B+B Sensors N321 User manual

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

DescriptionDescription

Content

Foreword 02

General Information 02

Symbols Employed 03

Warning Signs 03

Safety Instructions 04

Intended Use 04

Disposal 04

1. Product Description 05

1.1. Scope of delivery 04

1.2. Variations 04

1.3. Identication 04

1.4. Description of the buttons on the front of the Controller 05

1.5. Terminals 05

2. Operations 05

2.1. Level 1 - Setpoint Adjustment 06

2.2. Level 2 - Conguration - Parameters conguration Level 06

2.3. Level 3 - Calibration level 07

3. Working with the controller 07

3.1. Conguration Protection 07

3.2. Conguration Protection Usage 08

3.3. The Master-Password 08

4. Error messages 08

5. Electrical wiring 08

6. Technical data 09

Questions 09

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

1 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

Foreword

Dear customer,

We thank you for having purchased the controller N321 and we are very glad that you decided to buy a product of

B+B Thermo-Technik GmbH. We hope this product will fully satisfy you and will assist you effectively in your work.

This Device has been developed to be technically highly up-to-date and has been designed in accordance with the regnant European and

German national directives and rules. For a proper and effective usage of the product the customer shall observe the following Operating

Instructions. In the case that against one’s expectations any trouble occurs which you can not resolve yourself, please contact our service

centers or our authorized dealer. We will provide you rapid and competent help to minimize the risk of long time outfalls.

The following operating Instruction is an indispensable part of this Product. It contains important advices for the starting up and further use of

the device.

General information

This Operation Manual is intended to serve as an aid in the proper setup, installation and operating of the B+B product.

All essential details of the equipment and all actions required on the part are clearly presented and explained. We thus ask that you read

this manual carefully before proceeding to work with the equipment. Keep this manual available for ready reference in a convenient and

conspicuous location near the equipment.

Symbols employed

Sign Meaning Notice

Advice It is necessary to read the following advices before using the product. The used symbols in the manual

acts rst of all as eye catcher for security risks. The symbols do not replace the security advices. The text

must be read completely.

Necessarily to

observe

This symbol designates important advices and tips which are necessary for the success of a procedure.

They have to be followed in order to get good results.

Warning signs

Sign Meaning

This symbol advises the user of danger for persons, material or environment. The text gives information

that must be necessarily followed to avoid any risks

Caution against hot surfaces (BGV A8, GUV-V A8/W26) and hot liquids or substances

Caution against liquids and hot substances

Caution against dangerous explosive substances (BGV A8, GUV-V A8/W02)

Caution against moving maschines (W29)

Caution against moving parts

Caution against electromagnetic elds (BGV A8, GUV-V A8/W12)

Caution against severe cold (BGV A8, GUV-V A8/W17ice

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

2 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

Caution against dangerous high electrical voltage (BGV A8, GUV-V A8/W08)

Caution against dangerous explosive atmosphere (BGV A8, GUV-V A8/W21)

Electronic waste

Safety instructions

For damages caused by failure to observe these safety and operating instructions, takes over the B + B Thermo-Technik GmbH is not liable.

This device has been designed and tested in accordance to the safety regulations for electronic devices.

However, its trouble-free operation and reliability cannot be guaranteed unless the standard safety measures and special safety advises

given in this manual will be adhered to when using it.

Trouble-free operation and reliability of the device can only be guaranteed if it is not subjected to any other climatic conditions than those

stated under “Specication”.

If the device is transported from a cold to a warm environment condensation may result in a failure of the function. In such a case make sure

the device temperature has adjusted to the ambient temperature before trying a new start-up.

If device is to be connected to other devices the circuitry has to be designed most carefully. Internal connection in third party devices (e.g.

connection GND and earth) may result in not-permissible voltages impairing or destroying the device or another device connected.

Warning:

Only devices with mains input: If device is operated with a defective mains power supply (e.g. short circuit from mains voltage to output volt-

age) this may result in hazardous voltages at the device (e.g. at sensor socket) .

If there is a risk whatsoever involved in running it, the device has to be switched off immediately and to be marked accordingly to avoid re-

starting. Operator safety may be at risk if:

●there is visible damage to the device

●the device is not working as specied

●the device has been stored under unsuitable conditions for a longer time

In case of doubt, please return device to manufacturer for repair or maintenance.

Caution:

Do not use these product as safety or emergency stop devices, or in any other application where failure of the product could result in per-

sonal injury or material damage. Failure to comply with these instructions could result in death or serious injury and material damage.

