Bossong BOSS 4000 User manual

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 1

INSTRUCTION MANUAL CARTRIDGE OPERATED HAND-HELD FIXING TOOL

(translation of the original instructions in English)

BOSS 4000

Technical Assistance:

Bossong S.p.A.

Z.I.2 Via E. Fermi 51

24050 Grassobbio (Bergamo) ITALY

Tel. 0039 035 3846 011

Fax. 0039 035 3846 012

www.bossong.com

Dealer :

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 2

EC DECLARATION OF CONFORMITY

we declare that the machinery

BOSS 4000

Cartridge operated hand-held fixing tools to fixing metal nails in the concrete and steel

in single shoot version

Serial Number:

Placed on the market by

Bossong S.p.A.

Via Enrico Fermi –49/51

24050 Grassobbio - Italy

fulfils all relevant provisions of the directive 2006/42/EC.

Notified body which carried out the EC

type-examination referred to in Annex IX:

NB 2223

Banc National d’Epreuve

5 rue de Méons –BP 147 –ZI Molina Nord

42004 Saint-Etienne - France

number of the EC type-examination certificate

2223/5491/780/06/12/0017

Harmonized Standard Used:

EN 15895

According to EN 15895 statement, the vibration total value to which the hand-arm system is

subjected does not exceed 2,5 m/s2

Airborne noise emissions:

- LpA,1s,0 = 99 ±2 dB (A)

- LpC,peak = 130 ±6 dB (C)

- LWA,1s = 108 ±3 dB (A)

Determined according to EN 15895 annex D with .27 caliber RED cartridges and KR75 nails.

Grassobbio, date 26.09.2012

Mr Andrea Taddei

General Manager

Bossong S.p.a.

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 3

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 4

ENGLISH

READ CAREFULLY THE INSTRUCTIONS CONTAINED IN THIS GUIDE BEFORE USING THE TOOLS

BOSSONG tools must be used by adult expert personnel only, who knows well how to realize the work, as well as the safety rules, operational and

maintenance instructions contained in this user’s guide.

Technical assistance service offered by BOSSONG SpA can help the workers as far as the use and maintenance of the tools are concerned.

CHARACTERISTICS AND MAIN TECHNICAL SHEET

BOSS 4000 is an indirect-acting powder actuated tool. The power developed by the cartridges drives the piston, that then fixes the nail into the work surface.

The highest velocity of the fixing does not exceed 100 m/s (it is classified as Low Velocity tool, class A). The tool, once correctly placed on the work surface,

can fire under the pressure of at least 0,17 kN (17 kg).

The BOSS 4000 can be used in its single shot version.

The BOSS 4000 tool can fix nails until 75 mm.

Power regulator allows to use a wide range of available powers only employing the red cartridges. Please, only use cartridges 6.8x11 mm. Each cartridge

strip allows to shoot up to 10 nails.

Automatic cartridge advance system and semi-automatic reloading of piston.

Easy assembly and maintenance, very versatile.

Minimum recoil, low noise thanks to the interior silencer.

High power, capacity of penetration into steel up to 10 mm, suggested minimum penetration into concrete: 27 mm.

BOSS 4000: length: 355 mm weight: 3,15 kg

MAIN OPERATING AND SAFETY INSTRUCTIONS

BEFORE USING THE TOOL MAKE SURE THERE ARE NO CARTRIDGES LEFT INSIDE. WHEN YOUR WORK IS FINISHED UNLOAD THE POSSIBLE

CARTRIDGES AND NAILS.

WORKERS AND ASSISTANCE PERSONNEL WILL ALWAYS HAVE TO WEAR EYE AND HEARING PROTECTION WHEN SHOOTING.

NEVER PUT YOUR HAND OVER THE MUZZLE.

DO NOT PULL THE TRIGGER UNTIL THE TOOL IS RIGHTLY PLACED WITH THE MUZZLE ON THE WORK SURFACE.

DO NOT USE THE TOOL WHERE FLAMMABLE OR EXPLOSIVE VAPOURS, DUST OR SIMILAR SUBSTANCES ARE PRESENT.

DURING TRANSPORTATION AND LOADING, THESE TOOLS WILL HAVE TO BE POSITIONED HORIZONTALLY. KEEP TOOLS POINTED IN A SAFE

DIRECTION. NEVER POINT POWDER-ACTUATED TOOLS AT ANYONE.

WHEN SHOOTING, ALWAYS USE THE SPALL SHIELD INSTALLED ON THE TOOL.

