(1/n)

LEN080334

CONTENTS

1. General Description............................................................................................................................... 2

2. Specification .......................................................................................................................................... 2

3. Configuration Conditions of CC-Link System ........................................................................................ 3

4. Parameter Settings................................................................................................................................ 4

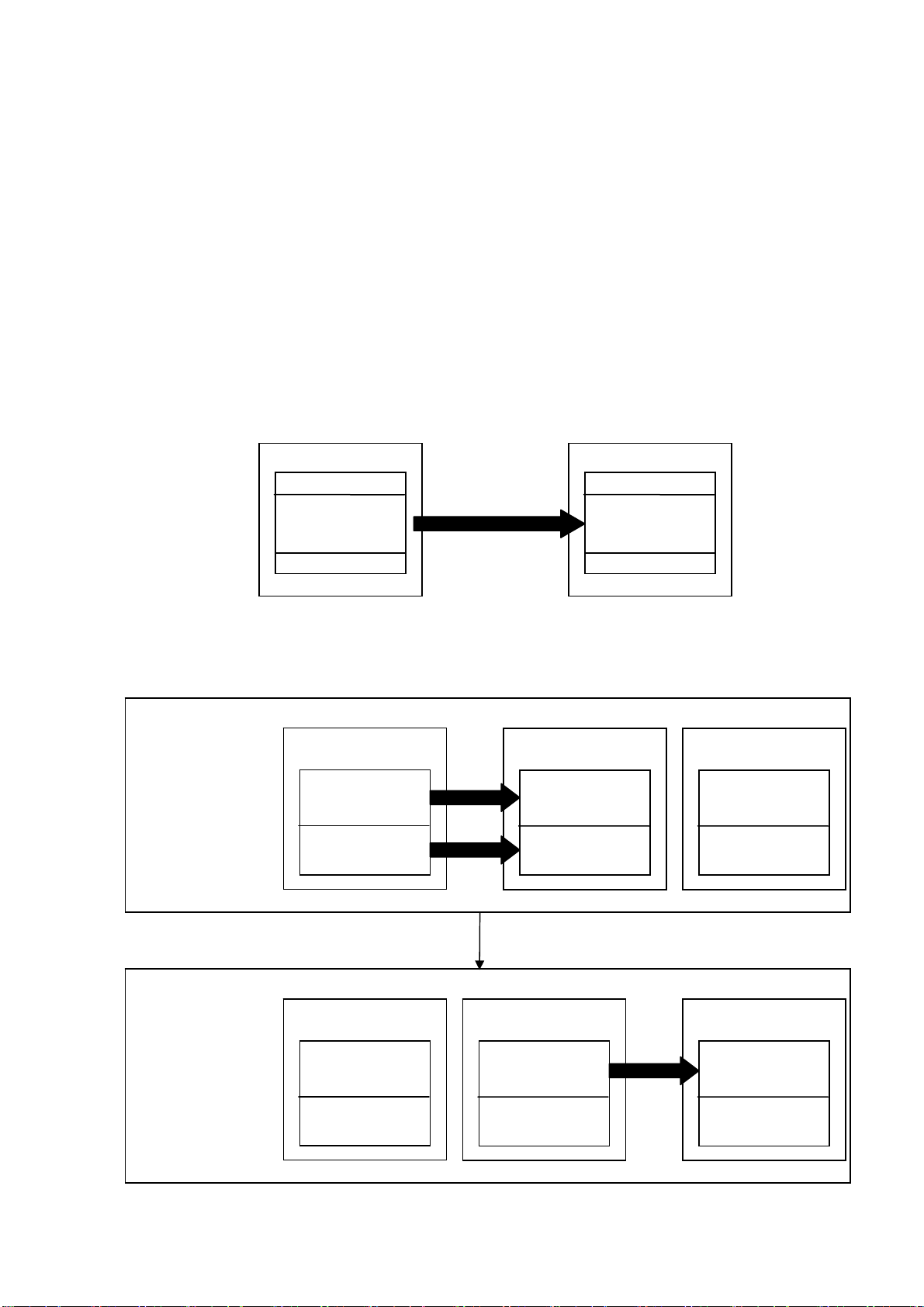

4.1 Procedure from Parameter Settings to Data Link Startup .............................................................. 4

4.1.1 CPU Parameter Area and Master Module Parameter Memory ............................................... 4

4.1.2 Procedure for Parameter Settings to Data Link Startup with GX Developer............................ 4

4.2 Parameter Setting Items ................................................................................................................ 5

4.3 Example of Parameter Settings with GX Developer....................................................................... 6