Intended Use

The use of the unit in elds other than those indicated under “SAFETY INSTRUCTIONS” is not allowed for safety reasons.

This instruction manual does not at all substitute any additional instruction manual of connected accessoriy!

Disposal

This unit has been marked in accordance with the European Device 2002/96/EC on waste electrical and electronic equipment (WEEE)

At the end of its operating life-time, dispose of the unit as electrical scrap.

Please ask either B+B Thermo-Technik GmbH or your specialist dealer for information on your local collection point.

Within the scope of application of this Directive, B+B Thermo-Technik GmbH is responsible for proper disposal of this unit.

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

3 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

1. Product description

The Controller N321 is a temperature controller to measure, display and control of temperature. It can be used various types of

sensors: Pt1000, Pt100, NTC and thermocouples type K, J and T. The controller can be easily programmed for the application

by the user. (cooling or heating). The internal 10 A relay can be used to control of refrigeration compressors or heaters with on /

off function. An offset correction of the sensor is provided. The output can be used as control or alarm. The characteristics of the

model (sensor-type, sensor-range, power, etc.) can be found on the label located on the controller housing.

2. Scope of delivery

Articlename Articleno. Description

Controller N321 0556 0108 xxx 1 x Controller N321, 1x User Manual

1.2. Variations

Articlename Articleno.

Controller N321 for Pt1000 0556 0108

Controller N321 for NTC 10K incl. Probe (-50 to +120°C)* 0556 0108-01

Controller N321 for Pt100 0556 0108-02

Controller N321 for Thermoelement J, K und T 0556 0108-03

Controller N321 2 x NTC 10K incl. Probe (-50 to +120°C)* 0556 0108-04

1.3. Identication

The rating plate is located on the housing of the data logger. Verify that the properties described the same as your job.

The following controls can be found on the front page of the data logger.

Programming keys

Display

Messages

*0556 0108-01 and 0556 0108-04 incl. NTC 10K Probe

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

4 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

1.4. Description of the buttons on the front of the Controller

1.5. Terminals

The gure below shows the controller connections to sensor, main and outputs.

Pt100 with 3 conductors: Terminals 11, 12 and 13 must have the same wire resistance for proper cable length compensation.

For 2 wire Pt100, short circuit terminals 12 and 13.

2. Operations

The controller requires the internal parameters to be congured according to the intended use for the instrument.

The parameters are organized in 4 groups or levels:

Level Function

0 Temperature measurement

1 Setpoint adjustment

2Conguration

3 Calibration

Upon power-up, the N321 display shows for 1 second its rmware version. This information is useful when consulting the

factory. Then, the temperature measured by the sensor is shown on the display. This is the parameter level 0 (temperature

measurement level).

To access level 1, press for 1 second until the “SP1” message shows up. Pressing again to go back to level 0.

To access level 2 of paramenters, press for 2 seconds until the “uNT” message is shown. Release the key to

remain in this level. Each new pressing on the key will advance to the next parameter in the level. At the end of the level,

the controller returns to the rst level (0). Use the and keys to alter a parameter value.

Notes:

1. A parameter conguration is saved when the key is pressed to advance to the next parameter in the cycle.

The conguration is stored in a non-volatile memory, retaining its value when the controller is de-energized.

2. If no programm key is detected for over 20 seconds, the controller saves the current parameter value and returns to the

measurement level.

Programm-key (P)

Back-key (R)

Up-key

Down-key

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

5 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

2.1. Level 1 - Setpoint Adjustment

In this level only the Setpoint (SP) parameter is available, alternating the name with its respective value. Adjust the desired

temperature for setpoint by clicking on the and keys.

Level Function

SP (Set Point) Temperature adjustment for control OUTPUT 1. SP value is limited to the values programmed in SPL and SPk in the

programming level (Parameter conguration, level 2).

2.2. Level 2 - Conguration - Parameters conguration Level

Contains the conguration parameters to be dened by the user, according to the system’s requirements.

Use and keys to set the value. The display alternates the parameter name and respective value.

Level Function

Unt Temperature Unit: Selects display indication for degrees Celsius or Fahrenheit.

0- Temperature in degrees Celsius

1- Temperature in degrees Fahrenheit

typ Input Type: Selects the input sensor type to be connected to the controller. Available only for thermocouple models, al-

lowing selection of types J, K and T.

0- Thermocouple type J

1- Thermocouple type K

2- Thermocouple type T

ofs Sensor Offset: Offset value to be added to the measured temperature to compensate sensor error.

spl SP Low Limit: Lower range for SP. spl must be programmed with a lower value than SPH.

