BOXER AGRI MW 6070 User manual

BALE WRAPPER

MW 6070

USER MANUAL

P. de Heus en Zonen Greup B.V.

Stougjesdijk 153

3271 KB Mijnsheerenland

The Netherlands

Tel: +31 (0) 18 66 12 333

E-mail: info@boxeragri.nl

Balewrapper|Usermanual August2022

EN | ENGLISH

TRANSLATION OF THE ORIGINAL MANUAL

CONTENTS

August2022Balewrapper|Usermanual

1. Introduction ............................................................................................................................... 4

2. Safetyofuse .............................................................................................................................. 5

2.1 Safetyfirst ............................................................................................................................................ 5

2.2 Responsibility ....................................................................................................................................... 5

2.3 Generalsafety ...................................................................................................................................... 7

2.4 Operatingsafety................................................................................................................................... 8

2.5 Storagesafety....................................................................................................................................... 8

2.6 Maintenancesafety.............................................................................................................................. 9

3. Generaldescription .................................................................................................................. 10

3.1 Intendeduse ...................................................................................................................................... 10

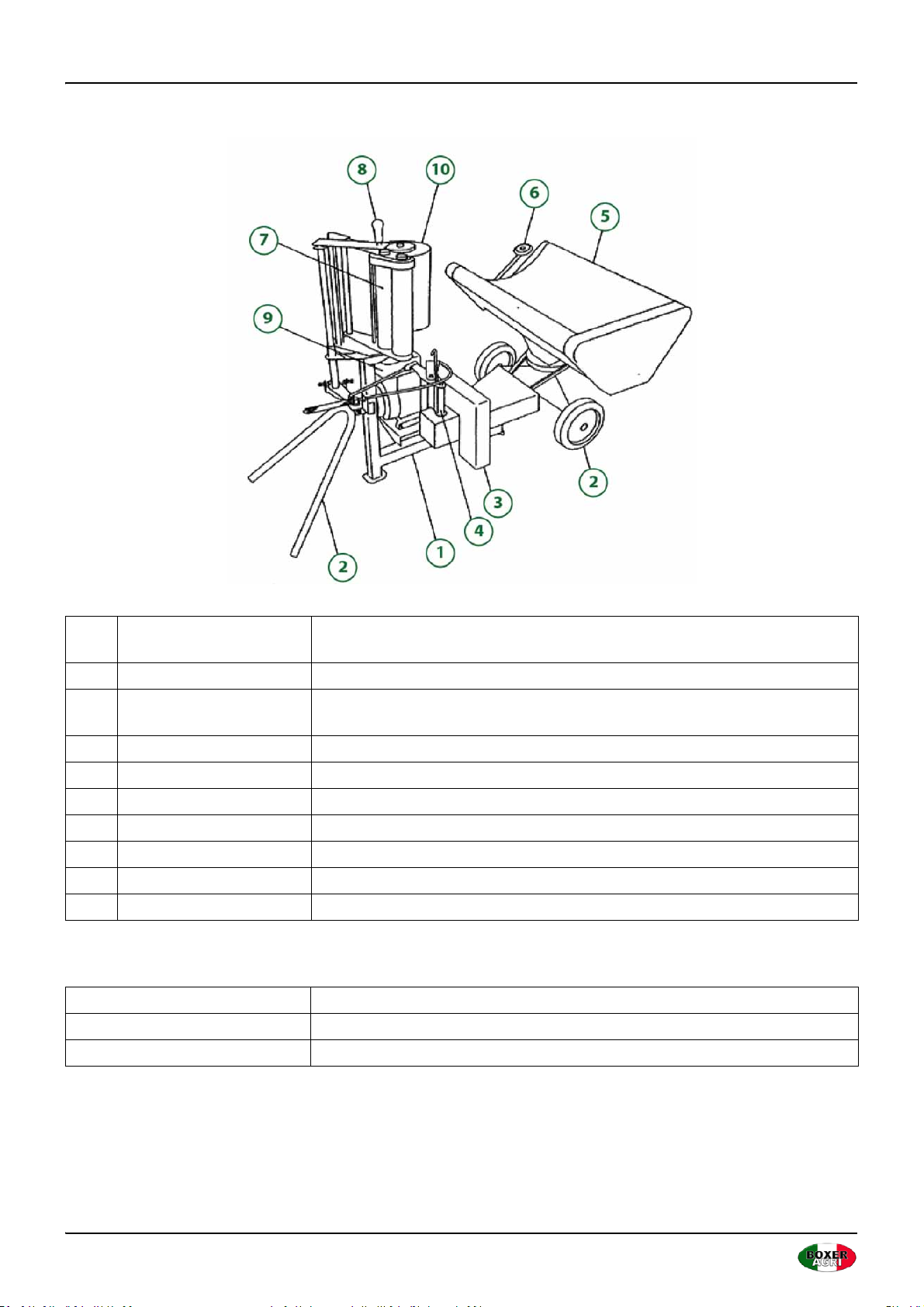

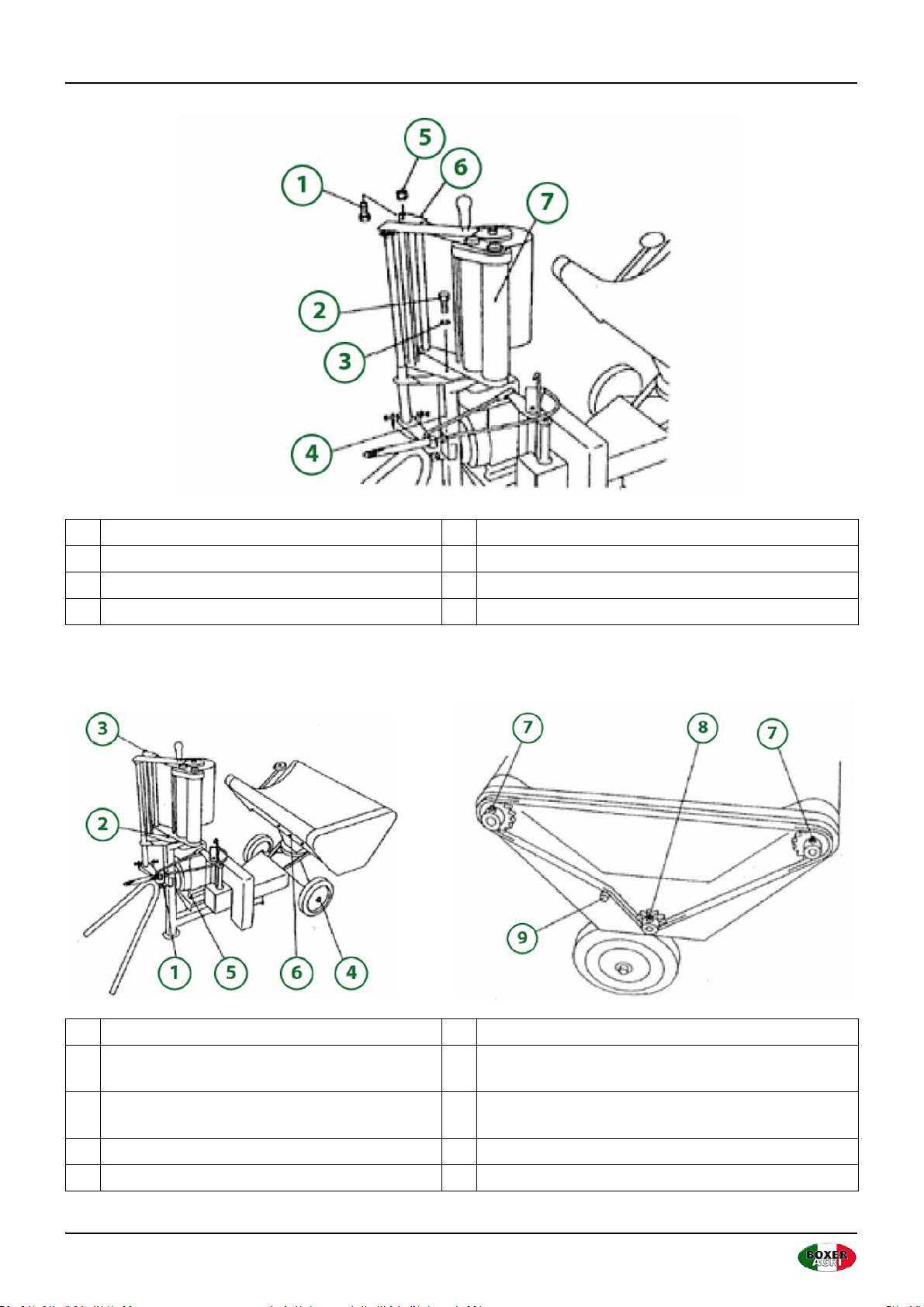

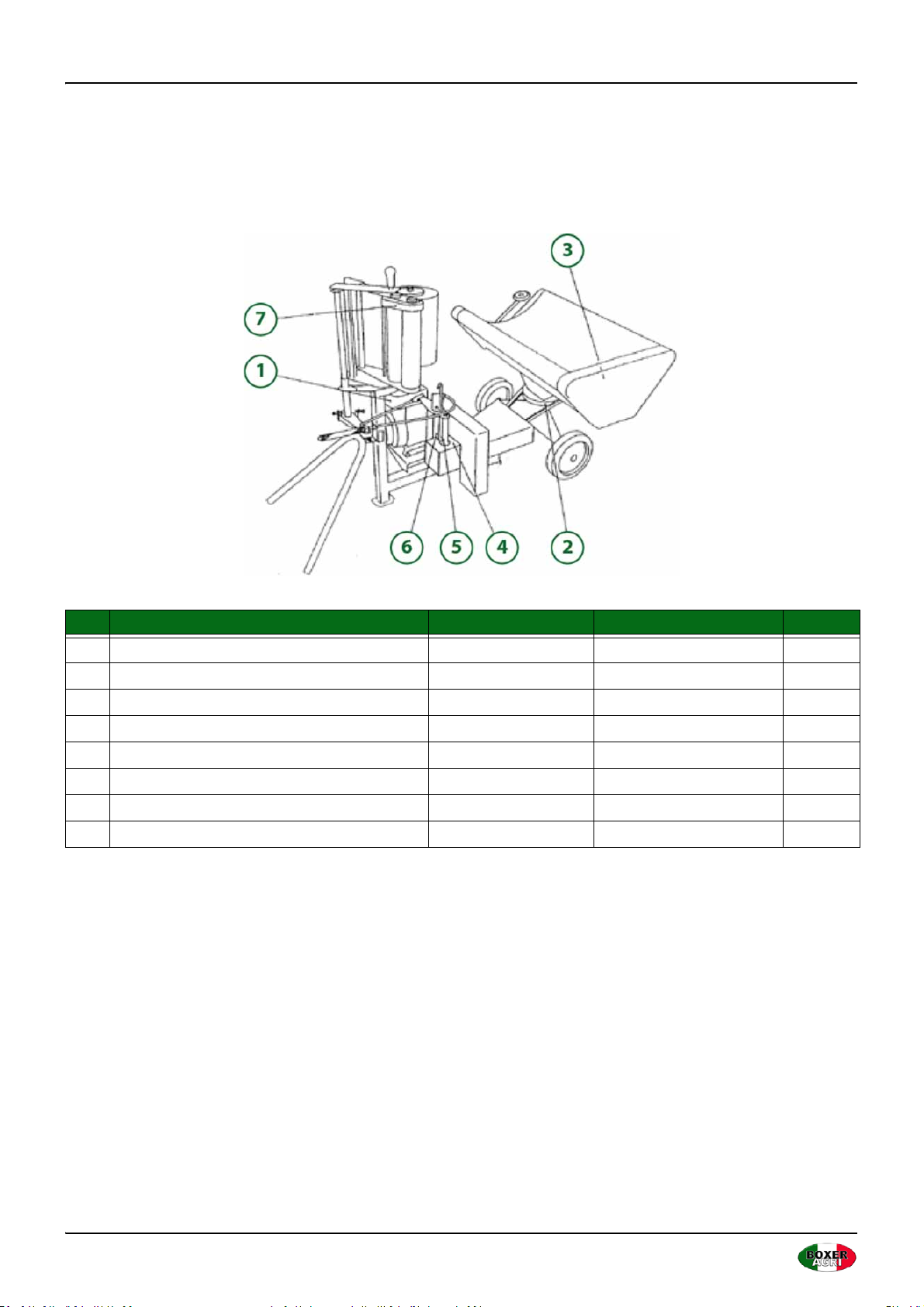

3.2 Componentsandnames .................................................................................................................... 11

4. Instructionsforuse .................................................................................................................. 12

4.1 Commissioning ................................................................................................................................... 12

4.2 Addinggasolinetotheengine(modelswithengine)......................................................................... 14

4.3 Installationofthemachineatyourworksite .................................................................................... 15

4.3.1 Assembly ............................................................................................................................. 15

4.3.2 Inspection............................................................................................................................ 16

4.3.3 Loadingandadjustment ..................................................................................................... 18

4.3.4 Startingandstopping.......................................................................................................... 21

4.3.5 Wrapping............................................................................................................................. 21

5. Startingoperationsofthemachinewrapping........................................................................... 22

6. Transportation ......................................................................................................................... 24

7. Storage..................................................................................................................................... 25

