Boxboro RibEye 600001 Instructions for use

October 2017

1

© 2017 Boxboro Systems LLC

HARDWARE USER MANUAL

RibEye™ Multi-Point Deflection Measurement System:

-Axis Version for the WorldSID 50

th

Male ATD

Boxboro Systems LLC

978-257-2219

www.boxborosystems.com

October 2017

2

© 2017 Boxboro Systems LLC

Table of Contents

Page

1.0 WorldSID RibEye Description ......................................................................................... 5

2.0 RibEye Installation ............................................................................................................ 9

2.1 LED installation ........................................................................................................ 9

2.1.1 LED assemblies ............................................................................................ 10

2.1.2 Mo nting rearward LEDs on the ribs ........................................................... 16

2.1.3 Mo nting center and forward LEDs on the ribs ........................................... 19

2.2 Installing the sensors on the spine ............................................................................ 19

2.3 Order of assembly (LEDs, ribs, and sensors) ........................................................... 23

2.4 Sensor cables ............................................................................................................ 24

2.5 Controller installation .............................................................................................. 25

2.5.1 Mo nting the adaptor plates ......................................................................... 25

2.5.2 Removing the controller end covers ............................................................. 27

2.5.3 Attaching the controller ................................................................................ 28

2.6 Cable ro ting ............................................................................................................ 30

2.6.1 Stat s cable ................................................................................................... 30

2.6.2 D mmy exit cable ........................................................................................ 30

2.6.3 LED cables ................................................................................................... 38

3.0 RibEye Operation ............................................................................................................. 40

3.1 Data coordinate systems ........................................................................................... 40

3.2 Stat s indicator ......................................................................................................... 41

3.3 Ethernet link and activity lights ............................................................................... 41

3.4 Batteries and charger ................................................................................................ 41

3.5 Error codes ............................................................................................................... 43

4.0 RibEye aintenance ........................................................................................................ 45

4.1 D mmy maintenance for RibEye ............................................................................. 45

Appendixes

A. RibEye Specifications and Cable Details ............................................................................ 46

A-1. Meas rement acc racy and range ............................................................................ 46

A-2. Power req irements .................................................................................................. 50

A-3. Data acq isition and storage .................................................................................... 50

A-4. Ethernet comm nication .......................................................................................... 50

A-5. Trigger circ its ......................................................................................................... 51

A-6. Armed-o t circ it ..................................................................................................... 51

A-7. RibEye cable details ................................................................................................. 57

B. Switching RibEye WorldSID from Left-Side to Right-Side Impact ................................... 67

October 2017

3

© 2017 Boxboro Systems LLC

List of Figures

Fig re No. Page

1 RibEye sensors mo nted in the d mmy ..................................................................... 5

2 RibEye LEDs mo nted in the d mmy........................................................................ 6

3 RibEye controller with connector covers in place ...................................................... 7

4 RibEye controller with connector covers removed .................................................... 7

5 Controller sensor connectors ...................................................................................... 8

6 Controller connectors for LED cables, stat s cable, and d mmy exit cable .............. 8

7 LED and angled mo nting block ............................................................................... 10

8 LED snapped into angled mo nting block ................................................................ 10

9 Sho lder center LED adaptor plate, inner rib clamp, and foam stopper plate ........... 11

10 Sho lder center LED assembly photo ....................................................................... 12

11 Inner rib clamp plate for thoracic and abdominal ribs............................................... 13

12 Thoracic 1 and abdominal 1 inner rib clamp plate .................................................... 14

13 Thoracic 2, thoracic 3, and abdominal 2 inner rib clamp plate ................................. 14

14 Rearward and forward LED locations ....................................................................... 15

15 Rearward LED placed on do ble-stick tape .............................................................. 16

16 Heat-shrink t bing placed over rearward LED ......................................................... 17

17 Cable ro ting for rearward and center LEDs ............................................................ 18

18 M5 x 10 flat-head cap screw with precision-machined sho lder .............................. 19

19 Sensor base with label ............................................................................................... 20