SPH SP High Limit: Upper range for SP. SPH must be greater than SPL.

Hy1 OUTPUT 1 Hysteresis: Denes the differential range between the temperature value at which the

OUTPUT 1 is turned on and the value at which it is turned off. (In degrees).

Ac1 Control action for OUTPUT 1:

0 - Reverse: For heating applications. Outputs turn on when temperature is lower than SP.

1- Direct: For cooling applications. Output turns on when temperature is above SP.

of1 (Off time) Off time: Denes the minimum off time for control OUTPUT 1. Once OUTPUT 1 is turned off, it remains so for at least the

time programmed in oft. For thermocouple inputs this parameter is not available. This parameter is intended for refrigera-

tion systems where longer compressor life is desired. For heating systems, program of1 to zero. Value in seconds, 0 to

999 s.

on1 (On time) On time: Denes the minimum on time for control OUTPUT 1. Once turned on, OUTPUT 1 remains so for at least

the time programmed in on1. For thermocouple inputs this parameter is not available. This parameter is intended for

refrigeration systems where increased compressor life is desired. For heating systems, program on1 to zero. Value in

seconds, 0 to 999 s.

dl1 (Delay 1) Delay time to start control: Upon power-on, control OUTPUT 1 is kept off until the time programmed in

dl1 is elapsed. Its usage is intended to prevent multiple compressors to start simultaneouly after the

turn-on of a system with several controllers. Value in seconds, 0 to 250 s.

Add (Adress) Adress: Controllers with the optional RS485 Modbus RTU communication interface have the Add parameter at the

Conguration level. Set a unique Modbus address for each equipment connected to the network. Address range is from 1

to 247.

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

6 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

2.3. Level 3 - Calibration Level

The controller is factory calibrated. The following parameters should be accessed only by experienced personnel.

To enter this cycle, the key must be kept pressed for 4 seconds.

Don’t press the and keys if you are not sure of the calibration procedures. Just press the key a few times until the

temperature measurement level is reached again.

Level Function

PAS Password: Enter the correct password to unlock write operations for the parameters in the following levels.

CAL Calibration low: Offset value of the input. It adjusts the lower measurement range of the sensor.

CAH Calibration High: Gain calibration. It adjusts the upper measurement range of the sensor.

CJL Cold Junction Offset calibration: This parameter is available only for thermocouple.

FAC Factory Calibration: Restores factory calibration parameters. Change from 0 to 1 to restore the calibration param-

eters with factory values.

Prt Protection: Denes the levels of parameters that will be password protected. See „Conguration

Protection“ for details.

PAC Password Change: Allows changing the current password to a new one. Values from 1 to 999 are allowed.

Sn2 Serial number: First part of the controller electronic serial number.

Sn1 Serial number: Second part of the controller electronic serial number.

Sn0 Serial number: Third part of the controller electronic serial number.

3. Working with the Controller

The Controller N321 energizes the output relay such as to maintain the process temperature on the setpoint value

dened by the user. The output status led P1 signals when the control output is on.

3.1. Conguration Protection

A protection system to avoid unwanted changes to the controller parameters is implemented. The level of protection can be

selected from partial to full. The following parameters are part of the protection system:

Pas: When this parameter is presented, the correct password should be entered to allow changes of parameters in the

following levels.

Prt: Denes the level of parameters that will be password protected:

1. Only calibration level is protected (factory conguration);

2. Calibration and Conguration levels are protected;

3. All levels are protected: Calibration, conguration and setpoints.

PAC: Parameter to dene a new password. The password is located in the calibration level, and can only be changed by

a user that knows the current password. Valid passwords are in the range 1 to 999.

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

7 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

3.2. Conguration Protection Usage

PAS -parameter:

PAS -parameter is displayed before entering a protected level. If the correct password is entered, parameters in all following

levels can be changed. If a wrong or no password is entered, parameters in the following levels will be read only.

Important notes:

1. After ve consecutive attempts to enter a wrong password, new tentative will be blocked for the next 10 minutes.

If the current valid password is unknown, the master password can be used only to dene a new password for the controller.

