BossPac WASP User manual

BossPac WASP™

(Wireless Acceleration Sensor Puck)

For use with the

BossPac NEST™

• Acceleration, Velocity, & Temperature

• CSA Class I Div 2*

• ATEX Zone 0 Pending

Bay 8, 1450 - 28 Street NE, Calgary, Alberta, Canada T2A 7W6

Phone: +1 (403) 216-1226 Toll Free: +1 (866) 616-1226 Fax: +1 (403) 216-5557

www.bosspac.com

www.bosspac.com

2

WARNING

READ THIS MANUAL BEFORE OPERATING THIS DEVICE.

WARNING

TO PREVENT EQUIPMENT FAILURE AND/OR DAMAGE

AND/OR PERSONAL INJURY, REGULAR CALIBRATION

AND INSPECTION OF THIS DEVICE IS REQUIRED.

WARNING - EXPLOSION HAZARD

SUBSTITUTION OF COMPONENTS MAY IMPAIR

SUITABILITY FOR CLASS 1 DIVISION 2.

WARNING - EXPLOSION HAZARD

DO NOT REPLACE OR REMOVE BATTERIES UNLESS AREA IS

KNOWN TO BE NON-HAZARDOUS.

WARNING – STRONG MAGNET

Strong magnetic field can cause personal injury or death to

individuals with medical implants or other magnetic field sensitive

medical conditions.

Keep tools and other metal objects away.

www.bosspac.com

3

Introduction

The BossPac WASP is a wireless acceleration, velocity and temperature sensing

device. It features a 3 axis accelerometer, with a frequency range of 2 to 400 hertz

and an amplitude of +/- 16 G.

With a mounting point temperature range of -40C to +185C the WASP can be mounted

directly to valve caps allowing the measurement of acceleration, velocity and

temperature.

With the ability to monitor up to 64 WASP’s, the BossPac NEST (Network Electronic

Sensor Terminal) can be used to monitor up to 64 locations on equipment from just

one controller.

Installing the Battery

Each sensor puck is shipped with a separate battery module. The battery module

contains a non-removable long lasting lithium battery.

To turn on and activate each sensor puck you must carefully attach the battery board

to the sensor unit. Plug the pins on the battery board into the corresponding connectors

on the sensor puck. See photo on the next page.

Once the pins make contact a LED on the underside of the battery module will flash to

indicate power on. During this time, the WASP device performs a power-on self test

(POST). If all is well, the LED will flash quickly for a couple of seconds and then turn off.

Should the POST fail, the device goes into a non-operational state and flashes the LED

in discernable patterns to help diagnose the source of the problem. See Appendix A of

this manual for information on troubleshooting the LED flash codes.

NOTE: Do not remove the screws from bottom of the sensor puck.

Doing so will void the product’s warranty.

WARNING - EXPLOSION HAZARD

DO NOT REPLACE OR REMOVE THE BATTERY UNLESS AREA IS

KNOWN TO BE NON-HAZARDOUS.

www.bosspac.com

4

Installation

When setting up measurement points on equipment it is important to take into account

bearings, bearing support housing, and other structural parts that will respond to the

vibrational forces the equipment will be subjected to.

To best monitor vibrational behaviour at each measuring point, it is necessary to take

measurements in 3 perpendicular directions (X,Y,Z axis). Figures 1 to 3 below show

suggested measurement points for 3 types of machinery. The WASPTM measures 3-

axis by default.

Detailed recommendations for specific machine types are provided in ISO document

10816.

The sensor pucks can be attached to the desired equipment by either magnet, epoxy

or stud mount. When using the magnet mount place a small dollop of thermal paste on

the center of the magnet prior to mounting.

The WASPTM has an effective range of up to 60 meters from the antenna.

Note: To ensure effective wireless transmission between the sensor pucks

and the antenna it is recommended that there is a direct line of sight between

the units.

www.bosspac.com

5

www.bosspac.com

6

Thermal Calibration of WASPs

To ensure the greatest accuracy of the monitored variables, it is advised to do thermal

calibration of each WASP unit. The process of thermal calibration is as follows:

1. Ensure the machinery for which the WASP is to be attached is at operating

temperature.

2. Place the WASP(s) units at their desired mounting points using thermal paste.

Allow 15 minutes for the temperature to stabilize.

3. Using a reference temperature source (ie. IR Temperature Gun1), record the

temperature value at the valve cap at the mounting point of the WASP unit.

4. At the NEST, adjust the display temperature to match the value of the thermometer

gun using the temperature calibration function. (See the section on temperature

calibration in the Setting Temperature Warning, Critical Error, and Offset Limits section

in the NEST User Manual).

