2

Express® Lavatory System SS-Series

SS-3/BIR/STD, SS-3/BIR/JUV Installation Instructions - For Service Only

5/11/04 Bradley Corporation • 215-1461 Rev. A; EN 03-813

Pre-Installation Information

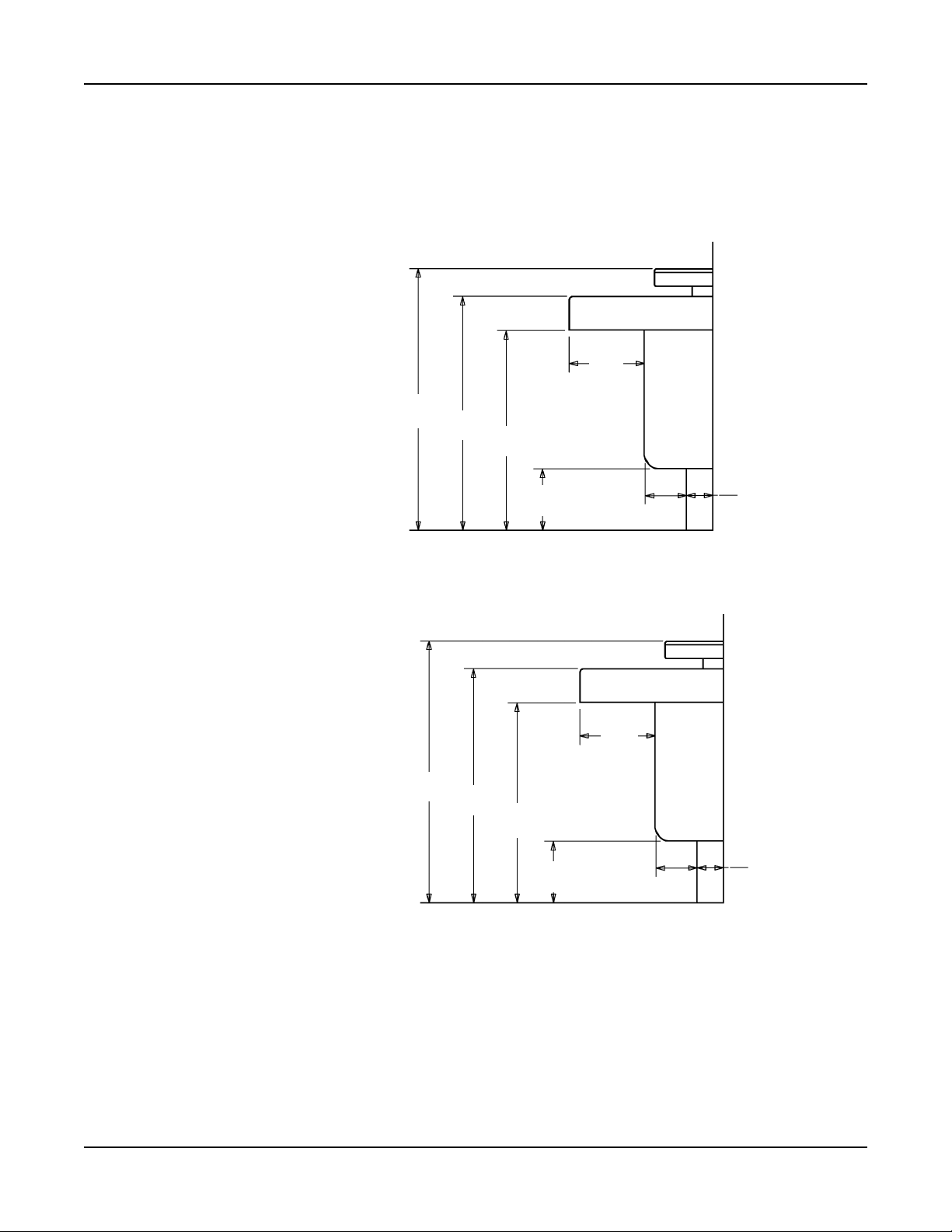

Barrier-free and ADA compliant - standard height mounting

The SS-3/BIR/STD Express® Lavatory System must have a rim height of 34" above finished

floor to be compliant with Americans with Disabilities Act (ADA). When mounted at 34" rim

height, the Express® meets ADA, ANSI and UFAS requirements for barrier-free clearances,

reaches and controls. Always check local codes and ordinances for compliance.

