BossWeld FX-PRO User manual

AUTO- DARKENING

WELDING HELMET

MANUAL

FX-PRO

2

The Solar-Powered Auto-Darkening Welding Helmet is suitable for most welding applications.

This helmet’s 1/30,000-second switch time automatically darkens the lens the moment you start

welding. No matter what shade the lter is set to, the UV/IR protection is always present.

ARC RAYS CAN INJURE EYES AND BURN SKIN

• Before welding, always inspect helmet and auto-darkening lter (ADF) to be sure they are tted properly

and in good condition.

• Keep the sensors, solar cell and lter lens clean. Clean the lter cartridge using a soapy water solution

and soft cloth. Do not use solvents or abrasive cleaning detergent.

• Do not weld in the overhead position while using this helmet.

• Inspect the lter lens frequently and immediately replace any scratched, cracked, or pitted lter lens or

cover lenses.

• Always wear safety glasses or goggles under the welding helmet, and protective clothing to protect your

skin from radiation, burns and spatter.

WARNING

SAFETY WARNING

Thank you for choosing a BOSSWELD FX-PRO Auto darkening Welding Helmet

In this manual you will nd instructions on how to set up your welding helmet along with general welding

information safety information and helpful tips. We encourage you to go online to our website for more tips and

troubleshooting as well as many welding resources.

We truly hope you enjoy using your FX-PRO Auto darkening welding Helmet.

3

The device and packaging material are not toys! Children must not be allowed to play with the helmet and its

accessories. Plastic parts and packaging are choking risks for children.

• Open the packaging and remove the helmet carefully.

• Check that the delivery is complete.

• If possible, store the packaging until the warranty period has expired.

PERSONAL PROTECTIVE EQUIPMENT (PPE)

GLOVES AND PROTECTIVE CLOTHING

Use protective gloves and re resistant protective clothing when welding.

Avoid exposing skin to ultraviolet rays produced by the arc.

WELDING HELMET

Under no circumstances should the welder be operated unless the operator is wearing a

welding helmet to protect the eyes and face. There is serious risk of eye damage if a helmet is

not used. The sparks and metal projectiles can cause serious damage to the eyes and face.

The light radiation produced by the arc can cause damage to eyesight, and burns to skin.

Never remove the welding helmet whilst welding.

SAFETY GLASSES

After welding use appropriate safety glasses when brushing, chipping or grinding the slag from

the weld.

OTHER PERSONS

Ensure that other persons are screened from the welding arc and are at least 15 metres away

from the work piece. Always ensure that the welding arc is screened from onlookers, or people

just passing by. Use screens if necessary, or non-reecting welding curtain. Do not let children

or animals have access to the welding equipment or to the work area.

SWITCHING OFF

When the operator has nished welding they must switch the welder off.

DO NOT put the electrode holder down with the welder switched ON.

When leaving the welder unattended, move the ON/OFF switch to the OFF position and

disconnect the welder from the electrical mains supply.

Do not leave hot material unattended after welding.

FUMES &GASES ARE DANGEROUS

Smoke and gas generated whilst welding or cutting can be harmful to people’s health. Welding

produces fumes and gases. Breathing these fumes and gases can be hazardous to your health.

• Do not breathe the smoke and gas generated whilst welding or cutting, keep your head out of

the fumes

• Keep the working area well ventilated, use fume extraction or ventilation to remove welding

fumes and gases.

• In conned or heavy fume environments always wear an approved air-supplied respirator.

Welding fumes and gases can displace air and lower the oxygen level causing injury or

death. Be sure the breathing air is safe.

• Do not weld in locations near de-greasing, cleaning, or spraying operations.

The heat and rays of the arc can react with vapours to form highly toxic and irritating gases.

• Materials such as galvanized, lead, or cadmium plated steel, containing elements that can

give off toxic fumes when welded. Do not weld these materials unless the area is very well

ventilated, and or wearing an air supplied respirator.

GENERAL WARNINGS FOR WELDING

4

Ensure a clear, well lit work area with unrestricted movement for the operator.

The work area should be well ventilated, as welding emits fumes which can be dangerous.

Always maintain easy access to the ON/OFF switch of the welder, and the electrical mains supply.