AT THE END OF WORK PLACE THE TOOL CAREFULLY IN THE ORIGINAL BOX. USE ONLY THE ORIGINAL BOX FOR THE TRANSPORTATION.

ONLY ORIGINAL BOSSONG CONSUMABLES, COMPONENTS AND SPARE PARTS MUST BE USED IN THE TOOL.

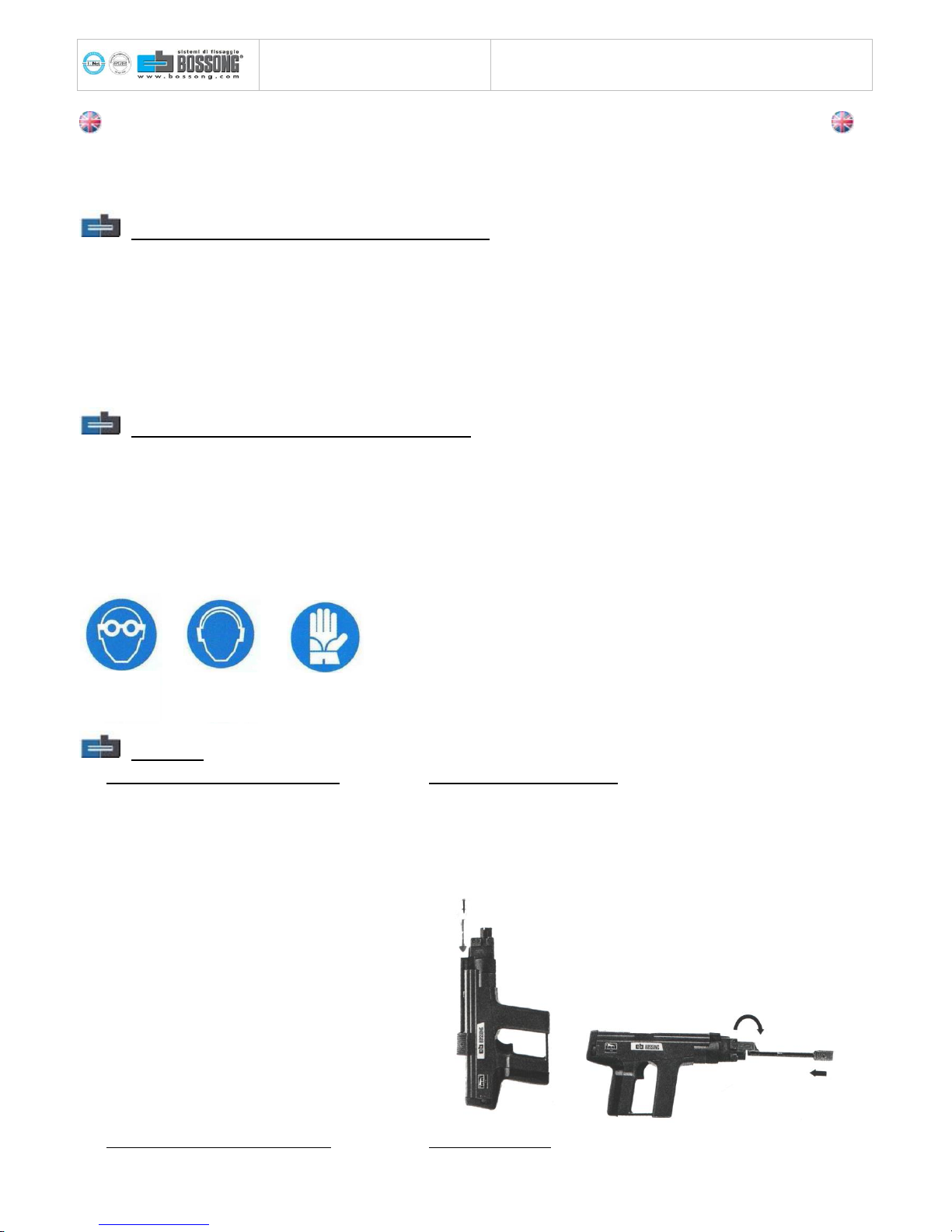

WORKING

1) PRELIMINARY OPERATIONS

Before loading nails and cartridges check that the guide

moves easily and that the firing chamber or the areas

where piston and nails will move during the shooting are

free from any obstruction.

2) INSERTION OF NAILS

The nails to be used with this tool are only those created for shooting; do not use

common nails. The material and the treatment must be adequate to the use.

