Metso Nordberg MP Series Product manual

Nordberg MP Series Cone Crusher

This Technical Reference Manual provides guidance to first time operators of the Crusher as well as

providing technical procedures as a reference for the experienced crusher operator. Read — study — and

keep for future reference.

Illustrations and instructions guide the operator through correct procedures for checking, installing,

operating and maintaining the Crusher and accessories. Separate instruction manual supplements for the

lubrication system, hydraulics and crusher drive are now included in the MP Cone Crusher Technical

Reference Manual.

Operating techniques outlined in the book are basic. Operating skills and additional techniques will

develop as the operator gains knowledge of the Crusher and its capabilities.

Continuing improvement and advancement of product design may result in changes to your new machine

which may not be included in this publication, however each publication is reviewed and revised, as

required, to up-date and include appropriate changes in the later editions.

The description and specifications in this manual were in effect at the time this manual was approved for

printing. Metso Minerals reserves the right to discontinue models at any time and to change specifications

or design, without notice and without incurring obligation.

Whenever a question arises regarding your Crusher, or this publication, please consult your Metso

Minerals representative for the latest available information.

This manual is to be used as a general guide concerning technical information. All technical information

required for correct installation of your crusher must be obtained from the installation drawings and

technical data furnished for your particular Crusher.

MP®, Nordberg® and Metso Minerals® are registered trademarks of Metso Corporation.

SAFETY

Basic rules regarding safety in and around a crushing plant are outlined in Section 0,

entitled Safety of the main cone crusher instruction manual.

Operator safety and the safety of others depends upon reasonable care and judgement

in the operation of this Crusher. A careful operator is good insurance against an

accident.

Most accidents, no matter where they occur, are caused by failure to observe and

follow simple fundamental rules or precautions. For this reason most accidents can be

prevented by recognizing hazards and taking steps to avoid them before an accident

occurs.

Regardless of the care used in the design and construction of this type of equipment,

there are conditions that cannot be completely safeguarded against without interfering

with reasonable accessibility and efficient operation. Warnings are included in this

instructional manual to highlight these conditions.

FOREWORD

Table of Contents

Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 0

General Crusher Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 1

General Installation Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 2

M. Frame, Adj. Ring, Tramp Rel. & Clrng Jack Assy . . . . . . . . . . . . . . . . . . . . . . . . . Section 3

Countershaft, Ctrshaft Box & Sheave Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 4

Eccentric Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 5

Socket Assembly. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 6

Head, Mantle and Feed Plate Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 7

Bowl, Bowl Liner and Hopper Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 8

This Section Intentionally Left Blank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 9

Lubricating System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 10

Operating Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 11

Hydraulic Systems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section 12

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Section I

The lubrication, hydraulic and drive supplements are now integrated in this Technical Reference manual.

Section 0

Safety

0.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-1

0.1.1 General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-1

0.1.2 Definitions: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-2

0.2 General Safety Instructions for a Crushing Plant or Plant Environment . . . . . . . . . . . . . . . . 0-3

0.2.1 Safe Products and the Crushing Plant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-3

0.2.2 Safety and You . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-3

0.2.3 Typical Risks in Crushing Plant Working Environment. . . . . . . . . . . . . . . . . . . . . . . . . . 0-7

0.2.4 Personal Protective Equipment and Clothing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-19

0.3 Machine Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-22

0.3.1 Protective Devices and Accessories for Machine Safety . . . . . . . . . . . . . . . . . . . . . . . . 0-22

0.3.2 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-25

0.3.3 Towing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-25

0.3.4 At the work-site . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-25

0.4 Safety During Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-26

0.4.1 General Information and Safety Lockouts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-26

0.4.2 Mechanical Safety During Maintenance and Repair. . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-27

0.4.3 Electrical Safety During Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-29

0.4.4 Hydraulic Safety During Maintenance and Repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-30

0.4.5 General Maintenance Work . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-31

0.5 Safety Plates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-33

0.5.1 Safety Plates — ANSI. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-33

0.5.2 Safety Plates — EN . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0-43

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL 0-1

Safety SECTION 0

0.1 INTRODUCTION

0.1.1 General

This manual, together with specific instruction

manuals for individual equipment, has been

prepared by Metso Minerals to increase the

knowledge and awareness of all persons involved

in the operation, supervision, service and

maintenance of crushing and screening equipment

with regard to safety and operations. A copy of this

manual must be provided to and studied by each

person entering the machine areas of the Crushing

Plant, or otherwise involved in the operation of the

Crushing Plant. It is the responsibility of the Owner

to always keep this manual and other written

instructions either in the Crushing Plant or its

vicinity for Operator reference.