Do not expose the welder to rain and do not operate in damp or wet locations

WORK AREA WHEN WELDING

Where welding must be undertaken in environments with increased risk of electric shock, conned spaces

or in the presence of ammable or explosive materials, it is important that the environment be evaluated in

advance by an “expert supervisor”. It is also recommended that welding in these circumstances be carried

out in the presence of persons trained to intervene in emergencies.

AVOID ELECTRICAL CONTACT

Use adequate electrical insulation with regard to the electrode, the work piece and any accessible earthed

metal parts in the vicinity. Avoid direct contact with the welding circuit. The no load voltage between the

earth clamp and the electrode can be dangerous under certain circumstances.

Note: For additional protection from electric shock. It is recommended that this welder be used in conjunction

with a residual current device (RCD) with rated residual current of 30MA or less.

In general the use of extension leads should be avoided. If used however, ensure that the extension lead is

used with the welder is of a suitable current rating and heavy duty in nature that MUST have an earth

connection. If using the welder outdoors, ensure that the extension lead is suitable for outdoor use. Always

keep extension leads away from the welding zone, moisture and any hot materials.

WELDING SURFACES

Do not weld containers or pipes that hold, or have held, ammable liquids or combustible gases or pressure.

Do not weld on coated, painted or varnished surfaces as the coatings may ignite, or can give off dangerous

fumes.

WORK PIECE

When welding, the work piece will remain at high temperature for a relatively long period. The operator must

not touch the weld or the work piece unless wearing welding gloves. Always use pliers or tongs. Never touch

the welded material with bare hands until it has completely cooled.

VOLTAGE BETWEEN ELECTRODE HOLDERS OR TORCHES

Working with more than one welding machine on a single work piece, or on work pieces that are connected,

may generate a dangerous accumulation of no-load voltage between two different electrode holders or torch-

es, the value of which may reach double the allowed limit.