Keep the nailer up. Insert the nail with the point down into the charger level.

Turn forward the charger lever and push inside the nailer the nail, moving the plastic

handle up to the end.

3) LOADING OF CARTRIDGES

Only use the following types of color-coded cartridges:

caliber 6,8/11 green (min strength)

4) SHOOTING

Once loaded, the tool is ready to shoot.

Place the muzzle of the fastening tool against the work surface at a right angle.

Wear eye

protection

Wear protective

gloves

Wear ear

protection

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 5

caliber 6,8/11 yellow (medium strength)

caliber 6,8/11 red (max strength)

Cartridges should be protected from heat and humidity during

storage.

Insert the cartridges into the tool through the slot below it

and push until they are completely inside. You should see

the plastic cover of the cartridges from the slot on the

upper part of the tool.

To eject the cartridges or simply move them inside the tool

pull them from the slot on the upper part of the tool.

Allow only trained, competent and authorized persons to

load a tool.

Cartridges must not be forced during the loading, or

inserted using other tools.

This kind of cartridges (FOR TECHNICAL USE ONLY)

cannot be used for guns.

Keep it balanced. The worker should position himself behind the tool, in range with

the axis of the tool guide. The assistance personnel should be behind the worker.

Push the tool against the surface pressing at the same time the little lever which is

behind the grip and pull the trigger.

Please shoot only if no one is in a dangerous position around or inside the working

area.

After the shot release the tool; the worker will be aware of the fact that it will

inevitably recoil

FOR A NEW SHOT, INSERT THE NAIL AS DESCRIBED ABOVE IN THE ITEM 2

AND SHOOT AS DESCRBED IN THE ITEM 4.

WHEN ALL CARTRIDGES ARE OVER, REMOVE THE CARTRIDGES PLASTIC

CONTAINER FROM THE UPPER HOLE OF THE TOOL, REPEAT ITEMS 1 TO 4

FOR NEW FIXINGS.

DO NOT FIX WHEN A PRECEEDING ATTEMPT FAILED.

FASTENING

Because of differences in hardness of concrete and thickness of steel, fastenings to these materials requires different strength of power.