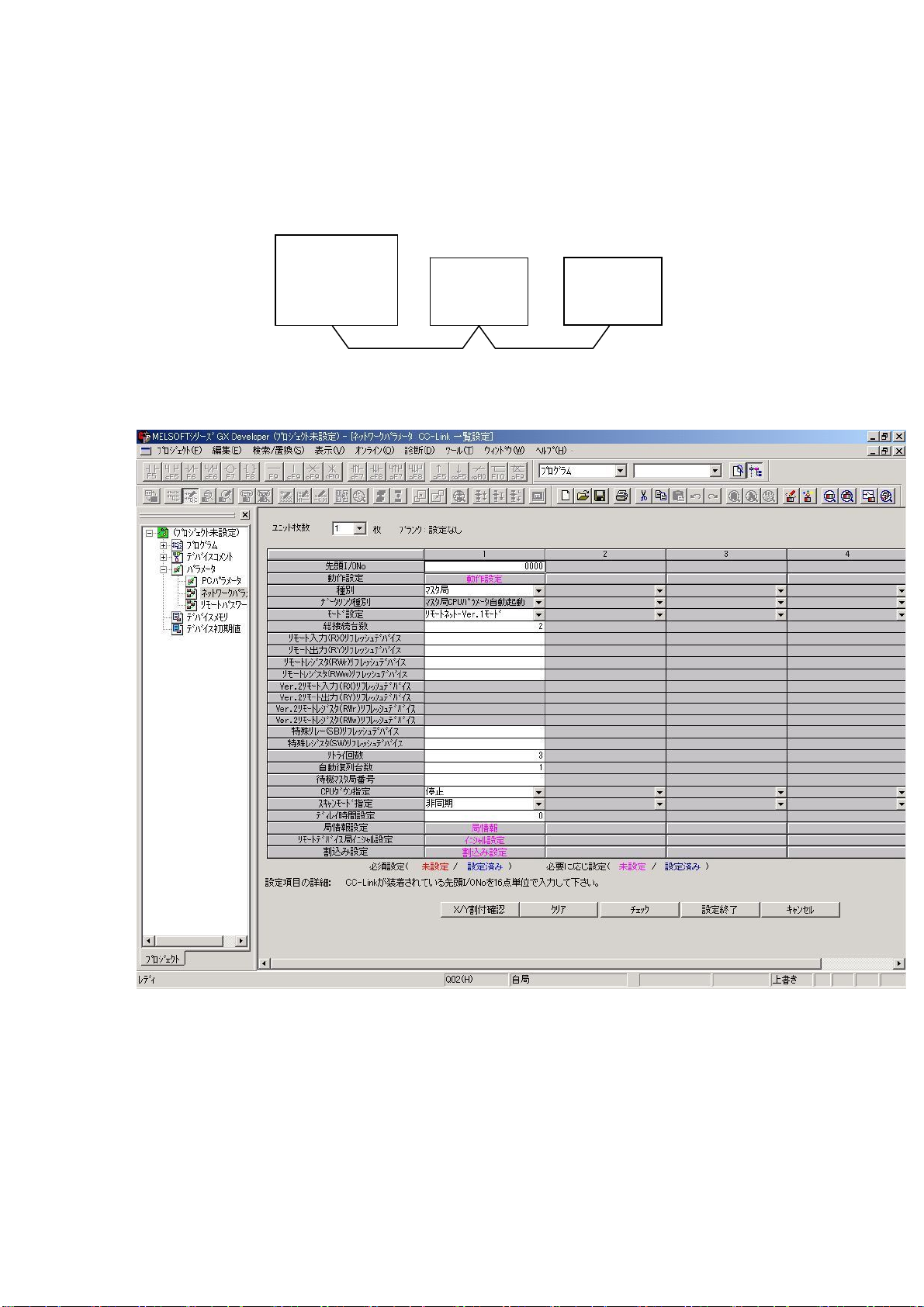

4.3.1 Master Station Network Parameter Settings ........................................................................... 6

4.3.2 Master Station Automatic Refresh Parameter Settings ......................................................... 10

5. Communication Between the Master Station and ME96NSR.............................................................. 12

5.1 Communication Guideline ............................................................................................................ 12

5.2 Initial Communication................................................................................................................... 13

5.3 Normal Communication................................................................................................................ 14

5.4 Error Communication ................................................................................................................... 14

6. Remote I/O and Remote Register ....................................................................................................... 15

6.1 Remote Input RX, Remote Output RY ......................................................................................... 15

6.1.1 Remote input RX................................................................................................................... 15

6.1.2 Remote Output RY................................................................................................................ 16

6.2 Remote Register (RWr, RWw)...................................................................................................... 17

6.2.1 Supported Command............................................................................................................ 17

6.2.2 Details of Commands............................................................................................................ 18