5

Specications Description

Viewing Area 98×62mm

Cartridge Size 115×115mm

Arc Sensor 4

UV/IR Protection UP to shade DIN 16 at all times

Light State DIN 4

Dark State Variable shade 5~8/9~13

Sensitivity Control 5 Adjustments by Button from low to high

Switch Time 1/ 30,000S, from Light to Dark

Delay Control 5 Adjustments by Button from fast to slow 0.1-1.0s

Power Supply Solar cell +1 Replaceable CR2450 lithium battery

Grinding YES

TIG AMP Rating DC ≥ 5, AC ≥ 5

Operating Temperature -5°C to +55°C

Storing Temperature -20°C to +70°C

Other Functions On/Off Button & Low Voltage Indicator

FX-PRO HELMET SPECIFICATIONS

6

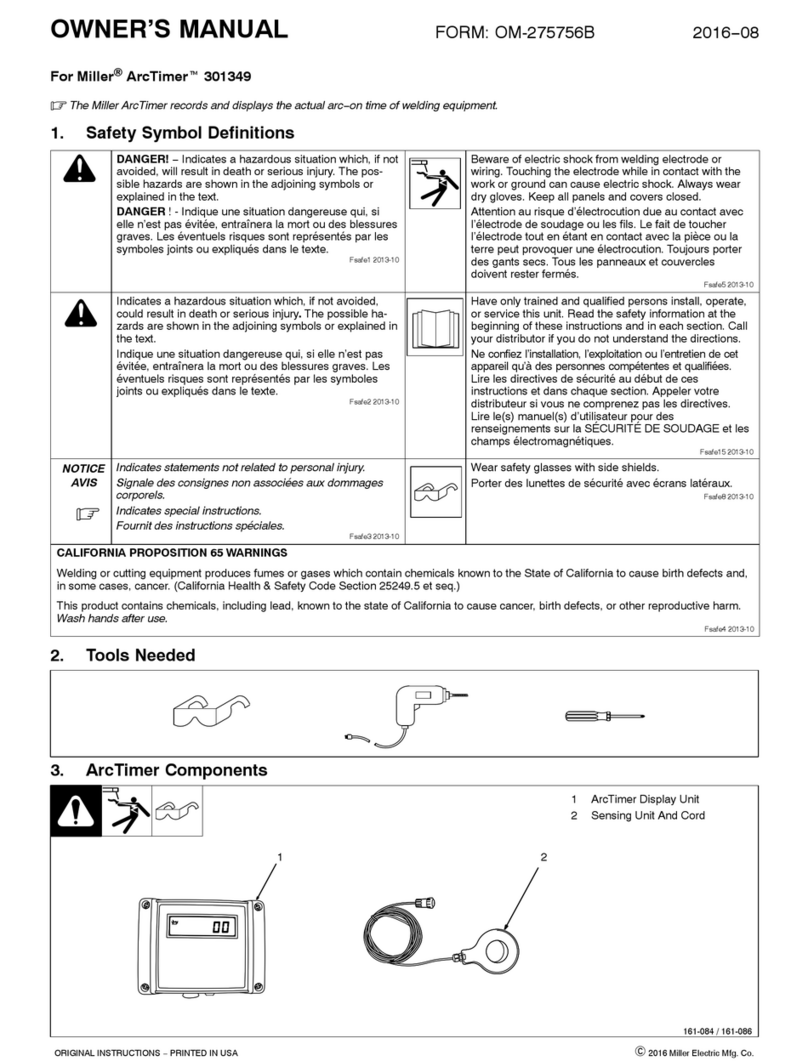

Headgear Adjustment

1. Adjust the headgear diameter with the twist knob on the back.

Twist clockwise to tighten and counterclockwise to loosen.

2. Adjust the height by locking the pin

into the hole to lock securely in place.

3. To adjust the viewing angle, loosen the knob

on both sides of the helmet and change angle

locker to the desired tilt position

(positioned in the middle by default).

Once achieving the desire angle, tighten the knobs

until snug. The helmet should still swing up,

but it should not drift downward when in place

for welding.

4. To adjust the distance between the user’s face

and ADF, press down on the two lockers until the

headband can move back and forth freely,

reposition the headband at one of the 6 slots as

desired. This should be done one side at a time

and both sides should be located at the same

position for proper auto-darkening lter operation.