8. Inspectionandmaintenance .................................................................................................... 26

8.1 Adjustmentofcomponents................................................................................................................ 26

9. Troubleshootingandproblemsolving ...................................................................................... 28

10. EECDeclarationofConformity.................................................................................................. 30

Page4/30

Balewrapper|Usermanual August2022

1. Introduction

BoxerAgricultureEquipmentB.V.wantstothankyouforhavingchosentheMW6070balewrapper.Thetechnological

evolutionandthenewrequestoftheagriculturalworldhavepushedourcompanytoacontinueimprovement,

focusedontheproduct,onthequalityofthematerialsandonthequalityofwork.

Thismanualcontainsthedescriptionofthemachineandthenecessaryinstructionstocorrectlyuseit,alongwiththe

instructionsforordinaryandperiodicmaintenanceofthemachine.

Youwillfindonthechassisofeachmachine:theECbrandandaplateindicatinginformationaboutthe

manufacturer,themodelandserialnumber,theyearofconstruction,andtheweight.

Thisplatewithitsserialnumberwillbenecessaryforanyclaimandservice.

ExampleCEIdentificationPlate

Model Duration Enginepower

(hp)

Weight

(kg)

Sizebale

(cm)

MW6070 40sec.perbale 6 85 60x70

Page5/30

August2022Balewrapper|Usermanual

2. Safetyofuse

IMPORTANT

Makesureallpotentialoperatorsofthisequipmentreadandunderstandthismanualandallsafetymessages

containedwithin.

2.1 Safetyfirst

Readthesesafetyrulesattentivelyandstrictlyfollowsuggestedprecautionstoavoidanypotentialdangerand

safeguardyourhealthandpersonalsafety.

ThepurposeofthismanualistofamiliarizetheoperatorwiththeoperationandregularservicingoftheMW6070

balewrapper.Rememberthatthetimespentonmaintenanceextendsthelifeofyourmachine.

Thesafetyinformationgiveninthismanualdoesnotreplaceanysafetycodes,insuranceneeds,federal,stateand

locallaws.Makesureyourmachinehasthecorrectequipmentrequiredbyyourlocallawsandregulations.

TheMW6070balewrapperismadeinaccordancewithallapplicablesafetyregulations.Toensuresafeuse,pay

attentiontoallwarningsandinstructions.

CAUTION

Thissymbolindicatesimportantsafetymessagesinthismanual.Whenyouseethissymbol,carefullyreadthis

messagethatfollowsandbealerttothepossibilityofpersonalinjuryordeath.

2.2 Responsibility

OperatorsareresponsibleforthesafeoperationandmaintenanceoftheirMW6070balewrapper.Eachoperator

mustensurethatyouandanyoneelsewhoisgoingtooperate,maintainorworkaroundthebalewrapperbe

familiarwiththeoperatingandmaintenanceproceduresandrelatedsafetyinformationcontainedinthismanual.

Thismanualwilltakeyoustep‐by‐stepthroughyourworkingdayandalertsyoutoallgoodsafetypracticesthat

shouldbeadheredtowhileoperatingtheMW6070balewrapper.

Remember,operatorsarethekeytosafety.Goodsafetypracticesnotonlyprotectoperatorsbutalsothepeople

aroundthem.Makethesepracticesaworkingpartofyoursafetyprogram.BecertainthatEVERYONEoperatingthis

equipmentisfamiliarwiththerecommendedoperatingandmaintenanceproceduresandfollowsallthesafety

precautions.Mostaccidentscanbeprevented.

Page6/30

Balewrapper|Usermanual August2022

DONOTriskinjuryordeathbyignoringgoodsafetypractices:

• MW6070balewrapperownersmustgiveoperatinginstructionstooperatorsoremployeesbeforeallowing

themtooperatethemachine,andatleastannually.

• Themostimportantsafetyfeatureonthisequipmentisasafeoperator.Itistheoperator’sresponsibilityto

readandunderstandallSafetyandOperatinginstructionsinthemanualandtofollowthese.Mostaccidents

canbeavoided.

• Apersonwhohasnotreadandunderstoodalloperatingandsafetyinstructionsisnotqualifiedtooperatethe

machine.Anuntrainedoperatorexposeshimselfandbystanderstopossibleseriousinjuryordeath.

• DONOTmodifytheequipmentinanyway.Unauthorizedmodificationmayimpairthefunctionand/orsafety

andcouldaffectthelifeoftheequipment.

