clean cloth. If the valve stem is bent, or the seating

surface is nicked or marred, replace it with a new

assembly (09M24).

3. The sealing 'O'-ring located in the front end of the

handle, behind the attaching nut, may require re-

newal periodically. Remove it by catching it with a

scriber, orastiffwire hook, and pull it out. Squeeze

a new ring (P/N 85W64) into the head, and then

pushitevenlyintothe recess behind the locking nut

with a blunt instrument.

4. Each torch tip is equipped with a filter-screw, which

holds a mixer disk in place. If flow of gas through

the tip appears to be restricted, remove the filter-

screw with a 1/8-in. socket key ('Allen wrench') and

replace both filter-screw and mixer disk.

PRECAUTIONS & SAFE PRACTICES

A. DO NOT let acetylene or LP-Gas escape near

any possible source of ignition. Accumulations

of either in certain proportions may explode if

ignited.

B. NEVER store acetylene or LP-Gas tanks (cylin-

ders) in a closed or confined space, such as a

closet, tool box, or automobile trunk.

C. NEVER solder a container that contains or has

contained flammable liquids or vapors (includ-

ing gasoline, benzene, solvents, and other simi-

larmaterials) unlessthe container has been thor-

oughly purged of all traces of flammable mate-

rial and vapors.

D. Before starting work always test for leaks

around all joints with a soapy water solution.

E. NEVERuse a flameto test forleaks of flammable

gases.

F. NEVER use a tank with a leaking valve.

G. DO NOT attempt any repairs to an acetylene or

LPGastank,except totighten the packing-gland

nut on the valve.

H. NO NOT abuse or drop tanks or handle them

roughly.

I. NEVER use a tank as a roller or support.

J. NEVER use a hammer, wrench, or pliers on a

tank valve equippedwith a handwheel. Onsmall

acetylene tanks, always use PREST-O-LITE

valve wrench (box type, P/N 505L00).

K. DO NOT open tank valve more than 1-1/2 turns.

(Preferably no more than 3/4 of a turn.)

L. Leave valve wrench on tank valve stem so that

tank valve can be closed quickly in caseof emer-

gency.

M. NEVER allow full tank pressure to enter the

hose. Always use a regulator when there is a

needle valve on the torch handle.

N. NEVER lay a torch down unless the gas flow

has been shut off. If you want to maintain a

pilot flame when you stop work for short inter-

vals, provide a rack or stand for the torch, away

from combustible materials. Do not leave it

unattended unless you are sure there is no dan-

ger of it being disturbed by unauthorized per-

sons.

O. Examine your hose for leaks frequently. Dip-

ping it in a bucket of clean water, with the pres-

surein the hose,is the quickest andeasiest way.

P. DO NOT use hose that is worn, or any equip-

ment that is in need of repairs.

Q. Do NOT start fires. Be very careful when work-

ing near combustible material.

R. Fuel gas tanks (cylinders) are equipped with

fusible-metal safetydevices. NEVER store tanks

near radiators, furnaces, or other heat sources.