Knowledge of the machines and the potential

hazards they present are essential to a safe

workplace. Knowledge of and compliance with all

state, provincial, and federal safety laws, safety

regulations, and Crushing Plant safety procedures,

warnings and instructions also are essential to a

safe workplace. Failure to do so can result in

serious injury or death.

When in doubt — don’t! Never bypass instructions

or procedures to save time. Never place foreign

items, tools, rods, or any part of your body into an

operating machine. Never reach over, around or

beyond safety devices. Never operate a machine if

safety devices are missing or disabled. Never

replace an OEM safety device with a non-OEM

device.

Never service equipment until all potentially

moving parts are secured and power has been

locked out and tagged out to prevent unexpected

movement.

The Operator is responsible for using care and

common sense at all times.

Remember, safety is everyone’s business. You are

responsible not only for your safety, but for the

safety of those around you.

Read this manual carefully. Know its contents. If

you have any questions, contact your Metso

Minerals representative without delay for advice.

Keep in mind that there are different types of risks,

hazards and injury types (see Section 0.2.3 Typical

Risks in Crushing Plant Working Environment),

which are related to each other. Foresee and prevent

such risks and hazards as well as resulting injuries

and other consequences from occurring by all

available means. Never compromise when the

question is safety!

Metso Minerals, as the machinery manufacturer

and supplier, regards safety as of utmost

importance, and deems the following as essential

prerequisites to the safe operation of the Crushing

Plant:

– That the Owner makes available this

manual, before using the machinery, to

each person involved with the operation,

supervision, service, or maintenance of the

Crushing Plant.

– That compliance with and adherence to

this manual be mandated and supervised

by the Owner.

– That all personnel involved in the

operation, supervision, service, or

maintenance of the Crushing Plant

become familiar with the contents of this

manual prior to such involvement.

– That every person involved in the

operation, supervision, service, or

maintenance of the Crushing Plant be

properly trained and have adequate

professional skills as required for the

performance of the respective tasks.

SECTION 0 - SAFETY

0-2 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

– That all visitors to the Crushing Plant be

properly informed of applicable safety

precautions and risks, and that safety

precautions be adequately maintained and

in connection with any such visits,

including, but not limited to, adherence to

this manual.

No changes shall be made in the operation of the

machinery supplied by Metso Minerals or the

contents of this manual without express written

approval of Metso Minerals. All operation, service,

maintenance, handling, modifications, or other use

of Crushing Plant equipment and/or systems is the

responsibility of the Owner. Metso Minerals shall

not be liable for any injury, death, damage or cost

caused by any act or omission on the part of the

Owner, Operator or other personnel, agents,

contractors, vendors, or others. All applicable

safety rules, regulations, standards, instructions,

and procedures must be followed; as must be those

of this manual as well as any other instructions,

specifications, and recommendations by Metso

Minerals.

This manual is based upon the safety laws, rules

and regulations in effect on the date hereof. The

owner and operator bear sole responsibility for

complying with any amendments, additions or

other changes to safety law, rules or regulations

arising subsequent to the date on which this manual

was drafted.

Although these instructions are intended to be as

comprehensive as possible, there may be hazards

that cannot be anticipated, hazards associated with

a particular work-site or hazards covered by special

company safety programs. The information

contained in this manual is not intended to replace

safety codes, insurance requirements, federal, state

and local laws, rules and regulations.

If you have questions or concerns regarding safety

aspects of machinery supplied by Metso Minerals,

contact us before using, operating, servicing or

repairing the machinery.

0.1.2 Definitions:

“Crushing Plant” means a combination or part of

various equipment, components, systems and parts

for crushing and/or screening of rock, minerals,

recycling or other crushable materials. For the

purposes of this manual, the Crushing Plant also

means stand-alone crushing or screening equipment

as applicable. Throughout this manual, words such

as “machine”, “machinery”, “equipment” and

“crusher” are used interchangeably to refer to the

Crushing Plant and its component parts.

“Owner” means the entities or individuals who

own or lease the Crushing Plant and/or the entities

or individuals who are in charge of operating and/or

servicing the Crushing Plant.

“Operator” means the individuals who either

operate the Crushing Plant or perform actual

maintenance, service, repairs, supervision or any

other activity on or for it.

“This manual” means, as applicable, these general

safety instructions, together with any specific

instructions for individual equipment, as amended

from time to time, provided by or on behalf of

Metso Minerals.

NOTICE

Safe operation of the machine requires

alertness and safety-consciousness on the

part of all operating personnel. It should be

operated only by knowledgeable and trained

personnel.