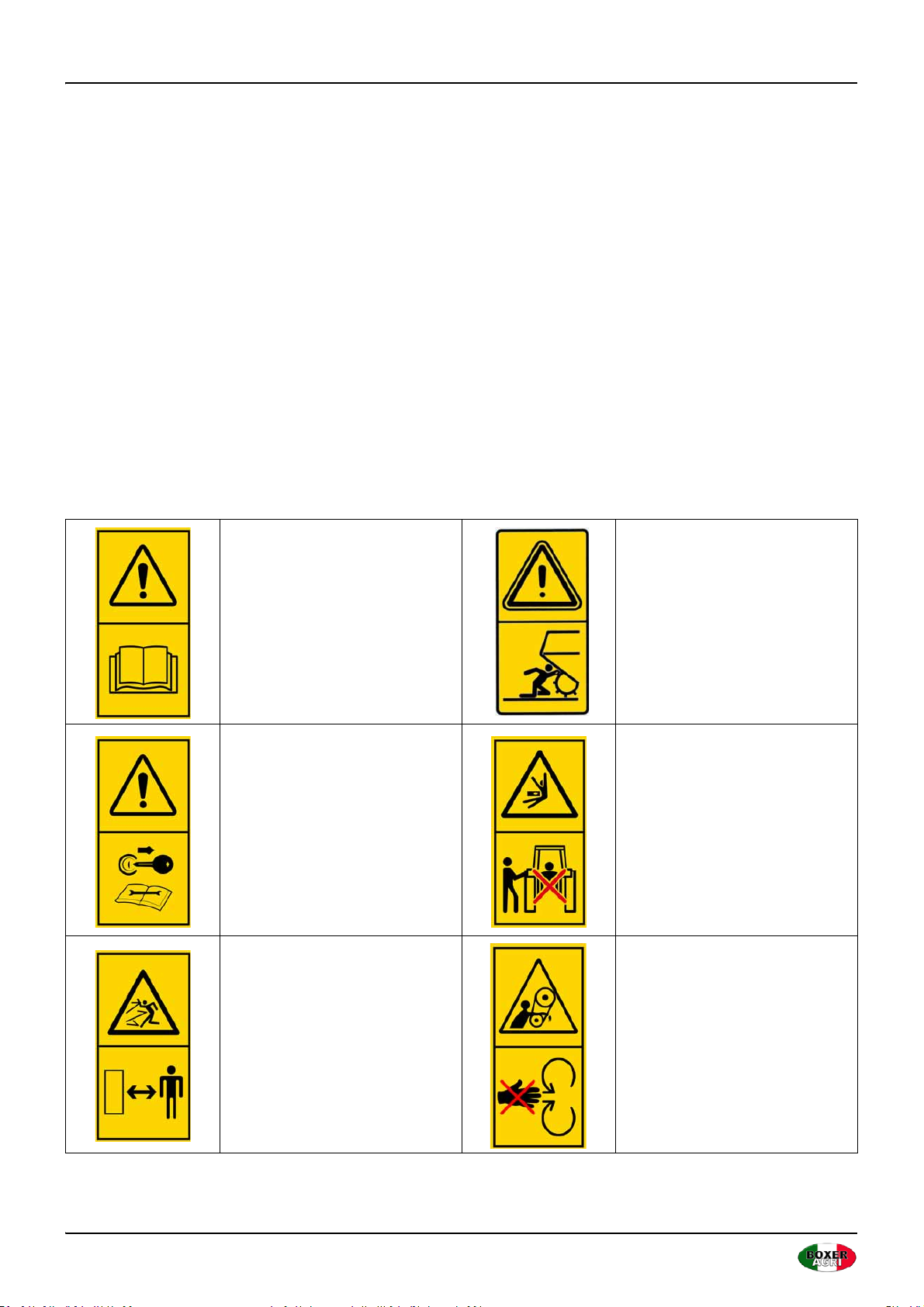

Safetysigns

1. Keepsafetysignscleanandlegibleatalltimes.

2. Replacesafetysignsthataremissingorhavebecomeillegible.

3. Ifacomponentwithasafetysign(s)affixedisreplacedwithanewpart,makesurenewsafetysign(s)are

attachedinthesamelocationsasthereplacedcomponents.

4. SafetysignsareavailablefromyourauthorizedDistributororDealerPartsDepartmentorthefactory.

Readtheinstructionmanual

beforeyoustartusingthe

machine.

DONOTattemptanyrepairson

themachineinoperation.

Switchofftheengineand

removetheignitionkeybefore

beginningmaintenanceor

repair.

DONOTstandneartherodsof

thepowerliftwhiletheliftis

controlled.

Keepasafedistancefromthe

machine.DONOTallowanyone

tobeatthedistanceoflessthan

50mfromthemachine.

DONOTopenandremove

protectiveguards,iftheengine

isworking.

Page7/30

August2022Balewrapper|Usermanual

2.3 Generalsafety

1. Readtheoperator’sManualandallsafetysignscarefullybeforeoperating,maintaining,adjustingor

unpluggingthebalewrapper.

2. AllownoridersontheMW6070balewrapper.

3. Operateonlyatsafedistancefrombystanders.Cleartheareaofpeople,especiallysmallchildren,before

starting.

4. StopPTObeforedismountingtractor.

5. KeepfeetandhandsfromundertheMW6070balewrapperatalltimes.

6. Keepallshieldsinplace.Ifshieldremovalbecomesnecessaryforrepairs,replacetheshieldpriortouse.

7. DONOTstaybetweenthetractorandthemachine.

8. DONOTapproachtheMW6070balewrapperuntilallmotionhasstopped.

9. Allrotarybladeshavetheabilitytodischargeobjectsathighspeeds,whichcouldresultinseriousinjuryto

bystandersorpassers‐by,usewithextremecaution.

10. Placeallcontrolsinneutral,stoptractorengine,setparkbrake,removeignitionkeyandwaitforallmoving

partstostopbeforeservicing,adjusting,repairingorunplugging.

11. ReviewsafetyrelateditemsannuallywithallpersonnelwhowilloperateormaintaintheMW6070bale

wrapper.

12. DONOToperatemachineifyoufeelunwellorphysicallyunfit,inwhichcaseyoushouldstopworking.

13. Thismachinewasdesignedwithsafetyverymuchinmind.However,thereisnorealsubstituteforcautionand

attentioninpreventingaccidents.Onceanaccidenthashappened,itistoolatetothinkaboutwhatyoushould

havedone.

14. UseatractorequippedwithaRollOverProtectiveStructure(ROPS).Alwayswearyourseatbelt.Seriousinjury

orevendeathcouldresultfromfallingoffthetractor–particularlyduringaturnoverwhentheoperatorcould

bepinedundertheROPSorthetractor.