OPERATION

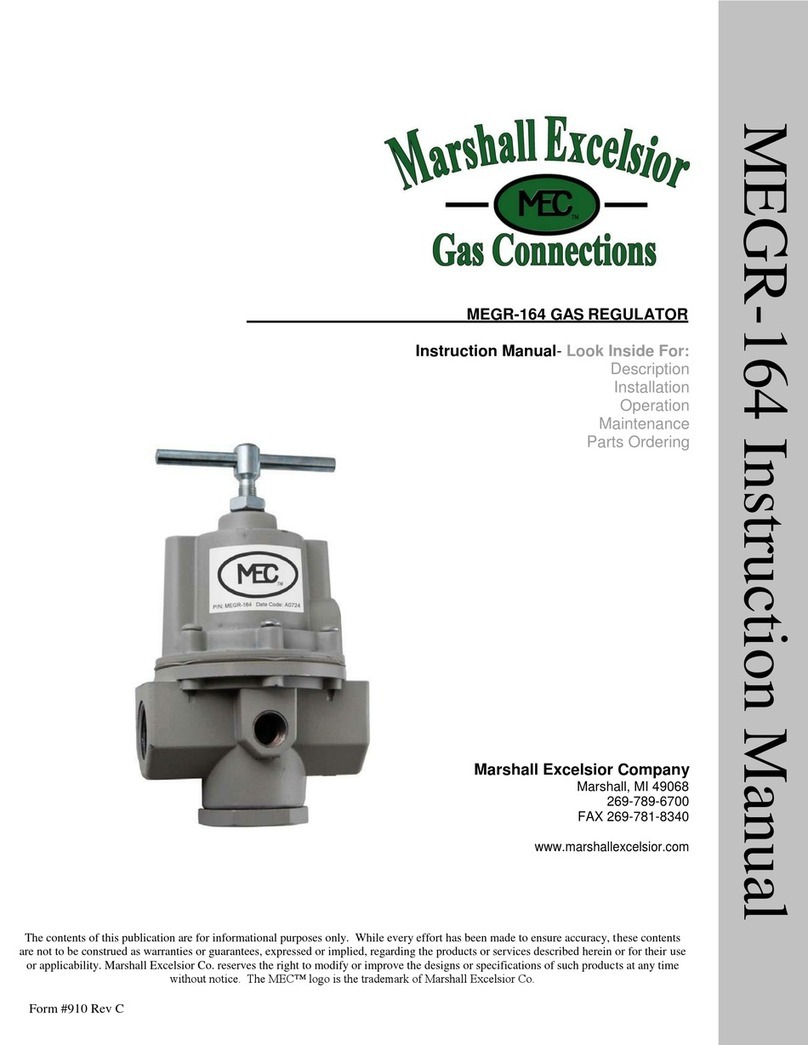

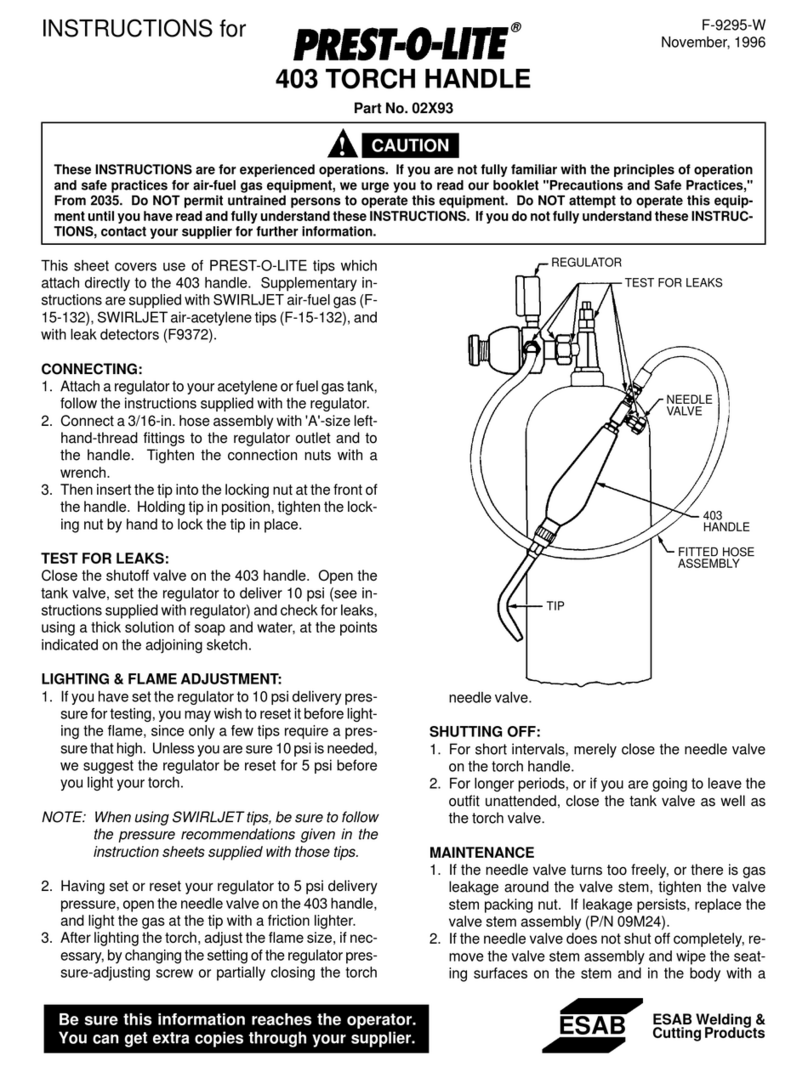

FX-PRO BREAKDOWN

Part No: Description

1 Delay Switch Button

2 Sensitivity Switch Button

3 Shade Switch Button

4 Display Screen

5LCD

6Power ON/OFF Button

7Mode Button

8Low Battery Indicator

9Battery Case

10 Solar Cell

11 Arc Sensor (x 4)

12 UV/IR Filter

Tighten

Loosen

Tighten

Loosen

Press Adjustment 1- 6

Press

Angle Adjust

1 2 3 4 5 6 7 8 129 10 11

7

HELMET CONTROLS

Shade Control

Select the shade DIN 9 to 13 based upon the welding process you will use by consulting the

“Shade Guide Table” below. The variable shade control knob is for external adjustment.

The welding helmet can also be used to protect the face when cutting, from shade DIN 5 to 8.