Notes:1. IR Temperature Guns commonly have accuracy ratings of +/- 2% and the

readings can be affected by the distance and angle that the measurements are

taken from.

www.bosspac.com

7

Appendix A

Troubleshooting LED Flash Codes

The following table contains a brief description of all flash codes reported by the device:

FLASH CODE DESCRIPTION ACTION

1 Flash:

Accelerometer Failure Device cannot communicate with the

accelerometer Not user serviceable.

Replace sensor.

2 Flashes:

Battery Failure Device battery is either too low or too

high. Replace Battery as per the

Battery Installation section

of this manual.

3 Flashes:

Temperature Sensor Failure Temperature Sensor readings are

outside of the start-up temperature

window, from -40°C to 100°C

Ensure that the mounting

point temperature is within

the allowable temperature

range and replace the

battery as per the Battery

Installation section of this

manual. If error persists

the sensor may need to be

replaced.

4 Flashes:

Radio Failure Device could not initialize the radio. Not user serviceably.

Replace sensor.

5 Flashes:

Regulator Failure The onboard regulator is not able to

maintain the required voltage for

correct operation.

Replace Battery as per the

Battery Installation section

of this manual, if error

persists the sensor may be

faulty and need

replacement.

Support

For support contact BossPac Engineering & Technology toll free at

866-616-1226.

www.bosspac.com

8

FCC & IC Statements

FCC Class B Part 15

This device complies with part 15 of the FCC Rules. Operation is subject to the

following two conditions:

• This device may not cause harmful interference, and

• This device must accept any interference received, including interference that may

cause undesired operation.

Changes or modifications not expressly approved by BossPacEngineering Technology

Inc. may void the user’s authority to operate the equipment.

IC RSS 210

This device complies with Industry Canada licence-exempt RSS standard(s). Operation

is subject to the following two conditions: (1) this device may not cause interference,

and (2) this device must accept any interference, including interference that may cause

undesired operation of the device.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux conditions

suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de

l'appareil doit accepter tout brouillage radioélectrique subi, même si le brouillage est

susceptible d'en compromettre le fonctionnement.

FCC/IC RF Exposure Statement

This equipment complies with FCC radiation exposure limits set forth for an uncontrolled

environment.

Cet équipement est conforme à l'exposition aux radiations de FCC et d'Industrie

Canada établies pour un environnement non contrôlé.

Bay 8, 1450 - 28 Street NE, Calgary, Alberta, Canada T2A 7W6

Phone: +1 (403) 216-1226 Toll Free: +1 (866) 616-1226 Fax: +1 (403) 216-5557

Table of contents

Other BossPac Accessories manuals

Popular Accessories manuals by other brands

Fisher Scientific

Fisher Scientific Isotemp 60L Incbtr Grvity 120V user manual

rollease acmeda

rollease acmeda AUTOMATE Programming instructions

Browan

Browan TBHV110-915 Reference manual

MOB

MOB MO6815 user manual

Pittway

Pittway SYSTEM SENSOR 2251 Installation and maintenance instructions

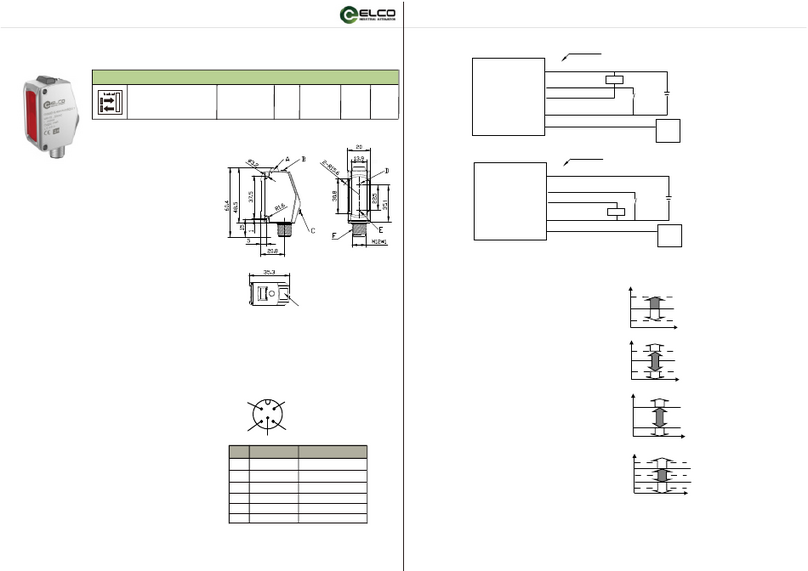

elco

elco OSM40 instruction manual