20 RibEye sensor bases mo nted to spine ...................................................................... 21

21 RibEye sensor front piece .......................................................................................... 22

22 RibEye sensor label on back and alignment pins ...................................................... 22

23 RibEye sensor assemblies mo nted to spine ............................................................. 23

24 Sensor cables ro ted to back of d mmy .................................................................... 24

25 Sensor cables tied to o ter ribs near spine plate ........................................................ 24

26 Sensor cables ro ted over the top sensor and below the neck assembly ................... 25

27 Controller adaptor installed on thoracic 1 rib ............................................................ 26

28 Controller adaptor installed on abdominal 2 rib ........................................................ 26

29 Controller end cover attachment screws .................................................................... 27

30 Controller (sensor connector end) attached to adaptor at thoracic 1 rib .................... 28

31 Controller (cable connector end) attached to adaptor at abdominal 2 rib .................. 29

32 Exit cable connector in RibEye controller ................................................................. 30

33 Cable option for DTS DAS ....................................................................................... 32

34 Cable option for Kistler NXT32 DAS ....................................................................... 33

35 Cable option for generic DAS (separate exit and breako t cables) ........................... 34

36 Cable option for generic DAS (single exit/breako t cable) ...................................... 35

37 Cable option for Kyowa DAS ................................................................................... 36

38 Cable option for Kistler KiH b/KiDa DAS ............................................................ 37

39 Sensor cables tied to controller.................................................................................. 39

October 2017

4

© 2017 Boxboro Systems LLC

List of Figures, continued

Fig re No. Page

40 RibEye coordinate system ......................................................................................... 40

41 Battery pack ............................................................................................................... 41

42 RibEye battery pack Cell-Con charger and exit cable charger receptacle ................. 42

43 Plot overlay verifying whether LED moved o t of range ......................................... 44

A1 RibEye meas rement range in X-Y plane – all ribs .................................................. 47

A2 RibEye meas rement range in Y-Z plane – pper three ribs .................................... 48

A3 RibEye meas rement range in Y-Z plane – lower three ribs .................................... 49

A4 Generic trigger inp t circ it ...................................................................................... 52

A5 Trigger inp t config red for DTS MDB-s pplied trigger ......................................... 53

A6 Trigger inp t config red for Kistler NXT32-s pplied trigger .................................. 54

A7 Spare inp t and o tp t circ its .................................................................................. 55

A8 Trigger switch wiring example for generic pigtail cable assemblies ........................ 55

A9 Armed-o t circ it for generic pigtail cable assemblies ............................................. 56

A10 Example of armed-o t indicator light wiring for generic pigtail cable assemblies ... 56

B1 RibEye sensor positions and cable ro ting for right-side impact .............................. 67

List of Tables

Table No. Page

1 S mmary of LED positions and mo nting methods .................................................. 9

2 Sensor base part n mbers and angles ........................................................................ 20

3 Wire colors for breako t cable 70201 and exit/breako t cable 70026 ...................... 38

4 Cell-Con battery charger modes ................................................................................ 42

A1 DTS DAS exit cable 70011 ....................................................................................... 57

A2 Kistler NXT32 DAS exit cable 70020 ....................................................................... 58

A3 Generic DAS exit cable 70025 .................................................................................. 59

A4 Generic DAS breako t cable 70201 .......................................................................... 60

A5 Generic DAS exit/breako t cable 70026 ................................................................... 61

A6 Kyowa DAS exit cable 70027 ................................................................................... 62

A7 KiH b/KiDa exit cable 70028 ................................................................................. 63

A8 LED cables 70001-70006 .......................................................................................... 64

A9 Sensor cables 70001-70006 ....................................................................................... 65

A10 Stat s LED cable ....................................................................................................... 66

October 2017

5

© 2017 Boxboro Systems LLC

HARDWARE USER MANUAL

RibEye™ Multi-Point Deflection Measurement System:

-Axis Version for the WorldSID 50th Male ATD

1.0 WorldSID RibEye Description

The RibEye for the WorldSID anthropomorphic test device (ATD) provides X, Y, and Z position data for

18 light-emitting diodes (LEDs) mo nted on the WorldSID ribs. Three LEDs are mo nted on each of the

six ribs. The RibEye for the WorldSID can be mo nted on either side of the d mmy to meas re left-side

or right-side impacts. Appendix A provides the RibEye meas rement range and other specifications,

incl ding details on the cables and connector pino ts. Appendix B explains how to switch the WorldSID

RibEye from left-side to right-side-impact.

Up to 25 seconds of data can be collected at a 10-kHz sample rate. Two types of non-volatile flash

memory are installed in the controller: a Micro-SD card stores all 25 seconds of data from a test, and

onboard flash memory stores 1.7 seconds of data (from –200 ms to 1500 ms) that is retained after power

is t rned off. If external power is lost, the RibEye will operate on internal batteries. Comm nication to

the RibEye is via Ethernet.

Two sets of three sensors monitor the LED positions, as shown in Fig re 1. The top set of sensors ses

red optical filters and monitors the red LEDs mo nted on the first three ribs: the sho lder rib, the thoracic

1 rib, and the thoracic 2 rib. The bottom set of sensors ses bl e optical filters and monitors the bl e

LEDs mo nted on the lower three ribs: the thoracic 3 rib, the abdominal 1 rib, and the abdominal 2 rib.

Figure 1. RibEye sensors mounted in the dummy

(view from pelvis upward)

October 2017

6

© 2017 Boxboro Systems LLC

Three RibEye LEDs are mo nted on each rib. Fig re 2 shows the RibEye LEDs installed in the

WorldSID d mmy. The center LEDs are lined p along the d mmy’s left or right side. The forward

LEDs are closer to the front of the d mmy and the rearward LEDs closer to the d mmy’s back.

Figure 2. RibEye LEDs mounted in the dummy

(view from pelvis upward)

The RibEye controller mo nts on the non-str ck side of the d mmy. The controller enclos re also

contains the RibEye’s battery pack. Fig res 3–6 show the following views of the controller:

• Fig re 3 shows the controller as shipped, with connector covers installed at each end.

• Fig re 4 shows the controller with the two end covers removed.

• Fig re 5 shows the connectors for the sensors at one end of the controller.

• Fig re 6 shows the connectors for the LED cables, stat s cable, and d mmy exit cable at the

other end of the controller.

October 2017

7

© 2017 Boxboro Systems LLC

Figure . RibEye controller with connector end covers in place

Figure 4. RibEye controller with connector covers removed

October 2017

8

© 2017 Boxboro Systems LLC

Figure 5. Controller sensor connectors

Figure 6. Controller connectors for LED cables,

status cable, and dummy exit cable

October 2017

9

© 2017 Boxboro Systems LLC

2.0 RibEye Installation

This section explains how to mo nt the RibEye components into the WorldSID 50

th

Male ATD. The

instr ctions cover the installation of the LEDs, sensors, and controller, as well as the cable ro ting. Some

components are mo nted before the ribs are assembled in the d mmy, and others d ring or after rib

assembly. See section 2.3 below for the specific order of assembly.

2.1 LED installation

Table 1 s mmarizes the LED positions and mo nting methods for all 18 LEDs. The following sections

describe in detail how to mo nt the LED assemblies onto the ribs. The forward LEDs are closer to the

front of the d mmy and the rearward LEDs closer to the d mmy’s back. Please refer back to Fig re 2 for

a vis al showing three LEDs mo nted onto each of the six ribs.