Grind mode DIN 4 prevents lter lens from auto-darkening for grinding use.

Sensitivity Control

Five grades 1, 2, 3, 4, 5 available, from low to high, by button “SENSITIVITY.”

According to welding art and ambient light, it can be set through button “SENSITIVITY”.

Selecting “1” is suitable for weld with heavy current, in the bright light or the surrounding where

light is interfered

Selecting “5” is suitable for welding with low current and in a darker place, especially in low

current argon arc welding.

Delay Time Control

Five grades 1, 2, 3, 4, 5 available, from fast to slow (0.2-1.0S), by button “DELAY”

Delay time refers to the time cost by lter changing from dark to bright state. According to weld-

ing current and power of light, it can be quicker or slower by adjusting button “delay”.

Selecting “1”, delay time will be set at 0.20s, which is suitable to spot welding or short weld.

Selecting “5”, delay time will be set at 1.0s, which is suitable to heavy current welding or when

light is produced

MODE Control

Three modes available with button “MODE” for Grinding - Welding- cutting

Selecting mode “Grind”, the ADF will be suitable for Grinding use

Selecting mode “Weld”, the ADF will be suitable for Welding use, for shade No. is from 9 to 13

Selecting mode “Cut ”, the ADF will be suitable for Cutting use ,for shade No. is from 5 to 8

Cleaning and Storing

Keep the sensors, solar cell and lter lens clean. Clean lter cartridge and helmet shell by using a

soapy water solution and soft cloth. Do not use solvents or abrasive cleaning detergent. Switch

the product to Grind Mode and put it in a clean, dry location for storage.