SECTION 0 - SAFETY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL 0-3

0.2 GENERAL SAFETY INSTRUCTIONS

FOR A CRUSHING PLANT OR PLANT

ENVIRONMENT

0.2.1 Safe Products and the Crushing Plant

All machines require human involvement. Like any

other heavy machinery, a Crushing Plant has

inherent dangers that must be identified,

understood and taken into account in order to avoid

accidents and injuries. Metso Minerals, as

machinery manufacturer and supplier, is committed

to promoting safety at the Crushing Plant by

providing safety devices and features, and by

providing training, services, manuals and

instructions.

0.2.2 Safety and You

Safety is everyone’s responsibility; safety is your

responsibility.

Safety is the concern of all personnel. With your

actions, you participate in establishing the safety of

the working environment.

Metso Minerals products are designed and

constructed with safety in mind. The machines

incorporate high quality safety features.

To assure safe operation, all personnel must be alert

when operating or working on or around the

machine. Be aware of real and potential hazards.

Only properly trained personnel should operate,

supervise, maintain, or service the machine.

Personnel must carefully study all aspects of the

specific machine, including:

– operating instructions

– service, trouble-shooting and maintenance

instructions

– automated features and motions of the

machine

– specific safety features and instructions

0.2.2.1 Objective

The objective of these instructions is to minimize

risks and to avoid or prevent accidents and injuries.

Accidents are often caused by carelessness or

disregard of important instructions.

Knowledge of the machine operation and

continuous safety training are necessary for a safe

working environment.

Safety can be summarized in three main themes:

– MACHINE KNOWLEDGE

– SAFE OPERATION AND

MAINTENANCE

– GOOD HOUSEKEEPING

NOTICE

• If unsure of any procedure, check the

operation manuals and/or contact your

supervisor before proceeding.

• Follow all lockout and safety procedures

before entering the machine.

• Be constantly aware of the location of

each worker on or around the machine.

• Observe all safety instructions.

• Do not remove or disable any guard,

safety device, sign or warning.

• Report any item that needs attention,

repair, replacement, or adjustment.