6.2.3 About Error Occurrence ........................................................................................................ 34

7. Abbreviations and Special Terms ........................................................................................................ 35

8. Program Example................................................................................................................................ 36

8.1 Program Content.......................................................................................................................... 36

8.2 System Configuration................................................................................................................... 36

8.3 Device Allocation.......................................................................................................................... 37

8.4 Parameter Settings ...................................................................................................................... 38

8.4.1 Network Parameter Settings and Auto Refresh Parameter Settings ..................................... 38

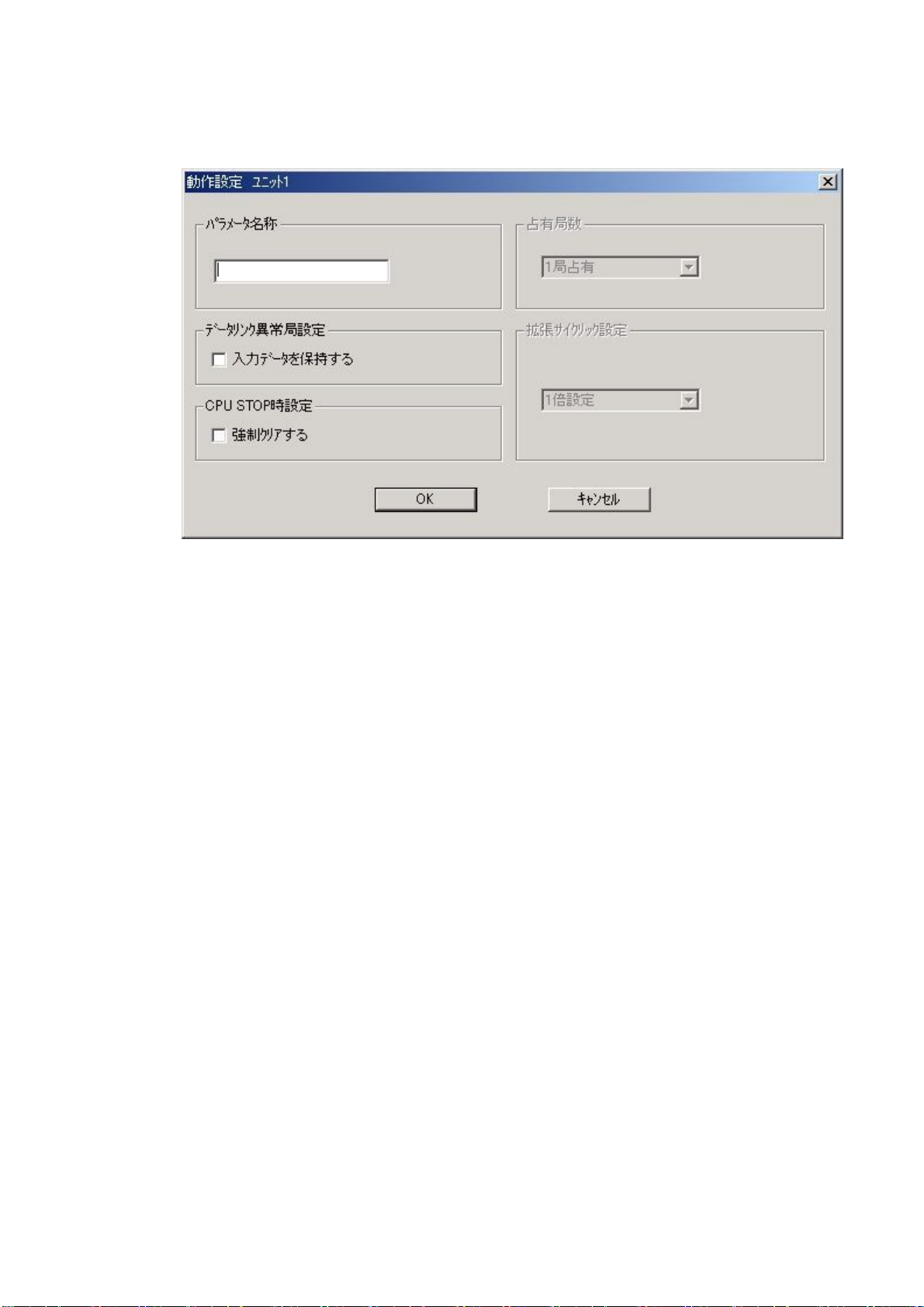

8.4.2 Operational Settings ............................................................................................................. 39

8.4.3 Station Information Settings .................................................................................................. 39

8.5 Program Example ........................................................................................................................ 40

9. Test Function Mode............................................................................................................................. 49

9.1 How to Test .................................................................................................................................. 49

9.2 Reply Data ................................................................................................................................... 49