2. The password for a brand new device is 111.

3.3. Master-Password

The master password allows user to dene a new password for the controller, even if the current password is unknown. The

master password is based on the serial number of the controller, and calculated as following:

[ 1 ] + [ higher digit of SN2 ] + [ higher digit of SN1 ] + [ higher digit of SN0 ]

for example the master password for the device with serial number 987123465 is: 1 9 3 6

as follows: 1 + sn2 = 987; sn1 = 123; sn0 = 465 = 1 + 9 + 3 + 6

How to use the master password:

1. Enter the master password value at „PaS“ prompt.

2. Go to PA( parameter and enter the new password, which must not be zero (0).

3. Now you can use this new password to access all controller parameters with modify rights.

4. Error Messages

Sensor measurement errors force the controller outputs to be turned off. The cause for these errors may have origin in

a bad connection, sensor defect (cable or element) or system temperature outside the sensor working range. The

display signs related to measurement errors are shown below:

5. Electrical Wiring

It is important to follow the recommendations below:

• Signal wires should be installed in grounded conduits and away from power or contactor wires.

• The instrument should have its own power supply wires that should not be shared with electrical motors,

coils, contactors, etc.

• Installing RC lters (47 R and 100 nF, series combination) is strongly recommended at contactor coils or any

other inductors.

• System failure should always be taken into account when designing a control panel to avoid irreversible damage

to equipment or people.

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

8 / 9

OPERATION MANUAL

Technical changes reserved

0141 0315-150 29.06.2016

Controller N321

6. Technical Data

Properties Values

Input Sensor Thermocouples J, K, T, Pt100, Pt1000 and NTC

Note: In the controller with NTC input, a 3 m sensor-cable is bundled with the

controller. The cable can be extended up to 200 m

Measuring range J 0 to 600°C (32 to 1400°F)

K -50 to 1000°C (-58 to 1832°F)

T -50 to 400°C (-58 to 752°F)

Pt100 -50 to 300°C (-58 to 572°F)

Pt1000 -200 to 530°C (-328 to 986°F)

Accuracy Thermocouples J, K and T: ±3°C (±5.4°F)

Pt100: ±0,7°C (±1,3°F)

Pt1000: ±0,7°C (±1,3°F)

Resolution from -19.9 to 199.9°C display units with NTC, Pt100 and Pt1000 = 0.1

from -19.9 to 199.9°C display units with Thermocouples = 1

Output 1 Relay SPDT, 1 HP 250 V AC / 1/3 HP 125 V AC (16 A Resistive)

Power supply 100 - 240 V AC (± 10%) or 24 V AC/DC

Mains frequency: 50-60 Hz, Power consumption: 5 VA

Caution: Check the power supply specication before energizing the controller

Environment Operating temperature: 0 to 40°C (32 to 122°F)

Storage temperature: -20 to 60°C (-4 to 140°F)

Relative humidity: 20 to 85%, non condensing

Case Polycarbonate UL94, V-2, Suitable wiring: up to 4,0 mm2

Ingress Protection Front panel: IP65, Box IP42

Dimensions 74 x 32 x 75 mm

Warm-Up 15 minutes

CE-Conformance EN 61326-1 according to 2014/30/EU

RS485 digital communication; RTU MODBUS protocol (optional)

Serial interface not isolated from input circuitry.

Serial interface isolated from input circuitry, except in 24 V powered model

Questions

If you still have questions concerning this product of B+B Thermo-Technik GmbH, please do not hesitate to

contact us at:

B+B Thermo-Technik GmbH Tel.: +49 771 83160

Heinrich-Hertz-Straße 4 Fax: +49 771 831650

Germany www.bb-sensors.com

We wish you a successful measuring!

Your Temperature-Partner

B+B Thermo-Technik GmbH

All technical information in this document are proved by us with high accuracy and shall inform you about all application possibilities. This information are not

conrmed by us and need to be proved by every user in regard to his intended use of the equipment. All foreign trade mark rights need to be considered.