SECTION 0 - SAFETY

0-4 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

0.2.2.2 Safety Signs, Labels And Symbols

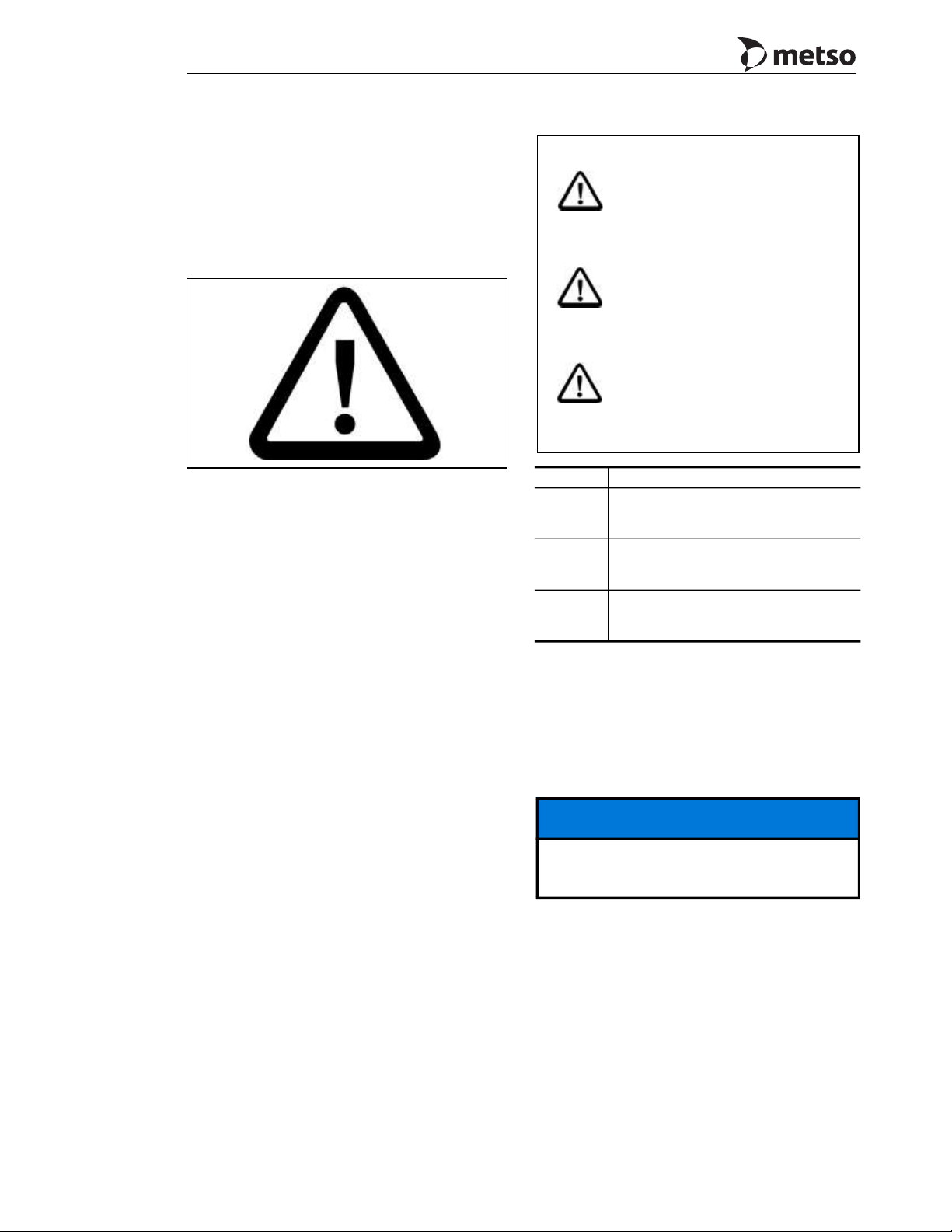

The following symbol is used in this manual and on

the machine to call attention to instructions which

will help prevent machine related injuries.

When you see this symbol on your machine or in

this manual, be alert to the potential for personal

injury.

Figure 0-1 Alert Symbol

This manual uses the alert symbol, with words such

as DANGER, WARNING or CAUTION, to alert

you and other Crushing Plant personnel of actions

or conditions that pose a potential safety hazard,

with an attending risk of personal injury (including

death) or property damage. The machine also

displays safety signs, labels and tags at appropriate

points to show safety risks that may exist.

Figure 0-2 Danger, Warning, Caution Signs and

their Meaning

This manual uses another convention to

communicate information which, if not followed,

will affect the performance of the equipment or

cause damage to the equipment. This is indicated

by the word NOTICE!

Figure 0-3 Important notice and its meaning

While such conditions and practices do not pose an

immediate threat of personal injury, the damage

that occurs over time can be hazardous.

Sign Description

DANGER

Immediate hazards or unsafe practices

that will result in severe personal injury

or death.

WARNING

Hazards or unsafe practices that could

result in severe personal injury or

death.

CAUTION

Hazards or unsafe practices that could

result in minor personal injury or

equipment damage.

NOTICE

Usually communicates information which, if

not followed, will affect the performance of

the equipment or cause damage.

DANGER

CAUTION

WARNING

SECTION 0 - SAFETY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL 0-5

0.2.2.3 Some General Safety Instructions

1. Do not remove, cover or disable any

installed safety devices, guards, warning

signs or tags. They are attached to

equipment to warn personnel of possible

danger and prevent injury. Use OEM

replacements in the event any safety

devices, warning signs or tags become

damaged or unreadable. Observe all

instructions. Keep warnings signs and tags

clean, visible and readable. (Warning signs

are listed and their locations described in the

machine safety instructions.)

2. Make sure that all required walkways,

handrails, barriers, safety devices, and

guards are in place before starting the

machine. Do not use non-OEM walkways,

handrails, barriers, safety devices or guards,

when such items are available from OEM.

3. Keep the machine itself and the area around

the machine clean and clear of obstructions.

Be aware of dust, smoke or fog, which may

obscure your vision.

4. Wipe up any substance, such as spilled oil,

grease, water or ice, which may cause a

person to slip or fall. Good housekeeping

practices prevent injuries. Be a good

housekeeper. Keep the machine environment

and walkways clean and free from oil,

grease, rags, cables, chains, buckets, rocks

and other obstructions. Keep loose parts in a

toolbox or return them there promptly.

5. Keep clothing and all parts of the body away

from nip points and rotating or moving

equipment. Be especially alert to avoid

contact with parts that move intermittently.

6. Know the weight limitations of lifting

devices and their loads. Never detach a

lifting device from a load until the load is

stable and secured from unintended

movement.

7. Do not climb or stand on equipment other

than in areas, which are designed for that

purpose. Do not overreach.

8. Emergency-Stop buttons should be tested on

a regular schedule for proper operation, as

should electrical interlocks and related limit

switches. Safety defects should be repaired

prior to continuing operation, and thereafter

tested and certified for appropriate operation

by skilled personnel.