Table 1. Summary of LED positions and mounting methods

Rib

number/type

Rearward LEDs Center LEDs Forward LEDs

Rib #1

(shoulder)

Position Bottom edge of rib

Mounting

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

LED ssembly lre dy

glued to LED d ptor pl te;

Screw LED d ptor pl te to

cl mp pl te

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

Rib #2

(thor cic 1)

Position Center of rib, mounted fl t

Mounting

T pe nd he t-shrink

in pl ce

LED ssembly lre dy

glued to cl mp pl te

T pe nd he t-shrink

in pl ce

Rib #3

(thor cic 2)

Position Top edge of rib

Mounting

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

LED ssembly lre dy

glued to ngled block;

Screw ngled block into

cl mp pl te

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

Rib #4

(thor cic 3)

Position Bottom edge of rib

Mounting

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

LED ssembly lre dy

glued to ngled block;

Screw ngled block into

cl mp pl te

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

Rib #5

( bdomin l 1)

Position Center of rib, mounted fl t

Mounting

T pe nd he t-shrink

in pl ce

LED ssembly lre dy

glued to cl mp pl te

T pe nd he t-shrink

in pl ce

Rib #6

( bdomin l 2)

Position Top edge of rib

Mounting

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

LED ssembly lre dy

glued to ngled block;

Screw ngled block into

cl mp pl te

Sn p LED ssembly

to ngled block;

T pe nd he t-shrink

in pl ce

October 2017

10

© 2017 Boxboro Systems LLC

2.1.1 LED assemblies

Fig re 7 shows a LED assembly, with its lead cable attached, and an angled mo nting block. The LED is

soldered onto a metal-clad printed circ it board (MCPCB). Fig re 8 shows the LED assembly snapped

into the angled mo nting block. If the LED does not snap tightly into the angle block, it can be held in

place with s per-gl e (cyanoacrylate) or epoxy.

Figure 7. LED and angled mounting block

Figure 8. LED snapped into angled mounting block

The angled mo nting blocks are sed on fo r of the d mmy’s six ribs – the sho lder, thoracic 2,

thoracic 3, and abdominal 2 ribs. On the sho lder and thoracic 3 ribs, the LEDs are mo nted on the

bottom edge of the ribs. On the thoracic 2 and abdominal 2 ribs, the LEDs are mo nted on the top edge

of the ribs.

On the d mmy’s other two ribs – the thoracic 1 and abdominal 1 – all three LEDs are mo nted flat,

witho t a block. This becomes more clear if yo refer back to Fig re 2, which shows three LEDs mo nted

on each rib.

October 2017

11

© 2017 Boxboro Systems LLC

The center LED on the sho lder rib is epoxied on to a LED adaptor plate. The adaptor plate is attached to

the sho lder inner rib clamp sing two 2-56 x 1/4 b tton-head cap screws (BHCS). An optional foam

stopper plate intended to prevent the sho lder foam from dropping in front of the LED can be attached to

the top of the sho lder inner rib clamp with two 4-40 x 5/16 cross-head screws.

The sho lder center LED assembly, adaptor plate, inner rib clamp, and foam stopper plate are shown in

Fig re 9. Also shown in Fig re 9 are two plastic wire clamps that are bolted to the inner rib clamp plate

with 2-56 x 1/4 BHCS. There are two sizes of plastic wire clamps. The smaller wire clamp (0.093-inch

diameter) is sized for a single LED cable and is mo nted on the left side of the inner rib clamp for the

cable that goes to the rear LED. The larger wire clamp (0.125-inch diameter) holds two LED cables and

is mo nted on the right side of the rib clamp for the two cables that come from the controller, past the

front LED.

The cable clamps are from Micro Plastics Inc.:

• 22CC16A0093-B for the 0.093-inch-diameter clamp

• 22CC16A0125-B for the 0.125- inch-diameter clamp.

Figure 9. Shoulder center LED adaptor plate,

inner rib clamp, and foam stopper plate

Shoulder inner

rib clamp plate

LED adaptor plate

Foam stopper plate

October 2017

12

© 2017 Boxboro Systems LLC

Fig re 10 shows a photo of a sho lder center LED assembly on the sho lder rib clamp. In the pict re,

stainless-steel screws and nat ral nylon wire clamps are shown for clarity. However, black screws and

black wire clamps are shipped with the RibEye. These sho ld be sed to prevent reflections.