8

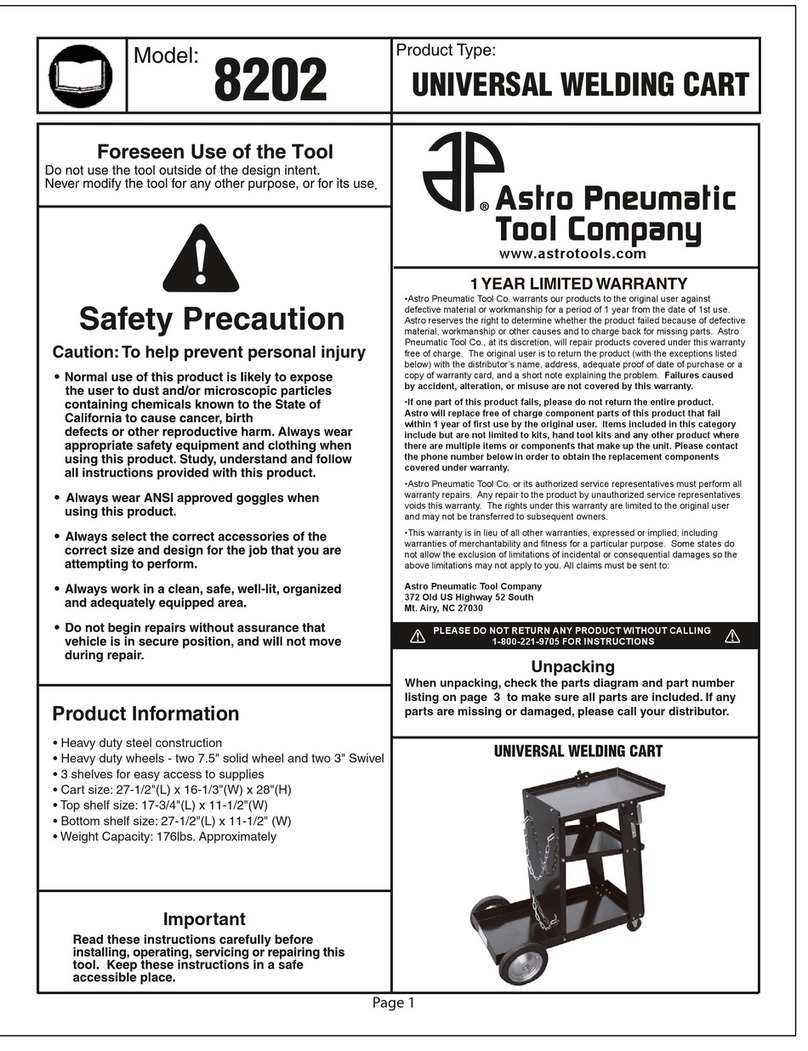

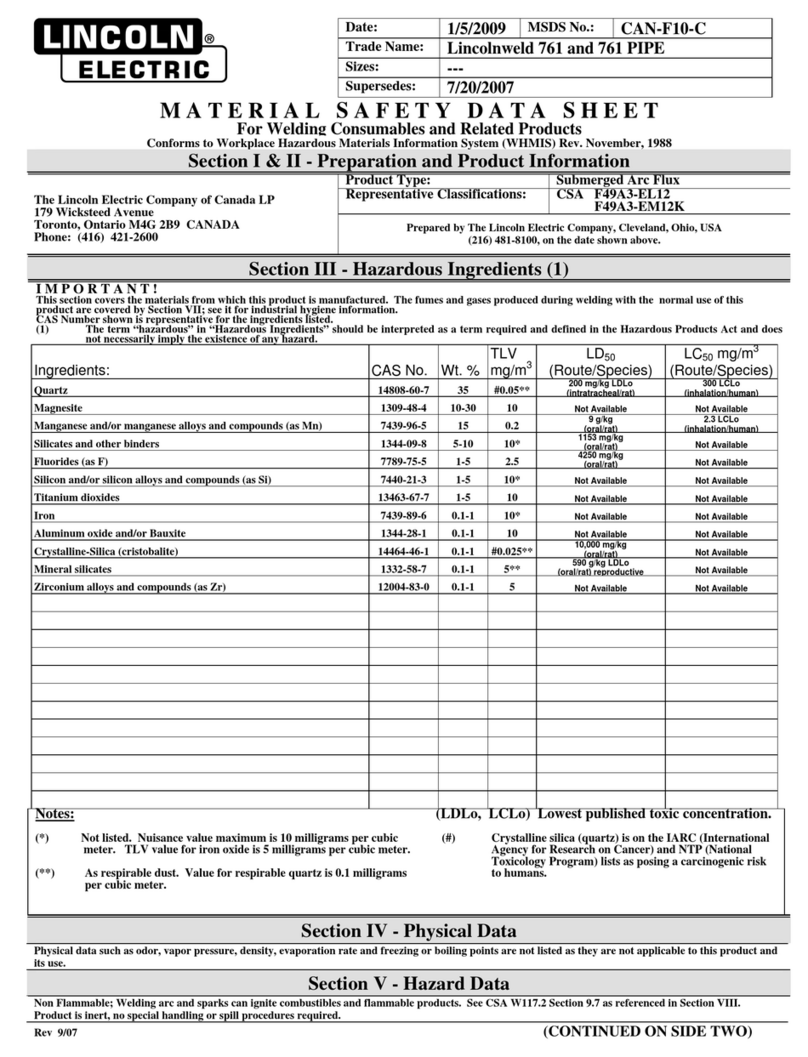

Front Cover Lens Replacement

Replace the front cover lens if it is damaged (cracked, scratched, pitted or dirty).

• Release and remove the headgear rst for easy access to locking pins

• Remove the old front cover lens by pressing two lock switches in the inside of the helmet and slide out.

• Remove the plug front the outside of the helmet,Take the old front cover lens out, and installing the

new one.

Inside Cover Lens Replacement

Replace the inside cover lens if it is damaged (cracked, scratched, pitted or dirty). Place your

nger or thumb into the recess and ex the inside cover lens upwards until it releases from one

edge. Then remove any protective lm before installing the new one.

Batteries Replacement

When low voltage indicator (inside the helmet, on the left) turns red,

you have to change battery.

• Release the lens holder by pressing the locking button on the bottom of

the lens inside the helmet, and remove the holder and lens.

• Release the lens by pressing on the lock, Slide the lens upward out of the holder.

• Slide battery cover open and replace the old battery by one new CR 2450.