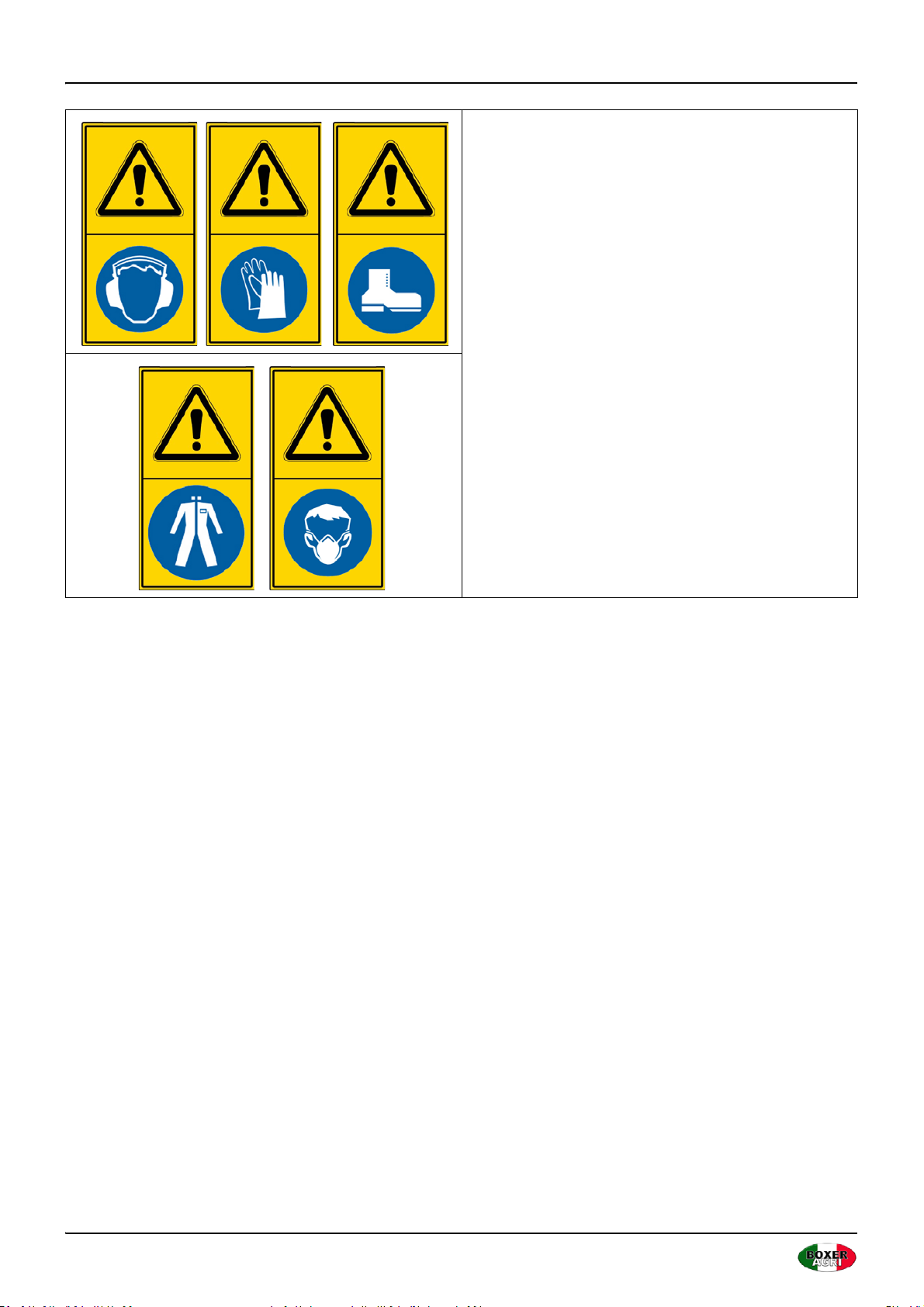

Usetherequestedindividualprotectiondevices.

Page8/30

Balewrapper|Usermanual August2022

15. Neverexceedthelimitsofapieceofmachinery.Ifitsabilitytodoajob,ortodososafety,isinquestion–DON’T

TRYIT.

16. Clearworkingareaofstones,branchesorhiddenobstaclesthatmightbehookedorsnagged,causinginjuryor

damage.

2.4 Operatingsafety

1. ReadandunderstandtheOperator’sManualandallsafetysignsbeforeoperating,servicing,adjusting,

repairingorunplugging.

2. DONOTallowriders.

3. Installandsecureallguardsandshieldsbeforestartingoroperating.

4. Keephands,feet,hairandclothingawayfrommovingparts.

5. Placeallcontrolsinneutral,stoptractorengine,setparkbrake,removeignitionkeyandwaitforallmoving

partstostopbeforeservicing,adjusting,repairingorunplugging.

6. Placealltractorandmachinecontrolsinneutralbeforestarting.

7. Neverstartoroperatemachineunlesssittingontractorseat.

8. Cleartheareaofbystanders,especiallysmallchildren,beforestarting

9. StayawayfromPTOshaftandmachinewhenengagingPTO.Keepothersaway.

10. Cleanreflectors,SMVandlightsbeforetransporting.

11. Usehazardflashersontractorwhentransporting.

12. DONOTputhandsorfeetundermachinewhiletractorengineormachineisrunning.

13. DONOToperateFinishingmowerintheraisedposition.

14. Objectscanbethrownoutfromundermachinewithsufficientforcetoseverelyinjurepeople.Stayawayfrom

machinewhenitisrunning.Keepothersaway.

15. Alwaysknowwhatyouarecutting.NeveroperateFinishingmowerinanareathathashiddenobstacles.

Removesticks,stones,wireorotherobjectsfromworkingareabeforestarting.

16. Reviewsafetyinstructionswithalloperatorsannually.

2.5 Storagesafety

1. Storethemachineinanareaawayfromhumanactivity.

2. DONOTpermitchildrentoplayonoraroundthestoredmachine.

3. Storethemachineinadry,levelarea.Supporttheframewithplanksifrequired.

Page9/30

August2022Balewrapper|Usermanual

2.6 Maintenancesafety

1. Goodmaintenanceisyourresponsibility.Poormaintenanceisaninvitationtotrouble.

2. Followgoodshoppractices.

3. Keepserviceareacleananddry.

4. Besureelectricaloutletsandtoolsareproperlygrounded.

5. Useadequatelightforthejobathand.

6. Makesurethereisplentyofventilation.Neveroperatetheengineofthetowingvehicleinaclosedbuilding.

Theexhaustfumesmaycauseasphyxiation.

7. Beforeworkingonthismachine,shutofftheengine,setthebrakes,andremovetheignitionkey.

8. Neverworkunderequipmentunlessitisblockedsecurely.

9. Usepersonalprotectiondevicessuchaseye,handandhearingprotectors,whenperforminganyserviceor

maintenancework.Useheavygloveswhenhandlingblades.

10. Whenreplacementpartsarenecessaryforperiodicmaintenanceandservicing,genuinefactoryreplacement

partsmustbeusedtorestoreyourequipmenttooriginalspecifications.Themanufacturewillnotbe

responsibleforinjuriesordamagescausedbyuseofunapprovedpartsand/oraccessories.

11. Afireextinguisherandfirstaidkitshouldbekeptreadilyaccessiblewhileperformingmaintenanceonthis

equipment.

12. Periodicallytightenallbolts,nutsandscrewsandcheckthatallpinsareproperlyinstalledtoensureunitisin

asafecondition.

13. Whencompletingamaintenanceorservicefunction,makesureallsafetyshieldsanddevicesareinstalled

beforeplacingmachineinservice.

Page10/30

Balewrapper|Usermanual August2022

3. Generaldescription

3.1 Intendeduse

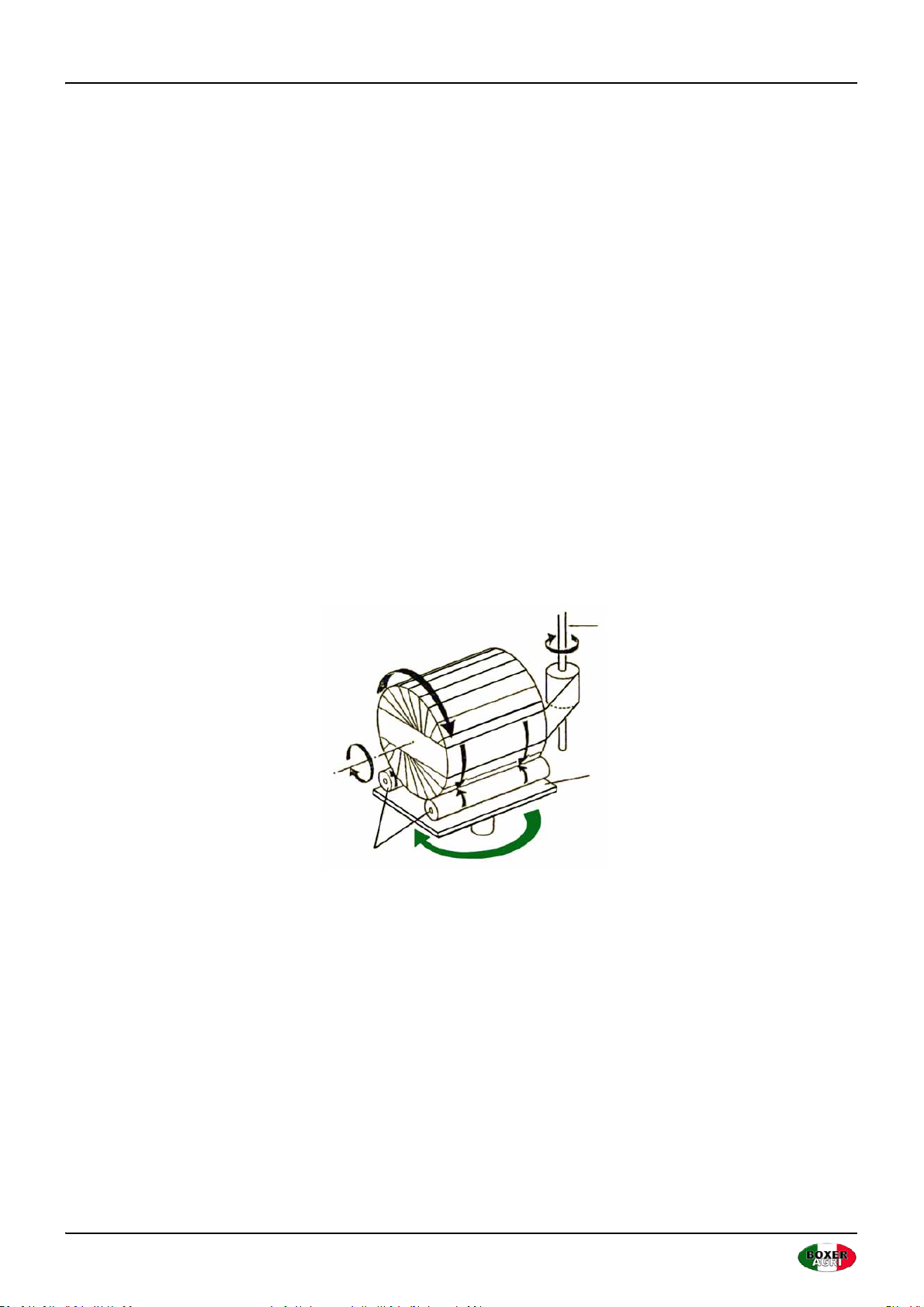

• Aplasticbandisplacedoveralargebale(cylindricalorprismatic)toisolateitfromcontactwithoxygeninthe

air.