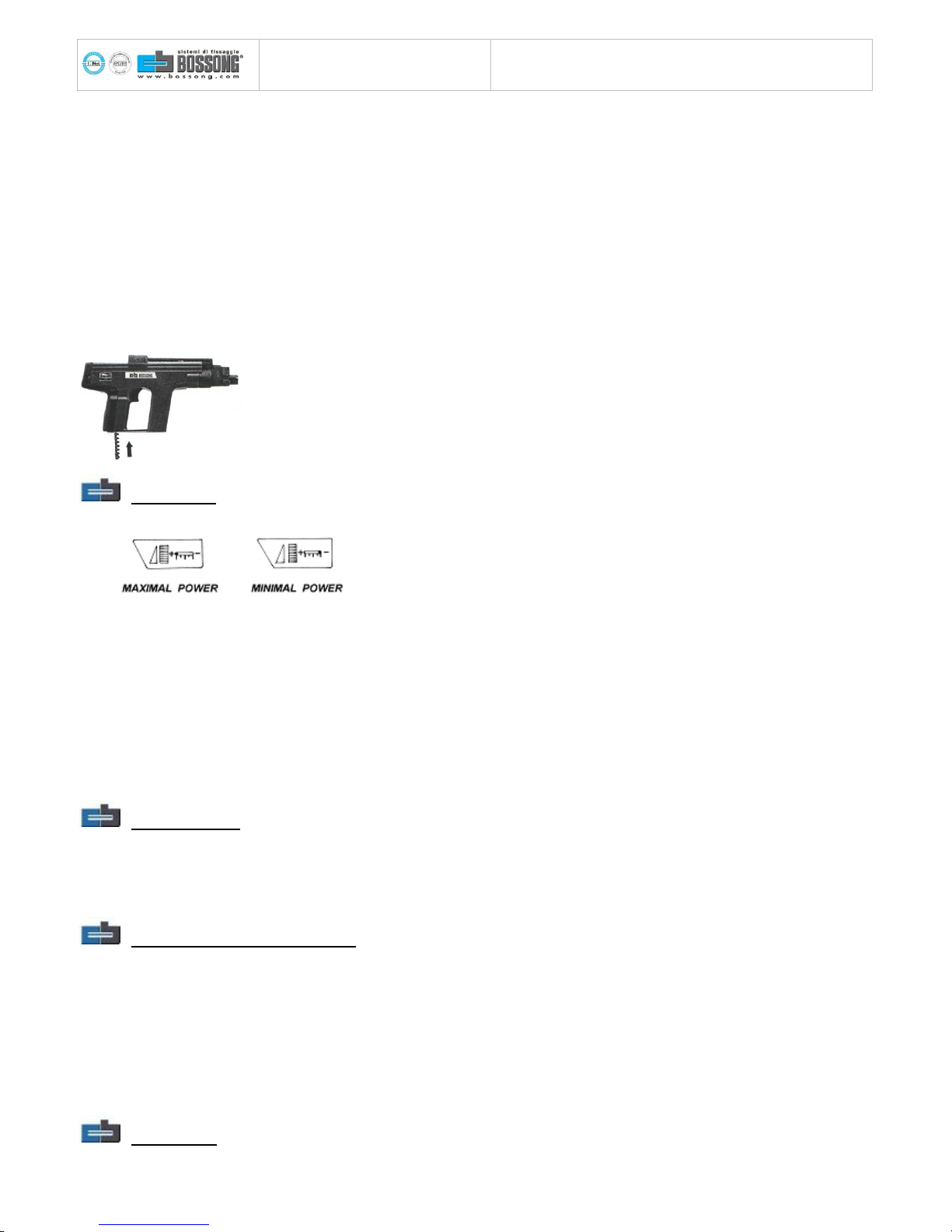

Using tool you have a possibility of stepless power regulation by turning the

handwheel until the resistance of required power is reached.

The proper power selection is the matter of experience and needs a number

of trial fastenings.The first test should be made with the lowest power, and

then power should be increased until desired penetration is reached.

MINIMUM CENTRE DISTANCE: nails should be fixed with a distance not less than 80 mm the one from the other in concrete. For fixing on steel the

minimum distance should be at least of 20 mm.

MINIMUM EDGE DISTANCE : When nails are fixed into concrete keep a distance of at least 80 mm. When nails are shot into steel keep an edge distance of

at least 20 mm.

MINIMUM THICKNESS OF THE BASE MATERIAL: For fixings into concrete min. 80 mm, for fixings into steel min. 4 mm.

DO NOT FASTEN ITO STEEL THINNER THAN THE FASTENER SHANK DIAMETER.

The fixing will be visible after the shoot.

To eliminate spalling, a Spall Shield should be used.

You should not use your tool to do fastenings into roof tiles, hollow bricks, glazing bricks, surface-hardened steel. It is forbidden to use the tool for fixing

fragile material, even if is hard, such as cast iron, hardened steel, marble, granite, glass, ceramic material, drilled bricks, etc. NEVER DO FASTENINGS

INTO PERFORATED OR BRITTLED MATERIAL. NEVER DO FASTENINGS INTO WELDED SURFACES.

ALWAYS POINT THE TOOL PERPENDICULAR TO THEWORK SURFACE.

NEVER FIRE THE TOOL WITHOUT FASTENER - IT MAY DAMAGE THE TOOL.

NEVER FIRE INTO A HOLE.

MAINTENANCE

To replace parts of the tool, must be used only original spare parts from BOSSONG.

Should follow each day’s work or each 1000 shots.

The tool must be checked, cleaned and oiled at the end of such day and it must be send at least once a year to the manufacturer or to an authorized

technician for a general overhaul.

Firing no more than 200 shots per hour in order to guarantees the safety and an optimal durability of piston returner.

TROUBLES DURING SHOOTING

If a cartridge misfires, hold the tool against the work surface and pull the trigger again. At the case of failure to do so, keep the tool in the above position

for about 30 seconds. Take the tool away from the work surface and depress it again to advance the next cartridge. Please make sure that the misfired

cartridge can not be used again.

If you hear a very low noise shooting, it means that the cartridge power has not completely burned. In this case you must disasseble the tool and clean

carefully the barrel, the head of the piston and the bottom of the barrel hole.

If the barrel assembly sticks, shake it downwards firmly. At the case of failure to do so , take away the cartridge, dismantle and clean the tool as

described above.

If you have any problem with the cartridge, please stop and call our technical service.

If the shooting power is diminished , check the rubber returner and replace if necessary.

If the tool does not appear to be working properly and if it cannot be unloaded, leave it in safe place and inform the « BOSSONG After Sales Service ».