Figure 10. Shoulder center LED assembly photo

October 2017

13

© 2017 Boxboro Systems LLC

The center LEDs on the thoracic and abdominal ribs are mo nted to inner rib clamp plates. A CAD

drawing of an inner rib clamp plate is shown in Fig re 11:

• Hole A is for installing the angled blocks, which are screwed to the clamp plates sing a 1/4-inch

long, 2-56 b tton-head screw that engages in a captive 2-56 n t inside the angled blocks.

• Recess B is for gl ing flat LED assemblies to the clamp plate. The clamp plates for the thoracic 1

and abdominal 1 ribs are shipped with the LED assemblies already gl ed into recess B.

• The two C holes are for mo nting the nylon wire clamps sing 2-56 x 1/4 BHCS screws.

• The two D holes are for mo nting a 7264-type accelerometer on any rib. We recommend that the

accelerometers be removed when sing the RibEye, as they can ca se reflections or block the

LED light to the sensors. If accelerometers m st be sed, they sho ld be painted with flat black

paint or covered with flat black tape to prevent reflections.

Figure 11. Inner rib clamp plate for thoracic and abdominal ribs

As noted earlier, the forward LEDs are closer to the front of the d mmy and the rearward LEDs closer to

the d mmy’s back. These rearward and forward LEDs on all ribs are held in place with high-strength

do ble-sided foam tape and heat-shrink t bing. The foam tape is 3M #4952 (1/2-inch wide, VHB acrylic

tape). The heat-shrink t bing is 1-1/4 inches in diameter. The heat-shrink t bing s pplied with the

RibEye is made by Q altek, 2:1 shrink ratio, 1-1/4 inches in diameter, part n mber Q2-Z-1 1/4-01-

MS50FT.

A

B

C

C

D

October 2017

14

© 2017 Boxboro Systems LLC

Fig res 12 and 13 show the inner rib clamp plates with the LEDs and wire clamps installed for

1) the thoracic 1 and abdominal 1 ribs and 2) the thoracic 2, thoracic 3, and abdominal 2 ribs. In both of

these photos, stainless-steel screws and nat ral color nylon cable clamps are shown for clarity, b t the

RibEye ships with black screws and black wire clamps, which sho ld be sed to prevent reflections.

Figure 12. Thoracic 1 and abdominal 1 inner rib clamp plate

with LEDs and wire clamps installed

Figure 1 . Thoracic 2, thoracic , and abdominal 2 inner rib clamp plate

with LEDs and wire clamps installed

October 2017

15

© 2017 Boxboro Systems LLC

The LED cables are r n from the bottom of the controller on the non-str ck side, p along the front of the

spine plates, and then across to the front of the inner ribs. The front, center, and rear LED cables are

attached to the inner rib, r nning from the front to the rear.

The rearward and forward LEDs are typically mo nted 35 mm from the center of the rib as shown in

Fig re 14. The 35-mm dimension is the straight-line distance to the edge of the angled block or LED

metal-clad circ it board.

Figure 14. Rearward and forward LED locations

As noted earlier, the LEDs m st be mo nted to the ribs before the ribs are installed in the d mmy. The

18 LED cables are marked with the rib n mber (1–6) and one of three LED positions as follows:

Rib #1 (sho lder) F (Forward)

C (Center)

R (Rearward)

Rib #2 (thoracic 1) F C R

Rib #3 (thoracic 2) F C R

Rib #4 (thoracic 3) F C R

Rib #5 (abdominal 1)

F C R

Rib #6 (abdominal 2)

F C R

October 2017

16

© 2017 Boxboro Systems LLC

Th s, for example, the LED with the cable marked 4-R sho ld be mo nted on the thoracic 3 rib in the

rearward position.