• Fermentationtakesplaceintheforageinsidethebale,whichhasahighmoisturecontent,allowingittobe

storedassilage.

• Thewrappingprocessshouldbecarriedoutshortlyafterthebaleisformed,andthemoisturecontentofthe

grassshouldnotbehigh(40‐45%drymatter).

• Thebaseofthemachineisahorizontalplatform,formedbytworollersthatarejoinedbyseveralplasticbands,

onwhichthecylindricalbalerests,whichrotatesaccordingtotheaxisofthecylinder.

• Aplasticcoilfixedonanarmisplacedonthesideanditistheplatformthatrotatesonitscentralaxis.

• Combiningtherotationalmovementthattheplatformprovidestothebalewiththatofthearmcontainingthe

plasticcoil,thebaleiscompletelycovered,beingnecessary2to3layersofplasticovertheentiresurface.

Duringwrapping,theplasticfoilisstretched(upto70%)forastrongholdbetweensuccessivelayers.

• Oncetheprocessiscompleted,theplastictapeisbrokenbytractionandtheplatformsupportingthebaleis

tiltedtoletthewrappedbalefalltotheground.Asitfalls,itcanrestononeofthebasesofthecylinder,which

isthestrongestareaofthecover.

Page11/30

August2022Balewrapper|Usermanual

3.2 Componentsandnames

INCLUDES:

1 Mainframe Themainframesupportsthemotor,thesteeringunit,theautomaticstop

device,theturningplatformandthebelttensioner.

2 Handlebarandwheels Thehandlebarandwheelsupportthatcanbeusedtomovethemachine.

3 Steeringunit Thisunitdeceleratestherotationofthemotor,andthebeltshaftisusedto

transmittherotationortoisolatetherotationoftheplatform.

4 Automaticstopdevice Thisdeviceautomaticallystopsthewrappingonthebale.

5 Rotatingplatform Itrotatesthebaleonittowrapthebale.

6 Sideroller Thisrollerholdsthebaleinpositionwhileitisbeingwrapped.

7 Tensioningdevice Thisdeviceisloadedwithafoilrollandtightensthefoiloverthebale.

8 Startlever Thislevelerisusedtoturnonorofftherotationoftheholder.

9 Engine Gasolineengine.

10 Plasticfoilsupport Supportshaftfor250mmplasticfoilroll(ESCINTPLAST250).

Screws M8x25,M8x20,M10x25

Nut HexagonalM8withflange,nutwithspringM8

Washer M10lockwasher

Page12/30

Balewrapper|Usermanual August2022

4. Instructionsforuse

4.1 Commissioning

Unpackingandinstallation

• Checkthatallthecomponents(e.g.supports,wheels,blades,pins,etc.)indicatedinthecharacteristicssection

areincludedwiththemachine.

• Paytheutmostattentiontosafetyduringloadingandunloadingoperations,tobecarriedoutbyqualified

personnel(loaders,truckoperators,etc.).

• Fortransport,themachinemustbeplacedonpalletsorspeciallydesignedstructures,fixedwithsuitable

straps,andmovedthankstoaloaderwithappropriateliftingability.

• DONOTliftthemachinewithstraps.

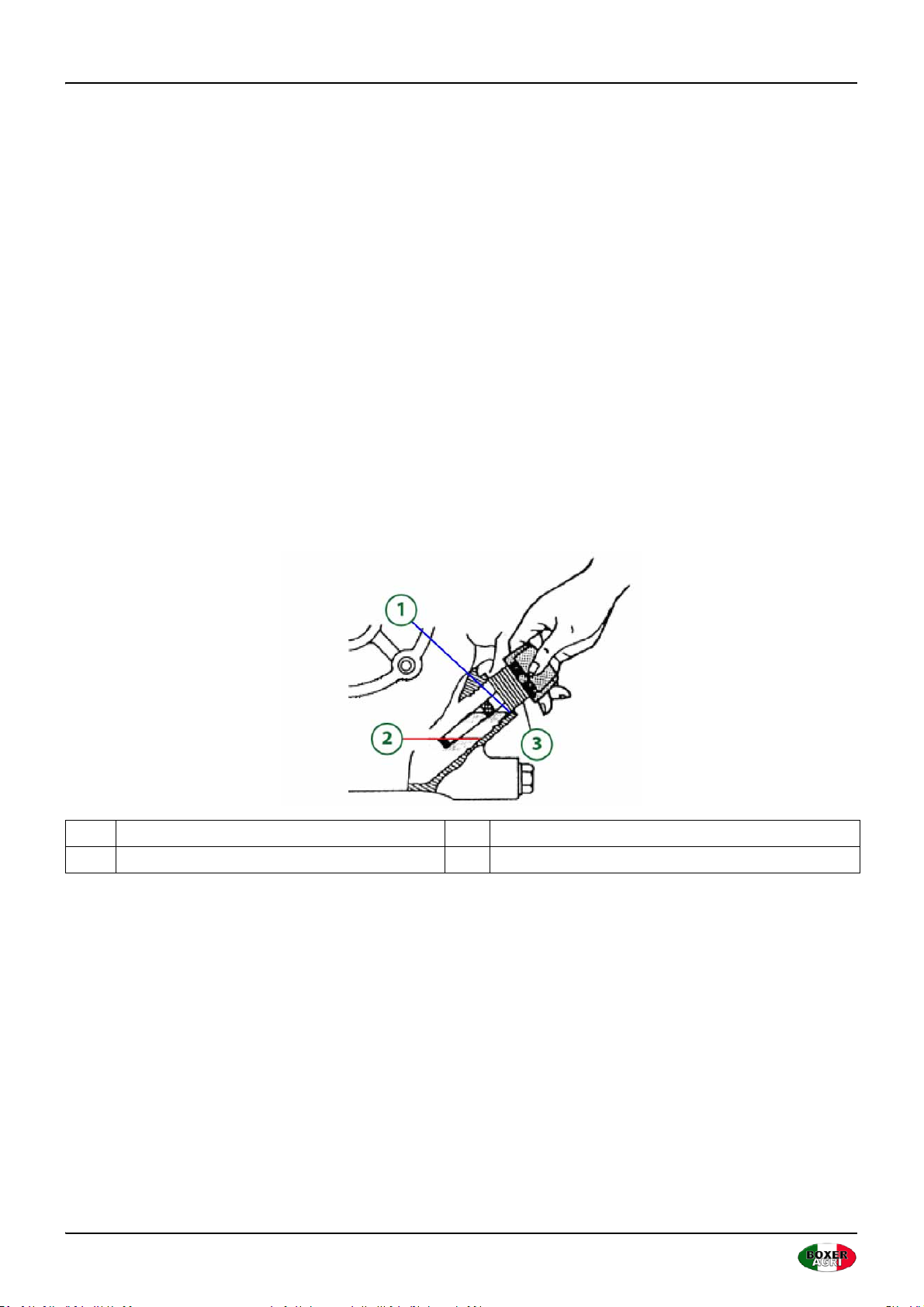

Addingengineoil(engine‐drivenmodels)