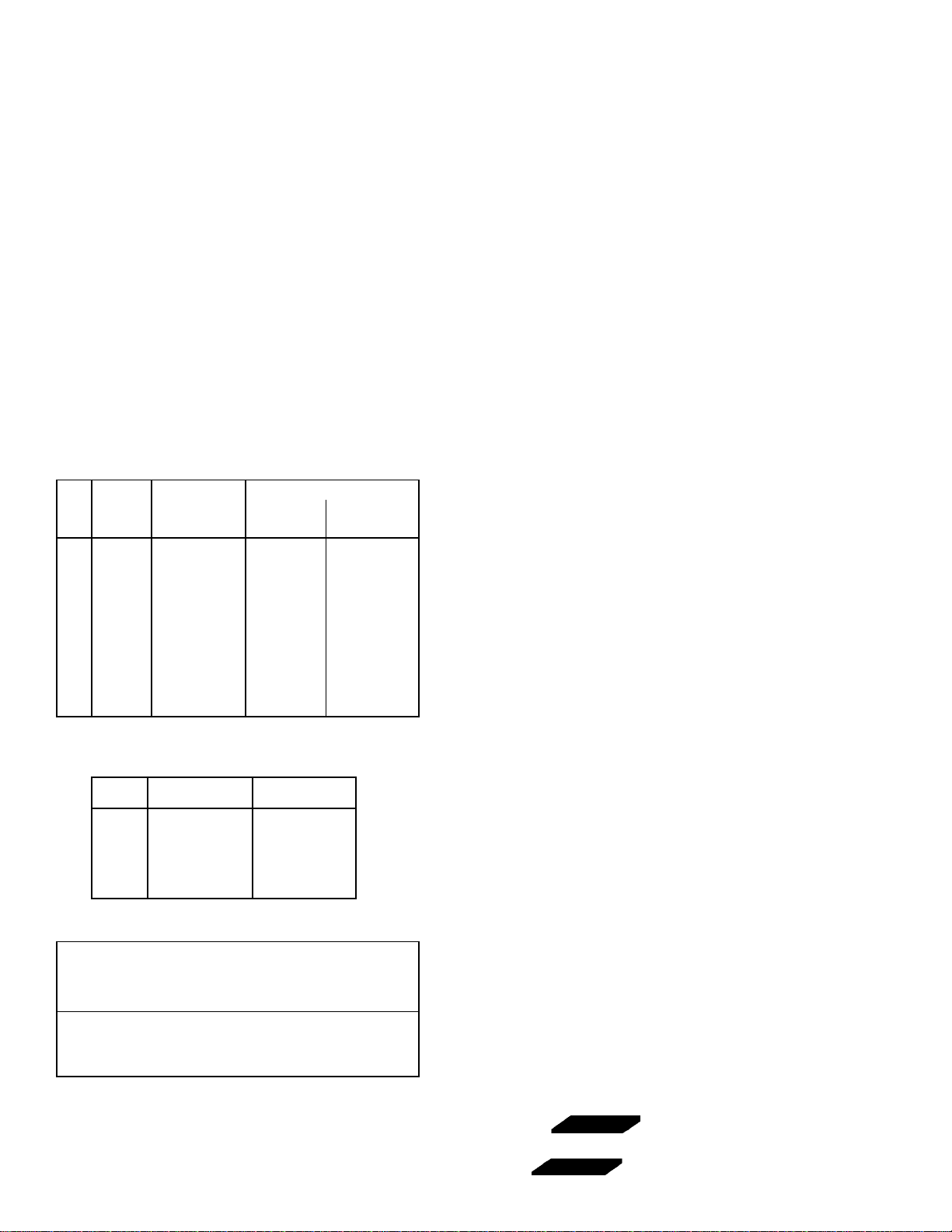

Standard Torch Tips

Replaceable Parts

Tip Mixer Disk Filter Screw

No. Part No. Type Part No. Part No.

1-A 638948 Fine 638783 998311

3 10X23 Light 150Z44 998311

4 10X24 Medium 150Z45 998311

5 10X25 Heavy 150Z46 998311

6 10X26 Extra-Heavy --- •

8 11X18 Soldering Iron 150Z20 998311

(pointed)

8-C 11X17 Soldering Iron 150Z20 998311

(chisel)

9 10X29 Paint Burner 150Z45 998311

'SWIRLJET' Tip Part Numbers

Air-Acetylene Air-Fuel Gas

No. 3 21471 21474

No. 4 21472 21475

No. 5 21473 21476

No. 6 __ 21477

Other Replacement Parts

Soldering Iron Parts: Stem Ass'y................60Y63

Chisel Tip...... 23S20 Flame Shield ............60Y55

Pointed Tip ... 23S32 Locknut ..................136Z17

403 Handle Parts:

Valve Stem Assembly .........................Part No. 09M24

"O" Ring (front end) ........................... Part No. 85W64

•Uses filter screen 82Z52

ESAB

ESAB Welding & Cutting Products

PO Box 100545, Florence SC 29501-0545

F-9295-W 11/96 25M Printed in U.S.A.

Prest-O-Lite and Swirljet are registered trademarks of ESAB Welding & Cutting Products