BOSSONG shall be exempted from all responsibility coming from bad and improper use of the tool, and if no attention shall be paid to the safety

regulations or to the operating and maintenance instructions contained in this instruction manual.

WARRANTY

Warranty: 1 year from the date of purchase of the Customer.

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 6

The warranty cover only defects in material and workmanship; the warranty is valid only if the tool is operated and handled correctly, cleaned and

serviced properly and in accordance with the operating instructions manual.

Only original Bossong consumables, components and spare parts must be used in the tool.

This warranty provides the replacement of defective parts only. Parts requiring repair or replacement as a result of normal wear and tear are not covered

by this warranty. For example: pistons, guides, rubber returner, advance cartridge system , etc. are not covered by warranty.

Warranty do not cover neither costs to repair the tool neither transport freight.

Bossong is not obliged for damages, losses or expenses in connection with the use or inability to use the tool.

For repair or replacement, send tool and/or parts immediately upon discovery of the defect to the address of the Bossong Distributor.

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 7

Tools and nails

Description

KR

GD6-12

GD8-12

BOSS 4000

X

X

X

CONCRETE

X

X

X

STEEL

KR20

GD6-12-

820

GD8-12-

1514

Tools

code

description

056000

BOSS 4000

code

description

nails

056005

KR 4 Pistone

KR-GD8

056020

GD6/8-4 Pistone

GD6

056022

GD6/12-4 Pistone

GD6

056024

GD6/20-4 Pistone

GD6

Accessories

code

description

000012

Oil spray

000011

Safety glasses

057199

Cleaning kit

000030

Cloth

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 8

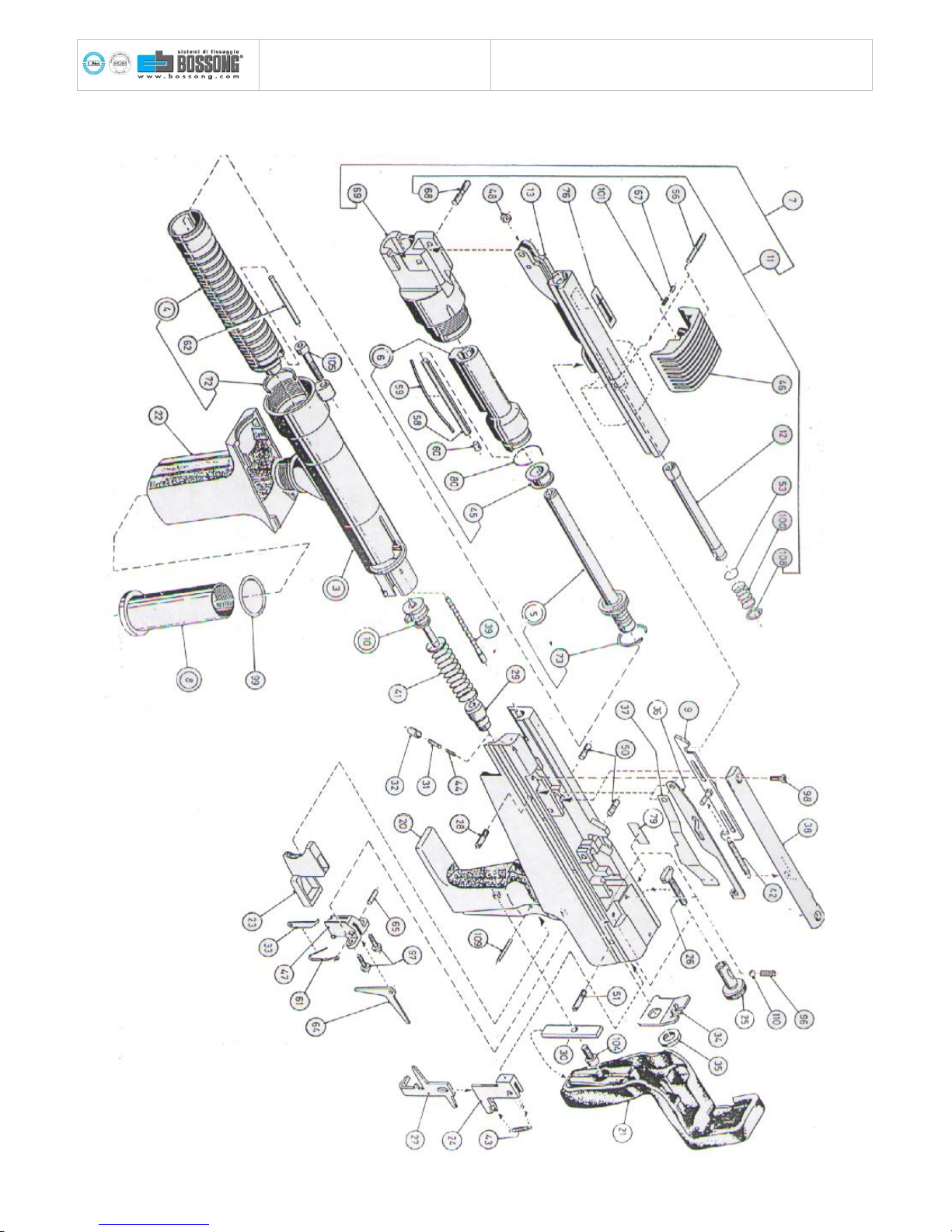

BOSS 4000

PARTS LIST

BOSS 4000

To replace parts of the tool, must be used only original spare parts from Bossong.

Nr

DESCRIPTION

CODE

3

BARREL GUIDE

057003

4

BARREL

057004

5

PISTON

056005

5

PISTON

056010

5

PISTON

056020

5

PISTON

056022

5

PISTON

056024

6

GROUP NAIL’S GUIDE

057006

8

NO NOISE SYSTEM ASSEM.

057008

9

TRANSPORT LEVER SPRING

057009

10

FIRING PIN RECEPTION

057010

11

GROUP LEVER SPRING

057011

12