9. Personal protective equipment and safety

uniforms, safety shoes, helmets, safety

glasses, heavy gloves, ear protection devices

etc. should be used at all times. Safety shoes

should be used by all personnel entering into

the Crushing Plant. Persons with loose

clothing, neck ties, necklaces, unprotected

long beard or long hair should not go near

the machine. Wrist watches and rings can be

dangerous. Rings should be removed or

covered with tape. Keep your pockets free of

loose objects.

10. Keep all non-operating and non-trained

personnel clear of the Crushing Plant at all

times. Injury or death may result if this is

not done.

11. The equipment at the control panel should

be handled with care. Do not place objects

on the keyboard, color display or other

equipment. All equipment can fail if put in

contact with liquids, or excessive heat or

excessive humidity. Allow good air flow

around the equipment at all times. Keep

magnets away from computer components,

particularly hard drives and PLC cabinets.

12. A knowledgeable and properly trained

Operator familiar with this manual, safety

requirements, and automatic operation of the

machine should be stationed at the controls

whenever the machine is operating.

13. Do not consume any alcoholic beverages or

other intoxicants before coming to work or

while on the job. Do not operate the

Crushing Plant after taking any medicines,

tranquilizers or other drugs, which can

impair the senses.

14. Familiarize yourself with the safety signs on

the Crushing Plant. Never remove or

damage any safety signs, nameplates or

other safety related warnings, symbols or

components. Replace them as necessary

with OEM equipment.

15. Do not paint over safety signs, name plates

or warnings.

SECTION 0 - SAFETY

0-6 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

0.2.2.4 Safety Instructions after Start-up

1. After equipment has been started, check all

gauges and instruments to be sure that

everything is operating properly.

2. Shut down immediately if any improper

readings are observed.

3. Test all controls for proper functioning.

4. Listen for and report any unusual noises.

5. Recheck alarms or other warning and safety

devices.

6. Do not take a chance with a defective

machine. Report it to your supervisor.

0.2.2.5 Report a Defective Machine

Inspect your machine daily. Check for loose, worn

or damaged parts. Report or correct any unsafe

conditions immediately, and do not operate the

machine until they have been corrected.

Even a minor defect can become serious. Report

any machine defects to your supervisor.

0.2.2.6 Stopping Safely

Be sure equipment is stopped before:

• cleaning

• servicing

• lubricating

• checking belt tension

• removing housing covers

• working on the hydraulic system

• making repairs

• or attempting to clear a plugged cavity.

0.2.2.7 Blasting

The use of the Crusher Plant’s radio control device

is strictly forbidden during blasting operations, as it

may cause a premature explosion. Move the mobile

Crushing Plant far enough away from dangerous

area when blasting. Do not store or transport

explosives on mobile crushing plant or screening

plants.

0.2.2.8 Portable Plants

If the Crushing Plant includes of portable

equipment (i.e. crushing and screening equipment

mounted on trailers), trailer footing or cribbing is

extremely important for safe operation. Your

machine must be on as solid and level footing as

possible. If the ground is not naturally level, it must

be leveled so that the unit will operate safely and

effectively. The ground must support the weight of

entire unit and keep it from sinking or shifting. Use

heavy timber mats as needed. Trailers must be

raised so that trailer wheels do not touch the

ground.

Place jacks at designated jacking locations. Consult

the portable plant instruction manual if these are

not marked on the chassis. Typically the four

corners are supported along with points in between

where crusher, screen or feeder forces are

concentrated. Jacks must be used in pairs directly

opposed to each other. After correct height and

level are achieved, adjust each jack until vibrations

are reduced to a minimum. Insert locking pins if so

equipped. If holes for locking pins do not align,

loosen the jack and place metal shims under the

jack until the holes align.

Periodically recheck the trailer footing for stability.

WARNING

Only qualified and properly trained

operators and servicemen should operate or

service the machine. Everyone else should

stay clear of the machine when it is

operating, or under service or maintenance!

NOTICE

Make no checks, adjustments or repairs of

any kind while the equipment is in operation.

SECTION 0 - SAFETY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL 0-7

0.2.2.9 Mobile Equipment Transportation

Use only appropriate transportation and lifting

equipment with adequate capacity. Provide a

supervisor to direct lifting operations. Follow all

disassembly and assembly instructions carefully.

Disconnect all external power supplies before

moving any part of the equipment. Transport or

hoist components and handle any parts in

accordance with the instructions and advice

provided. Fasten the lifting equipment only to the

points meant for lifting. Use only proper means of

transport with adequate transporting capacity.