1. Makesurethatthetapingmachineisonalevelsurface.

2. Unscrewtheoildipsticktoaddoil.

3. Refertotheenginemanual(separately)fortherequiredamountofSAE10W‐30engineoil;replacethedipstick.

4. Checktheoilleveldailyandaddasnecessary.Addoiltotheupperstopmarkedontheinlet.

1 Maximumoillevel(0.4L) 3 Dipstick

2 Minimumoillevel(refill)

Page13/30

August2022Balewrapper|Usermanual

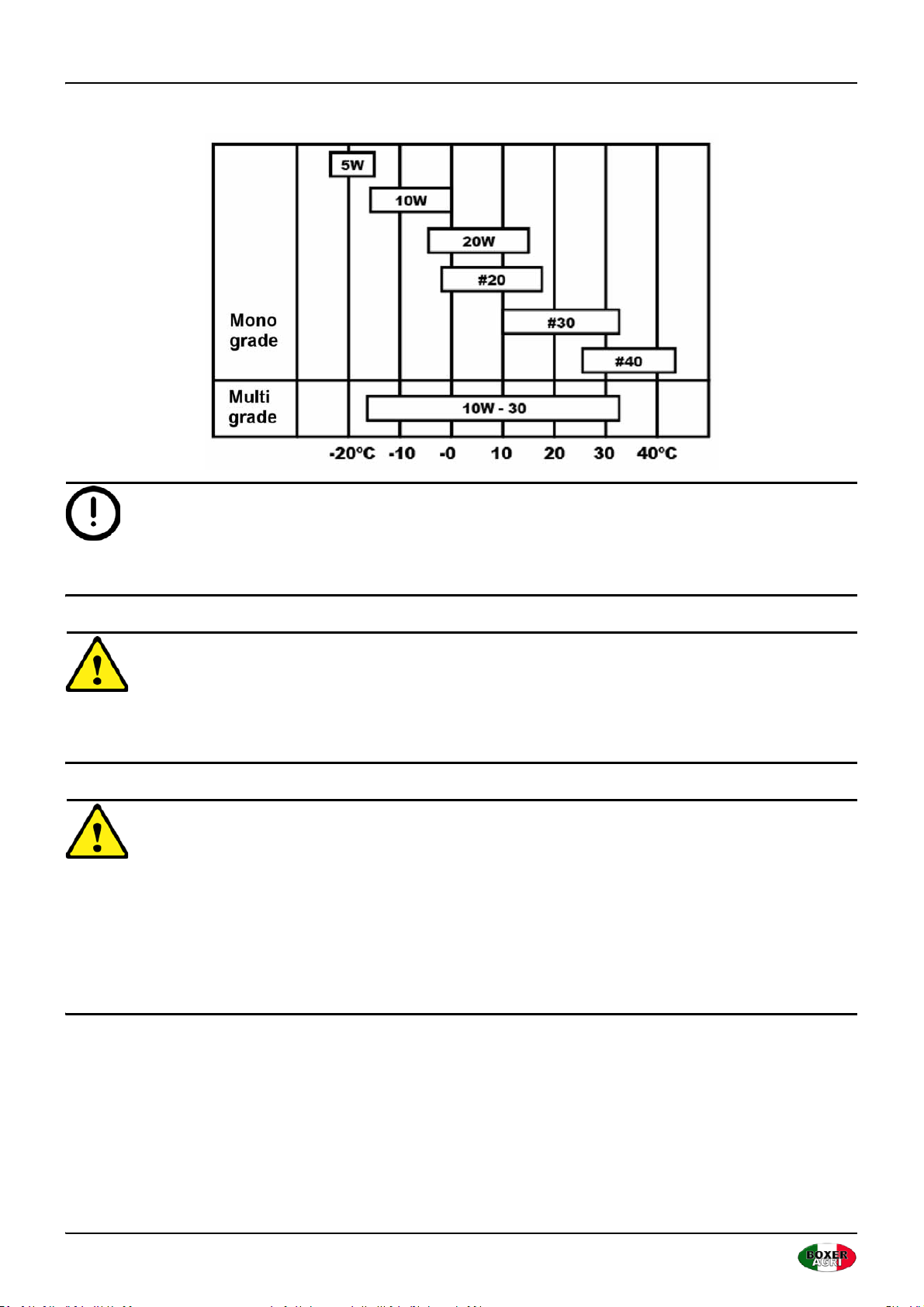

OILVISCOSITYSELECTIONCHARTBYOPERATINGTEMPERATURE

IMPORTANT

Duringtherestperiod,checktheoillevel.

CAUTION

DONOTattempttomaneuverorstarttheenginebeforeithasbeenproperlyrefilledwiththecorrecttypeand

amountoffuel.Damagetothemachinemayoccuriftheseinstructionsarenotfollowedandwillvoidthewarranty.

CAUTION

• Ifthequalityoftheengineoildecreases,aseizureproblemmayoccur.UseoilofSCclassqualityorhigher.

• Incasetheoutsideairtemperatureisbelow‐20°Corabove40°C,selecttheoilwithviscosityandquality

suitableforthelocalconditions.

• Notethatifamulti‐gradeoilisused,oilconsumptiontendstoincreasewhentheoutsideairtemperatureis

high.

Page14/30

Balewrapper|Usermanual August2022

4.2 Addinggasolinetotheengine(modelswithengine)

1. Useonlyregular,fresh,clean,unleadedfuelwithaminimumof86octane.

2. Thefueltankhasacapacityofapproximately1.5liters.DONOTmixoilwithfuel.

3. Removethefuelcapandslowlyaddfueltothefueltank.DONOToverfill,leaveoneinch(approx.2.5cm)of

spaceforthefueltoexpandfuelexpansion.

4. Screwonthefuelcapandwipeupanypossiblespillage.

CAUTION

Beforerefilling,checkthatthefuelfilterinthefueltankisinplace.

DONOTfillthetankindoorsorwhentheengineisrunningorhot.

DONOTexceedthepre‐determinedfilllimit,itmaycausespillageandbedangerous.

DONOTmixoilandgasoline.

DONOTlightcigarettesorsmokewhenfillingthefueltank.

Fuelvaporsandfuelitselfarehighlyflammableandhighlyexplosive.DONOTworknearfire,sparksorany

incandescentelements.

WARNING

DONOTusethemachineinsideanybuilding,enclosureorcompartment.Usethemachineoutdoorsonlyinawell‐

ventilatedarea.

Engineexhaustgasescontaincarbonmonoxide,apoisonous,colorless,odorlessgas.Breathingcarbonmonoxide

willcausenausea,dizziness,faintingordeath.Ifyoubegintofeeldizzyorfaint,breathefreshairimmediately.

A Input B Limitlinetofill

Page15/30

August2022Balewrapper|Usermanual

4.3 Installationofthemachineatyourworksite

IMPORTANT

Themachineshouldrestonthefloorandbestabilizedduringoperation.Ifitisnotstableorwellsupporteditmay

resultindamagetothemachine.

Placethemachineinsuchawaythattheprevailingwind/breezewillblowthefumes/smokeawayfromtheuser

areaandintoanareaclearofpeople.

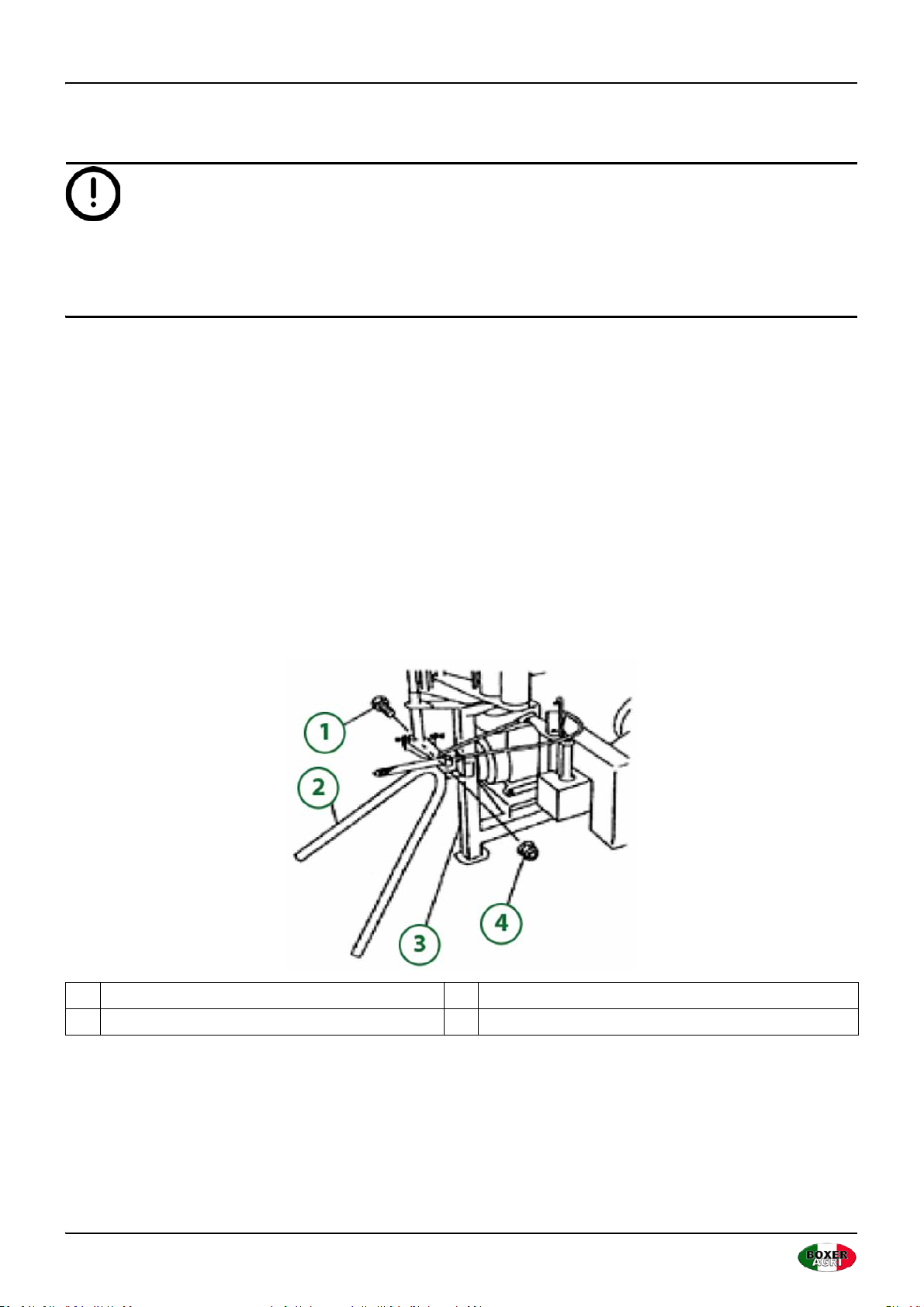

4.3.1 Assembly

Regardingtheboltsandnutsrequiredfortheassemblyoftherespectiveparts,refertothesymbolsindicatedinthe

packinglist.Whenassembling,adjustthetightnessoftheboltandnylonflangenuttoensurethatthehandlecan

moveverticallywithease.