Barrier-free and ADA compliant - juvenile height mounting

The SS-3/BIR/JUV Express® Lavatory System is compliant with Americans with Disabilities Act

(ADA) Accessibility Guidelines for Buildings and Facilities: Building Elements Designed for

Children's Use; Final Rule.

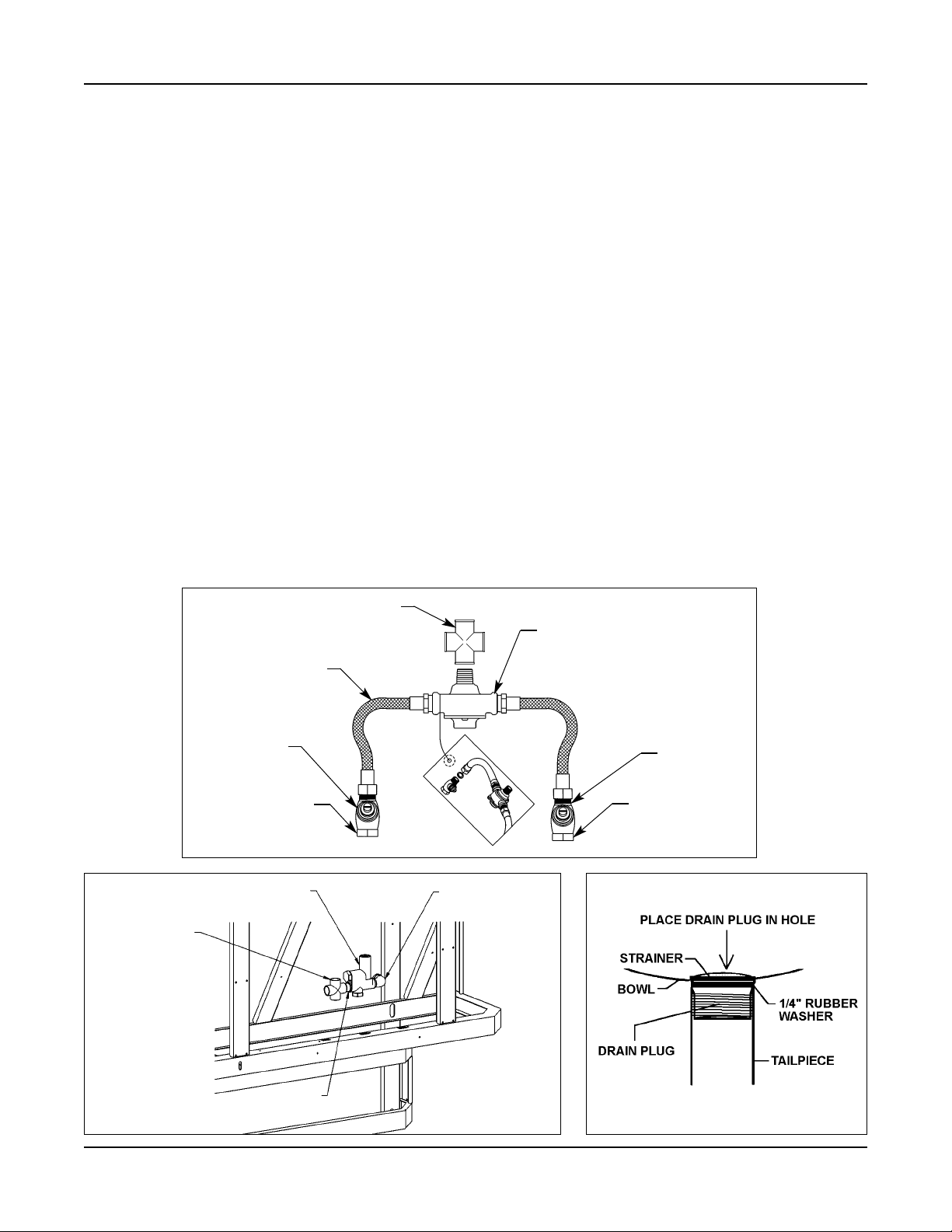

Infrared sensor and battery box

Each sprayhead is controlled by a separate sensor and and single-operation control box, enabling

each user to activate a single flow of water. Each valve uses less than half the maximum of hot

water allowed by the ANSI/ASHRAE/IESNA 90.1-1989-Standard.