Fasten the load carefully. For lifting use only the

fastenings shown in instructions. Secure all

component parts of the equipment immediately

after loading to avoid any accidental shifting.

Attach required warning signs to the load.

When moving your trailer, check bridges before

crossing. Make sure they will support the weight of

the machine. Check clearances under bridges, for

overhead lines or any overhead obstruction. Never

travel with near capacity loads. Check local laws,

especially on weight limitations. When travelling

on the highway make sure all headlights, clearance

lights and tail lights are on, as applicable. Use

proper traffic warning flags and signs.

Remove all shipping brackets before re-starting the

Crushing Plant. Carefully assemble all of the parts

previously disassembled. Perform any start up in

accordance with the instruction manual.

After the system is running, check all gauges and

instruments to see that they are working correctly.

Check that all controls function normally and

properly. Listen for unusual noises. Shut system

down immediately if any component of the system

does not operate normally.

0.2.3 Typical Risks in Crushing Plant

Working Environment

Even though every Metso Minerals machine is

designed with many safety features, it is impossible

to design out all safety risks. There are potential

hazards, that must be recognized and avoided.

Noise levels may interfere with normal discussion

when the machine is operating. By their nature,

Crushing Plant and auxiliary equipment can create

dust. Crushing itself and some other machine

processes may momentarily obstruct the view of

some machine parts. In general, high levels of

respirable silica and other dust in the air may

expose Operator to health risks for lung disease

depending upon the length and amount of exposure

and type of material being crushed. In addition,

there are some risks or hazards which cannot be

completely guarded or avoided because of

interference with machine operations. Accordingly,

working on the Crushing Plant requires constant

alertness by all personnel in the area. Accidents

happen unexpectedly. Below are some typical

hazards and types of accidents of which everyone

working at, on or around the Crushing Plant should

be aware.

Typical Hazards

– nips, gaps, and pinch points

– poor housekeeping

– elevated or narrow working areas

– lifting and shifting heavy loads

– cranes and mobile cranes

– sharp edges

– high-pressure hydraulic equipment

– electrical equipment and power lines

SECTION 0 - SAFETY

0-8 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

– automatic functions and unexpected

start-ups

– toxic and corroding agents

– machine inertia

– hot surfaces and fires

– zinc

– conveyor belts

– dust

– noise and vibration

– improper work methods

– rotating equipment and moving

components

– ejection of material from the crusher

– falling material from conveyors, and from

loading, unloading and feeding operations

– crushing cavity

These typical hazards are discussed more fully in

Section 0.2.3.1 of this chapter. Be aware of these

hazards. All personnel working on or around the

machine should be properly trained in avoiding

these hazards.

Typical Injury Types

– crushing

– slipping, tripping and bumping

– falling

– cutting

– entanglement

– burns and electrical shocks

– respiratory organ illnesses

– asphyxiation

0.2.3.1 Typical Hazards

Nips, Gaps, and Pinch Points

An ingoing nip is formed by drive devices such as

belt and pulley, chain and sprocket or gears.

Similarly, a pinch point may be formed by rotating

or moving equipment.

Poor Housekeeping

Promote good housekeeping. Keep machine

environment, walkways, platforms etc. clean and

dry and free of debris. Oily or wet machine

environment, walkways, platforms, steps and hand

rails are slippery. In cold weather, watch out for ice

and snow. Wet spots, especially near electrical

equipment, are dangerous. Return tools to their

proper place after use. Even then extreme caution

should be used. Follow established Crushing Plant

safety procedures. Clean slippery deposits from

walkways, ladders and floors. Tidiness provides a

safer working environment by preventing or

reducing tripping, slipping, fire hazards and

electrical shocks.

DANGER

Nips and gaps are serious hazards in a

Crushing Plant. They are usually guarded

by nip guards, railings, or location. In all

cases, extreme care must be taken to avoid

nips, gaps, and pinch points or serious injury

or even death may occur.

SECTION 0 - SAFETY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL 0-9

Elevated or Narrow Working Location

Crushing Plants are tall structures. The walkways

and platforms, designed to be used during machine

operation, are furnished with railings to help

prevent falling.

When working on an elevated surface be aware of

machine movements and other activities in the area.

Do not run on the walkways. Do not reach over or

beyond walkway railings while the machine is

running. Do not stand on railings or toe plates.

There may be narrow access routes for maintenance

purposes. Do not use these routes while the

machine is operating.

Do not enter any close quarters within the Crushing

Plant when the machine is operating.

Lifting and Shifting Heavy Loads

• Cranes

Crushing Plants, like any other type of mechanical

equipment, require regular periodic maintenance.