On each rib, the rearward LEDs sho ld be mo nted first, then the center LEDs, and finally the forward

LEDs. Before mo nting the LEDs, remove grease and mold-release compo nd by wiping down the

mo nting area on the ribs and the back of the LEDs and mo nting blocks, sing isopropyl alcohol. When

installing the foam tape, sq eeze it onto the rib with at least 15 psi of force. When p tting the LED

assembly onto the foam tape, press it on with at least 15 psi of force; however, do not press on the soft

silicone face of the LEDs.

2.1.2 Mounting rearward LEDs on the ribs

The rearward LEDs sho ld be mo nted according to the following proced re:

Place a strip of do ble-stick tape on the rib at the rearward LED mo nting location. Add a second piece

of tape that will hold the LED cable in position. Place the LED on the first piece of tape and arrange the

cable on the second piece of tape so that the cable avoids the spot where the center LED will be mo nted

(see Fig re 15).

Figure 15. Rearward LED placed on double-stick tape

(with c ble rr nged to void center LED position)

October 2017

17

© 2017 Boxboro Systems LLC

Heat-shrink “sleeves” are provided with the RibEye (t bing that has been pre-c t and hole-p nched). To

make additional sleeves, c t a piece of heat-shrink t bing 1½ to 2 inches long and p nch a hole in the

t bing where the center of the LED will be (this can be done sing a standard paper hole p nch or similar

tool). Slide the t bing sleeve over the rib and LED as shown in Fig re 16. Center the hole directly over

the red or bl e sq are in the center of the LED.

NOTE: Do not use any glue-lined heat-shrink tubing because the glue can

bubble out of the LED hole and cover the LED, blocking its light.

Figure 16. Heat-shrink tubing placed over rearward LED

October 2017

18

© 2017 Boxboro Systems LLC

Caref lly begin shrinking the t bing sing a heat g n while holding the hole over the LED. The

heat-shrink t bing will shrink at temperat res of 70 to 100 degrees C.

Danger

: Some heat guns are very high temperature. Do not burn yourself.

Start heat-shrinking along the o tside of the rib. Then do the inner side of the rib, starting from the edges

of the heat-shrink t bing and working toward the center over the LED. When heat is applied to the hole

over the LED, the hole will expand, exposing the whole white rectang lar body of the LED. Yo might

need to stretch the ro nd hole with yo r finger so that it fits aro nd the rectang lar edge of the LED. Do

not to ch the soft silicone face of the LED with sharp objects. Fig re 17 (right-hand side) shows a

rearward LED after the t bing has been shr nk.

NOTE: It takes a little practice to master the techniq e of mo nting LEDs with heat-shrink t bing. Yo

can always c t off the t bing and try again.

Figure 17. Cable routing for rearward and center LEDs

October 2017

19

© 2017 Boxboro Systems LLC

2.1. Mounting center and forward LEDs on the ribs

The next step is to install the center LEDs and ro te the cables. As noted earlier, the center LEDs are

mo nted on the inner rib clamp plates, which either have the LED gl ed onto them or have the

LED/angled block screwed into them.

Temporarily install the inner rib clamp with LED assembly sing one of the M5 x 12 b tton-head cap

screws. Then place the do ble-stick tape for the forward LED and ro te the cables from the center and

rearward LEDs as shown in Fig re 17 above. Note how the LED cables are ro ted to avoid crossing in

front of any LEDs.

Place the forward LED in position on the do ble-stick tape and slide a piece of heat-shrink t bing over

the LED. The t bing sho ld also cover all three LED cables. Heat-shrink the t bing over the forward

LED in the same way described above for the rearward LED. When heat-shrinking is complete, the

t bing will hold the LED and the cables in place.

In addition, p t nylon zip-ties holding the cables from the forward LED position to where the rib is

attached. As an alternative to the zip-ties, yo can se short pieces of the heat-shrink t bing to sec re the

LED cables to the rib.