B+B Thermo-Technik GmbH | Heinrich-Hertz-Str. 4 | D-78166 Donaueschingen

9 / 9

Table of contents

Other B+B Sensors Controllers manuals

Popular Controllers manuals by other brands

Mitsubishi Electric

Mitsubishi Electric MELSEC iQ-F FX5 installation manual

TSUJI ELECTRONICS

TSUJI ELECTRONICS PM16C-16HW2 user manual

Woodward

Woodward LS-5 v2 Series Technical manual

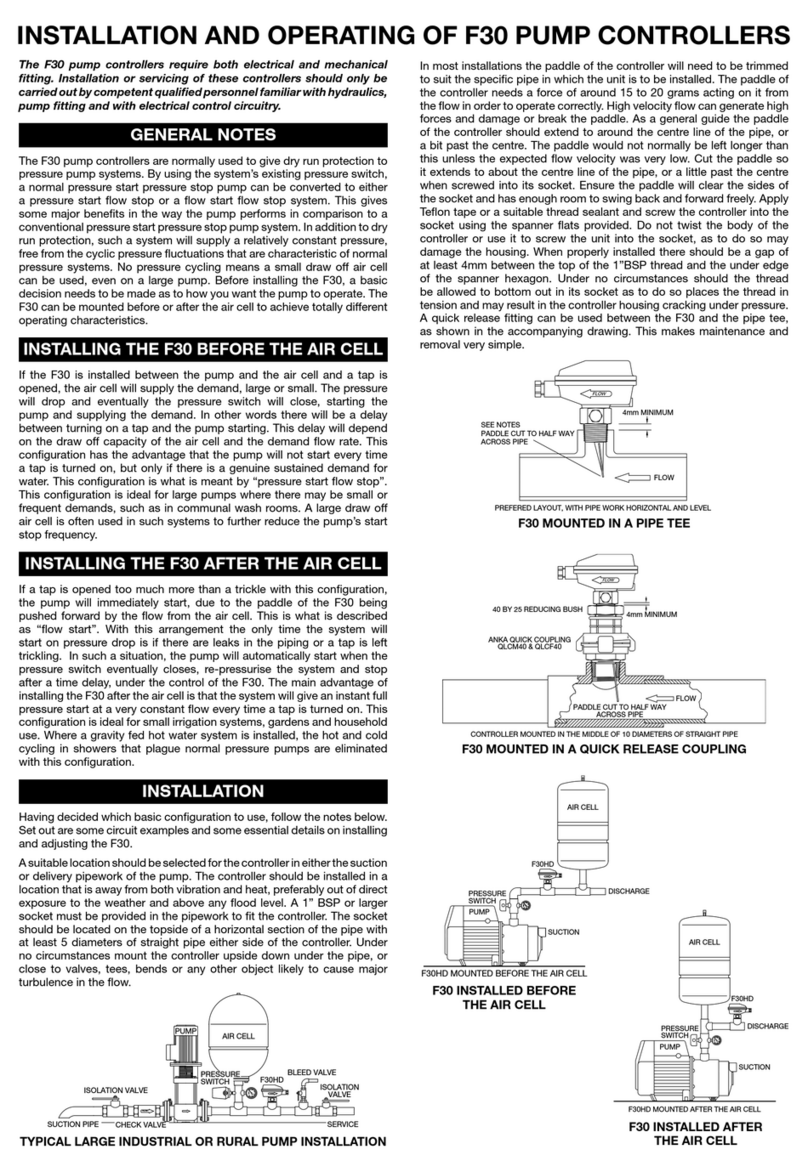

KELCO

KELCO F30 Installation and operating

Broadcom

Broadcom MegaRAID SAS 9380-8i8e Quick installation guide

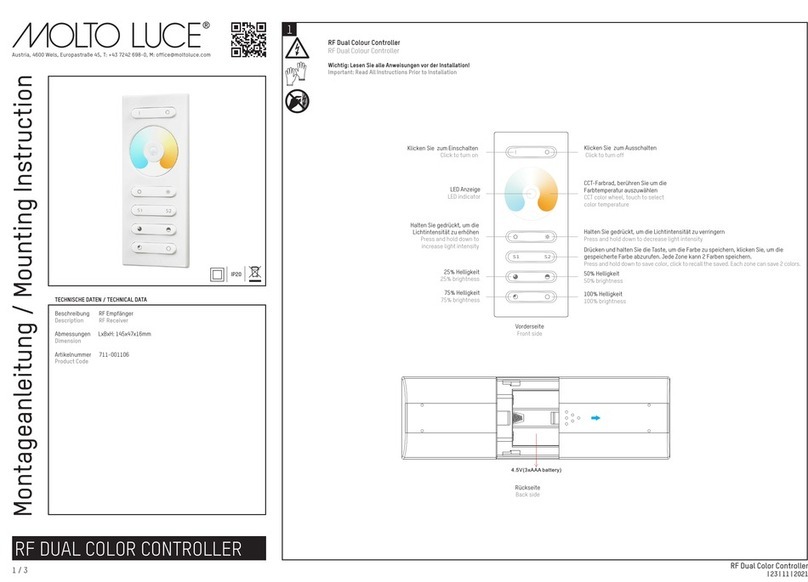

MOLTO LUCE

MOLTO LUCE 711-001106 Mounting instruction