TUBE

057012

13

LEVER SPRING

057013

20

HANDLE

057020

21

RUBBER HANDLE

057021

22

PLUG

057022

23

TRIGGER LEVER

057023

24

GUIDE LEVER FIRING PIN BARRIER

057024

25

REGULATION NUT

057025

26

SCREW

057026

27

LEVER FIRING PIN BARRIER

057027

28

SCREW

057028

29

GUIDE PIN

057029

30

STOP PIECE

057030

31

057031

32

BARREL GUIDE XXX

057032

33

057033

34

XXXX PIECE

057034

35

NUT

057035

36

TRANSPORT LEVER SPRING

057036

37

XXXXXX SPRING

057037

38

XXXXX PIECE

057038

39

057039

41

FIRING PIN SPRING

057041

42

TENTION SPRING

057042

43

FIRING PIN SPRING

057043

44

STOP SPRING

057044

45

PROTECTION

057045

46

057046

47

TRIGGER LEVER XXXXX

057047

48

LEVER RING

057048

50

057050

51

SCREW XXXX

057051

53

057053

56

SCREW XXXX

057056

58

057058

59

PIN XXXXX

057059

60

BARRIER SPRING

057060

61

STOP SPRING

057061

62

057062

64

TRIGGER LEVER

057064

65

XXX TRIGGER LEVER

057065

67

057067

68

057068

69

SAFETY BASEPLATE

057069

72

057072

73

PISTON RING

057073

76

NAIL LABEL

057076

79

REGULATION BOLT LABEL

057079

80

GUIDE RING

057080

96

XXX REGULATION NUT

057096

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 9

97

SCREW

057097

98

SCREW

057098

99

O RING

057099

100

SPRING

057100

101

SPRING

057101

104

SCREW

057104

105

SCREW

057105

108

CIRCLIP

057108

109

DOWEL PIN

057109

110

STEEL PIN

057110

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 10

BOSS 4000

BOSS 4000

Translation of the original

instructions

Bossong SpA

Via E. Fermi 49/51 24050 Grassobbio (Bergamo) Italy

Tel. +39 035 3846 011 - Fax +39 035 3846 012

Pag. 11

ONE YEAR

GARANZIA - WARRANTY- GARANTIE

Modello - Model - Model

Model - Typ :

Numero di serie - Serial number - Serienummer

Numero de serie :

Data di Acquisto - Date of Purchase - Verkaufsdatum

Date d’achat - Aankoopdatum –Købsdato :

Cliente - Customer - Kunde - Client - Klant : Indirizzo - Address - Adresse - Adresse - Adres :

Timbro Distributore - Stamp of Distributor

Stempel des Vetreibers - Timbre Distributeur

Stempel van Dealer - Forhandlers stempel:

Spedire subito a Bossong. Envoyer immédiatement à Bossong. To be mailed immediately to Bossong. Sofort zum

Bossong schinken. Bij aankoop toestel direct terugsturen naar uw Bossong.

Table of contents