MAINTENANCE

Press

Press

Slide

Remove plug

Press Slide Lens upward out of

holder

Press

Slide Battery holder

out of lens and replace

9

TROUBLE SHOOTING

FX-PRO PARTS LIST

Part No: Description Part Number

1

Bossweld FX-PRO Lens Replacement Kit

Includes: Outer Protective Place

Shade 5 Side Screen Lenses

Side Plates Fixing Plug & Socket Kit

Inner Lens Cover

700580

2Bossweld FX-PRO Headgear 700585

PROBLEM(S) POSSIBLE CAUSE(S) SUGGESTED SOLUTION(S)

Difcult to see through lter Cover lens dirty Clean or replace cover lens

Filter lens dirty Clean lter lens

Filter does not darken when arc

is struck Grind Mode Selected Adjust Shade from 5-8/9 -13

Sensors or Solar Panel blocked Make sure sensors or solar panel are

exposed to weld arc without blocking

Set Sensitivity to LOW Adjust Sensitivity to required level

Low voltage of lithium batteries Replace with new lithium batteries if

indicator turns red

Filter darkens without arc Set Sensitivity to HIGH Adjust Sensitivity to required level

Filter remains dark after welding Set Delay to MAX Adjust Delay to required level

1

1

2

10

Bossweld 16inch Welding Gloves

Bossweld 16 inch welding gloves available in Black

and Gold cow split leather.

CODE DESCRIPTION

700010 Bossweld 16”” Black & Gold Welding Glove

Bossweld Goat Skin Tig Glove

White goat skin TIG glove, reinforced tipping on back of 2nd

and 3rd ngers, black cow split cuff, Kevlar stitching, unlined.

Features

Reinforced tipping on the back of the 2nd and 3rd ngers

Black cow split cuff

Kevlar stitching

Goat skin gloves

Soft feel

Bossweld Leather Welders Jacket

Leather welding jacket with metal snaps.

Unlined, the jacket has heavy duty sewing.

Features

Heavy duty chrome leather

Double studs for extra protection

Several sizes available

Heavy duty sewing

Bossweld Leather Welding Blanket

Chrome leather welding blanket. Ideally suited to covering items

to protect against weld spatter. Commonly used in panel industry.

Features

Heavy duty chrome leather blanket

Excellent heat resistance

Several sizes available

For the protection around welding zones

CODE DESCRIPTION

700015M Bossweld “GoaTig” Tig Welding Glove - Medium

CODE DESCRIPTION

700001M Bossweld Leather Welder’s Jacket (Medium)

700001L Bossweld Leather Welder’s Jacket (Large)

700001XL Bossweld Leather Welder’s Jacket (X Large)

700001XXL BossSafe Leather Welder’s Jacket (XX Large)

700001XXXL BossSafe Leather Welder’s Jacket (XXX Large)

CODE DESCRIPTION

700120 1.0m x 2.0m Leather Welding Blanket

700123 1.8m x 1.8m Leather Welding Blanket

700121 2.0m x 2.0m Leather Welding Blanket

700122 3.0m x 3.0m Leather Welding Blanket

CONSUMABLE OPTIONS

11

Bossweld Spring Handle Chipping Hammer

Used for slag removal, and cleaning up weld beads post weld,

Spring handle for increased comfort.

Features

• Robust Spring Handle

• Hardened point and chisel for long life

• Trade quality

• 500 Gram head

Bossweld Wire Brush

Wooden handled wire brushes used for cleaning & preparation

of metals pre & post welding.

CODE DESCRIPTION

500088 Bossweld Spring Handle Chipping Hammer

CODE DESCRIPTION

500080 Bossweld 4 Row Engineer Wire Brush Wood Handle

Bossweld Chrome Leather Apron

Chrome leather full apron. Two piece style with heavy duty

sewing. 60cm x 90cm.

Features

• Heavy duty chrome leather

• Leather neck and waist adjustable strap

• Heavy duty sewing for reliability

• Excellent protection (60cm x 90cm)

CODE DESCRIPTION

700002 Bossweld Chrome Leather Full Apron 60 x 90cm

OTHER PRODUCTS IN OUR RANGE

• ELECTRODES

• TIG RODS

• WELDING HELMETS

• WELDING MACHINES

• TORCH SPARE PARTS

• WELDING ACCESSORIES

• MIG WIRE

• GAS EQUIPMENT

• WELDING SAFETY

• MIG TORCHES

• TIG TORCHES

• WELDING CABLE

Table of contents