5

MAINTENANCE: CLEANING THE WORKSTAND

The exterior of the workstand can be cleaned with a soft bristle brush and a mild detergent.

The cradle can be cleaned separately by removing the attachment screw, located on the

bottom of the workstand.

MAINTENANCE: REPLACING THE SWIVEL BUSHING

1. Turn off shop air.

2. Unscrew air hose from the desolder tool.

3. Using an adjustable wrench, unscrew the swivel bushing.

Note: the swivel bushing is secured in the tool with a sealant so it may be difficult to

remove.

4. When you remove the swivel bushing, you will see a spring. Keep it in place.

5. Make sure the area where the swivel bushing screws in is clean of foreign materials

(this may require removing the spring temporarily).

6. Wrap Teflon pipe sealant around the end of the swivel bushing and with the spring

in place, screw the swivel bushing into the back of the desolder tool using a torque

wrench to 30-50 in-lbs.

7. Screw in the air hose onto the swivel bushing.

8. Turn on shop air and check for leaks.

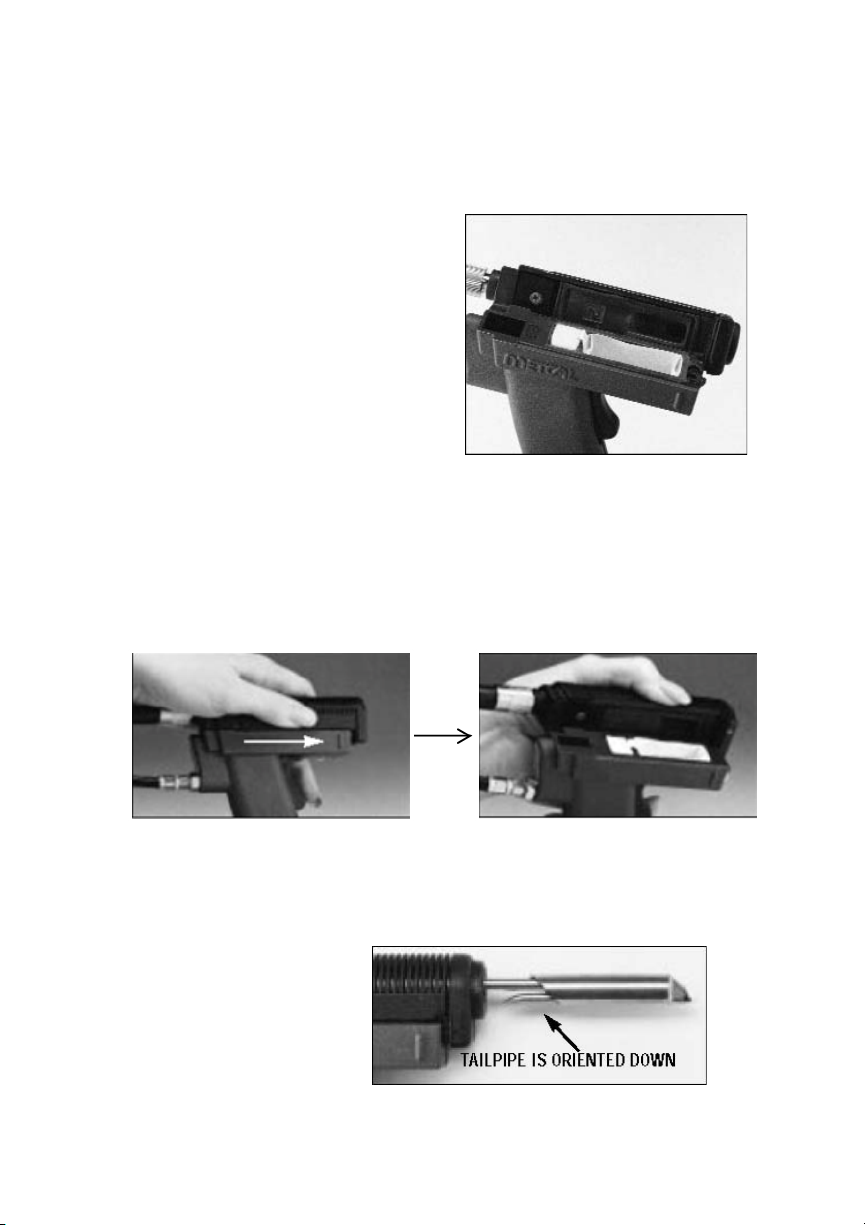

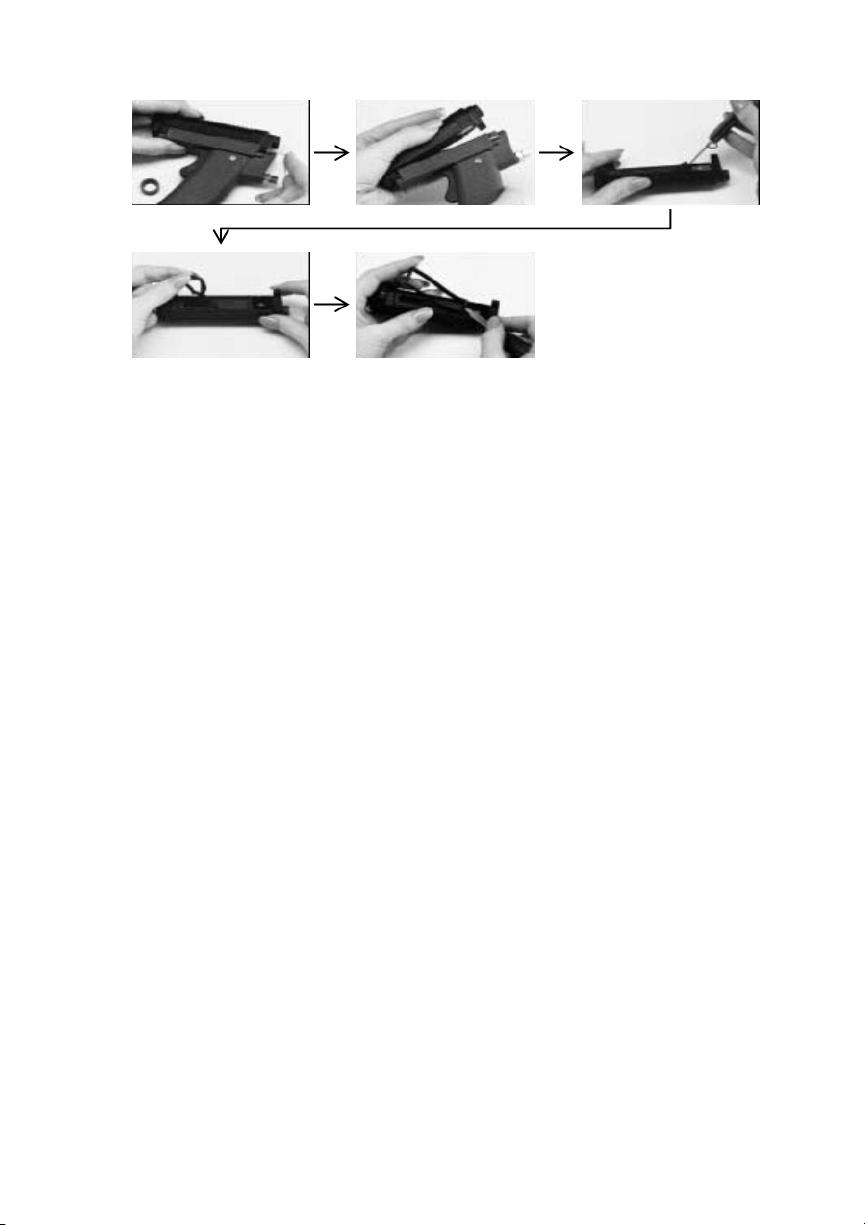

MAINTENANCE: REPLACING THE UPPER CHAMBER

For an illustration of many of the steps in this technique, see following page.

1. Remove the power cord from back of the upper chamber.

2. Open the upper chamber.

3. Insert a long, thin tool in the back hinge where the upper chamber hinges to the tool

handle assembly.

