Do not place flammable objects near the

compressor.

• Switch the pressure regulator to the “0”

position (OFF) during dwell time.

• Never aim the air jet at persons or animals.

• Do not transport the compressor with the tank

pressurised.

• N.B.: some parts of the compressor such as

the head and the feed-through pipes may

reach high temperatures. Do not touch these

parts to avoid burns.

• Transport the compressor by lifting it or by

using the special grips or handles.

• Children and animals should be kept far away

from the area of operation of the machine.

• If you use the compressor to spray paint:

a) Do not work in enclosed spaces or near

naked flames.

b) Make sure that the environment in which you

will be working has dedicated ventilation.

c) Protect your nose and mouth with a

dedicated mask.

• Do not use the compressor when the electrical

cable or the plug is damaged, and instruct an

authorised Support Service to replace them

with an original part.

• When the compressor is placed on a surface

higher than the floor, it should be secured to

prevent it from falling down during operation.

• Do not put objects or your hands in the

protective covers to avoid physical damage

and damage to the compressor.

• Do not use the compressor as a blunt

instrument against persons, objects or animals

in order to prevent serious damage

.

• If the compressor is no longer in use, always

take the plug out of the plug socket.

• Always make sure that compressed-air

hoses are used for compressed air and which

are characterised by a maximum pressure

adjusted to that of the compressor. Do not try

to repair the hose if it is damaged.

3. AIR SUPPLY AND

CONNECTIONS

Never use any oxygen, inflammable

gases or compressed air from gas

bottles to supply pressure to this

appliance, due to the hazard of explosion

and the potential for serious injury.

Quick-detachable couplings

Connect an air hose to the appliance using a QD

(quick-detachable) coupling. The QD coupling

also disengages the air pressure from the tool

when it is disconnected.

Air hoses

Air hoses should be able to sustain a working

pressure of at least 10 Bar. The air supply hose

should be equipped with a QD coupling to enable

”quick uncoupling” from the air stapler.

Compressed air

Only use clean, regulated compressed air for this

tool.

Pressure regulator

For safe operation of the air stapler, a pressure

regulator with an operating range of 4-7 Bar is

required for regulation of the working pressure. Do

not connect the air stapler to an air pressure that

might possibly exceed 10 Bar, as this may cause

damage to the air stapler, and could also result in

injuries.

Operating pressure

Never exceed the recommended maximum

pressure, as this will cause a substantial increase

in the rate of wear. The air supply must be

sufficient to maintain the appliance’s working

pressure. Should the pressure diminish, the

driving power of the air stapler will be reduced.

See “TECHNICAL SPECIFICATIONS” for the

correct working pressure of the air stapler.

Oil and water separator

Dirt and water in the air supply are the main cause

of wear on pneumatic tools. An oil and water

separator will help to ensure clean air pressure

for the best performance and least wear on the

air stapler. The oil and water separator must be

regularly tapped off, in order to function effectively

Table of contents

Languages:

Other Ferm Nail Gun manuals

Popular Nail Gun manuals by other brands

Metabo HPT

Metabo HPT NR 3675DD Instruction and safety manual

EXTOL PREMIUM

EXTOL PREMIUM 8894580 Translation of the original user manual

DeWalt

DeWalt XR Li-Ion DCN680D2 Original instructions

Performance Tool

Performance Tool M643 owner's manual

Hitachi

Hitachi VH650 - Fencing Nailer, Full Head instruction manual

Parkside

Parkside PET 25 B1 Operation and safety notes