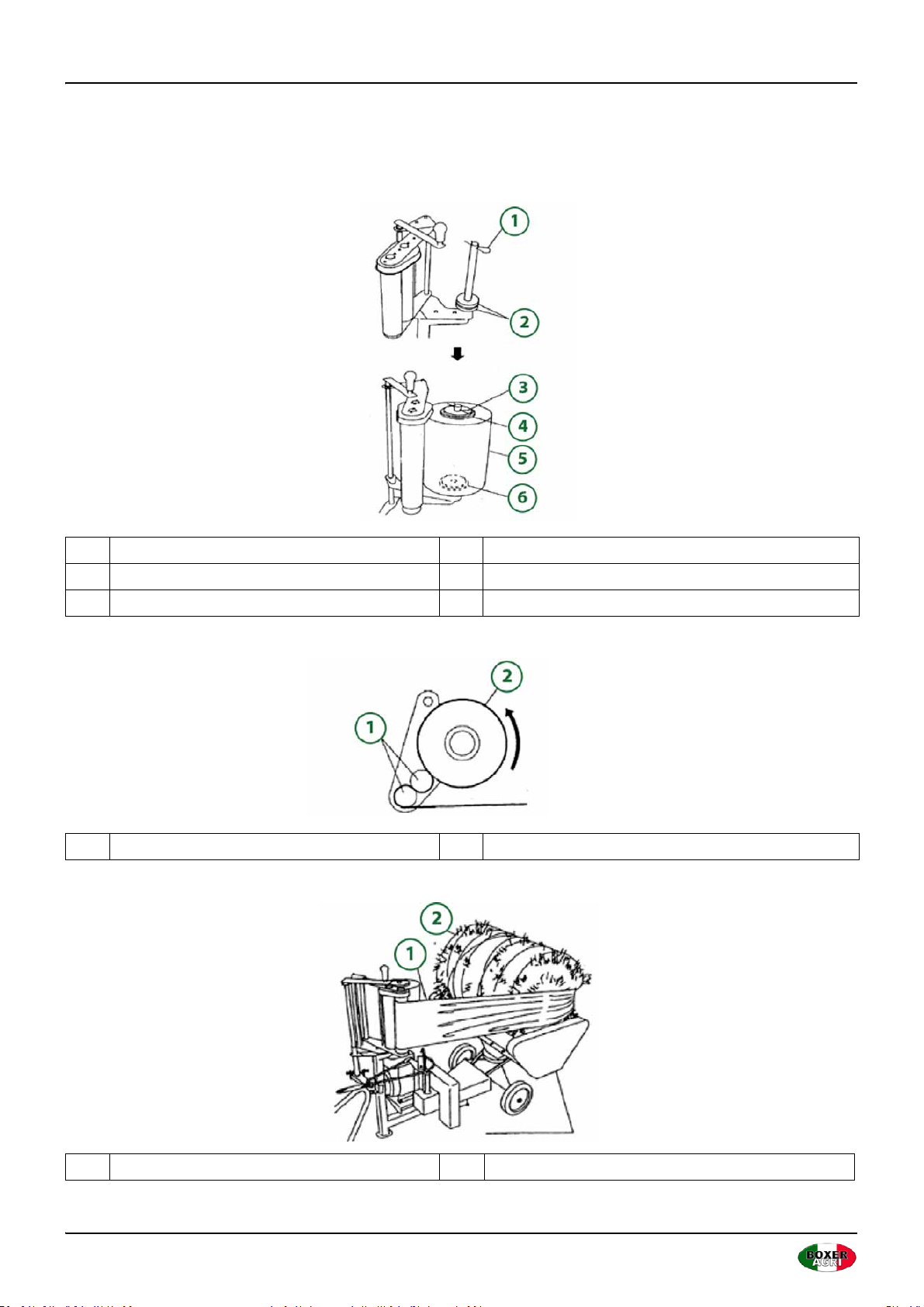

Stretchingdeviceassembly

Mountthestretchingdevicefromaboveonthefrontsideofthemainframeofthemachineandinsertabushing

intotheholeatthetipoftheplatefromabove.

Mountingthehandle

Mountthehandleonthefrontsideofthemainframeofthemachine.

Mountingofstretchingattachment

Mountthestretchingattachmentfromaboveonthefrontsideofthemainframeofthemachineandinserta

bushingintotheholeatthetipoftheplatefromabove.

1 SmallboltM8x25 3 Mainframe

2 Handlebar 4 NylonnutwithM8flange

Page16/30

Balewrapper|Usermanual August2022

4.3.2 Inspection

Checkthattheboltsandpinsareinplace.Checkeachofthesepartsofthemachine:

1 SmallboltM8x20 5 SmallnutwithspringM8

2 SmallboltM10x25 6 Sheetmetal

3M10lockwasher 7Clampingsystem

4 Mainframe

1 Handlebarfixingboltandnut 6 Turntableanchoringboltsandnuts

2 Anchorboltandnutonthebottomofthe

tensioningdevice

7 35‐20Tuppergearwheels(platform)anchorbolts

andnuts

3 Thescrewonthetopandthenutonthetopof

thetensioningdevice

8 Screwandnutofuppergearwheel(platform)

4 Fixingpinsandanchoringofthewheels 9 Belttensioningscrew

5 Motoranchorboltsandnuts

Page17/30

August2022Balewrapper|Usermanual

Checkbelttensionwhetheritistoolooseortootight.Checkforsufficientgreasingofthegears.Ifanylubrication

orgreasingisinsufficient,applyasindicatedinthemaintenancesection.

Greasingpointsandlubrications

Theoilusedforlubricationorprotectionmustbeclean.Whengreasing,greaseuntilalltheoldgreasecomesout.

Themachineisgreasedatthefactoryforoperation.However,checkitbeforeuse.

No. Lubricationpoint Type Renewalperiod

1 Engine Motoroilforvehicles Ca.0.4L

2 Gearbox(rotatingsupport) Coatinggrease Every30workinghours

3 Chainsupport(rotatingsupport) Oil

4 Chainsupport(automaticstopdevice) Oil

5 Armslidingscrew(automaticstopdevice) Oil Afteruse

6 Slidingarm(automaticstopdevice) Oil Afteruse

7 Gears(tensioningdevice) Oil Every30workinghours

Bearingsandotherslidingparts Greaseoroil Afteruse

Page18/30

Balewrapper|Usermanual August2022

4.3.3 Loadingandadjustment

Loadingthefoil

Removethepinandonerollerfromthetensioningdevicetopositionthefoil.Then,inserttherollintothecylinder,

placetherollerandfixthepin.

Positionthefoilsothattheunwindingdirectioniscounterclockwise.Passbetweenthetwotensionrollers.

Stretchfilmforunwindingbyhookingitintooneofthestringsononesideofthebale.