4. Push tool inwards and pull the upper chamber away from the tool handle assembly.

5. Completely remove upper chamber.

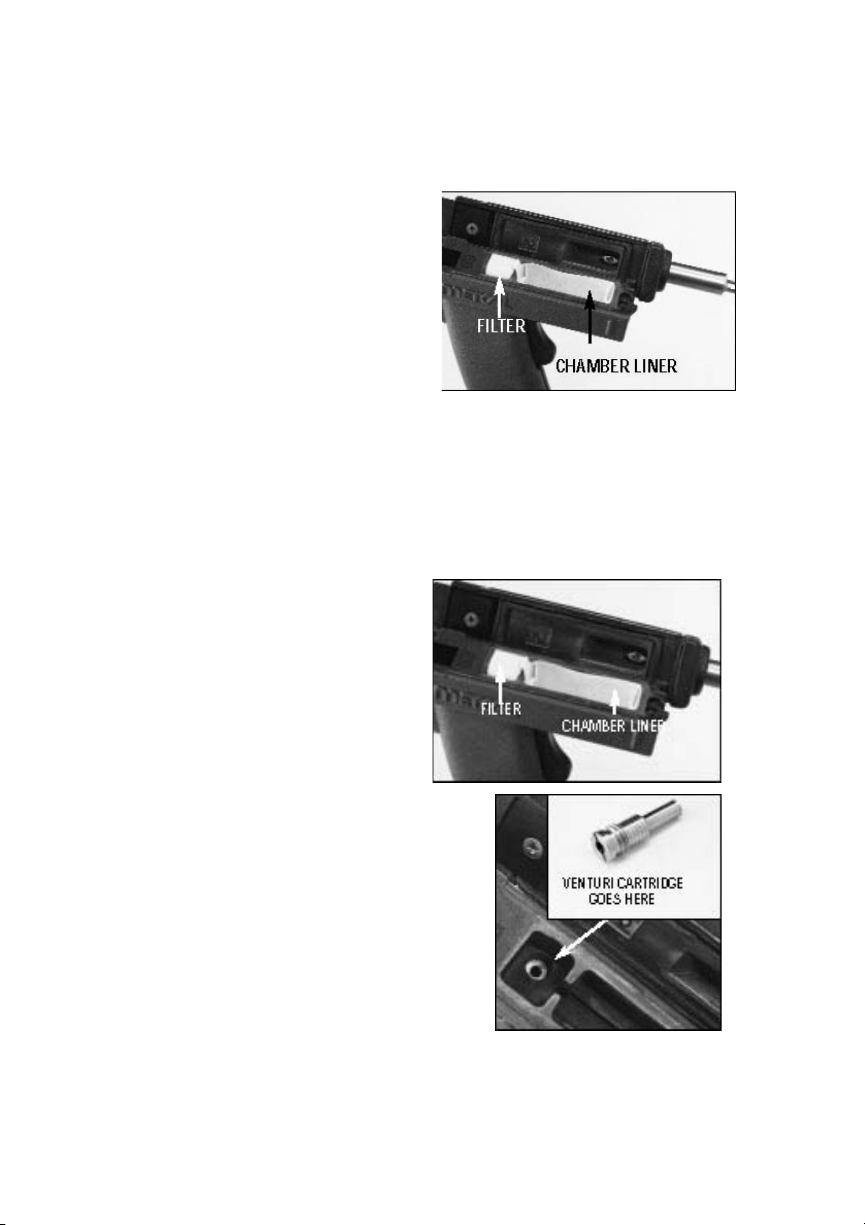

6. Remove old pins and springs from the front and back pin bores.

7. Insert two new springs, and two new hinge pins, into the pin bores on either end of

the tool handle assembly. Ensure that the smaller, tapered ends of the hinge pins,

are pointing outward.

8. Install upper chamber assembly onto tool handle assembly by pushing the hinge

pins into their bores until the arms of the upper chamber assembly will slide onto the

handle assembly. The hinge pins should slide out into their pilot holes in the arms

of the upper chamber.

9. Check the functioning of the slide latch and hinge by operating the latch, opening

and closing the upper body a few times. The parting lines (gaps) between the rear

of the chamber and the top rear of the right handle should be parallel.

MAINTENANCE: REPLACING CARTRIDGE SEALS

1. Turn off the system and remove the desolder cartridge.

2. Pry out the cartridge seal (at the front end of tool) by gently prying it out with a small

screwdriver, paper clip, or other blunt instrument.

3. Replace the cartridge seal by pushing it in.

MAINTENANCE: REPLACING CHAMBER SEALS

1. Remove the air line and power cord from the desoldering handle.

2. Open the desoldering handle and lay it down with the hinge side facing up toward

you

3. Before removing the hinge pins, cover the hinge area with your hand as you remove

the top. They are spring loaded and might shoot out of the tool as the top is

removed. Take the end of a paper clip and push it into the small hole at the front or

rear of the hinge. This will push the hinge pin into the tool. You can then wiggle the

top of the tool away from the hinge pin. Repeat this with the other hinge.

4. Remove the top half of the tool.

5. Remove the solder chamber seal using a knife.

6. To install the new chamber seal, start with a short side, and use a screwdriver or

other blunt tip to tuck the seal lip into the retaining grove