NOTE: It is important to secure all the cables so that they do not block the light from the

LEDs to the sensors during a test.

2.2 Installing the sensors on the spine

NOTE: For c stomers who will be connecting the RibEye exit cable to Kistler NXT32 DAS systems

mo nted between the spine plates, yo sho ld attach the RibEye exit cable to the NXT32 now. The

RibEye exit cable for the NXT32 system (cable n mber 70020) connects to the last NXT32 in the chain.

The last NXT32 is mo nted at the top of the d mmy’s thorax between the spine plates.

To access the connector on the NXT32 interface mod le, remove the neck adaptor from the top of

the thorax by removing the six M6 x 10 flat-head cap screws (three on each side) that hold the neck

bracket to the spine plates. Yo can then pl g in the Harwin connector end of the RibEye exit cable to the

mating receptacle on the last NXT32 interface mod le. Replace the neck bracket with the six M6 x 10

screws.

The RibEye’s sensor assemblies take the place of the existing rib-to-spine clamps. Each sensor assembly

has a front piece that contains the sensor and a base for mo nting to the spine. It is the sensor bases that

act as the rib clamps.

The sensor bases are installed to the spine’s existing rib-mo nting holes sing fo r special M5 x 10 flat-

head cap screws that have precision-machined sho lders. Fig re 18 shows the M5 x 10 sho lder screws.

The sho lder screws ens re that the sensor bases are properly aligned to the spine.

..

Figure 18. M5 x 10 flat-head cap screw with precision-machined shoulder

Shoulder

October 2017

20

© 2017 Boxboro Systems LLC

The sensor bases have different angles depending on their mo nting positions (Table 2).

Table 2. Sensor base part numbers and angles

Rib Sensor Base Part Number

Base Angle, degrees

Shoulder 10071-11 11

Thor cic 1 10071-0 0 (fl t)

Thor cic 2 10071-23 23

Thor cic 3 10071-20 20

Abdomin l 1 10071-0 0 (fl t)

Abdomin l 2 10071-20 20

The sensor bases have a sticker on the inside with the RibEye serial n mber (S/N), rib n mber, the rib

name, and the screw installation order, as shown in Fig re 19. To install the sensor bases, se fo r

sho lder screws. Install the first screw in the pper-left hole (position 1) and tighten the screw loosely –

“finger tight”, so the base can still rotate abo t the screw. Next, install the second screw in the lower-

right hole (position 2) and tighten the screw finger tight. Then p t in screws in positions 3 ( pper-right)

and 4 (lower-left). Finally, tighten the screws in the order 1-2-3-4.

Figure 19. Sensor base with label

Table of contents

Other Boxboro Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Precision Digital Corporation

Precision Digital Corporation PROVU Series instruction manual

PureAire

PureAire Air Check O2 KF-25 instruction manual

Tektronix

Tektronix RSA306 Technical reference

Endress+Hauser

Endress+Hauser Gammapilot FMG50 operating instructions

Chauvin Arnoux

Chauvin Arnoux AEMC JM810A user manual

SolaX Power

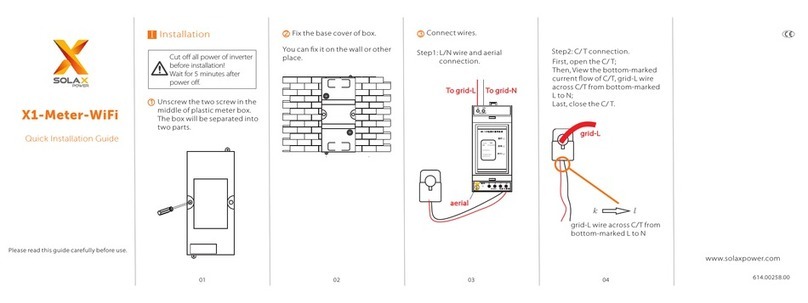

SolaX Power X1-Meter-WiFi Quick installation guide