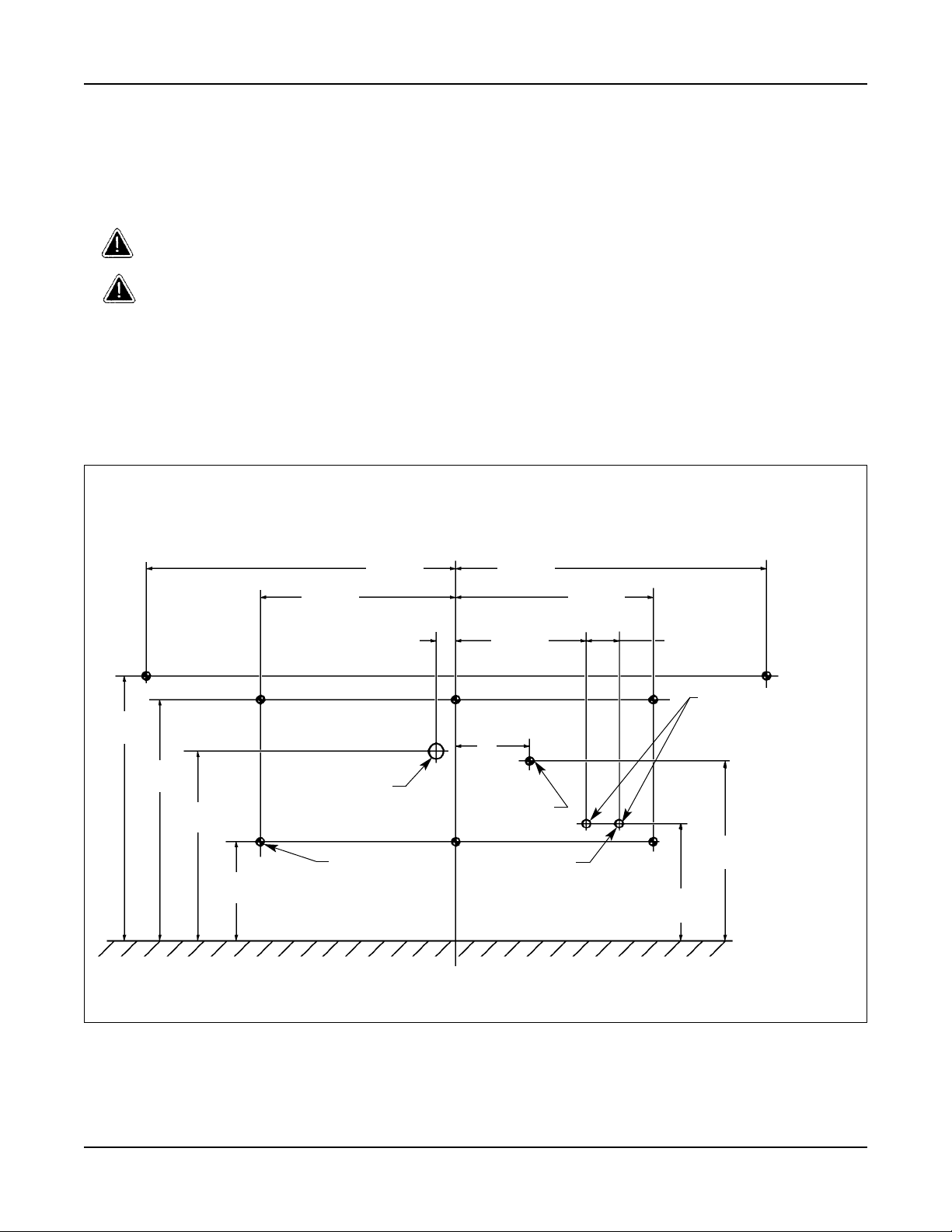

Supplies required for installation:

• (8) 3/8" wall anchors, bolts and washers to mount frame and bowl to wall

(minimum pull-out rating of 1,000 lbs.)

• 1/2" NPT tempered supply piping

• 1-1/2" NPT drain piping

• (18) “AA” alkaline batteries

• (1) 1/4" wall anchor, bolt and washer to mount center battery box to wall