One of the most flagrant Crushing Plant safety

violations is the use of inadequate and unsafe lifting

equipment. Although a Crushing Plant is a finely

tuned piece of equipment, the internal parts of a

Crushing Plant should be assembled and

disassembled with crane facilities that have the

capability of gently and slowly lifting and lowering

the various parts that make up a Crushing Plant.

Do not use chain hoists (chain blocks) to assemble

or disassemble a Crushing Plant. These lifting

devices lack the stability and robustness required in

lifting and positioning heavy components.

Do not use impact hammer boom or any other

equipment which are not designed for lifting, for

assembly or disassembly purposes.

Affix the load securely to its destination. Never

detach a lifting device from a load until the load

is stable and secured from unintended movement.

When it comes to safety, don’t compromise!

• Mobile cranes

Safe ratings are based on operating the crane on

firm, level ground. Outriggers must be properly

extended and/or lowered whenever required. Avoid

fast swings, hoists or sudden braking. These can

cause overloads. Do not handle large, heavy loads

in strong winds. When moving your crane, check

bridges before crossing, make sure they will

support the total weight in question. Check

clearances under bridges for overhead electrical

lines and any overhead obstruction. Be sure your

hitcher is clear before starting lift. Make sure the

load is securely attached.

NOTICE

When using a crane, always operate within

the rated capacity of the crane. The safe

rated capacity includes weight of hook,

block and any materials handling devices

such as cables, slings, spreader bars, etc.

Subtract the weight of all these items from

the rated capacity to find the true maximum

weight load that can be handled safely.

Always follow the crane manufacturer’s

operational and safety instructions.

NOTICE

The weight indicated on machine plates tells

the weight of standard configuration. In

many cases the actual weight may differ

greatly from that indicated on a machine

plate due to, casting variations, options, or

ancillary equipment. Always verify the

weight of the object you are lifting before

attempting to lift it.

SECTION 0 - SAFETY

0-10 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

Take the following precautions when lifting heavy

loads:

– Follow all established Crushing Plant

procedures.

– Follow all instructions and safety

procedures recommended by the crane

manufacturer.

– Plan the lifting and maintenance

procedures in advance. Read and

understand specific instructions for proper

use of lifting equipment prior to using

(e.g., instructions of the machine, lifting

device and local regulations).

– Clean the working environment

beforehand to prevent slipping and

tripping hazards.

– Make sure that the crane and other lifting

devices such as chains and slings have

sufficient capacity and are in good

working order.

– Do not attempt to ride or sit on moving

loads.

– Be sure that crane operators, riggers and

other personnel are properly trained.

– Rig the load firmly to prevent any

unintended movement and assure stable

and accurate positioning.

– Make sure nobody is below or in the path

of the load and transfer routes are clear

and proper protective clothing and gear

are used.

Sharp Edges

Sharp edges may occur on any metal structures.

Equipment damage may uncover or produce

unexpected sharp edges. Sharp edges may inflict

deep and serious cuts. Wear protective gloves when

handling materials, parts, etc. with sharp edges.

Repair or guard detected sharp edges immediately.

High-Pressure Equipment — Hydraulic or Air

High pressure oil can be dangerous. Relieve all

pressure before opening or removing any hydraulic

or air pressure lines, valves, fittings, etc. Use a

mirror, cardboard or other appropriate techniques to

look for leaks. Do not touch pressurized

components since the pressure from a pin hole leak

is so strong that it can easily penetrate the skin or

eyes. Always exercise caution when handling

hydraulic devices.

NOTICE

When using a mobile crane, always operate

within the rated capacity of the machine to

avoid buckling the boom or tipping.

WARNING

Hydraulic oil under pressure can penetrate

body tissue causing serious injury and

possible death. When troubleshooting a

hydraulic system for leaks, always use a

mirror, cardboard, wood or other appropriate

techniques as a detector. DO NOT USE

YOUR BARE HANDS. If you are injected

with hydraulic oil or any other fluid,

immediately seek treatment from a doctor

trained in the treatment of penetrating fluid

injuries.

SECTION 0 - SAFETY

MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL 0-11

Regularly check the condition of hoses, pipes,

valves and various connections. Replace them as

necessary.

Before starting any maintenance work, stop all

hydraulic pumps, lock out pump motors, and

depressurize the system, bringing all components to

a zero energy state. Remember to also depressurize

the accumulators through the bleed valve for each

accumulator. Do not disconnect any hoses until the

actuator has been brought to a zero energy state and

properly secured.