1 Pin 4 Roller

2 Rollers 5 Foilroll

3 Pin 6 Roller

1 Tensioningarms 2 Foilroll

1Foil 2Bale

Page19/30

August2022Balewrapper|Usermanual

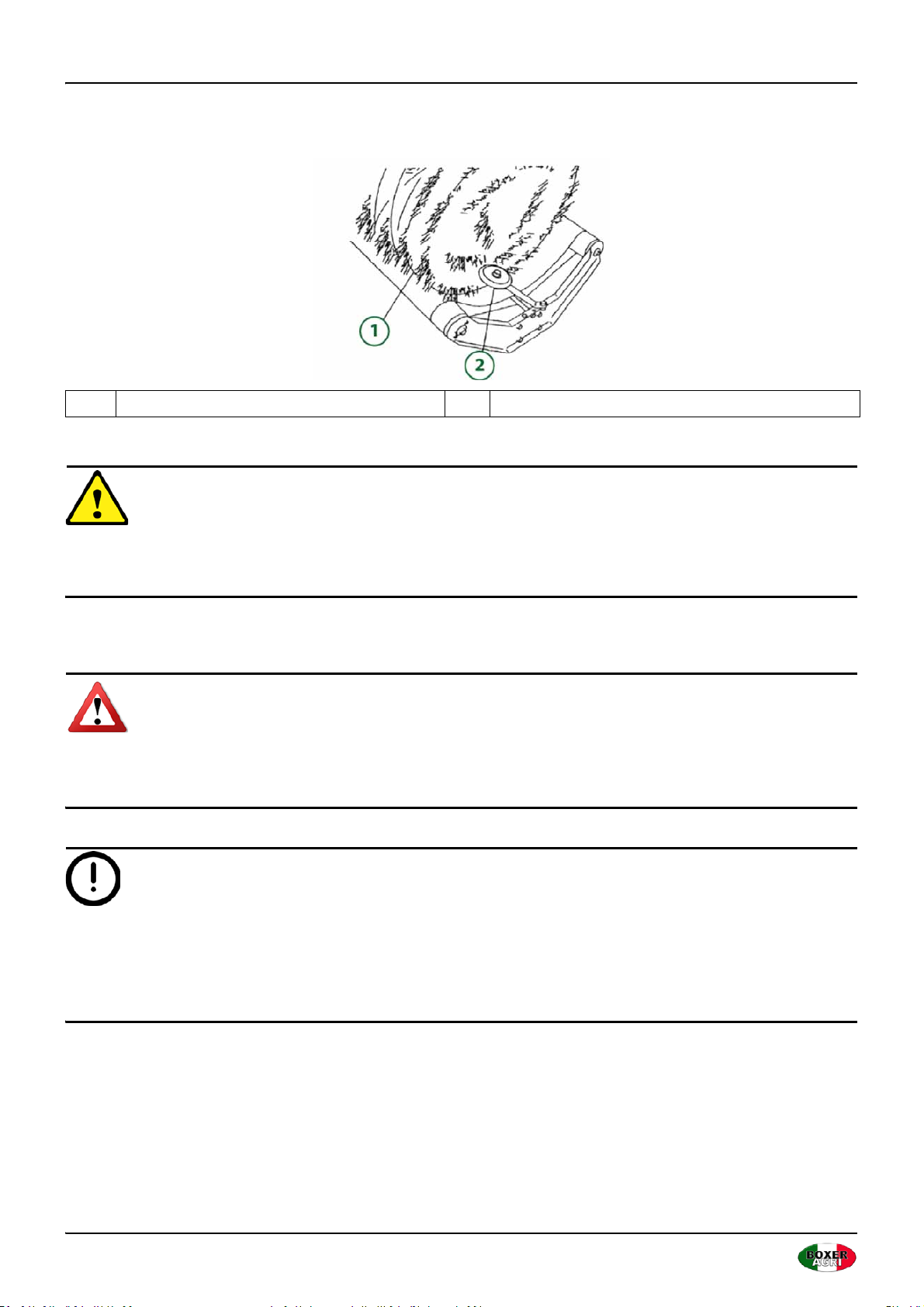

Adjustingthesideroller

Placethebaletobewrappedalongthesideplatformontheturntable.

Adjustthesiderollertofitthewidthofthebale,andsecureusingtheboltwithitsnut.

CAUTION

Whenadjustingthesideroller,maintainaclearanceof20to50mmbetweentheendofthebaleandthesideroller.

Aftercompletingtheadjustments,tightentheboltandnutfirmly.

DONOTloadbalesheavierthan30kgonthismachine.DONOTdropthebalefromheight,deposititonthe

turntable.Otherwisedamagetothemachinemayoccur.

WARNING

Touchingortamperingwiththeturntableduringoperationmaycauseseriouspersonalinjury.DONOTallowpeople

intheworkingarea.Ifabalethatisirregularlyshapedortoolightistobewrapped,itmaybeejected,injuringpeople

inthevicinity.DONOTwrapthesebales.

IMPORTANT

DONOTopenanycoverduringhandlingorrotatingoperations.Ifyoutouchthefoilortensioningrollerwhilethe

foilisbeingstretched,itmaybedamaged,trappingyouandcausingseriousdamage.DONOTtouchthefoilor

tensionerduringoperation.Adjustingthemachineorremovinganymaterialwithoutstoppingthemotorcancause

seriousdamage.Stopthemotorandcheckthatallpartsarestabilizedandstoppedbeforedoinganyother

operations.

1 Bale 2 Sideroller

Page20/30

Balewrapper|Usermanual August2022

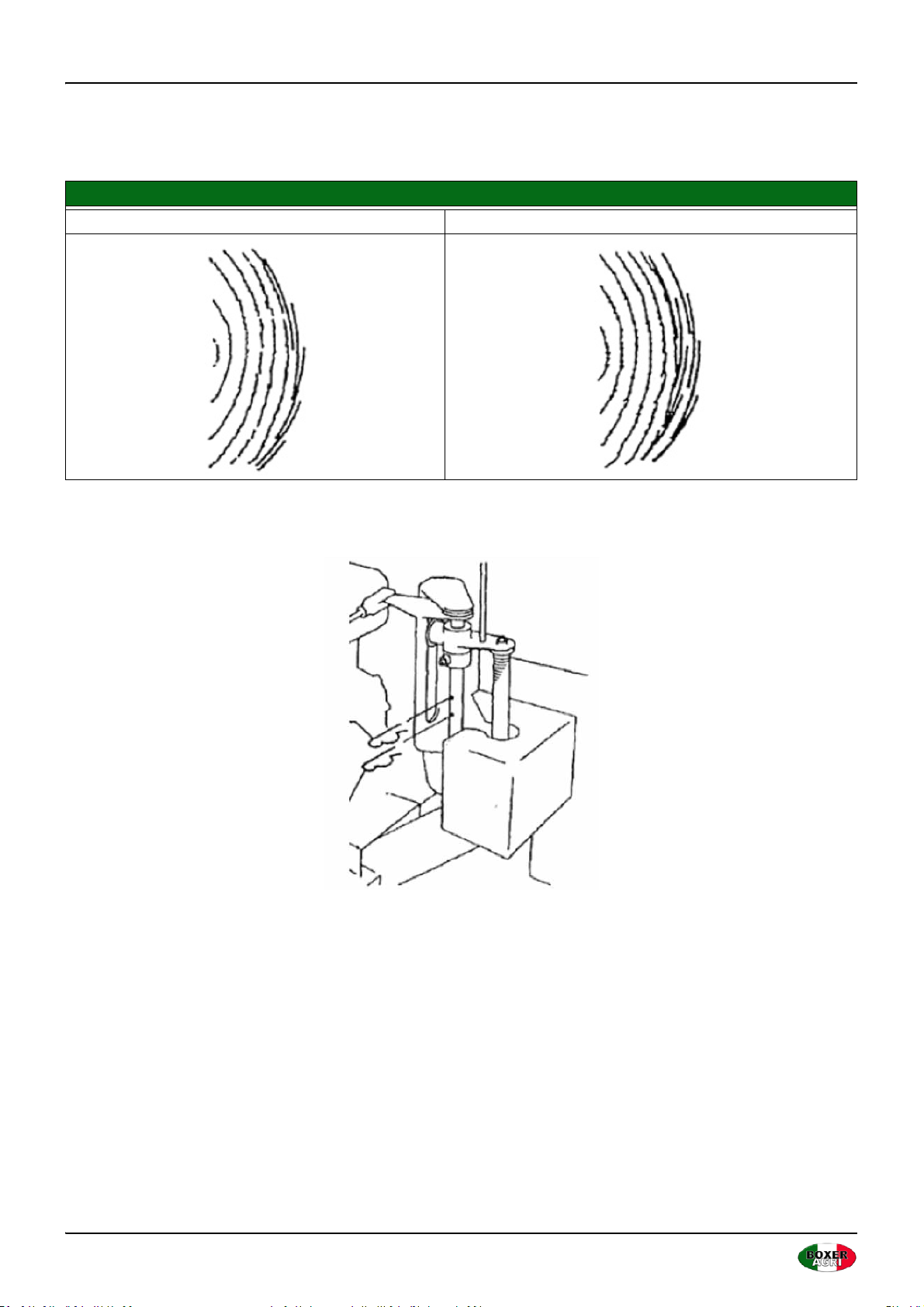

Numberofturnsofthefoil

Adjustthenumberofturnsofthefoil,dependingonthesituation.Topreservethesilageofthebaleforalongperiod

oftimewithgoodquality,windthefoilwithfourormorelayers.

Foilwindingadjustment

Thefoilwindingcanbeadjustedtotwolayersorfourlayerswith50%overlap.

Toadjust(Fortwolayerswith50%overlap)

1. Insertthepinintotheupperholeofthesliderarmoftheautostopdevice.

2. Fortwolayerswith50%overlap.Insertthepininthelowerholeofthesliderarmoftheautomaticstopdevice.

Balediameterfrom460to500mm

50%overlaponeturnofthecoil(two‐layercoil) 50%overlaptwoturnsofcoil(four‐layercoil)

Table of contents

Popular Farm Equipment manuals by other brands

Schaffert

Schaffert Rebounder Mounting instructions

Stocks AG

Stocks AG Fan Jet Pro Plus 65 Original Operating Manual and parts list

Cumberland

Cumberland Integra Feed-Link Installation and operation manual

BROWN

BROWN BDHP-1250 Owner's/operator's manual

Molon

Molon BCS operating instructions

Vaderstad

Vaderstad Rapid Series instructions