Bleed the hydraulic system regularly to remove

entrapped air that may interfere with normal

expected machine operation or cause a hazard

during maintenance.

Electrical Equipment

Be especially cautious when working with or near

electrical equipment. An electric shock can be fatal.

Crushing Plant electrical outlets must be grounded

and have ground fault interruption protection. Tools

plugged into the outlets must be double insulated.

Never expose electrical equipment to mechanical

damage or humidity. Protect all electrical

equipment from direct contact with water or high

humidity.

Protect electrical devices that move as part of the

machine from dirt and mechanical damage.

Regularly check the operability of these devices.

The lockout program, locks, tags and the

blocking/restraining devices provided are designed

for your protection. Your responsibility is to follow

the program and use the proper equipment.

Remember:

– Follow procedures.

– Stay alert.

– Do not take anything for granted.

– Verify lockout.

– Each person working on the unit must

have his own lock with only 1 key.

– Tag must identify the work being done and

the person(s) who locked and tagged the

control.

– Locks and tags are changed with each shift

that comes on.

Work to prevent injury or death. Follow proper

procedures at all times!

Maintenance, repair and installation of electrical

equipment must be performed only by qualified

personnel who are familiar with the machinery and

equipment in question.

WARNING

Poorly tightened or damaged hydraulic

components may create dangerous jets of

fluid. Before restarting the machine, be sure

that the hydraulic system is ready for

operation, and personnel are clear of

affected areas.

WARNING

Machine parts may move unintentionally

and cause a risk of injury. Before restarting

the machine, make sure that all personnel

are clear of affected areas where machine

movement may occur.

DANGER

There is a risk of an electric shock, if

sufficient precautions are not taken. An

electric shock can be fatal.

For maintenance work, disconnect all

devices from electric and hydraulic power

sources and follow Crushing Plant lockout

procedures.

SECTION 0 - SAFETY

0-12 MP SERIES CONE CRUSHER TECHNICAL REFERENCE MANUAL

Automatic Functions and Unexpected Start-Ups

Unexpected start-ups during maintenance:

– Lock out and tag machine controls before

performing maintenance or repairs to

avoid unexpected start-up. Failure to

properly lock out the machine can lead to

injury or death. Someone may accidentally

start the machine from the control room or

an unexpected occurrence may activate a

control. For example, a power surge may

alter the logic of the control system status

causing an unexpected machine

movement or sequence.

Welding Equipment

Weld repairs are to be performed only by qualified

personnel. Welders and welder’s helpers must wear

protective clothing and equipment.

Precautions must be taken when torch cutting

and/or welding due to the health hazards posed by

many metals. Anyone performing these types of

procedures should avoid breathing the fumes. Such

procedures should be done outdoors or in a well

ventilated area with either a separate clean air

supply provided to the mechanic or with local

exhaust of fumes. Please refer to EU, OSHA,

MSHA, or other applicable standards as

appropriate. One of the most frequently used tools

around the Crushing Plant is the cutting torch.

Crushing Plants which are equipped with hydraulic

components and/or conveyor belts and/or v-belts

should have these components depressurized and

adequately covered with flame-proof material so

that sparks, weld spatter, etc., cannot reach theses

areas. Ruptured high pressure hydraulic lines will

quickly vaporize the hydraulic fluid as it reaches

WARNING

Machine parts may move unintentionally

and cause a risk of injury. Absence of safety

functions may cause dangerous machine

movements.

Do not tamper with limit switches or other

safety devices included in the system.

DANGER

If danger zones are not respected during

machine operation or maneuvers there is a

risk of serious injury or death.

Many devices operate automatically,

following certain sequences which have

been programmed into the logic system

(e.g., programmable logic controller,

microcontroller, relay system or similar). The

danger zone is any area within the confines

of moving machine elements, feed material

or beneath any objects being lifted. Do not

enter these danger zones unless the

machine has been properly safeguarded

according to the Crushing Plant lockout

procedure and manufacturer’s instructions.

This manual suits for next models

2

Table of contents

Other Metso Industrial Equipment manuals

Metso

Metso JAMESBURY CC Series Operating and maintenance manual

Metso

Metso Lokotrack ST2.8 User manual

Metso

Metso HP Series Installation instructions

Metso

Metso Nordtrack CT85 User manual

Metso

Metso Nordtrack J90 User manual

Metso

Metso NORDBERG LT105 User manual

Metso

Metso NORDBERG C Series User manual

Metso

Metso Lokotrack ST4.8 User manual

Metso

Metso LOKOTRACK LT110C User manual

Metso

Metso Nordtrack J90 User manual